Water squeezing device of foam cotton head mop

A technology of water squeezing device and foamed cotton, which is applied in cleaning carpets, floors, cleaning equipment, etc. It can solve the problems that the collodion mop cannot be cleaned, and achieve good water squeezing effect, easy processing and use, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

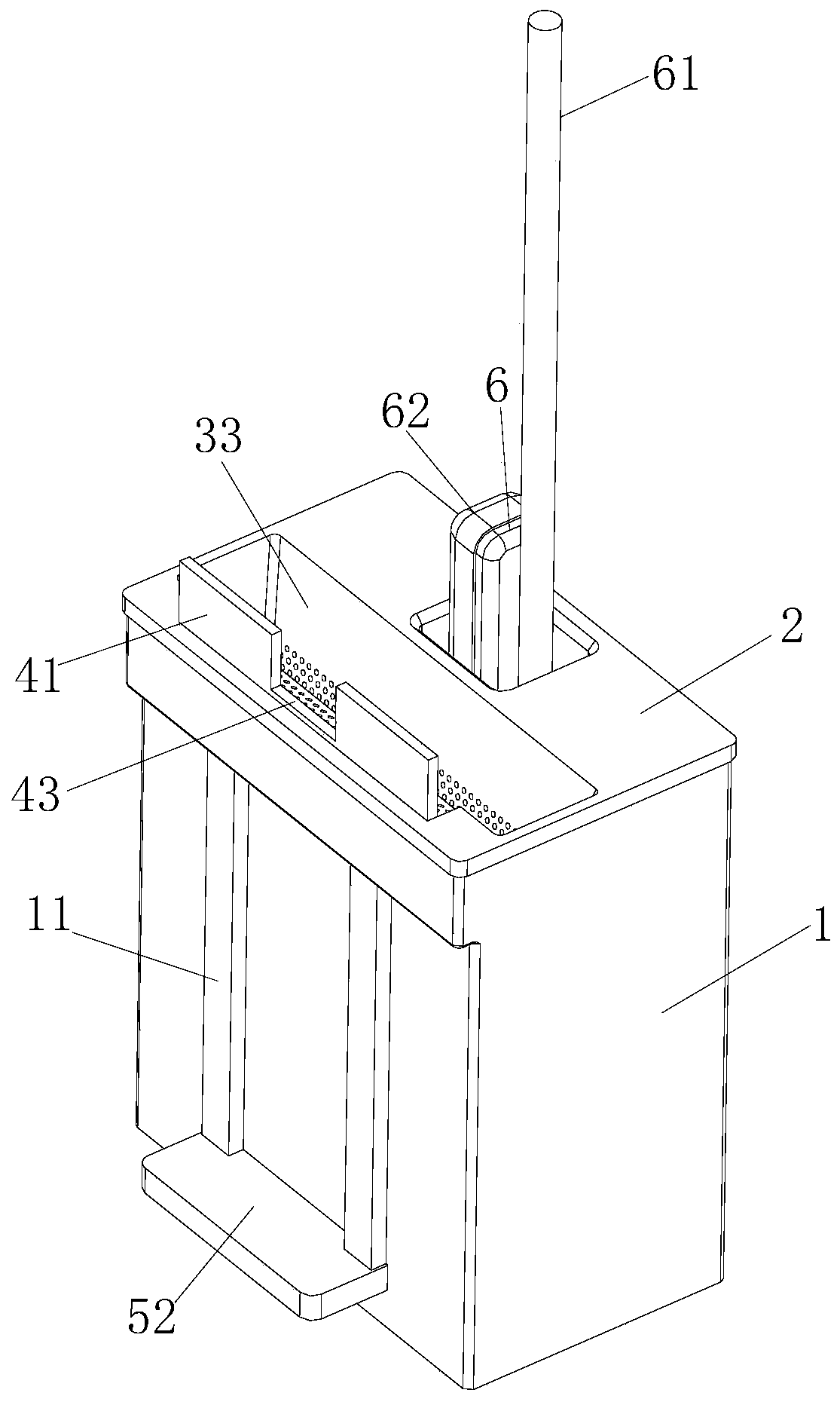

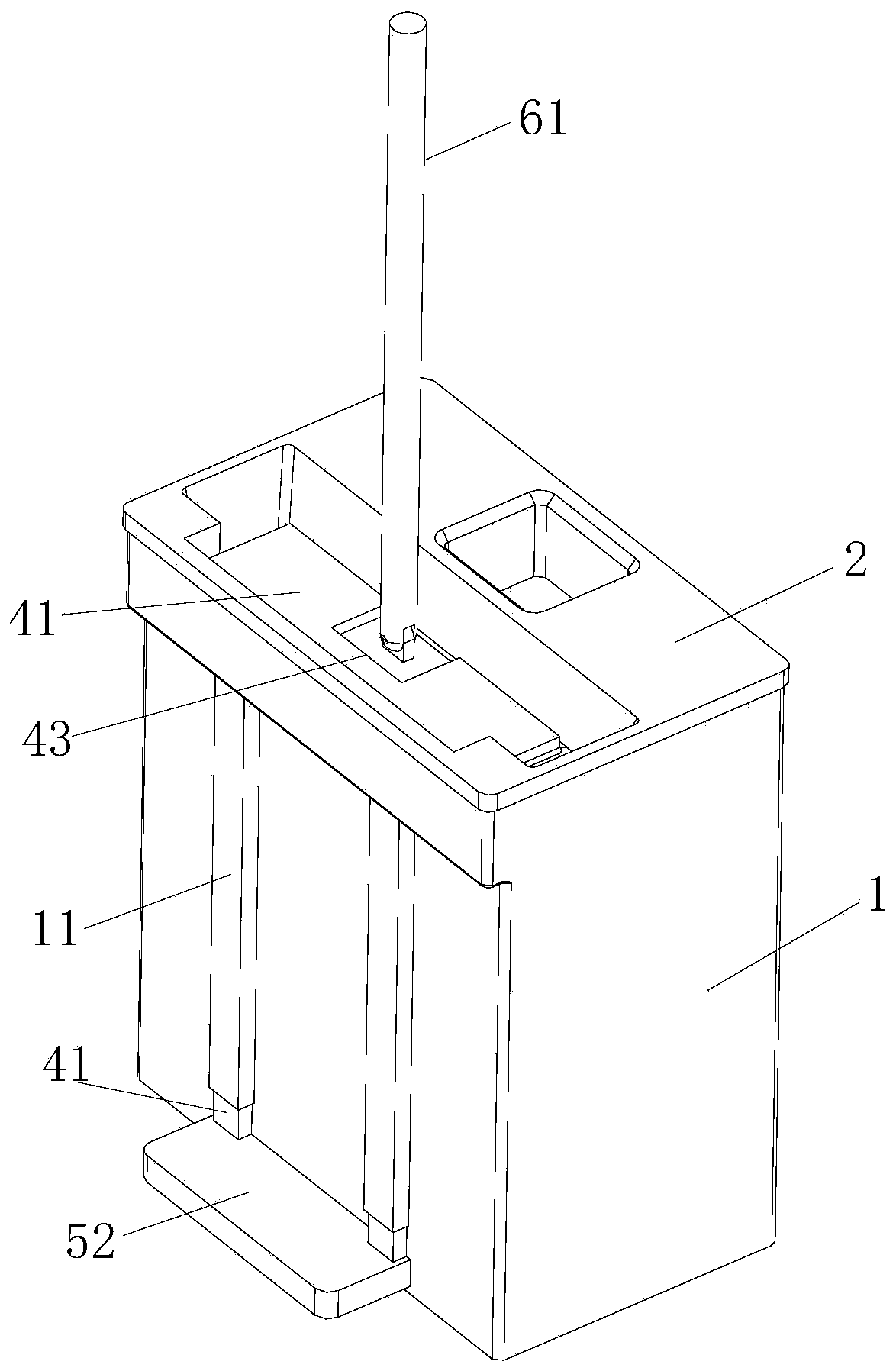

[0049] Embodiment one: if Figure 1-5 As shown, the water squeezing device of the foamed cotton head mop includes a housing 1, and the housing 1 forms a space for accommodating water. The housing 1 can be a closed container, or just a bracket, that is, The space for accommodating water may be a closed space or a space connected to the outside world, and the water squeezed out from the mop may be contained in the space or directly flow out to the outside world.

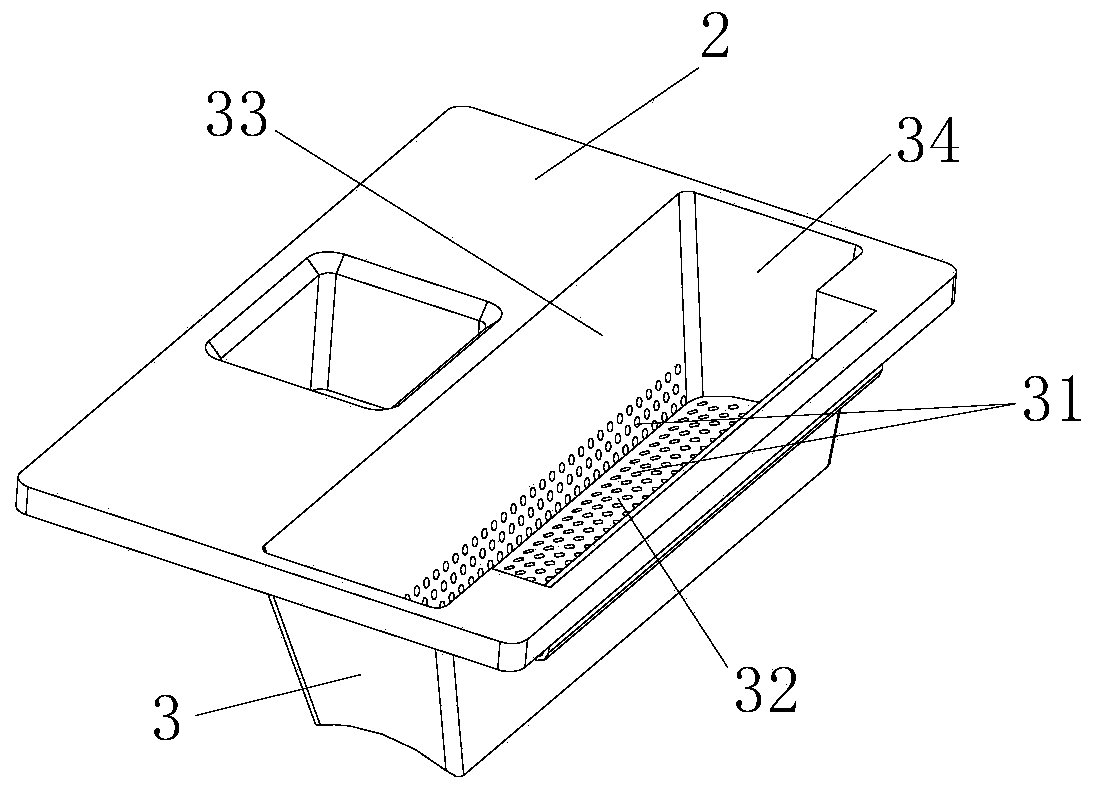

[0050] The shell 1 is provided with an extrusion frame 2, which is located above the shell 1, and is used to fix the water squeeze tank 3, and is used to position the water squeeze tank 3 at a vacated position above the shell 1, and the water squeeze tank 3 is emptied and set and squeezes the water tank 3 is provided with an upward opening, and at least part of the side surface 33 , the end surface and the bottom surface 32 of the water squeezing tank 3 are provided with water squeezing holes 31 . Such as Figure 1-5...

Embodiment approach

[0053] Moreover, in order to better squeeze water, the bottom surface 32 may be an upward convex surface, for example, the cross section of the bottom surface 32 in the width direction is arc-shaped. And it should be pointed out that the bottom surface 32 may be arc-shaped in cross-section along the width direction, may also be arc-shaped in cross-section in the length direction, or may be arc-shaped convex in both directions. Such setting, through the upward protrusion of the bottom surface 32, makes the foamed cotton head more easily and well squeezed out the water. And those skilled in the art can also understand that, as long as at least part of the bottom surface or the surrounding surface of the water squeezing tank can squeeze the foamed cotton head of the foamed cotton head mop so that it can discharge water. Certainly, there is also the following embodiment: the cross section of the water squeezing groove 3 gradually shrinks from top to bottom, combined with the arc-s...

Embodiment 2

[0060] Embodiment two: if Figure 6-8 Shown is the water squeezing device of the foamed cotton mop according to the second embodiment of the present invention. In this embodiment, the water squeezing tank 3' and the squeezing frame 2' are integrally formed, and the housing 1 is a closed structure with an opening at the top. , the extrusion frame 2' extends upwards from the inner bottom of the housing 1 to the top of the housing 1, the flushing sink 3' is located at the opening of the top housing 1 of the extrusion frame 2', and the squeezing groove 3' is located in the housing 1 One side of the top opening, the other side of the opening is open. Slots 31' are arranged on several sides and end faces of the water squeezing tank 3'. The slots 31' are evenly spaced and extend from the edge of the bottom surface 32' to the edge of the side surface 33'. There is no opening on the bottom surface 32'. holes, but are provided with upward protruding bumps 321, and the bumps 321 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com