Single-strand frame spinning fibre parallel processing method for soft yarn

A processing method and fiber technology, which can be used in spinning machines, continuous winding spinning machines, textiles and paper making, etc., can solve the problems of hard hand and poor gloss of fabrics, and achieve the effect of strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

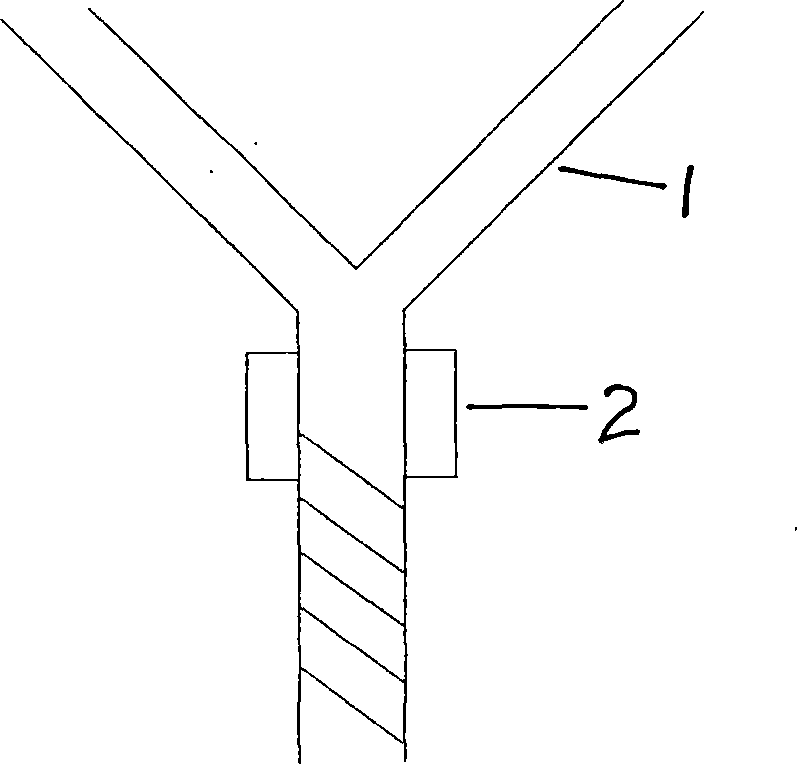

[0012] The method for processing the soft yarn in the parallel state of the single-strand ring-spun fiber described in the present invention, its processing flow is, before the strands (rovings) enter the nip of the front roller, the beam splitting mechanism of the fibers divides the strands (rovings) into beams For two or more fiber bundles, add a twist resistance slide block at the converging point of the twisting triangular area below the jaws of the front roller.

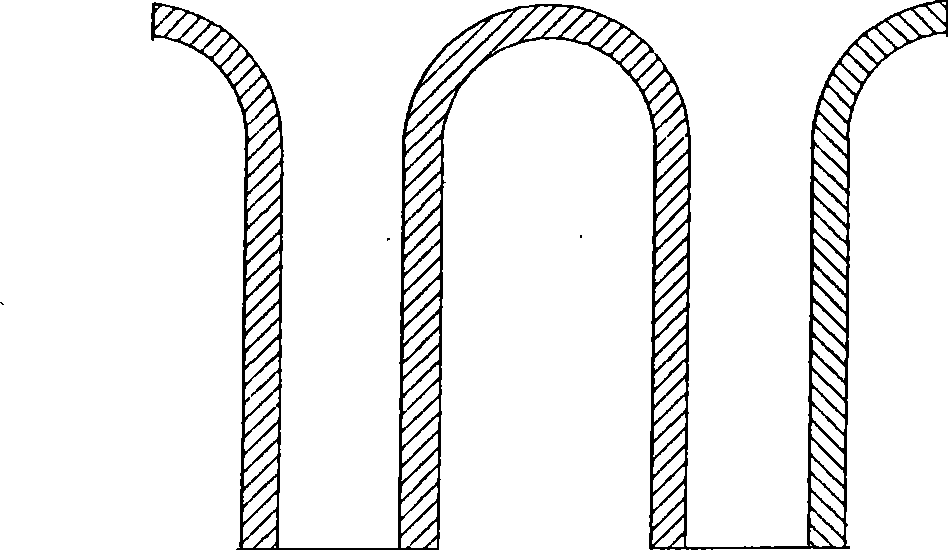

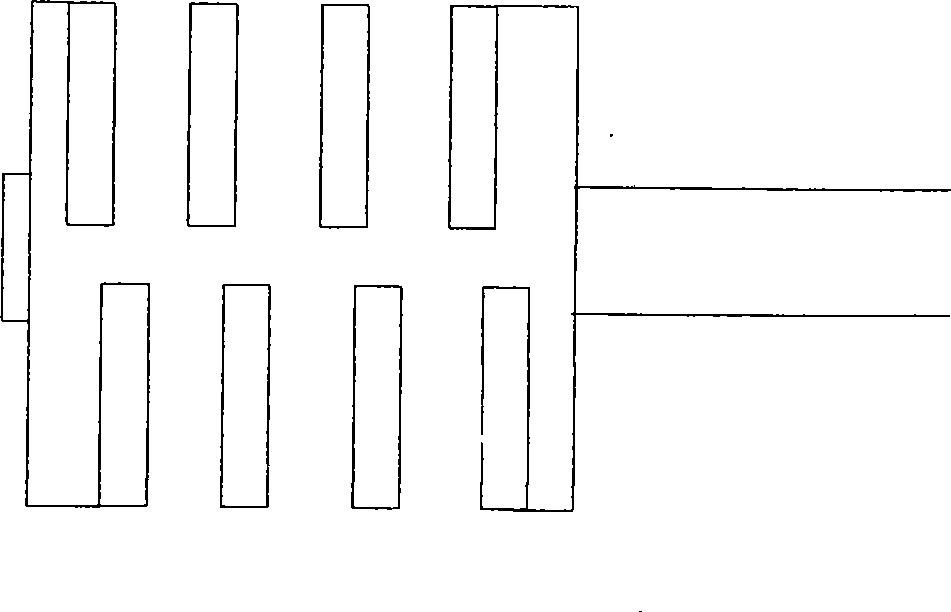

[0013] exist figure 1 Among them, the two-beam splitting mechanism of the roving is installed above the drafting zone and the twisting triangle zone, and its function is to separate the roving into two beams and separate them at a certain distance. figure 2 Multi-bundle splitting element for rovings. roving through figure 1 The two beam-splitting elements, and then through the figure 2 The multi-beam splitting element, in image 3 In the process, a twist-resistance slider 2 is installed below the convergin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com