Marine equipment hoisting method and hatch cover assembly for eliminating space obstacles

An equipment and marine technology, applied in the directions of ship parts, ship accessories, passenger handling equipment, etc., can solve the problems of insufficient hoisting space, reducing the structural strength of ship cabins, and difficult hoisting of marine equipment, so as to eliminate space obstacles and ensure normal performance. , the effect of increasing depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

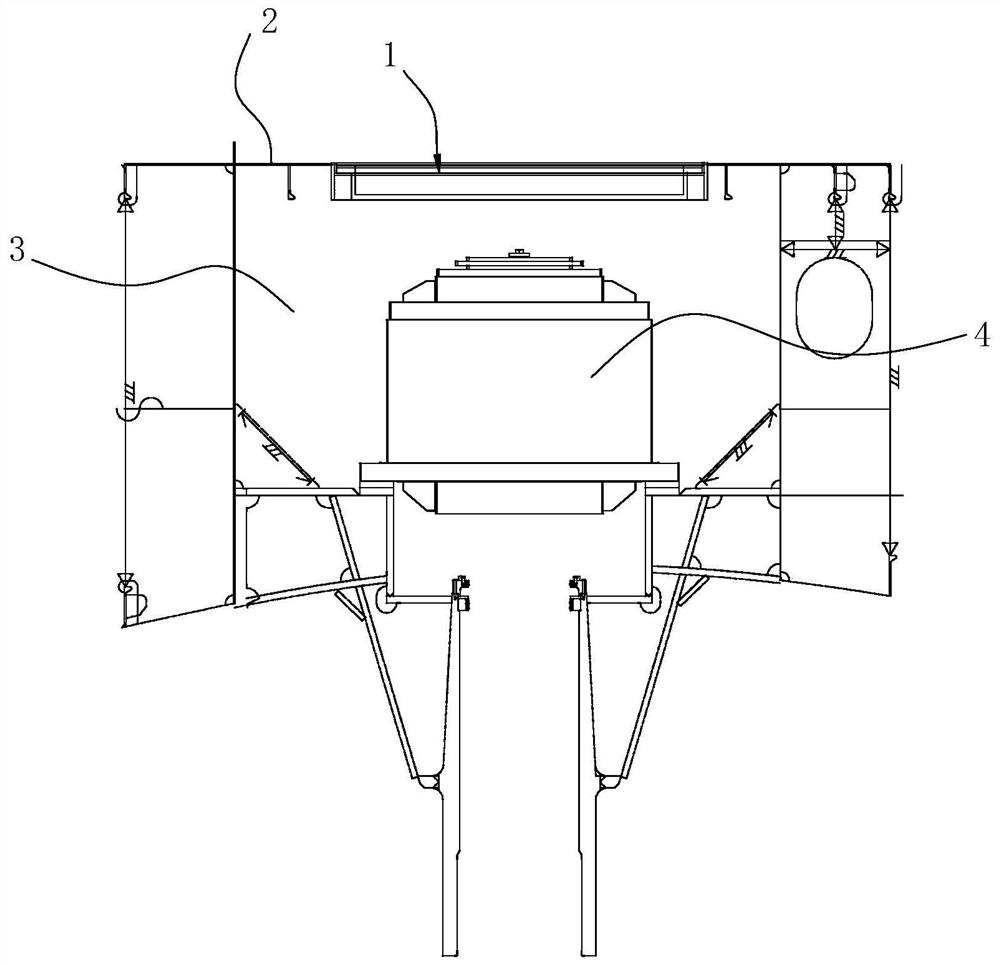

Embodiment 1

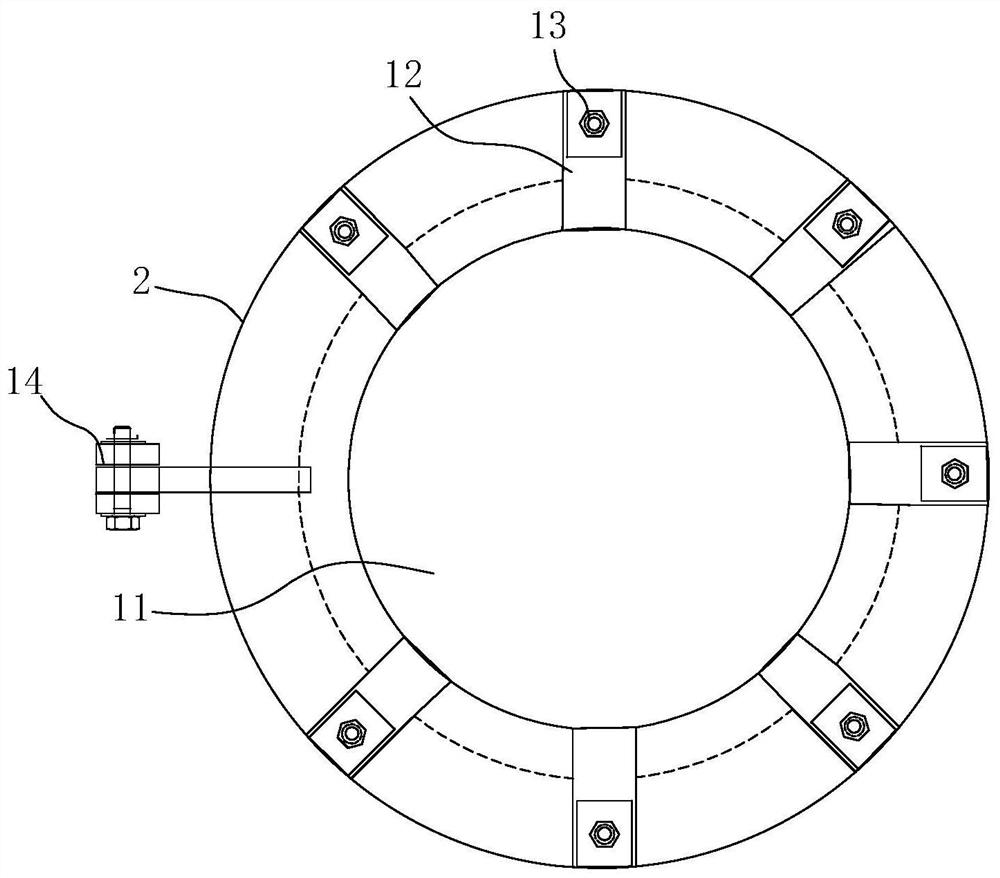

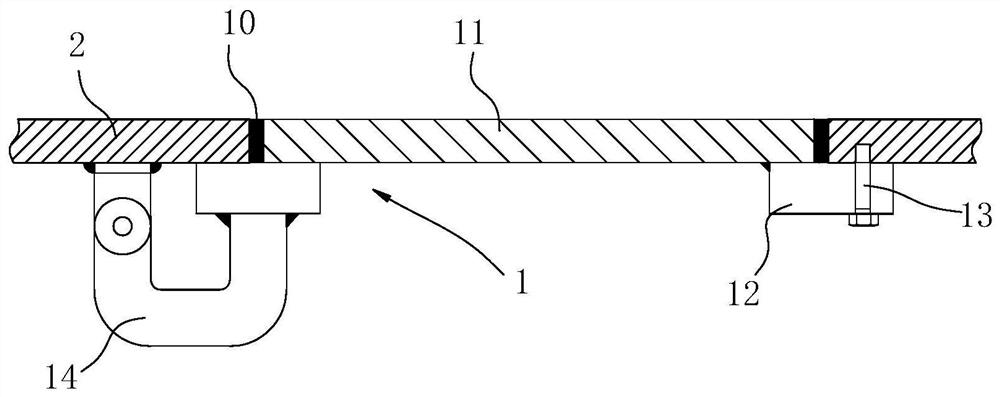

[0038] In this example, if figure 2 and image 3 As shown, a hatch cover assembly 1 is provided, wherein the hatch cover assembly 1 is applied to any of the methods for hoisting marine equipment for eliminating space obstacles mentioned above. The hatch cover assembly 1 mentioned above includes a cover body 11, and the cover body 11 can selectively cover the lifting hole. The cover body 11 seals the hoisting hole to avoid affecting the normal use of the ship cabin 3 due to the existence of the hoisting hole.

[0039] The hatch cover assembly 1 also includes a limiting plate 12 protruding toward the center of the hoisting hole, and the lower surface of the cover body 11 abuts on the limiting plate 12, through The limit plate 12 limits the cover body 11 at the hoisting hole, thereby realizing the lid sealing of the hoisting hole.

[0040] Preferably, the limiting plate 12 is located below the top plate 2 , and the upper end surface of the cover body 11 is flush with the uppe...

Embodiment 2

[0045] Such as Figure 4 As shown, the above-mentioned hatch cover assembly 1 includes a cover body 11, and the cover body 11 can selectively cover the lifting hole. The cover body 11 seals the hoisting hole to avoid affecting the normal use of the ship cabin 3 due to the existence of the hoisting hole.

[0046] The hatch cover assembly 1 also includes a limiting plate 12, which protrudes toward the center of the hoisting hole, and the lower surface of the cover body 11 abuts against the limiting plate 12. The position plate 12 limits the hoisting hole of the cover body 11, thereby realizing the blocking of the hoisting hole. Specifically, the lower surface of the cover body 11 and the upper surface of the limiting plate 12 .

[0047] In this embodiment, the limit plate 12 is arranged below the top plate 2 at intervals, a surrounding plate 15 is provided between the limit plate 12 and the top plate 2, and a cover is provided above the cover body 11. Cover 18, the cover 18 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com