Production method of knitted fabric containing antibacterial herbaceous fibers and knitted fabric

A technology of knitted fabrics and herbal fibers, applied in knitting, weft knitting, warp knitting, etc., can solve problems such as easy to twist and difficult to form fabrics, and achieve the effect of uniform bars, low twist, and no twist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a method for producing knitted fabrics containing antibacterial herbal fibers, comprising the following steps:

[0034] S1: Grass coral viscose fiber and pure cotton fiber are used, wherein the mass ratio of grass coral viscose fiber to pure cotton fiber is 0.4:1;

[0035] S2: Use a doubling machine to doubling grass coral viscose fiber and pure cotton fiber to form yarn;

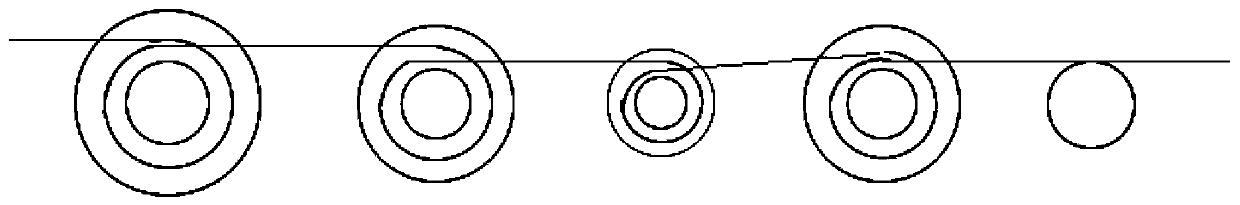

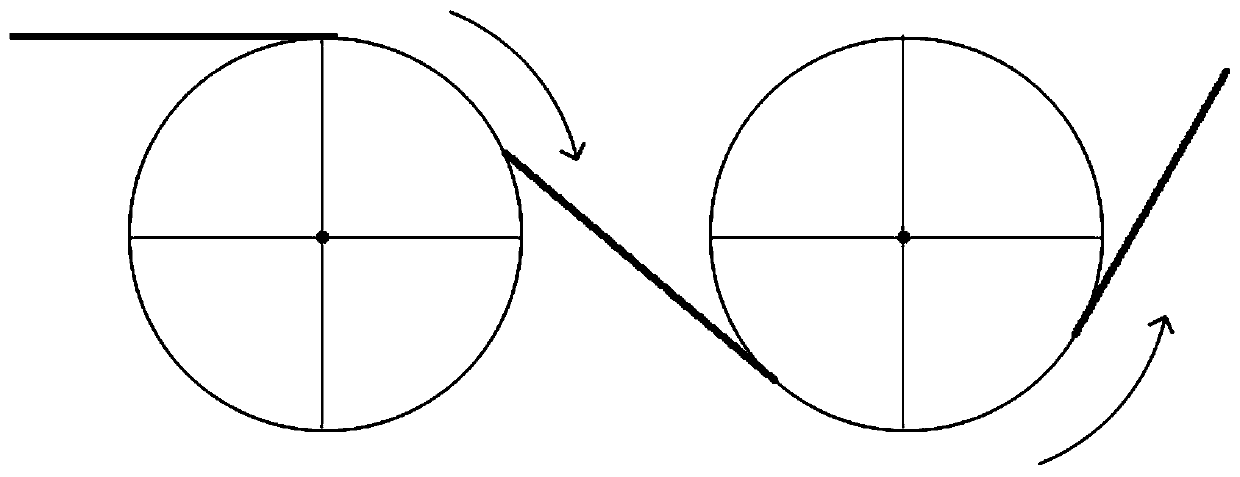

[0036] S3: adjust the twist of the yarn in the step S2 to 1050r / m, twist the yarn so that the yarn passes through a number of rotating conical tubes with different diameters arranged side by side, there are 4 conical tubes, the first One conical cylinder, the second conical cylinder, the third conical cylinder and the fourth conical cylinder are arranged successively, wherein the bottom surface diameter of the first conical cylinder is 15cm, the cone angle is 80 °, the bottom surface of the second conical cylinder Diameter is 10cm, cone angle is 60 °, and the bottom s...

Embodiment 2

[0040] The present embodiment provides a method for producing knitted fabrics containing antibacterial herbal fibers, comprising the following steps:

[0041] S1: Grass coral viscose fiber and pure cotton fiber are used, wherein the mass ratio of grass coral viscose fiber to pure cotton fiber is 0.45:1;

[0042] S2: Use a doubling machine to doubling grass coral viscose fiber and pure cotton fiber to form yarn;

[0043] S3: Adjust the twist of the yarn in the step S2 to 1100r / m, twist the yarn so that the yarn passes through a number of rotating conical tubes with different diameters arranged side by side, there are 4 conical tubes, the first One conical cylinder, the second conical cylinder, the third conical cylinder and the fourth conical cylinder are arranged successively, wherein the bottom surface diameter of the first conical cylinder is 16cm, the cone angle is 85 °, the bottom surface of the second conical cylinder Diameter is 12cm, cone angle is 65 °, and the bottom ...

Embodiment 3

[0047] The present embodiment provides a method for producing knitted fabrics containing antibacterial herbal fibers, comprising the following steps:

[0048] S1: Grass coral viscose fiber and pure cotton fiber are used, wherein the mass ratio of grass coral viscose fiber to pure cotton fiber is 0.5:1;

[0049] S2: Use a doubling machine to doubling grass coral viscose fiber and pure cotton fiber to form yarn;

[0050] S3: Adjust the twist of the yarn in the step S2 to 1150r / m, twist the yarn so that the yarn passes through a number of rotating conical tubes with different diameters arranged side by side, there are 4 conical tubes, the first One conical cylinder, the second conical cylinder, the third conical cylinder and the fourth conical cylinder are arranged successively, wherein the bottom surface diameter of the first conical cylinder is 18cm, the cone angle is 90 °, the bottom surface of the second conical cylinder Diameter is 14cm, cone angle is 70 °, and the bottom s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com