Tunnel road safety structure based on drainage system

A drainage system and safety structure technology, applied in drainage, safety devices, mining equipment, etc., can solve problems such as collisions on inner walls, rear-end collisions, traffic accidents, etc., and achieve the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

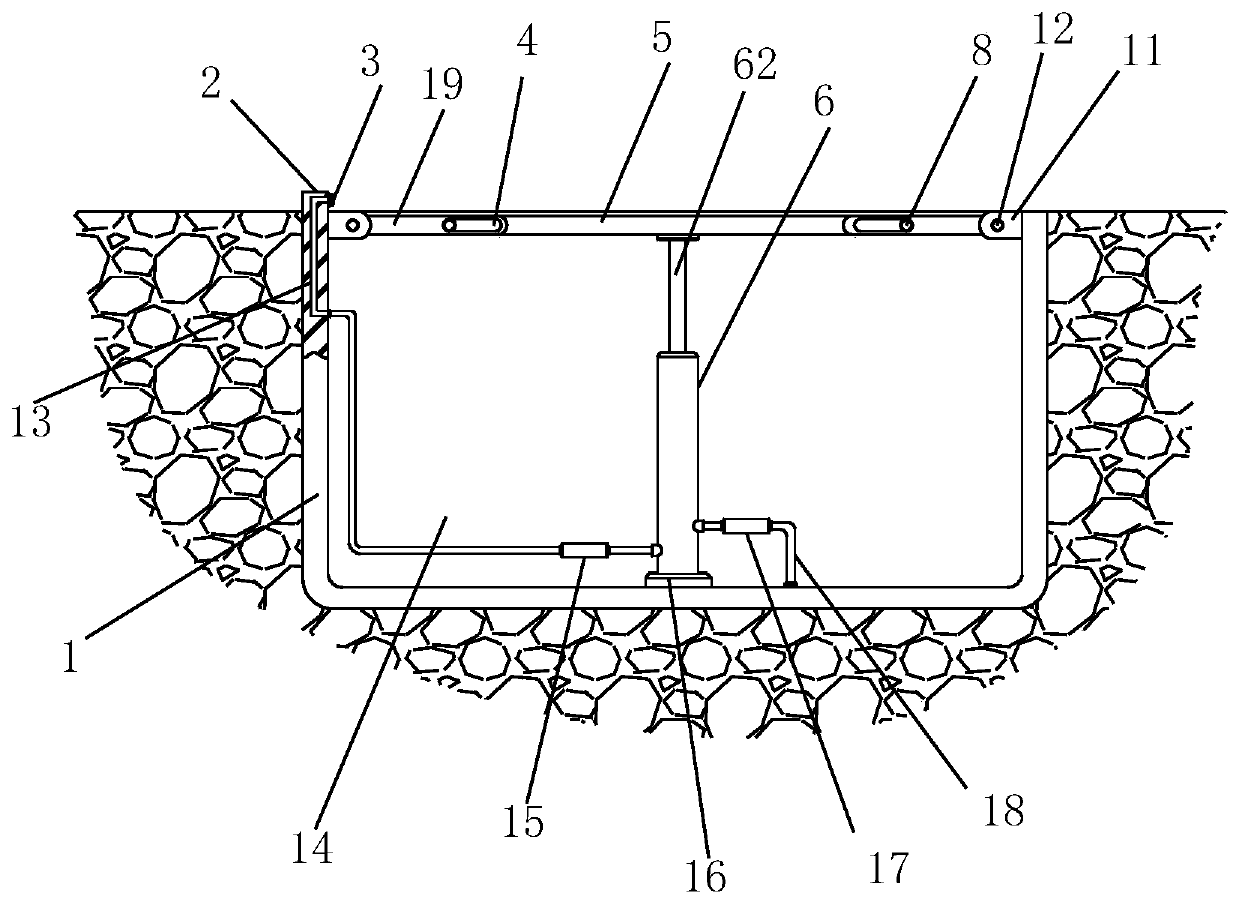

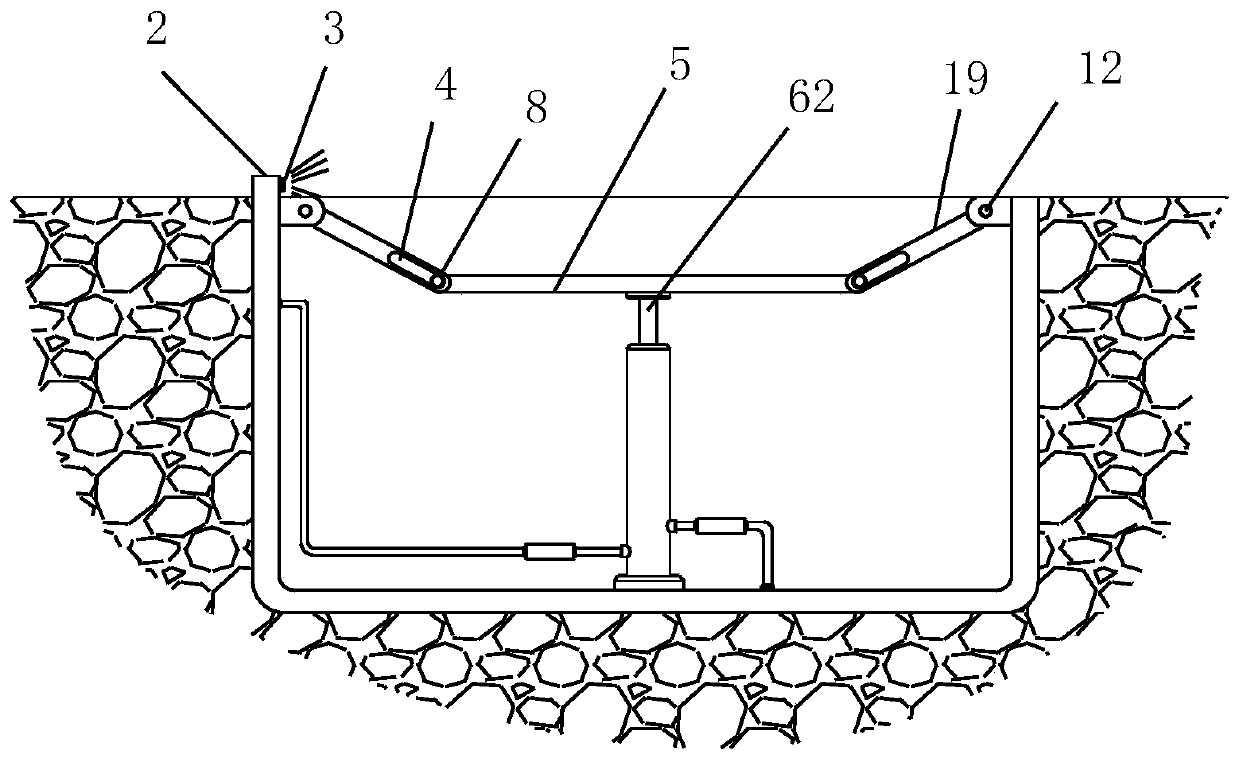

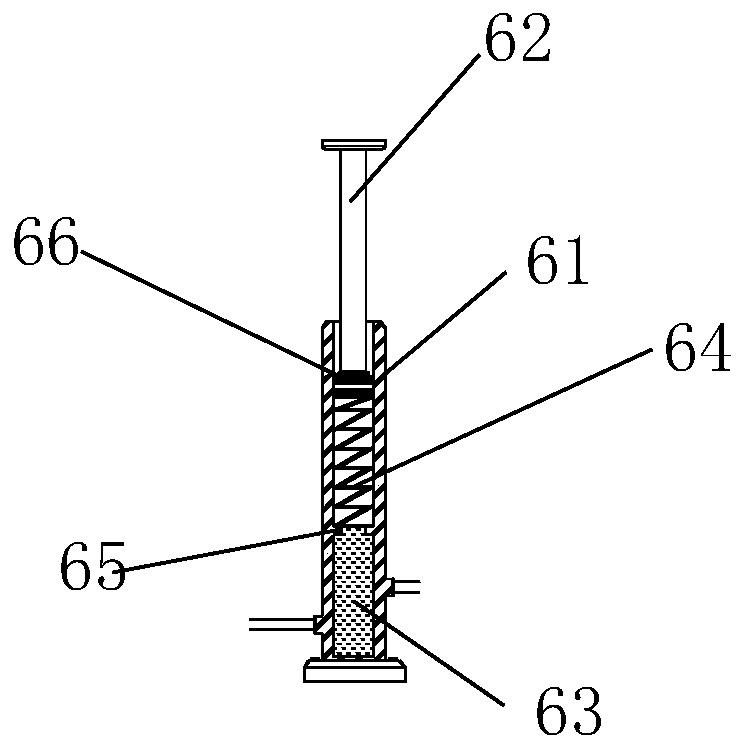

[0018] Such as figure 1 and Figure 4 As shown, the tunnel road safety structure based on the drainage system includes embedded parts 1 arranged on both sides of the tunnel. The upper end surface of the embedded part 1 is flush with the upper end surface of the tunnel ground. A drainage cavity 14 with an open top, and more than one composite protection rod is equidistantly arranged at the top opening end of the drainage chamber 14, and the composite protection rods are arranged equidistantly along the length direction of the embedded part 1, and the two sides of each composite protection rod They are all hinged on the connecting ear 11 on the inner wall of the drainage cavity. A buffer support 6 is provided at the bottom of each composite protection rod. The buffer support 6 lifts up the composite protection rod and makes the composite protection rod parallel to the horizontal plane.

[0019] In this embodiment, the composite protective rod includes two connecting rods 19 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com