Construction method of drainage opening of rear-mounted retaining wall

A construction method and technology for retaining walls, which are applied in water conservancy projects, soil protection, artificial islands, etc., can solve the problems of affecting the layout effect of decorative tiles on the wall body during the decoration stage, unable to ensure accurate positioning, and affecting the efficiency of backfilling. Conducive to finished product protection, fast construction, and convenient reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

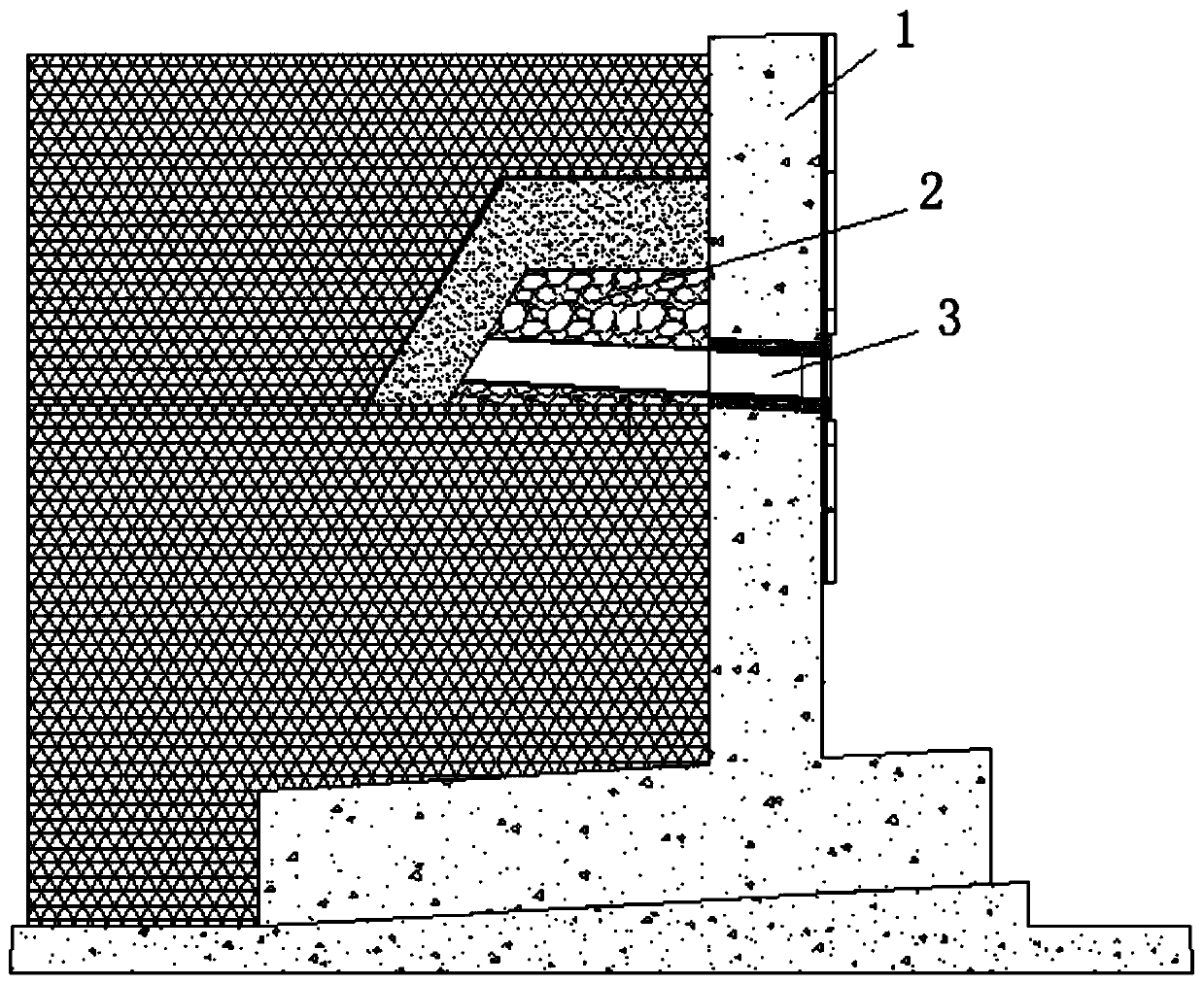

[0030] Below in conjunction with accompanying drawing, describe a kind of construction method of post type retaining wall weep hole in detail.

[0031] see figure 1 , a construction method for a post-mounted retaining wall drain hole, the construction process: wall reinforcement binding - casing pre-embedded - formwork support - concrete pouring - retaining wall backfill - earth reverse Excavation - burial of drain pipes - installation of filter bags - backfilling - plastering - tiling - installation of sleeves

[0032] During the construction, the "jumping warehouse method" is used to carry out the construction of each section of the retaining wall structure, and a certain strength foam board is used at the deformation joint to isolate from the foundation of the two adjacent retaining walls to the top of the wall. The specific construction steps are as follows:

[0033] 1. Binding of steel bars on the wall

[0034] After the concrete pouring of the foundation of the retain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com