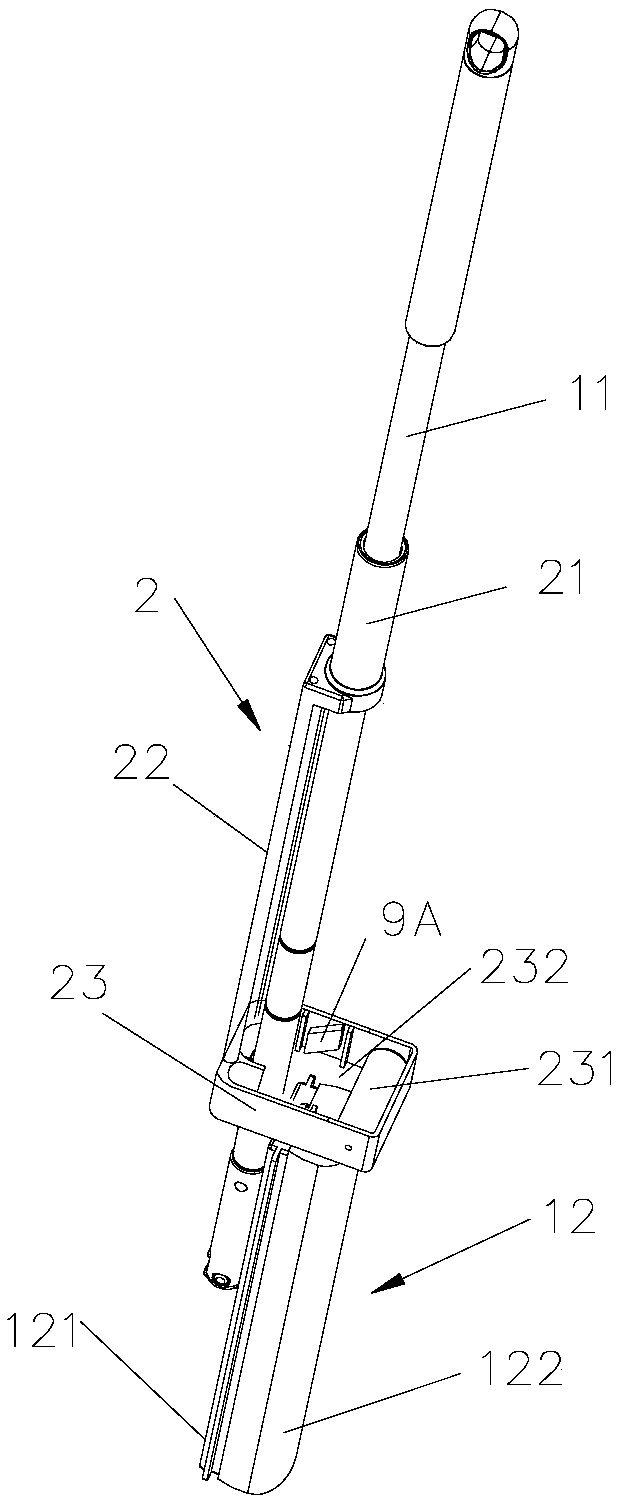

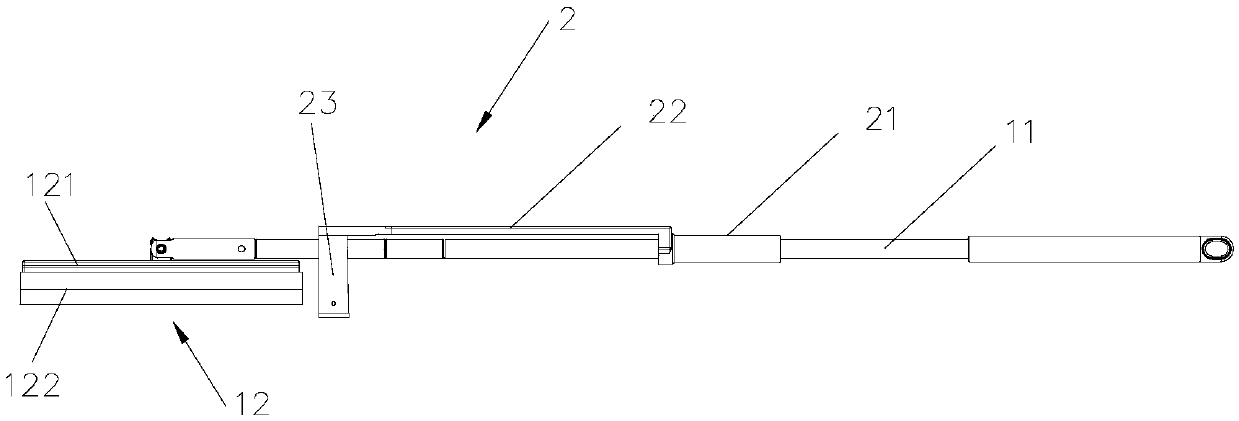

Foamed cotton mop with guiding structure

A technology of guiding structure and foamed cotton, which is applied in the direction of cleaning carpets, floors, cleaning equipment, etc. It can solve the problems that the water squeezing effect cannot be optimized to the maximum, and achieve the effect of improving the water squeezing effect and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

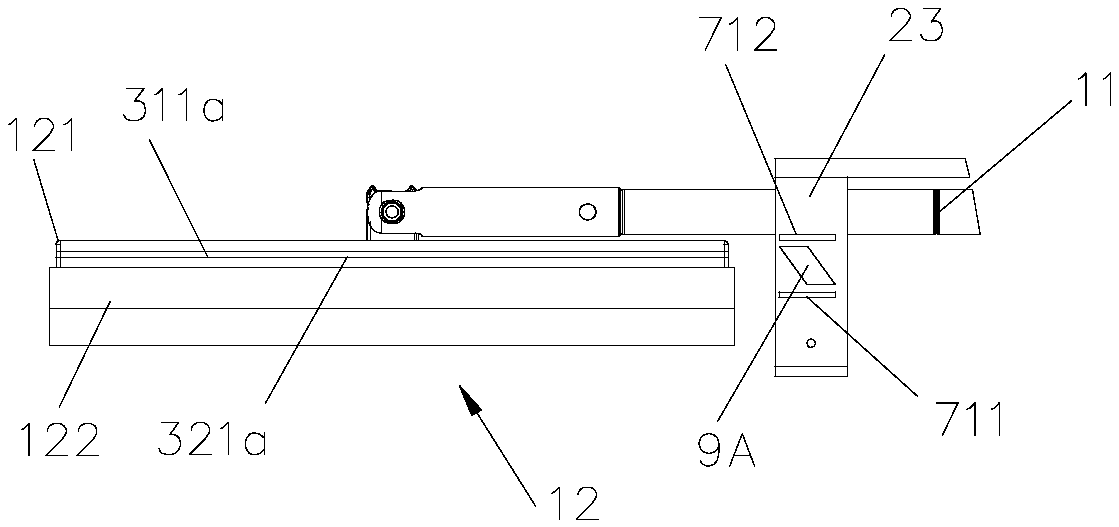

Embodiment 2

[0051] Embodiment two: if Figure 5 As shown, the difference from Embodiment 1 mainly lies in the guiding structure. The upward guiding structure 31b includes an upward guiding rib 311b fixed on the side of the mounting seat 121 and arranged axially along the mounting seat 121, and fixed on the inner wall of the opening 232, And the upward guide rail on the same straight line as the upward guide rib 311b, the upward guide rail includes an upward inclined rail 312b inclined towards the retreat direction, and an upward inclined rail 312b connected to the front end of the upward inclined rail 312b and arranged parallel to the axial direction of the mounting seat 121 When the upward straight rail 313b slides in the backward direction, the surface of the upward inclined rail 312b slides against the front end of the upward guide rib 311b, so that the front end of the upward guide rib 311b relatively slides to the position of the upward straight rail 313b, and the upward movement The...

Embodiment 3

[0052] Embodiment three: as Figure 6 , 7 As shown, the difference from Embodiment 1 mainly lies in the guiding structure. The upward guiding structure 41a includes an upward guiding rib 411a fixed on the inner wall of the opening 232 and arranged axially along the mounting seat 121, and fixed on the side of the mounting seat 121, And the upward guide rail on the same straight line as the upward guide rib 411a, the upward guide rail includes an upward inclined rail 412a inclined towards the forward direction, and is connected to the front end of the upward inclined rail 412a, and is arranged axially parallel to the mounting seat 121 When the squeeze head 23 slides in the forward direction, the front end of the upward guide rib 411a slides against the surface of the upward inclined rail 412a to the position of the upward straight rail 413a, and moves forward along the surface of the upward straight rail 413a. direction to move. The downward guide structure 42a includes a down...

Embodiment 4

[0054] Embodiment four: as Figure 8 As shown, the difference from Embodiment 1 mainly lies in the guiding structure. The upward guiding structure 41b includes an upward guiding rib 411b fixed on the inner wall of the opening 232 and arranged axially along the mounting seat 121, and fixed on the side of the mounting seat 121, And the upward guide rail located on the same straight line as the upward guide rib 411b, the upward guide rail includes an upward ramp 412b inclined towards the backward direction, and is connected to the rear end of the upward ramp 412b, and is parallel to the mounting seat 121 axially The set upward straight rail 413b, when the squeeze head 23 slides in the backward direction, the rear end of the upward guide rib 411b slides against the surface of the upward inclined rail 412b to the position of the upward straight rail 413b, and moves along the surface of the upward straight rail 413b toward Move in the backward direction. The downward guiding struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com