Comprehensive utilization method of lignocellulose biomass

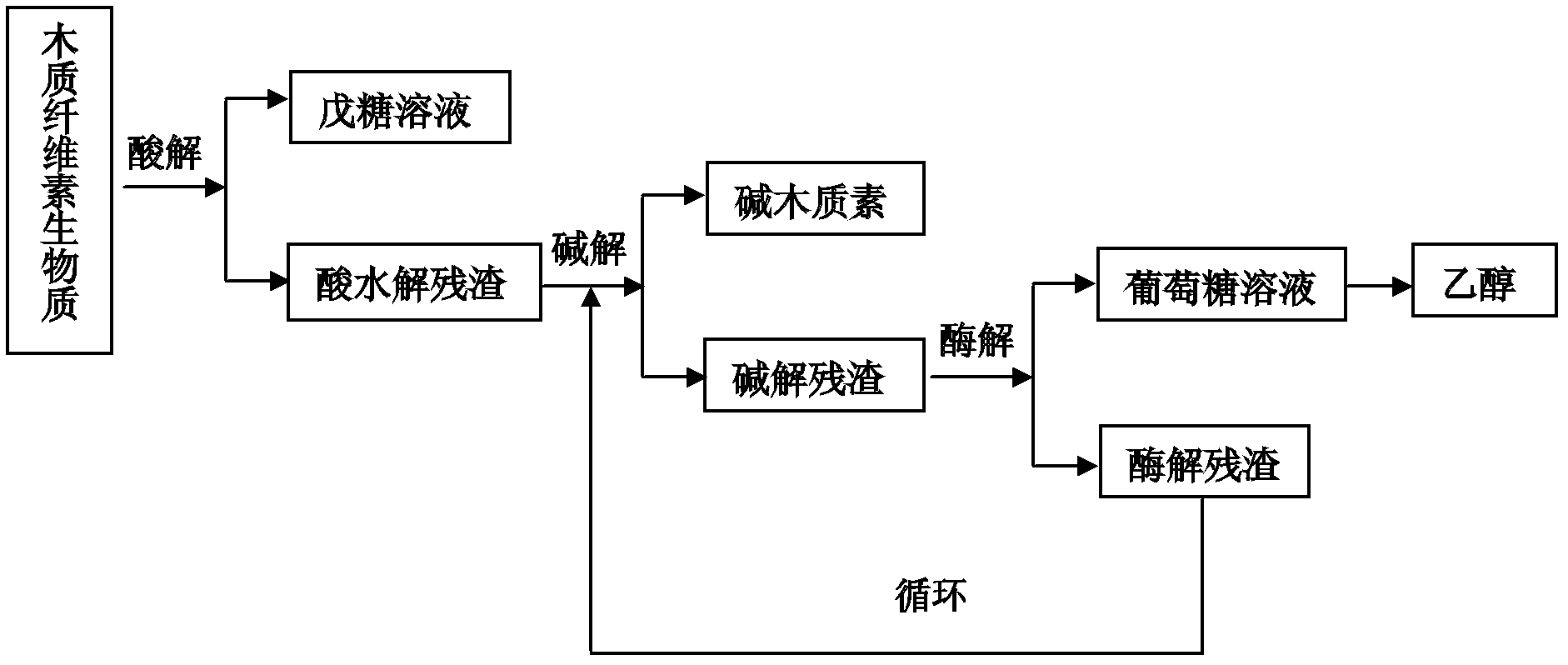

A lignocellulose and biomass technology, applied in the field of comprehensive utilization of cellulose, hemicellulose and lignin in lignocellulosic biomass, can solve the problem that high activity, high hemicellulose and cellulose extraction rate cannot be obtained at the same time, etc. problem, to achieve the effect of shortening the running time, maintaining the activity, and reducing the inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

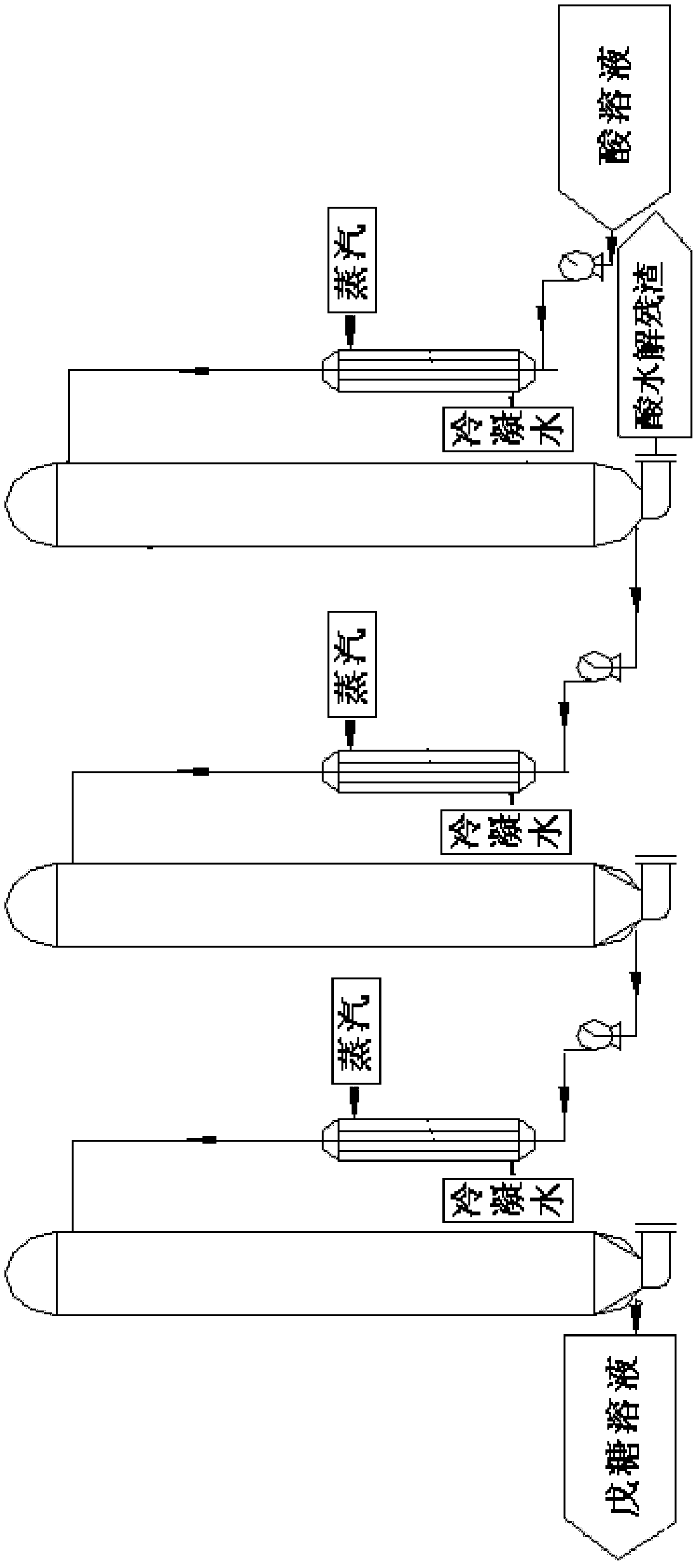

[0075] (1) N-level acid hydrolysis

[0076] In the present embodiment: what adopt is tertiary acid hydrolysis, at first corn cob (mass component composition: moisture 6.12%, cellulose 35.19%, hemicellulose 32.01%, lignin 23.7%, other 2.95%, the same below) Break it up, then add the newly prepared acid solution into the first-stage hydrolysis reactor, add the acid solution discharged from the first-stage acid hydrolysis reactor into the second-stage hydrolysis reactor, and then add the acid solution discharged from the second-stage hydrolysis reactor Add in the third-stage hydrolysis reactor, the acid solution discharged from the third-stage reactor is the final pentose solution, then take out the residue of acid hydrolysis in the first-stage hydrolysis reactor, then put in new corn cob raw materials, and then The original first-stage hydrolysis reactor is used as the third-stage reactor, the original second-stage reactor is used as the first-stage reactor, and the original thi...

Embodiment 2

[0094] (1) N-level acid hydrolysis

[0095] Raw material and method are with embodiment 1 step (1), and difference is: the time of first-order hydrolysis reaction is 3 hours, and the time of second-order hydrolysis reaction is 2 hours, and the time of third-order hydrolysis reaction is 1 hour, every The temperature of grade acid hydrolysis is 110 ℃; The weight of acid hydrolysis residue obtained is 1.95×10 3 kg (the water content is about 65%, the absolute dry content of hemicellulose is 11.48%, the absolute dry content of cellulose is 50.57%, and the absolute dry content of lignin is 33.36%), the pentose sugar solution is 8.05×10 3 kg, and the concentration of pentose sugar is 3.26%, the extraction rate of hemicellulose is 77%.

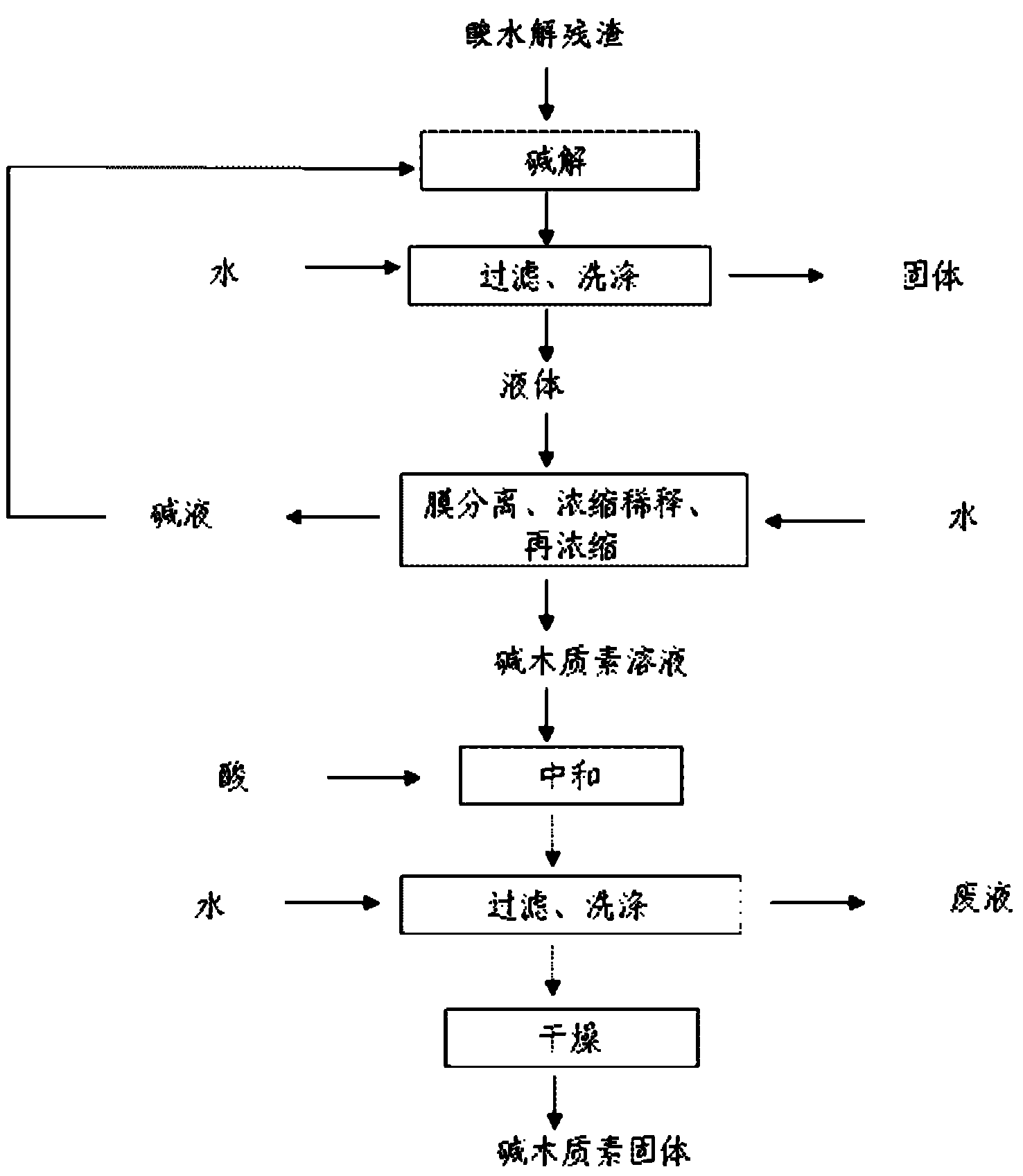

[0096] (2) Extraction of alkali lignin with alkaline solution

[0097] Mix the acid hydrolysis residue obtained in step (1) of this example with sodium hydroxide solution, wherein the liquid-solid volume ratio is 10:1, and the concentration of sodi...

Embodiment 3

[0104] (1) N-level acid hydrolysis

[0105] Raw material and method are with embodiment 1 step (1), and difference is that the time of first-order hydrolysis reaction is 1 hour, and the time of second-order hydrolysis reaction is 0.75 hour, and the time of third-order hydrolysis reaction is 0.5 hour, every The concentration of phosphoric acid hydrolyzed by grade acid is 10%; the weight of finally obtained acid hydrolysis residue is 2.02×10 3 kg (the water content is about 65%, the absolute dry content of hemicellulose is 13.51%, the absolute dry content of cellulose is 49.08%, and the absolute dry content of lignin is 32.9%), and the pentose sugar solution is 7.98×10 3 kg, and the concentration of pentose sugar is 3.08%, the extraction rate of hemicellulose is 72%.

[0106] (2) Alkali solution to extract alkali lignin

[0107] Get all the acid hydrolysis residues obtained in step (1) of the present embodiment, carry out alkali solution treatment according to the process meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com