Intelligent equipment mounting rack capable of being quickly assembled

A technology of intelligent equipment and mounting racks, which is applied in the direction of mechanical equipment, machines/brackets, supporting machines, etc., can solve the problems of low installation efficiency of mounting racks, and achieve high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

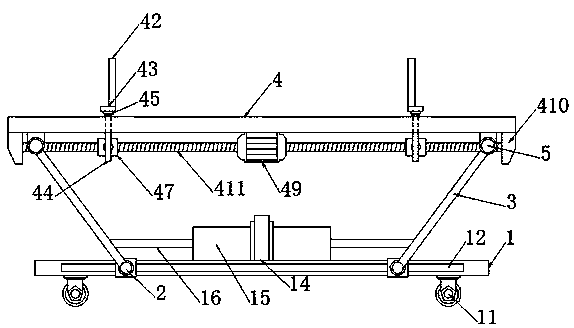

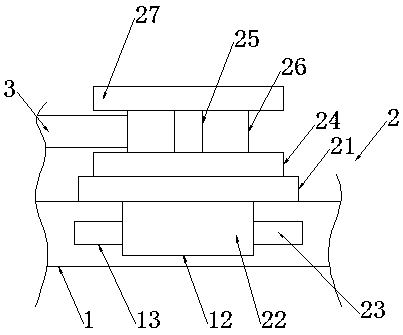

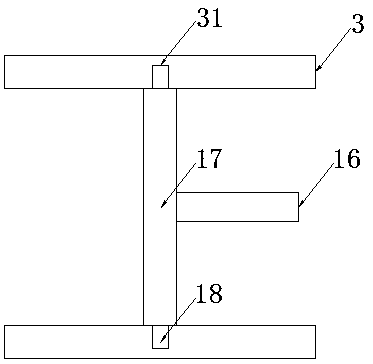

[0023] A quick-assembled smart device mounting frame, comprising a base plate 1, a sliding mechanism 2, a connecting rod 3, a carrier plate 4 and a fixing mechanism 5, two sliding mechanisms 2 are slidably installed on two opposite sides of the base plate 1, four The two sliding mechanisms 2 have the same specifications and are distributed in a rectangular array with each other. A carrier plate 4 is arranged directly above the substrate 1, and fixing mechanisms 5 are fixedly installed at the four corners of the lower end surface of the carrier plate 4. The two fixing mechanisms 5 have the same specification and are distributed in a rectangular array with each other, and the four fixing mechanisms 5 are connected to the four sliding mechanisms 2 through four connecting rods 3 respectively.

[0024] Among them, the four corners of the lower end surface of the substrate 1 are fixedly equipped with universal wheels 11, and the four universal wheels 11 have the same specifications a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com