Roasting rack imitating charcoal smudging

A technology of smoking and imitating charcoal, applied in the field of roasting racks, can solve the problems of affecting the quality of flavor, time-consuming, energy-consuming, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

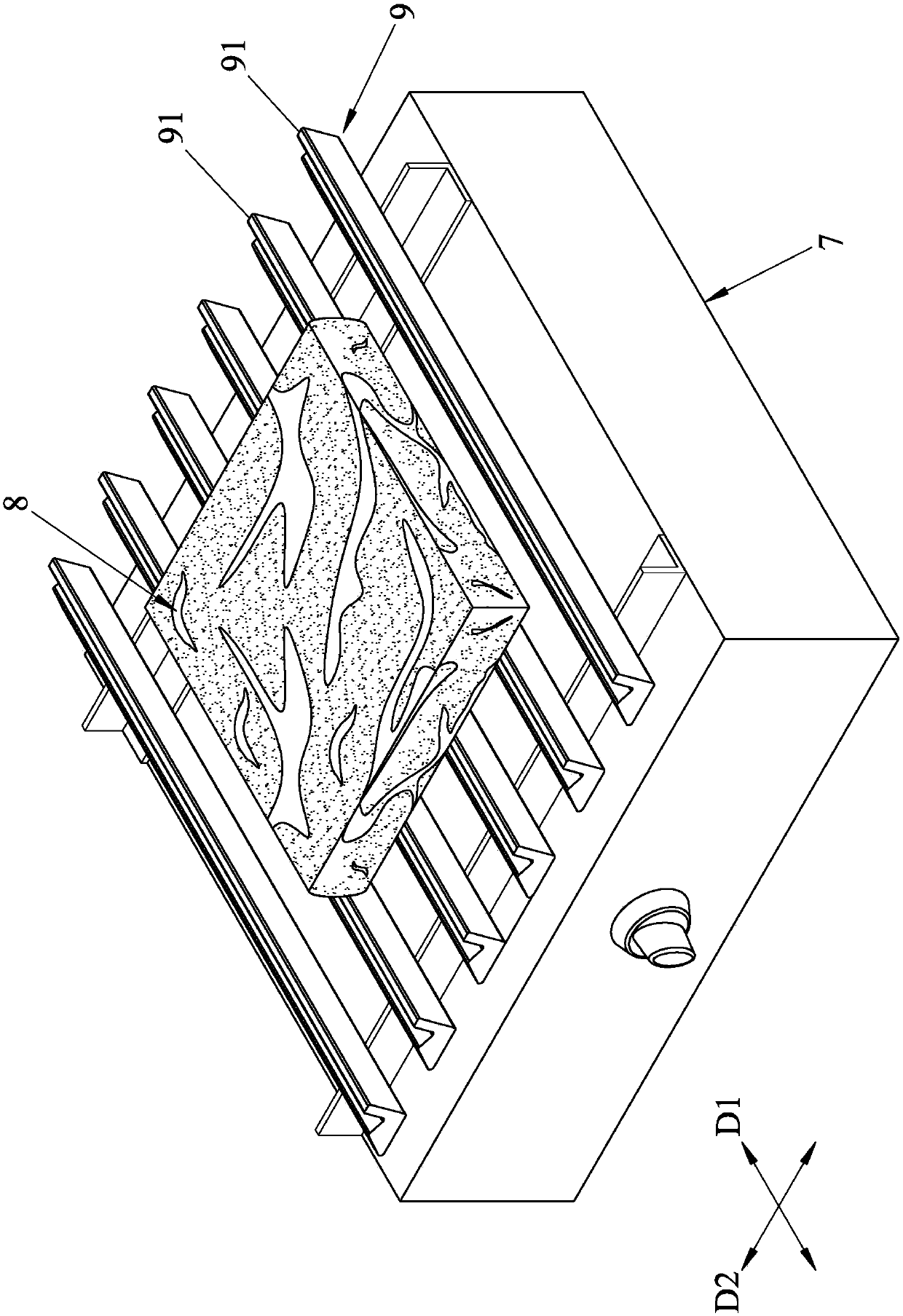

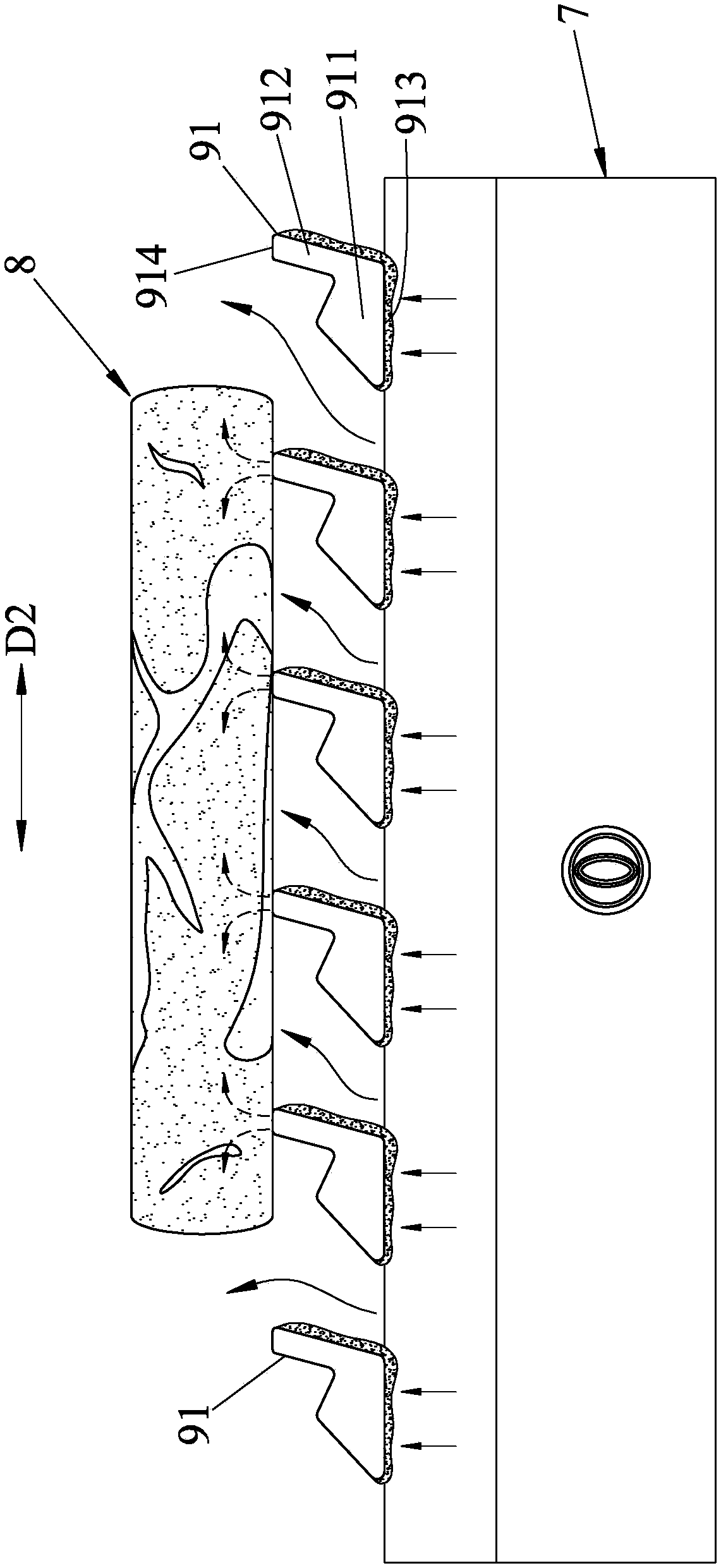

[0023] refer to image 3 , an embodiment of the charcoal-like smoking rack 3 of the present invention is suitable for placing on a heat source 2 and heating the meat piece 1. In this embodiment, six charcoal-like smoking racks are arranged side by side above the heat source 2. Burning rack 3, but the number of charcoal-like smoking racks 3 can vary according to actual needs and is not limited thereto. Each imitation charcoal smoking rack 3 includes a plurality of burning segments 31, and a plurality of Smoke section 32. Since the charcoal-like smoking and burning racks 3 have the same structure, only one of the charcoal-like smoking and burning racks 3 will be described below.

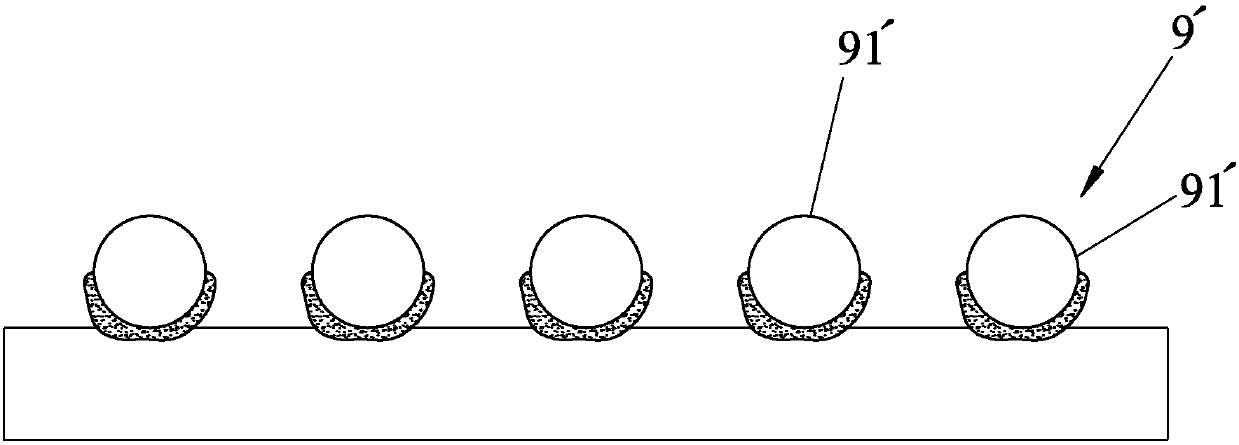

[0024] refer to image 3 , Figure 4 and Figure 5 , the burning segment 31 protrudes upwards, extends along a first axis D1 and is spaced apart along a second axis D2 perpendicular to the first axis D1, every two adjacent burning segments 31 The distance d along the second axis D2 is greater than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com