A self-adaptive control method for springback of sheet metal under pressure forming in viscous medium

An adaptive control and viscous medium technology, applied in the field of plate forming, can solve the problems of long springback time, limited improvement of dimensional accuracy and high cost, and achieve the effect of saving mold repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

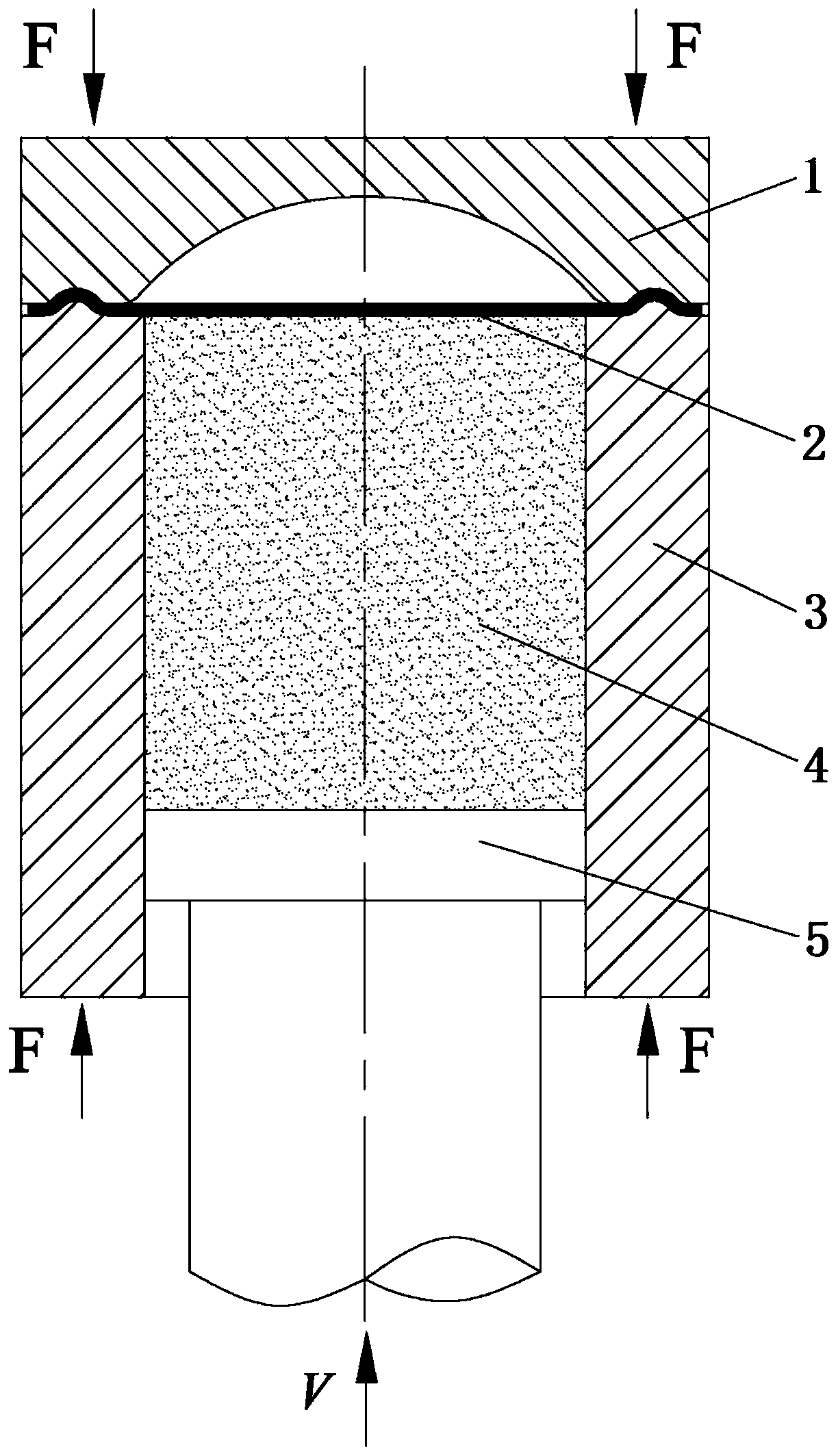

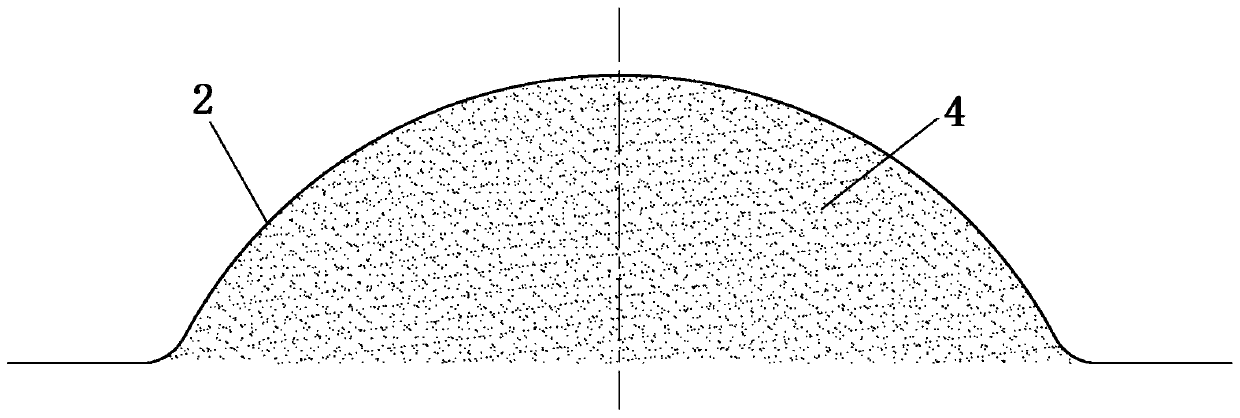

[0046] Embodiment 1: Choose a regular spherical concave mold 1.

[0047] 1. The material of slab 2 is stainless steel 304, 1.02×10 -3 Time,

[0048] The size of P is 130MPa; and when the viscous medium 4 is selected, the strain rate sensitivity index m is 0.1, ΔP is 25-27MPa, V 1 =0.8mm / s, V 2 Under the condition of =0.1mm / s, the duration t only needs to be 5s, and the sheet blank 2 can be formed without springback;

[0049] 2. The material of slab blank 2 is aluminum alloy AL1060, 1.81×10 -3 Time,

[0050] The size of P is 70MPa; and when the viscous medium 4 is selected, the strain rate sensitivity index m is 0.5, ΔP is 13~18MPa, V 1 =0.3mm / s, V 2 =0.01mm / s, the duration t only needs to be 7s, and the sheet blank 2 can be formed without springback;

[0051] 3. The material of slab blank 2 is high temperature alloy GH4169, 2.75×10 -3 Time,

[0052] The size of P is 150MPa; and when the viscous medium 4 is selected, the strain rate sensitivity index m is 0.9, ΔP is 6-8MPa, V 1 =0.1mm / ...

Embodiment 2

[0053] The second embodiment: The concave mold 1 with a stepped shape is selected, and the material of the blank 2 is aluminum alloy AL1060, 1.81×10 -3 When the value of P is 80MPa; and when the viscous medium 4 is selected, the strain rate sensitivity index m is 0.5, ΔP is 11MPa, V 1 =0.2mm / s, V 2 Under the condition of =0.06mm / s, the duration t only needs to be 8s, and the sheet blank 2 can be formed without springback;

Embodiment 3

[0054] The third embodiment: the die 1 in the shape of a variable diameter member is selected, and the material of the slab 2 is high temperature alloy GH4169, 2.75×10 -3 When the value of P is 170MPa; and when the viscous medium 4 is selected, the strain rate sensitivity index m is 0.9, ΔP is 5MPa, V 1 =0.1mm / s, V 2 Under the condition of =0.005mm / s, the duration t only needs to be 8s, and the sheet blank 2 can be formed without springback.

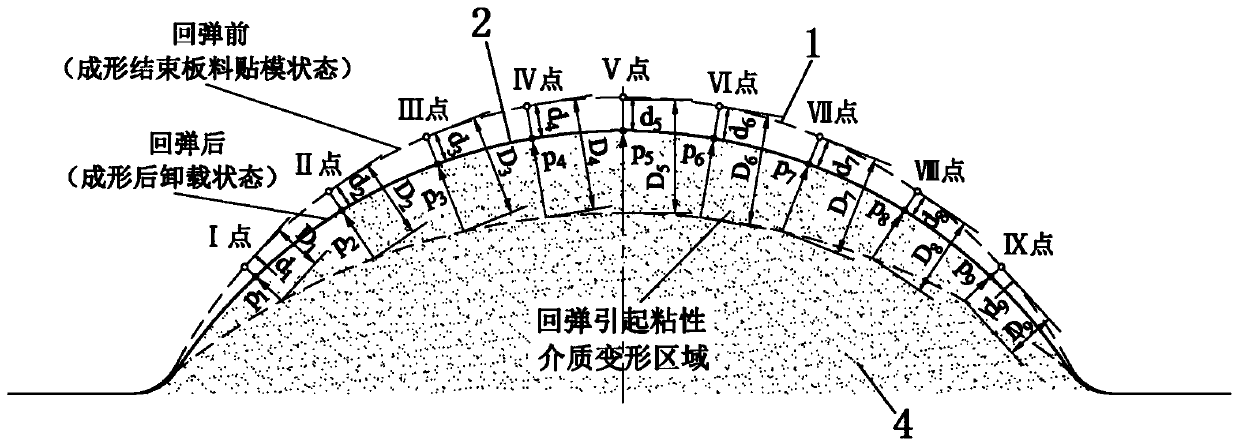

[0055] In summary, the present invention utilizes the strain rate sensitivity of the viscous medium 4, and its pressure can adapt to the change of the sheet shape. In the pressure forming of the viscous medium 4, by controlling the unloading method of the viscous medium 4 during the unloading process, the formed part is During the unloading process, the mold is repeatedly applied and the residual stress is gradually released, and the internal stress gradient of the final molded part is reduced. Not only can it achieve the purpose of controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com