Robot grinding gripper adapting to workpiece deviation

A robot and deviation technology, applied in the direction of manipulators, grinding workpiece supports, manufacturing tools, etc., can solve problems such as workpiece clamping, and achieve the effect of preventing workpieces from falling off, good stress state, and good dustproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

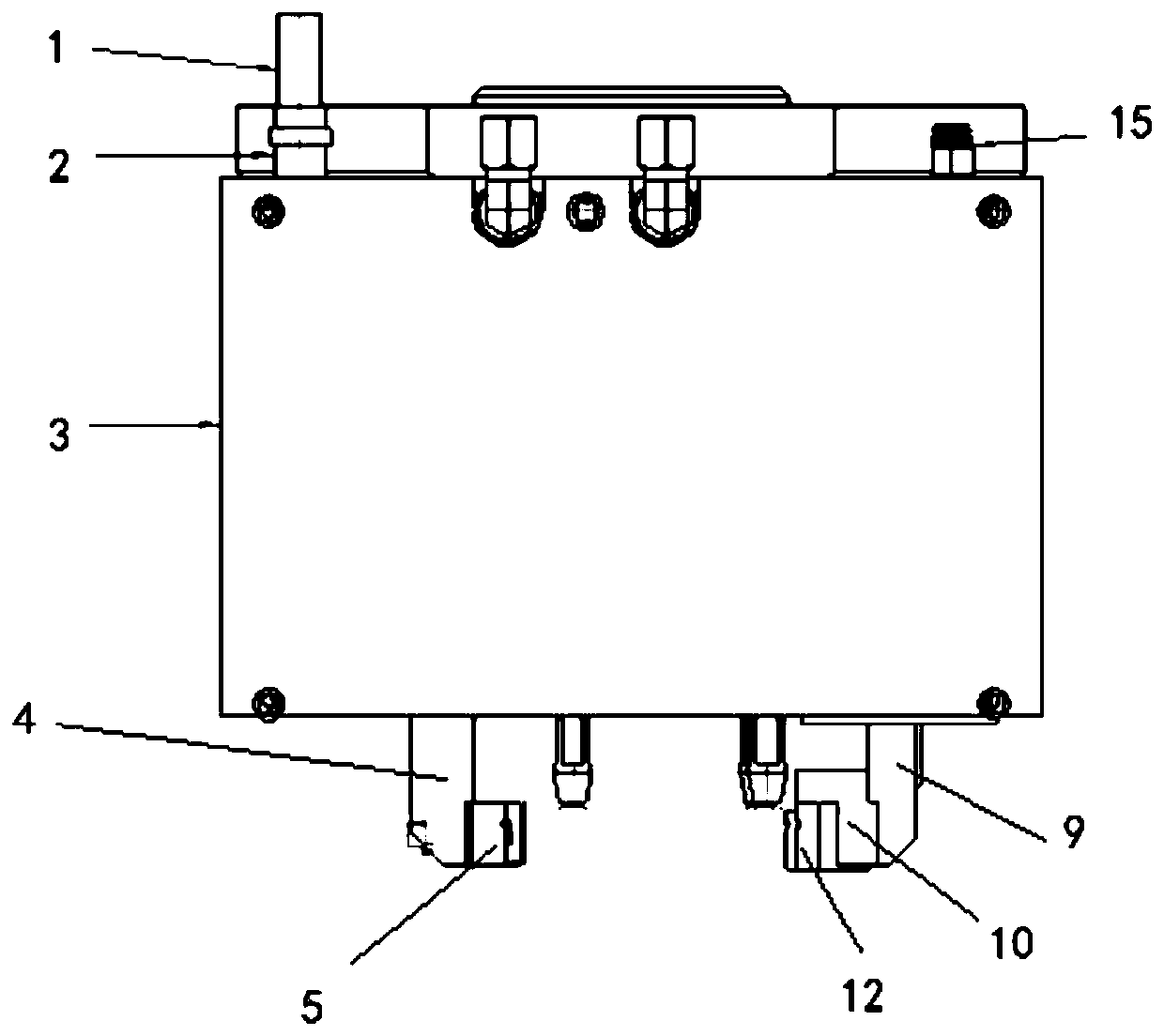

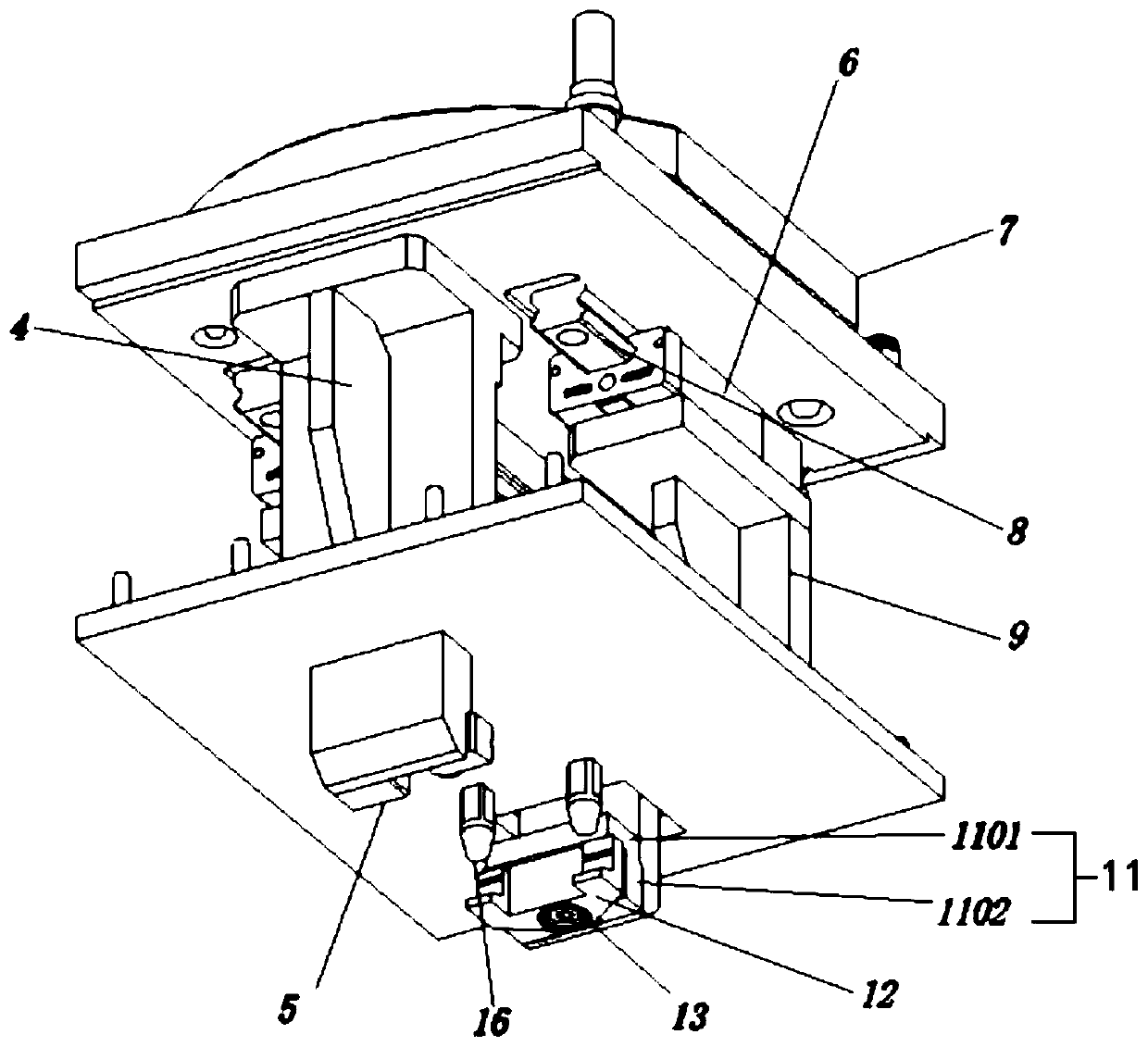

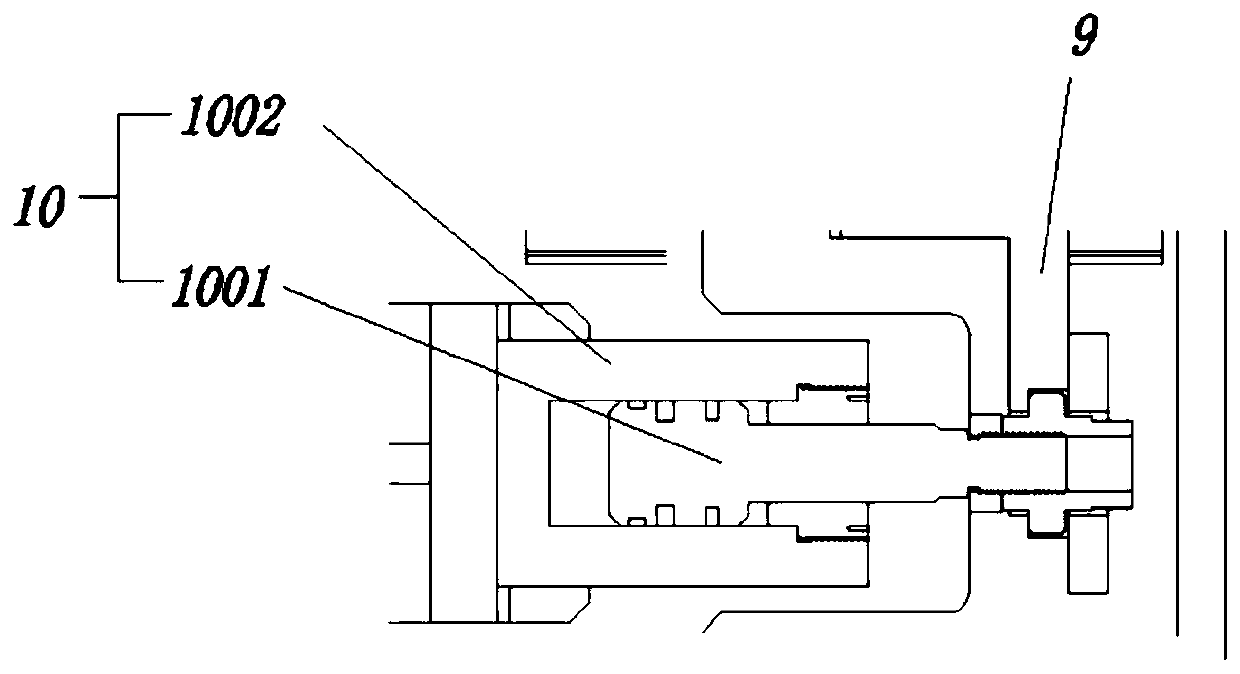

[0037] The following will combine Figure 1 to Figure 5 The robot grinding gripper adapted to the workpiece deviation provided by the present invention is described in detail. This embodiment is implemented on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are given. However, the protection of the present invention The scope is not limited to the following examples, and those skilled in the art can modify and polish them within the scope of not changing the spirit and content of the present invention.

[0038] Please refer to Figure 1 to Figure 5 , a robot grinding gripper adapted to workpiece deviation, including:

[0039] A casing 3, the casing 3 is surrounded by an upper cover, a side plate and a bottom plate to form an accommodating space, and the upper cover is connected to the robot flange through a connecting plate 7;

[0040] The oil cylinder 10 is installed in the casing 3;

[0041] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com