Injection molding machine

A technology for injection molding machines and molded products, applied in the field of injection molding machines, which can solve problems such as conflict between ejector rods and molds, conflicts, deformation of ejector rods, etc., and achieve the effect of reducing mold conflicts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

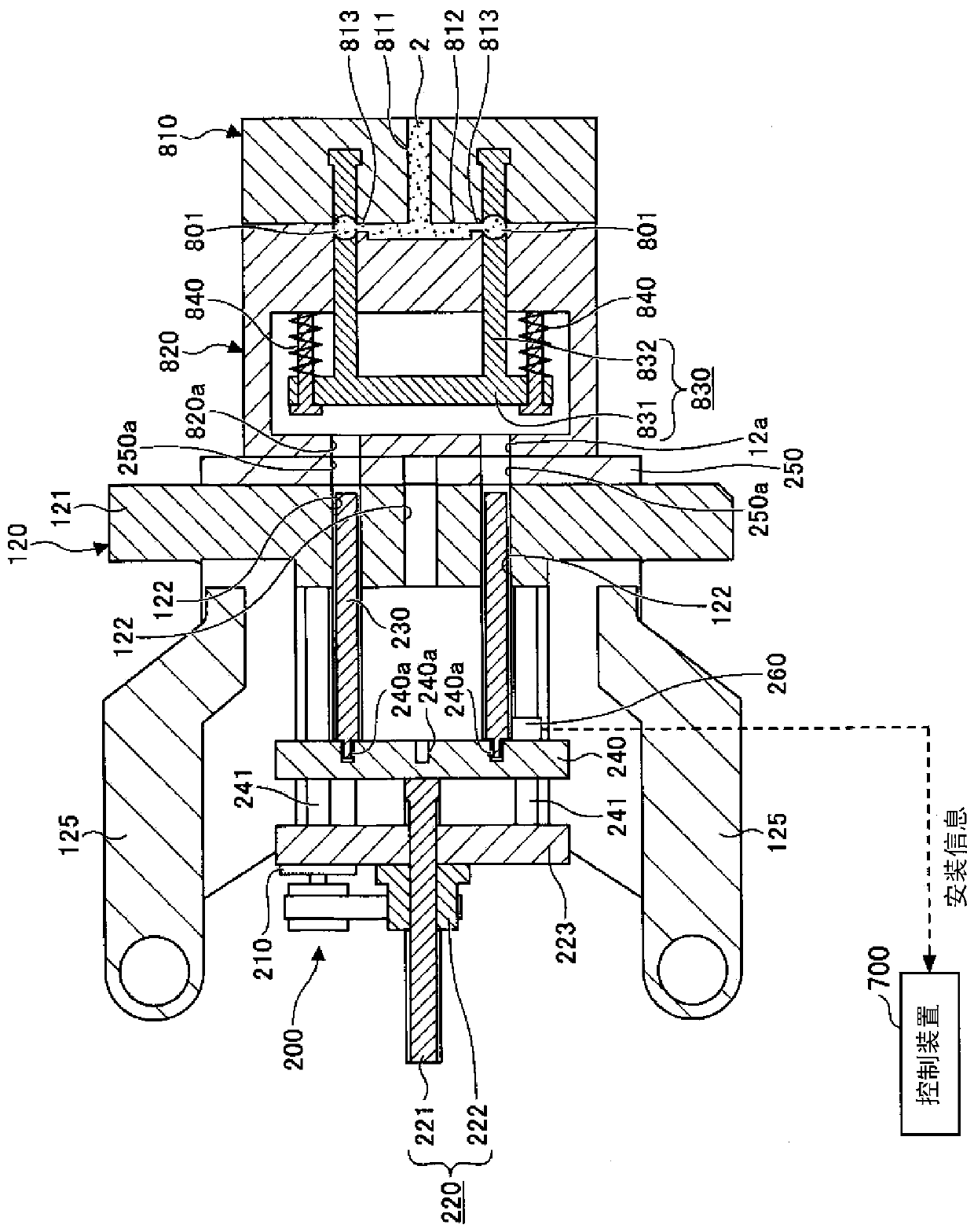

[0032] Hereinafter, modes for implementing the present invention will be described with reference to the drawings. In each of the drawings, the same or corresponding components are assigned the same or corresponding symbols to omit description.

[0033] (injection molding machine)

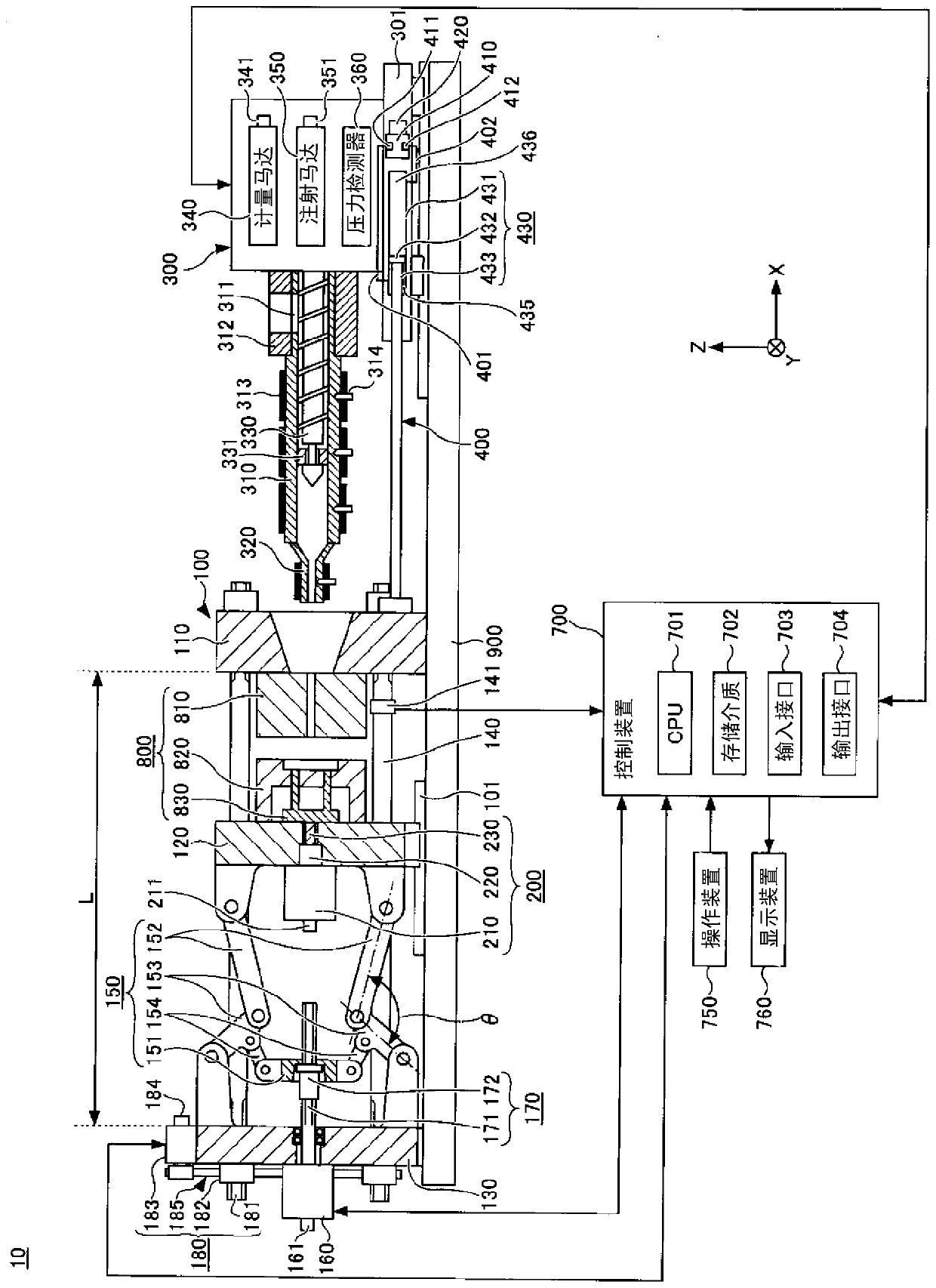

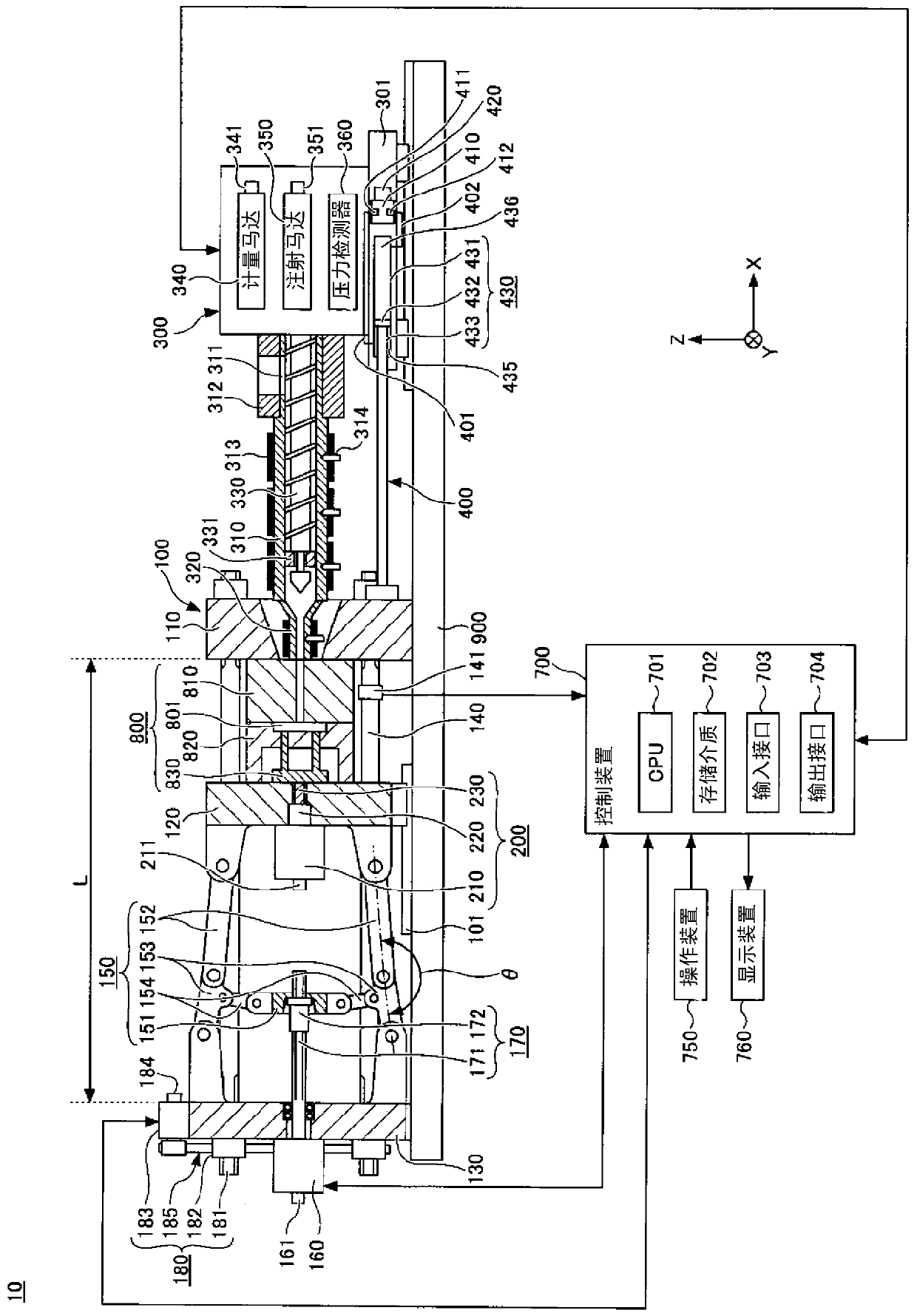

[0034] figure 1 It is a figure which shows the state at the end of mold opening of the injection molding machine of one embodiment. figure 2 It is a figure which shows the state at the time of mold clamping of the injection molding machine of one embodiment. figure 1 and figure 2 Among them, the X direction, the Y direction, and the Z direction are directions perpendicular to each other. The X direction and the Y direction represent the horizontal direction, and the Z direction represents the vertical direction. When the mold clamping device 100 is a horizontal type, the X direction is the mold opening and closing direction, and the Y direction is the width direction of the injection molding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com