Plain-weave plastic braiding machine

A plastic weaving machine, flat weaving technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of poor structural bending resistance, unsatisfactory water squeezing effect, etc., to improve the water squeezing effect, ensure quality, The effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

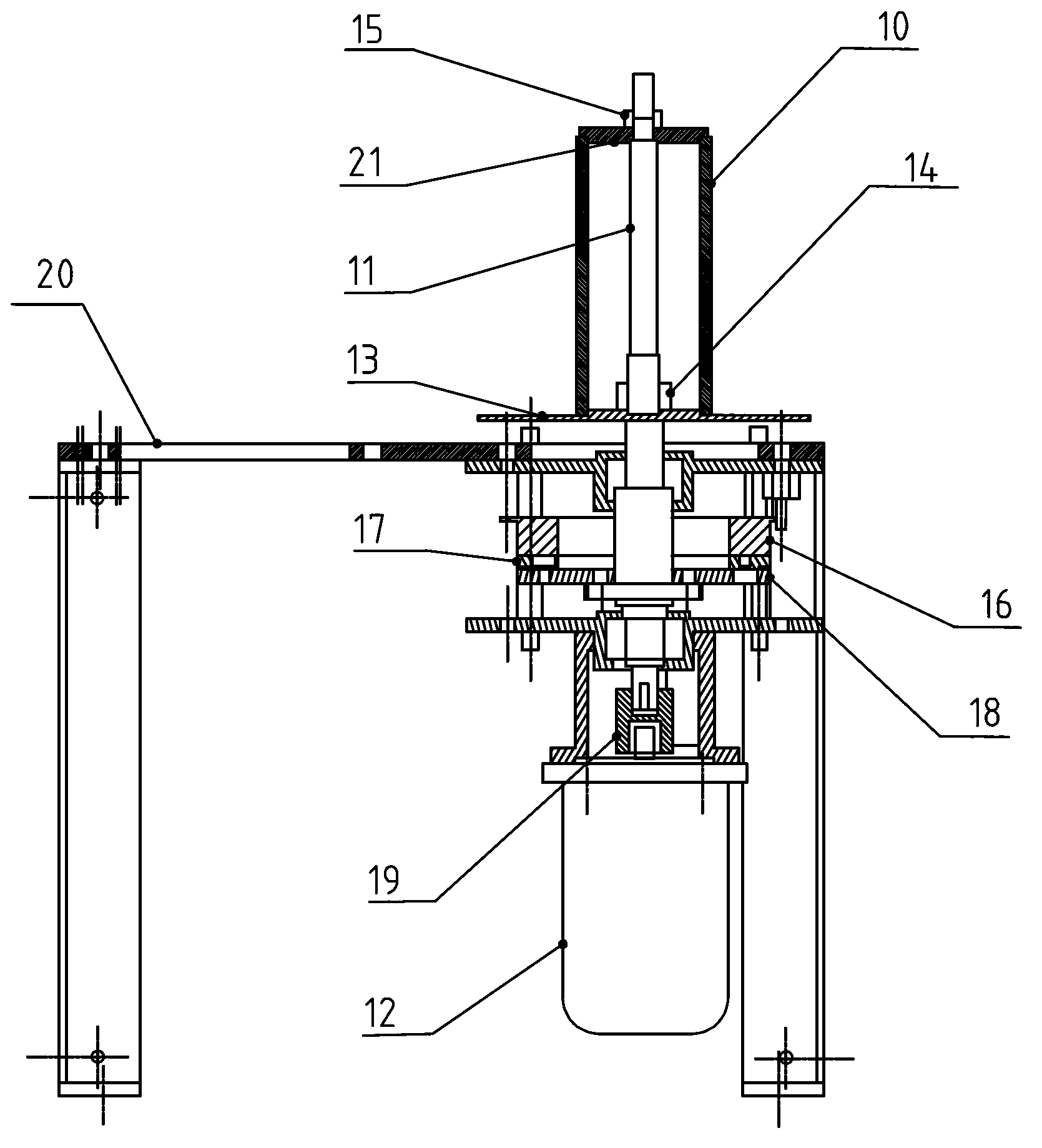

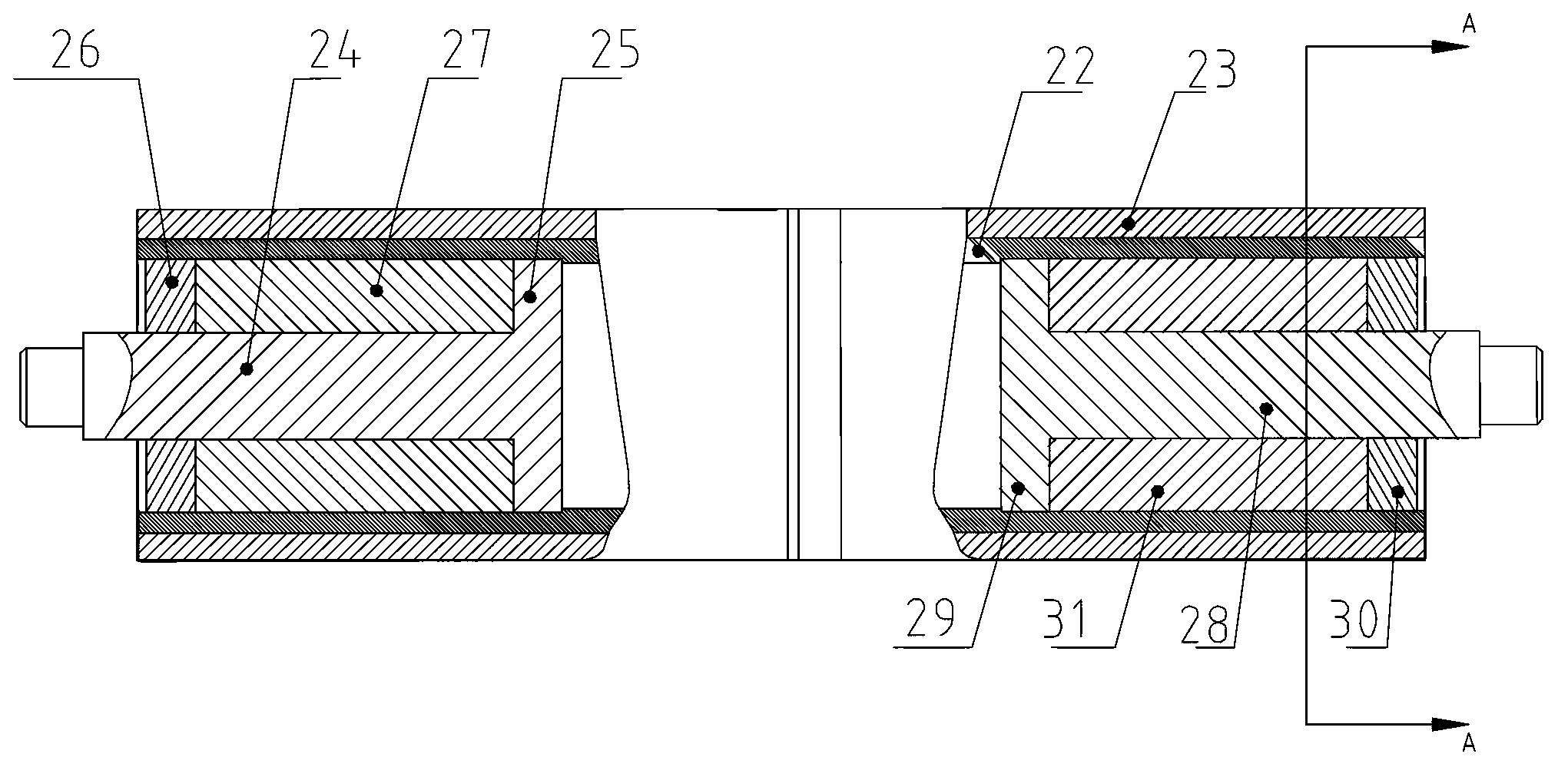

[0020] A flat weaving plastic knitting machine comprises a shedding mechanism, a water jet weft insertion mechanism, a weft beating mechanism, a let-off mechanism, a coiling mechanism and an auxiliary mechanism. In addition to the electronic weft cutter device and the electronic weft feeding device, the above-mentioned auxiliary mechanism can also include a length measuring device, a weft storage device, a hemming device and a warp breaking automatic stop device. Except the electronic weft yarn cutter device and the electronic weft feeding device described below, other mechanisms or devices can be realized by adopting or referring to existing technologies.

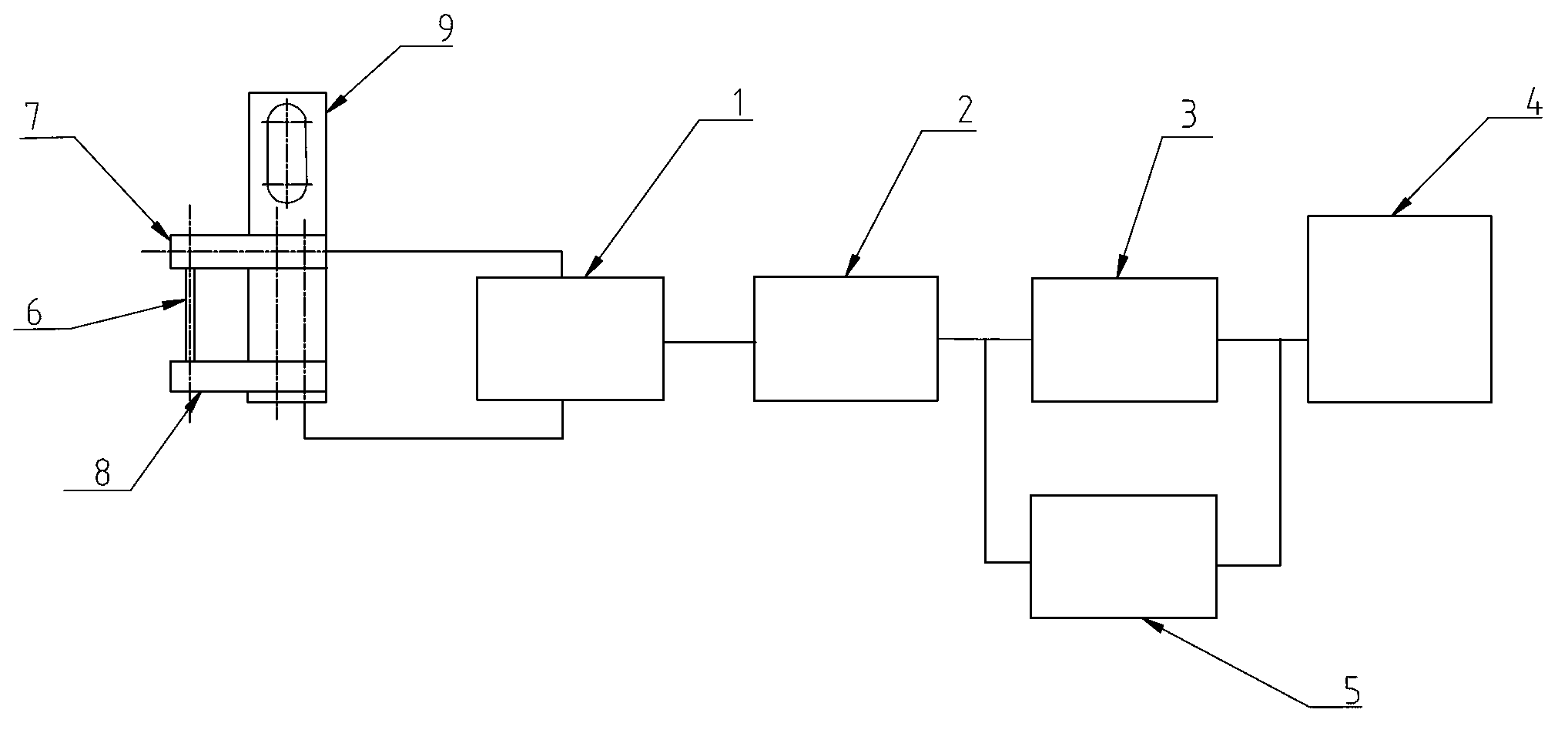

[0021] combine figure 1 , the above-mentioned electronic weft cutter device includes a main controller 5, a current relay 2, a current transformer 1, a No. 1 copper terminal 7, a No. 2 copper terminal 8 and a resistance wire 6 for scalding the weft yarn. The main controller is connected to the current relay, the current r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com