Low- and zero-twist cotton nylon and polyester dual core-spun compound yarn

A technology of core-spun and strands, applied in the field of strands, which can solve the problems of affecting the appearance of clothing, increasing slack, twisting and slipping of core yarn, etc., to improve the speed of sizing and dyeing, reduce slack, and make clothes tidy beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

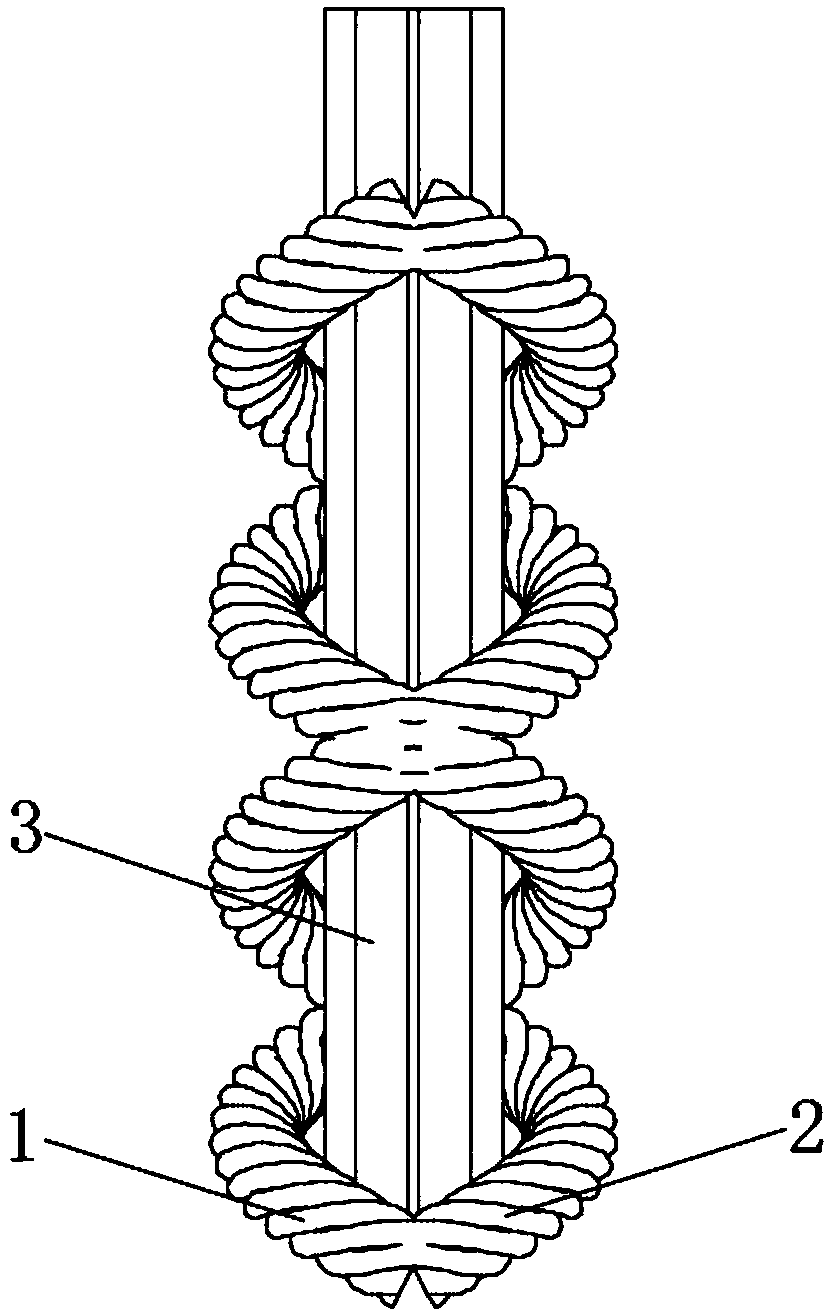

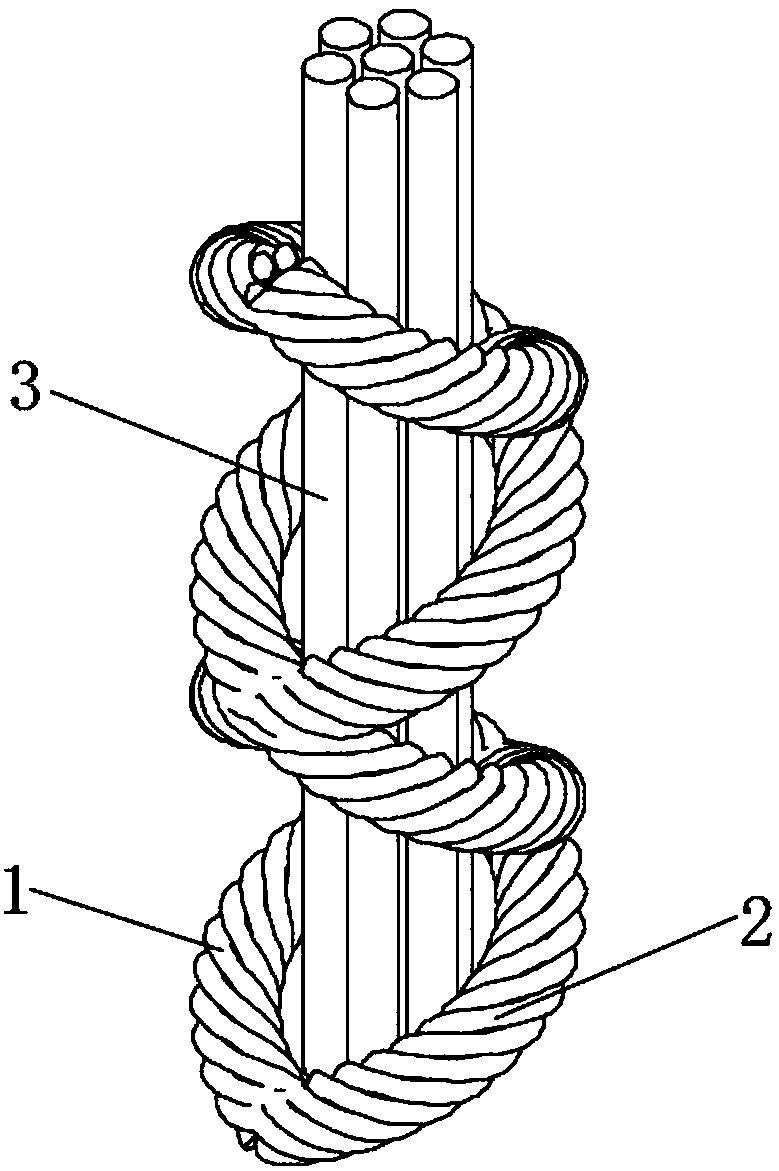

[0033] see Figure 1-4 , the present invention provides a technical solution: a low, untwisted cotton nylon, polyester double core-spun yarn, including yarn I 1, yarn II 2 and core yarn 3;

[0034] The yarn I 1 wraps the core filament 3 by rotating in the S direction, the yarn II 2 wraps the core filament 3 by rotating in the Z direction, and the yarn I 1 and the yarn II 2 cross-wrap the core filament 3;

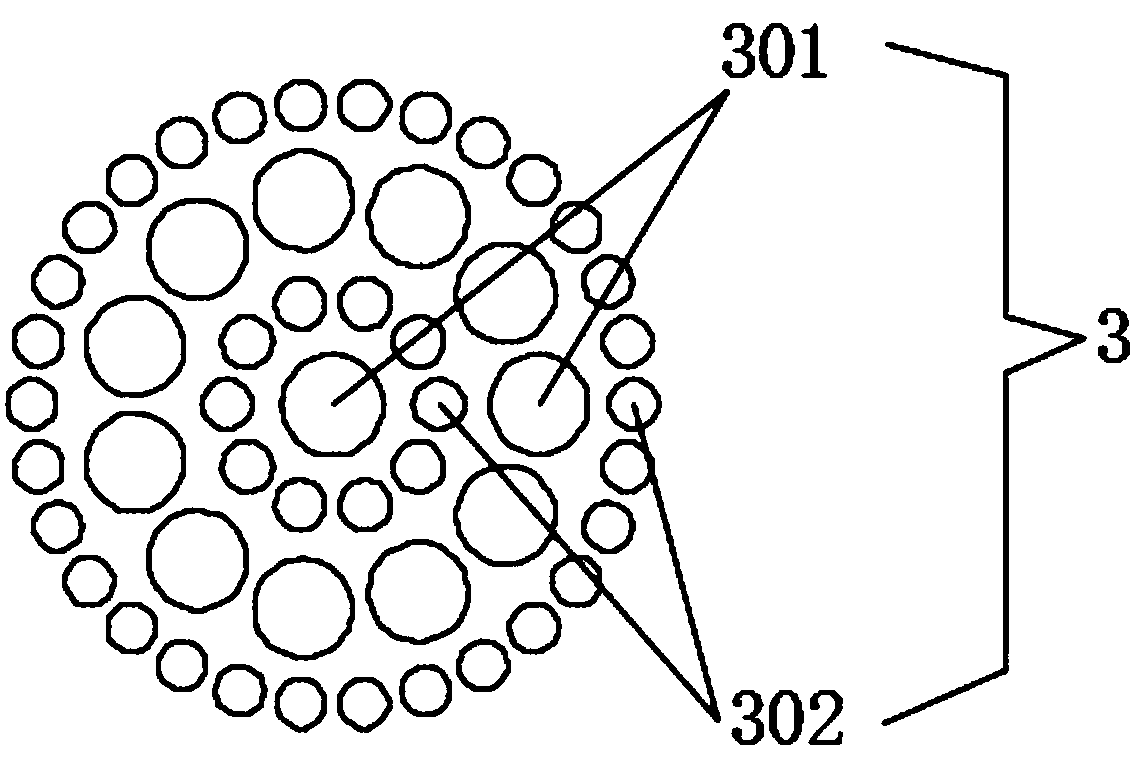

[0035] Core wire 3 is:

[0036] 1. 1F-48F nylon filament or polyester filament;

[0037] 2. Composed of four inner layers of raw silk, and two layers of raw silk are thick silk 301, and the other two layers of raw silk are thin silk 302, thick silk 301 and thin silk 302 are alternately stacked, and the core of the core silk 3 It is a thick wire 301 , and the core wire 3 is provided with equidistant bundle segments 303 .

[0038] Further, the yarn I 1 is an S-twisted cotton yarn, and the count of the yarn I 1 is 32, and the twist of the yarn I 1 is 90 twists.

[0039] Fur...

Embodiment 2

[0049] see Figure 1-4 , the present invention provides a technical solution: a low, untwisted cotton nylon, polyester double core-spun yarn, including yarn I 1, yarn II 2 and core yarn 3;

[0050] The yarn I 1 wraps the core filament 3 by rotating in the S direction, the yarn II 2 wraps the core filament 3 by rotating in the Z direction, and the yarn I 1 and the yarn II 2 cross-wrap the core filament 3;

[0051] Core wire 3 is:

[0052] 1. 1F-48F nylon filament or polyester filament;

[0053] 2. Composed of four inner layers of raw silk, and two layers of raw silk are thick silk 301, and the other two layers of raw silk are thin silk 302, thick silk 301 and thin silk 302 are alternately stacked, and the core of the core silk 3 It is a thick wire 301 , and the core wire 3 is provided with equidistant bundle segments 303 .

[0054] Further, the yarn I 1 is an S-twisted cotton yarn, and the count of the yarn I 1 is 32, and the twist of the yarn I 1 is 90 twists.

[0055] Fur...

Embodiment 3

[0065] see Figure 1-4, the present invention provides a technical solution: a low, untwisted cotton nylon, polyester double core-spun yarn, including yarn I 1, yarn II 2 and core yarn 3;

[0066] The yarn I 1 wraps the core filament 3 by rotating in the S direction, the yarn II 2 wraps the core filament 3 by rotating in the Z direction, and the yarn I 1 and the yarn II 2 cross-wrap the core filament 3;

[0067] Core wire 3 is:

[0068] 1. 1F-48F nylon filament or polyester filament;

[0069] 2. Composed of four inner layers of raw silk, and two layers of raw silk are thick silk 301, and the other two layers of raw silk are thin silk 302, thick silk 301 and thin silk 302 are alternately stacked, and the core of the core silk 3 It is a thick wire 301 , and the core wire 3 is provided with equidistant bundle segments 303 .

[0070] Further, the yarn I 1 is an S-twisted cotton yarn, and the count of the yarn I 1 is 40, and the twist of the yarn I 1 is 110 twists.

[0071] Fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com