Pushing and pulling rod of wire clamping device

A wire clamp and pull rod technology, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems such as the difficulty in recycling the wire clamp, and achieve the effect of convenient clamping and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

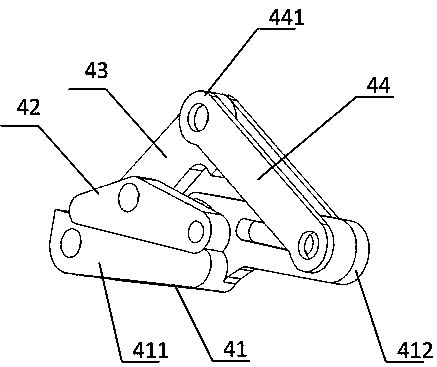

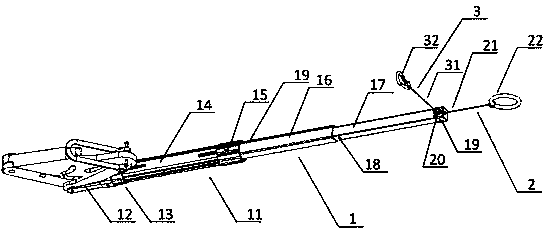

[0032] A wire clamp push-pull rod, such as figure 2 As shown, it includes a telescopic push rod 1 for pushing out the wire gripper, and a pulling part 2 for drawing the wire gripper closer. The telescopic push rod 1 includes a telescopic sleeve 11 and a connecting part 12. The telescopic sleeve 11 includes a large To the first sleeve pipe 14, the second sleeve pipe 16 and the third sleeve pipe 17 which are nested in turn, the second sleeve pipe 16 protrudes from one end of the first sleeve pipe 14, and the other end of the first sleeve pipe 14 is connected by The pipe 13 is fixedly connected with the connection part 12, the connection part 12 is a U-shaped part 12, and the U-shaped part 12 includes two opposite legs, and the two opposite legs are used to clamp the bolted end 441 of the pull plate and connect with the pull plate. The bolted end 441 is detachably bolted.

[0033] After the second sleeve 16 stretches out, the wall near one end of the first sleeve 14 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com