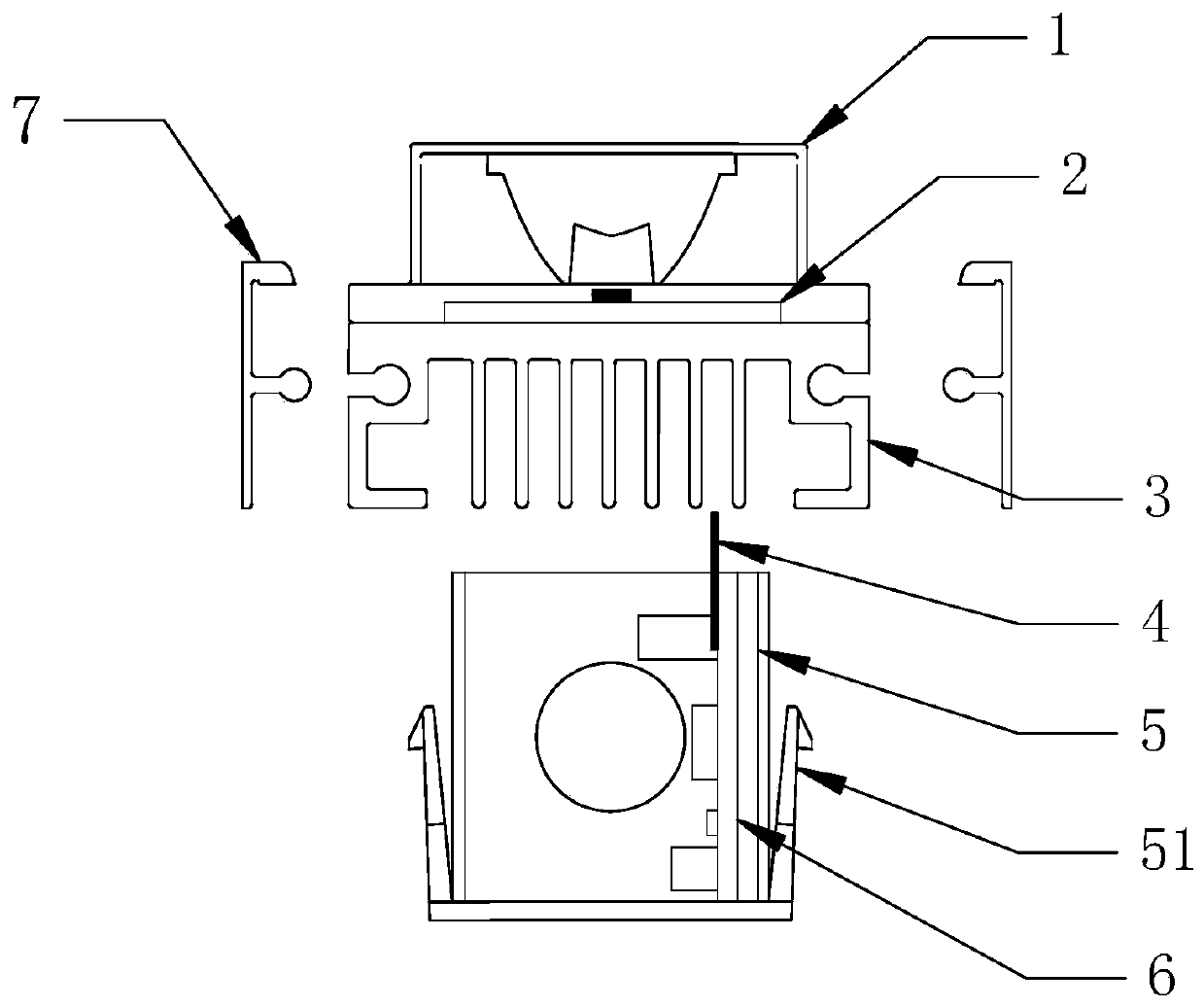

Modular wall washing lamp and assembling method thereof

A modular and lamp technology, applied in lighting devices, fixed lighting devices, gas-proof/waterproof devices, etc., can solve the problems of poor impact resistance of glass, complex structure, difficult to improve waterproof performance, etc., to improve product yield rate , control material inventory, and reduce operating costs

- Summary

- Abstract

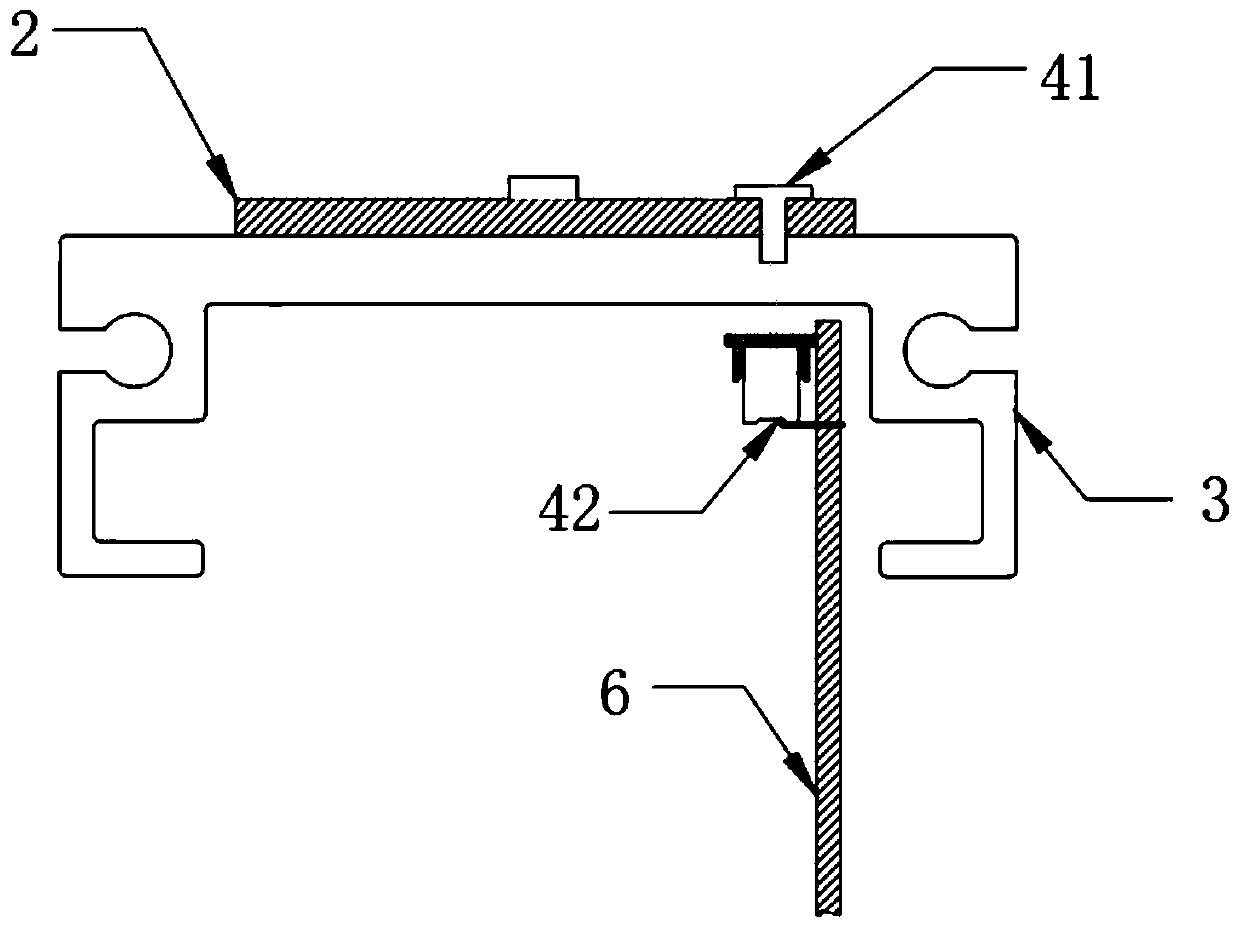

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

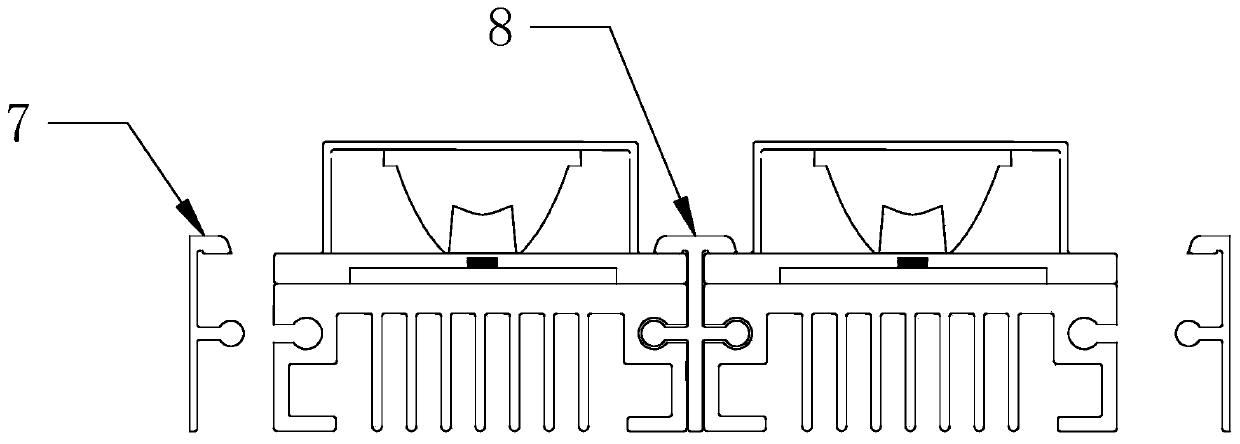

[0028] Embodiment two, such as Figure 3-5 Compared with Embodiment 1, this embodiment further includes a second buckle plate 8, the shape of the second buckle plate 8 is "dry", that is, it is composed of two sets of mirror-symmetrical first buckle plates 7, Both sides of the second buckle plate 8 are also set as buckle protrusions that match the grooves on both sides of the lamp body 3, so that the two groups of lamp bodies 3 can be connected by using the second buckle plate 8, and only the length of the second buckle plate 8 is required. Sufficient, multiple wall washer lamps can be superimposed vertically to combine tunnel lamps, flood lamps, street lamps and other lighting lamps.

[0029] Implementation three

[0030] An assembly method based on the above-mentioned lamps, which clamps two lamp bodies, which includes the following steps:

[0031] S1. According to the lighting requirements required by the installation location, calculate the number of lamp holders required...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com