Method for calibrating firearm firing accuracy

A firearm and gun calibration technology, which is applied in the field of correcting firearm shooting accuracy, can solve the problems of being unable to apply to various firearms and low work efficiency, and achieve the effects of being easy to promote and use, improving work efficiency, and improving shooting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The method for correcting firearm shooting accuracy of the present invention comprises the following steps:

[0042] A. Prepare an impact point distribution inspection ring. The impact point distribution inspection ring is a ring with an inner diameter of 120mm-180mm. Prepare a gun calibration device, prepare a chest ring target or a calibration target, and the width of the chest ring target or calibration target 500mm, the height of the breast ring target or school gun target is 500mm, prepare multiple test bullets;

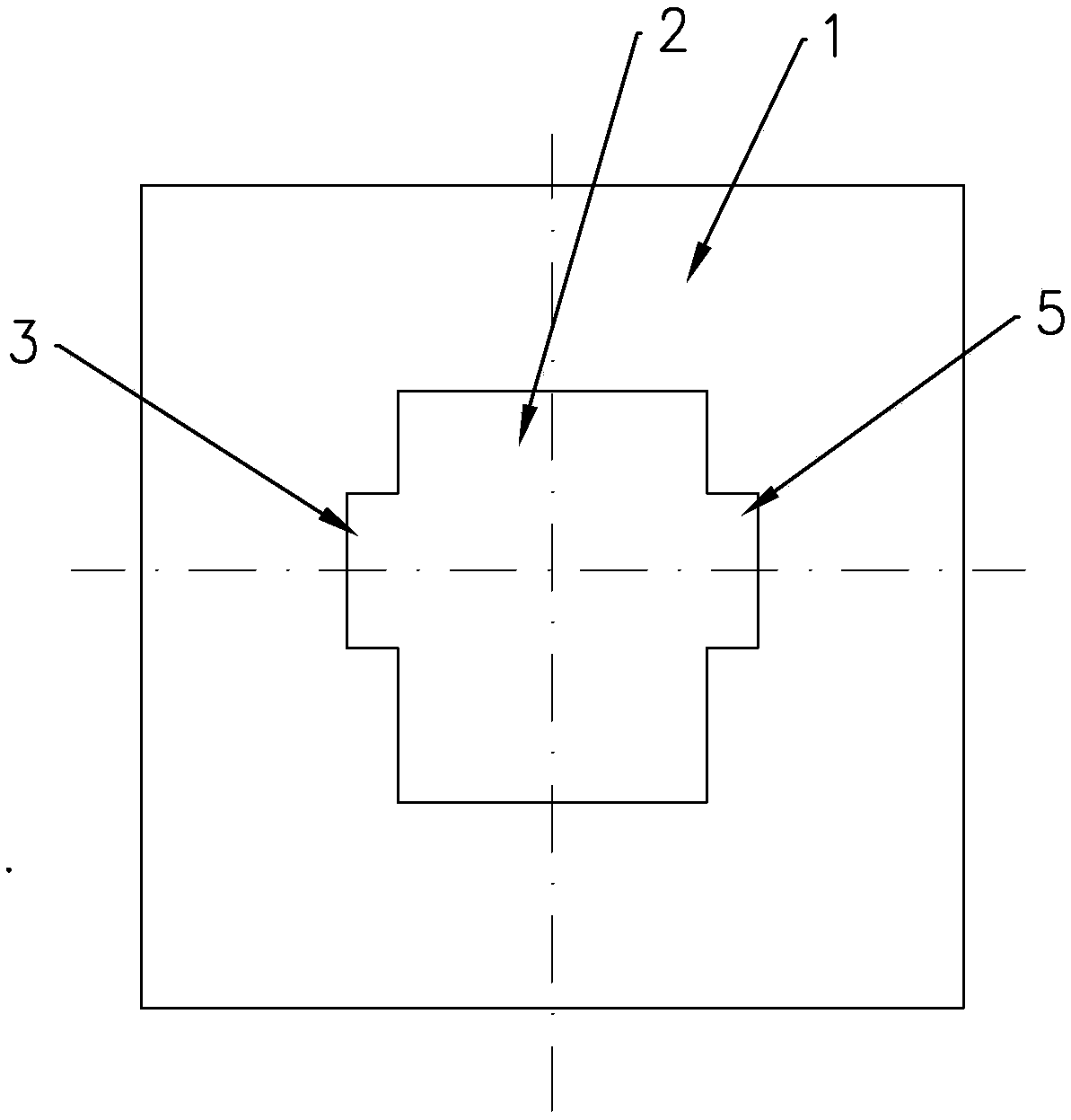

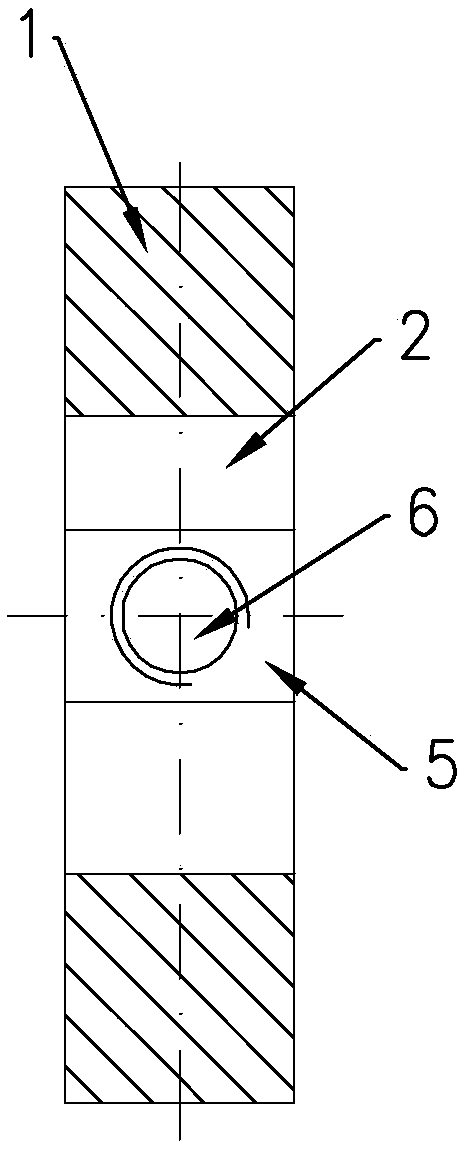

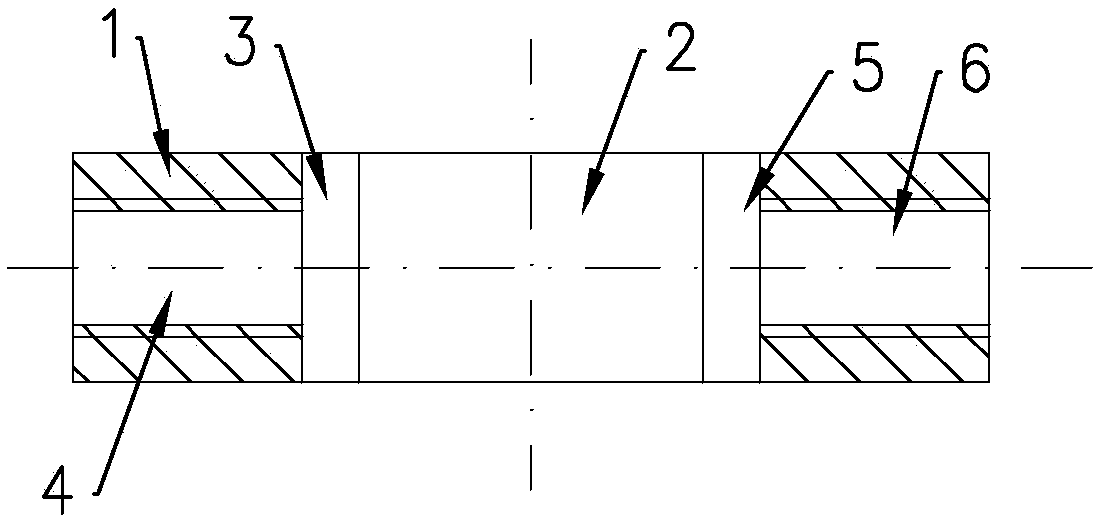

[0043] Such as figure 1 , figure 2 and image 3As shown, the calibrator includes a rectangular block 1, the middle part of the block 1 is provided with a sleeve barrel hole 2 along the front and rear horizontal directions, the cross section of the sleeve barrel hole 2 along the left and right vertical directions is rectangular, and the sleeve barrel hole 2 It runs through the block 1 along the front and back horizontal direction, and the middle part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com