Self-adhesive surface protection film

A self-adhesive and protective film technology, applied in the direction of film/sheet adhesives, adhesives, etc., to achieve the effect of excellent processing suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

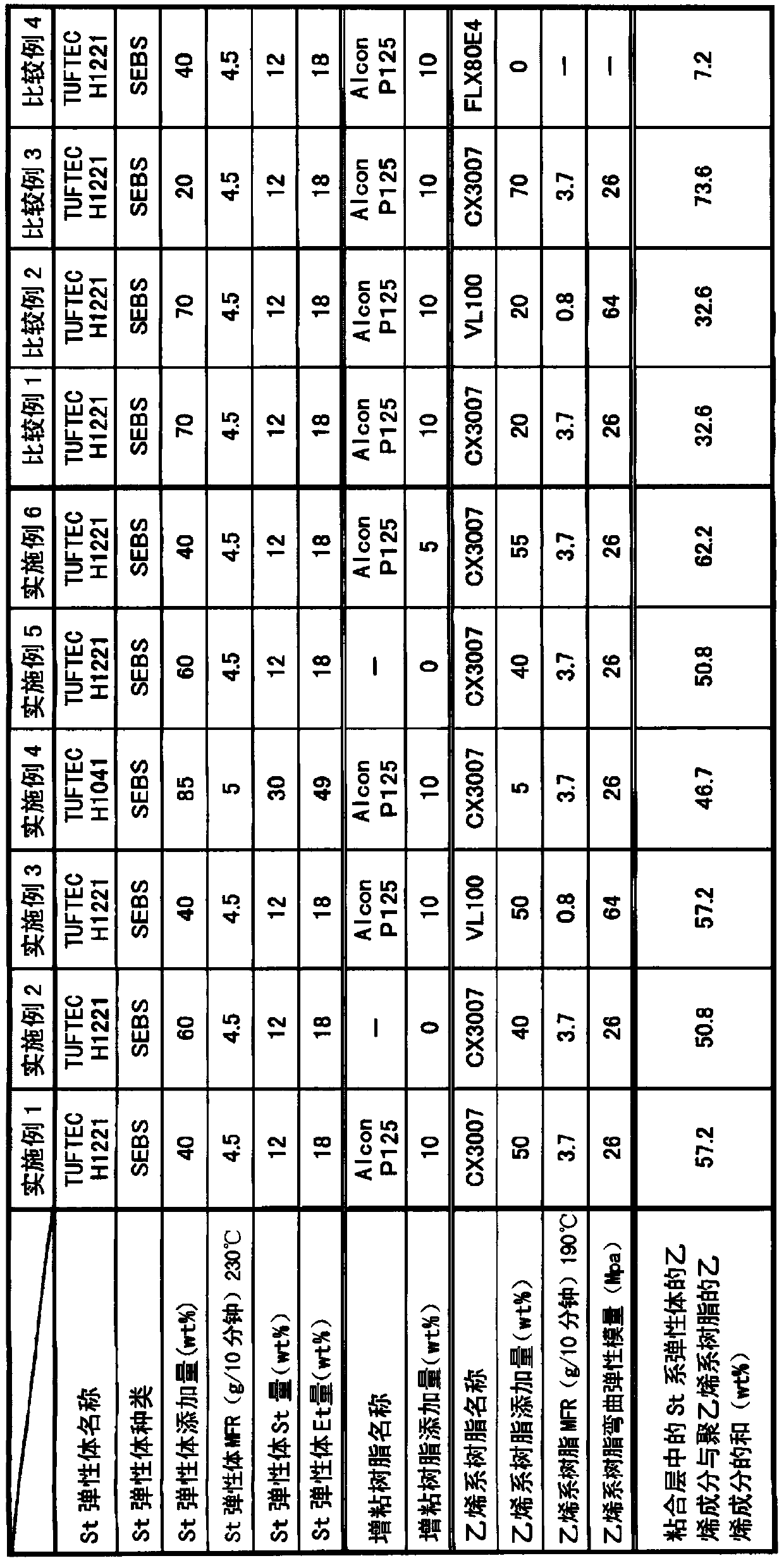

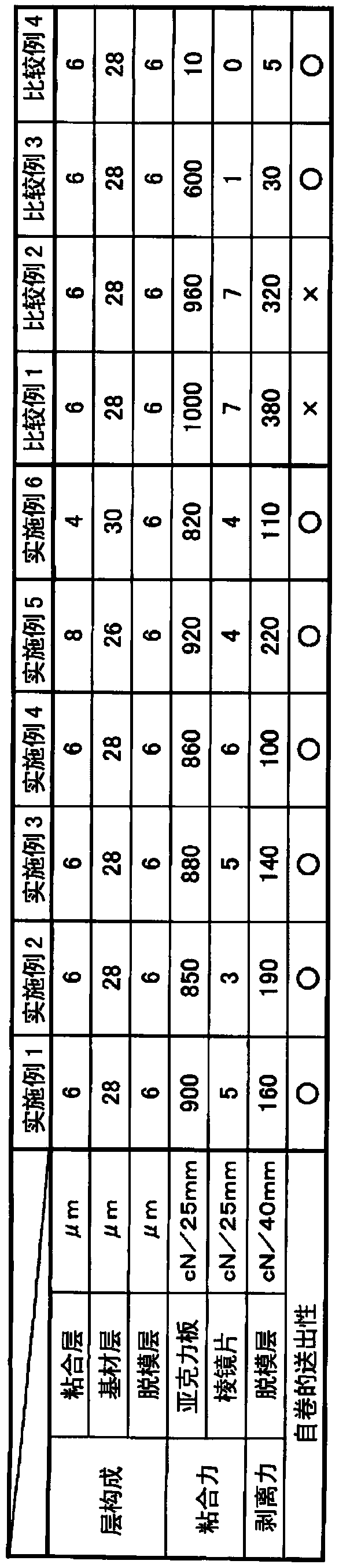

[0100] (Preparation of substrate layer)

[0101] Homopolypropylene resin (manufactured by Sumitomo Chemical Co., Ltd.: FLX80E4, 230° C. MFR: 7.5 g / 10 min) was used for 100 mass % A single-screw extruder was melt-extruded at 240° C. to form a substrate layer.

[0102] (Preparation of adhesive layer)

[0103] A styrene-based elastomer (hydrogenated block copolymer of styrene and butadiene, manufactured by Asahi Kasei Chemical Co., Ltd.: TUFTEC (registered trademark) H1221, a styrene component ratio of 12% by mass, an ethylene component ratio of 18% by mass, 230°C MFR: 4.5g / 10min) 40% by mass, ethylene-α-olefin copolymer (manufactured by Sumitomo Chemical Co., Ltd.: CX3007, 190°C MFR: 3.7g / 10min, modulus of elasticity: 26MPa) 50% by mass, and petroleum resin ( Manufactured by Arakawa Chemical Industry Co., Ltd.: 10% by mass of Alcon (registered trademark) P125) was melt-extruded at 210° C. with a 45 mmφ single-screw extruder to form an adhesive layer.

[0104] (production of ...

Embodiment 2

[0109] The base material layer and the release layer were the same as in Example 1, but the adhesive layer was changed to the following, and three types of three-layer unstretched films were obtained by the same manufacturing method as in Example 1.

[0110] (Preparation of adhesive layer)

[0111] Styrenic elastomer (manufactured by Asahi Kasei Chemical Co., Ltd.: TUFTEC (registered trademark) H1221, styrene component ratio 12 mass%, ethylene component ratio 18 mass%, 230°C MFR: 4.5g / 10min) 60 mass% and ethylene- α olefin copolymer (manufactured by Sumitomo Chemical Co., Ltd.: CX3007, 190°C MFR: 3.7g / 10min, elastic modulus: 26MPa) 40% by mass was melt-extruded at 210°C with a 45mmφ single-screw extruder to make a bonded layer.

Embodiment 3

[0113] The base material layer and the release layer were the same as in Example 1, but the adhesive layer was changed to the following, and three types of three-layer unstretched films were obtained by the same manufacturing method as in Example 1.

[0114] (Preparation of adhesive layer)

[0115] A styrene-based elastomer (hydrogenated block copolymer of styrene and butadiene, manufactured by Asahi Kasei Chemical Co., Ltd.: TUFTEC (registered trademark) H1221, a styrene component ratio of 12% by mass, an ethylene component ratio of 18% by mass, 230°C MFR: 4.5g / 10min) 40% by mass, ethylene-α-olefin copolymer (manufactured by Sumitomo Chemical Co., Ltd.: VL100, 190°C MFR: 0.8g / 10min, modulus of elasticity: 64MPa) 50% by mass, and petroleum resin ( Manufactured by Arakawa Chemical Industry Co., Ltd.: 10% by mass of Alcon (registered trademark) P125) was melt-extruded at 210° C. with a 40 mmφ single-screw extruder to form an adhesive layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com