Patents

Literature

35results about How to "Improve and ensure quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

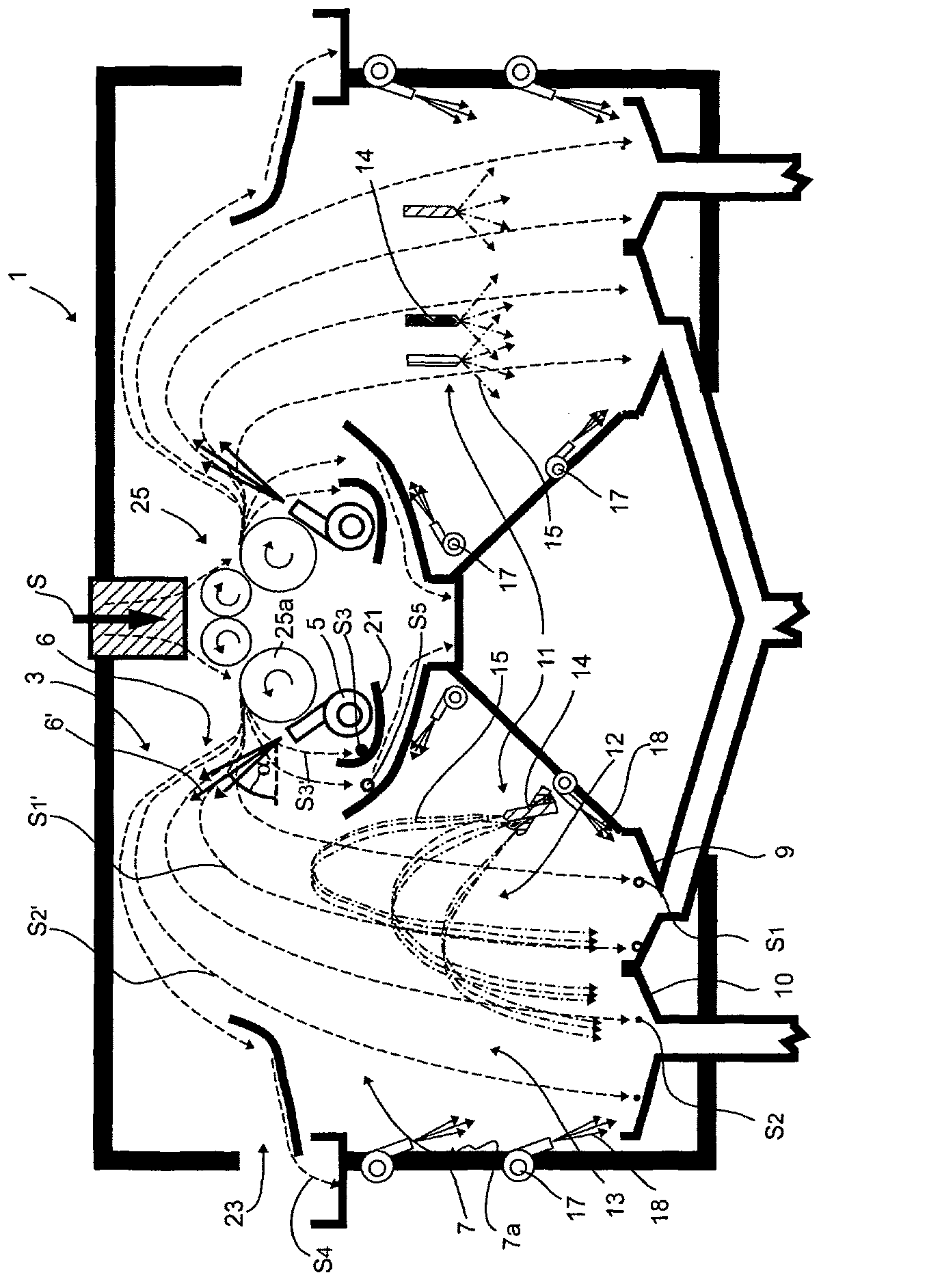

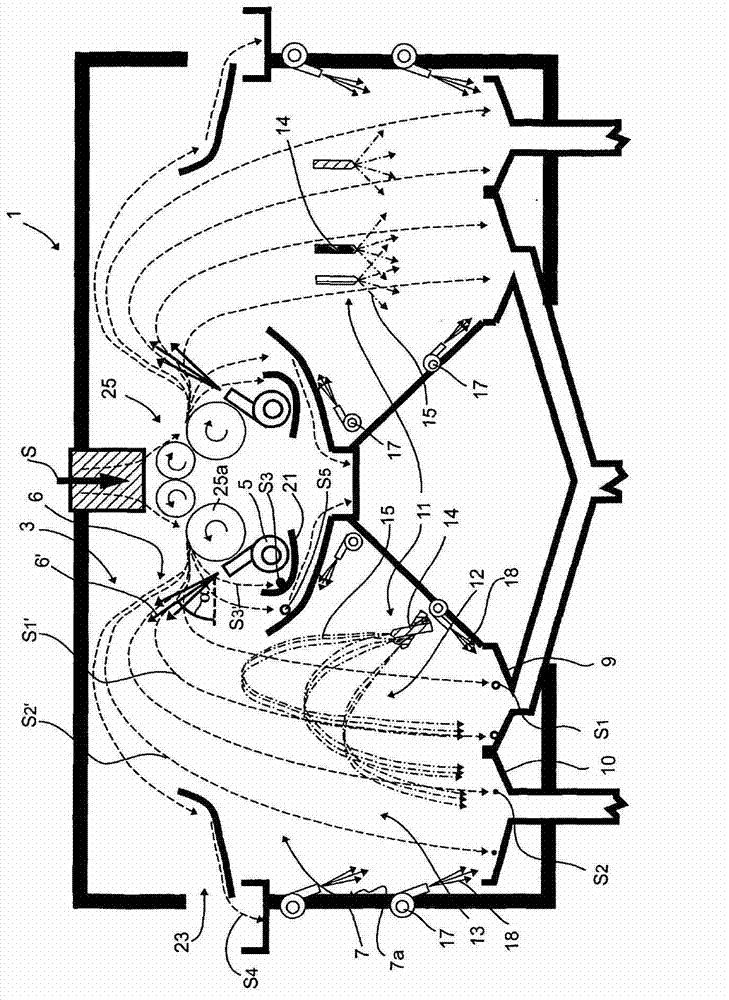

Full-automatic speaker magnetic circuit assembling machine

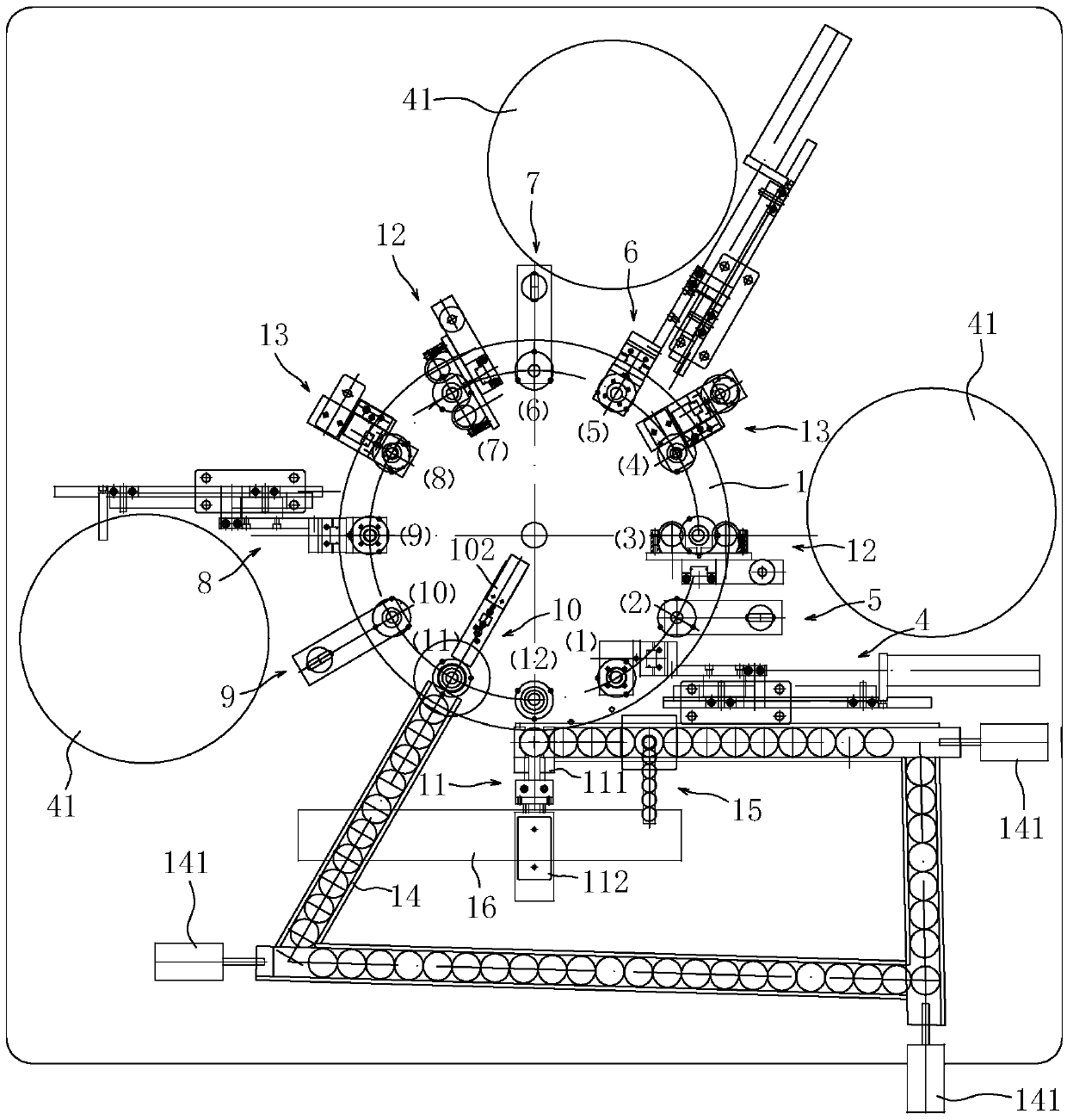

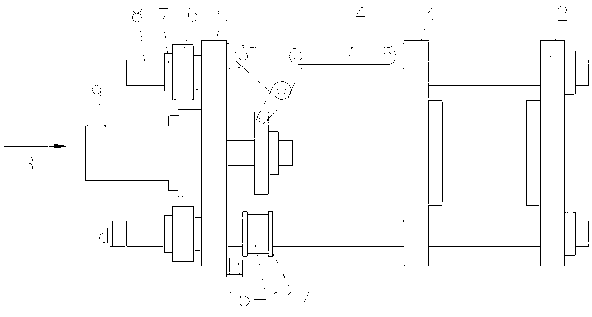

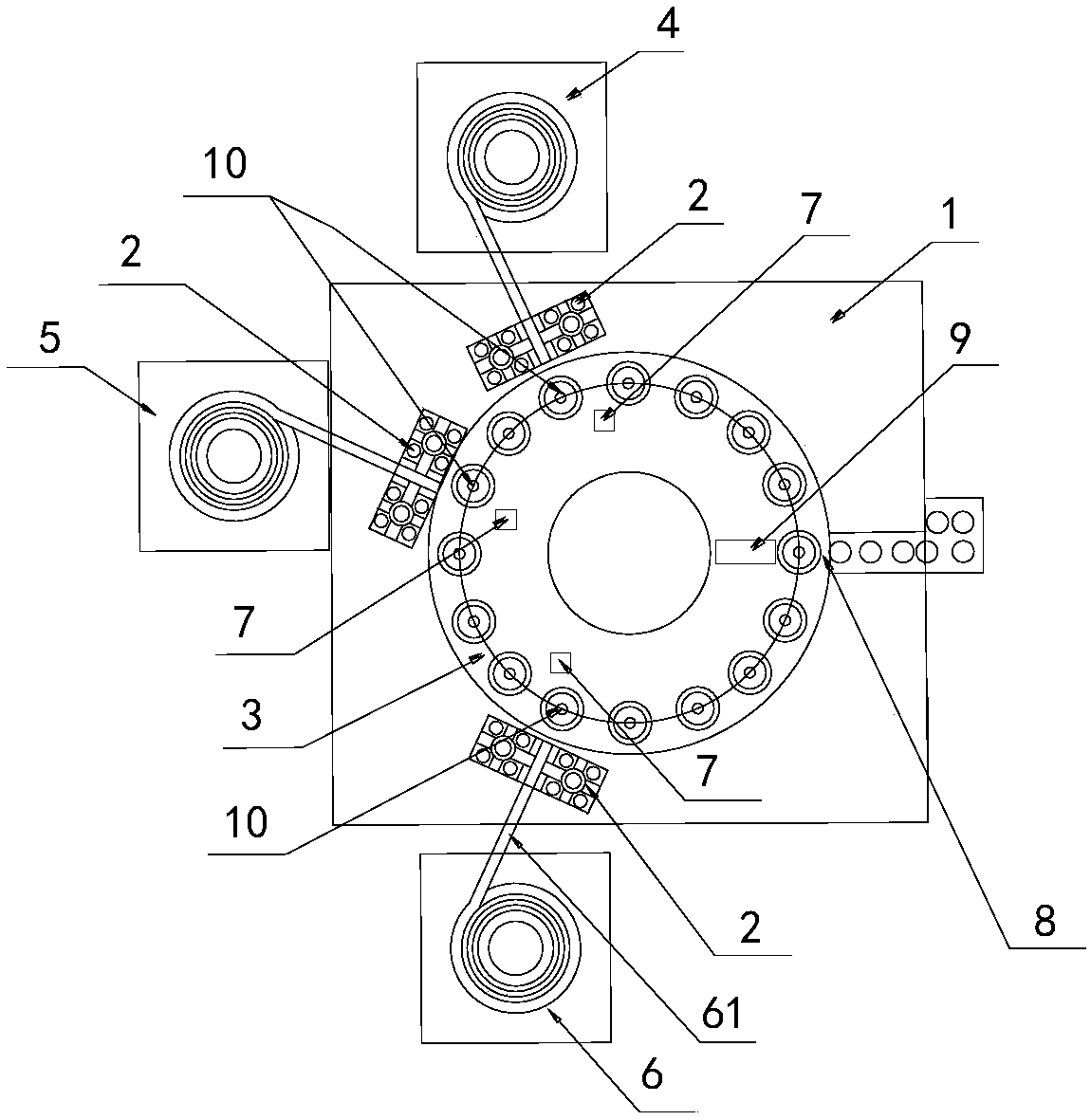

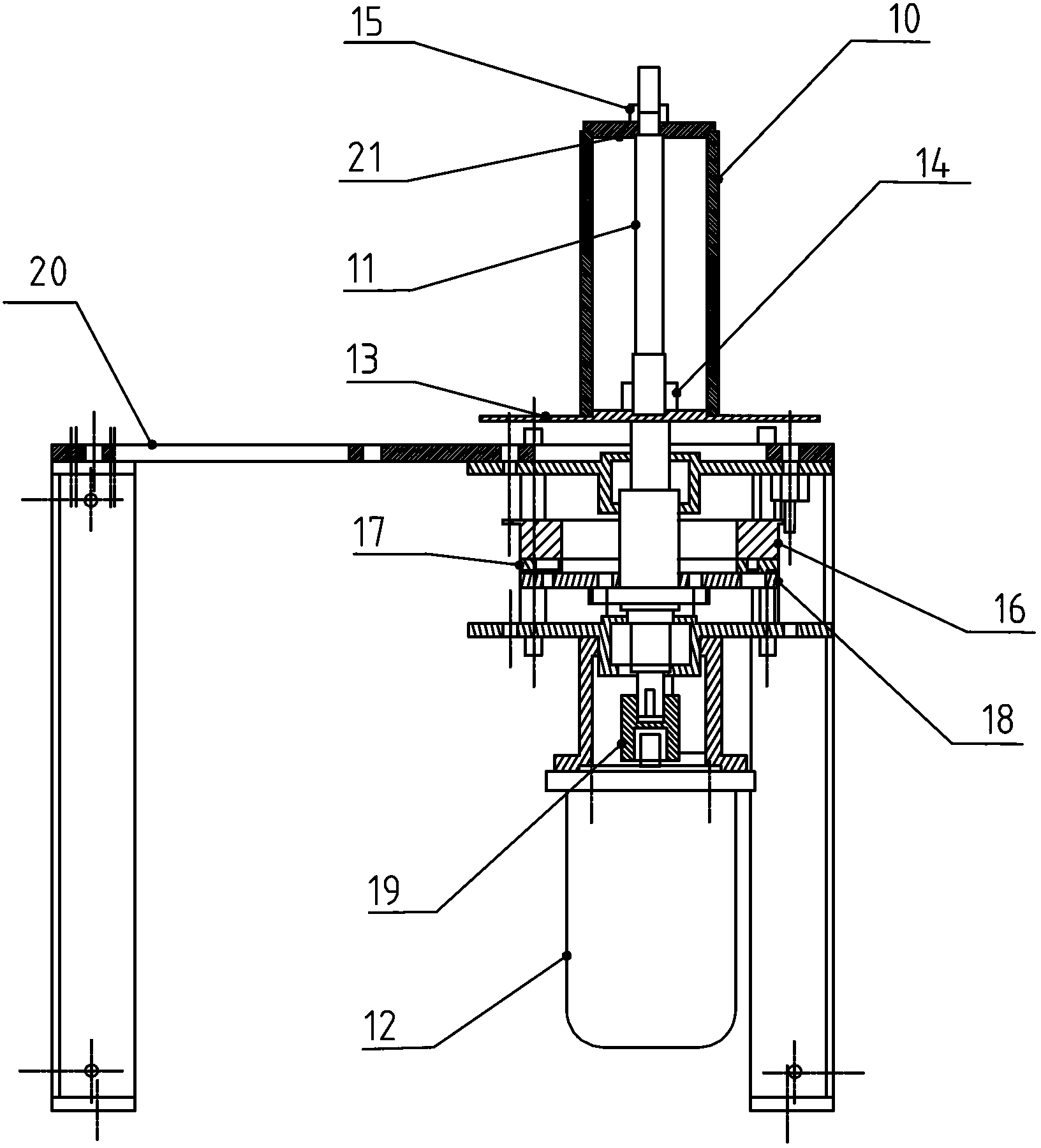

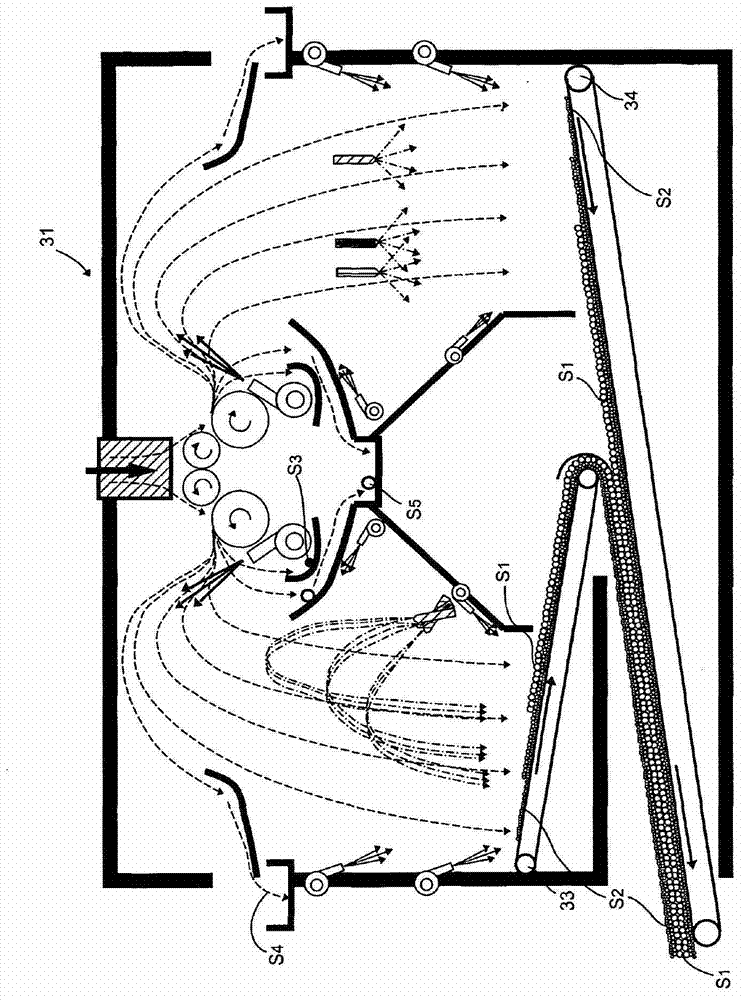

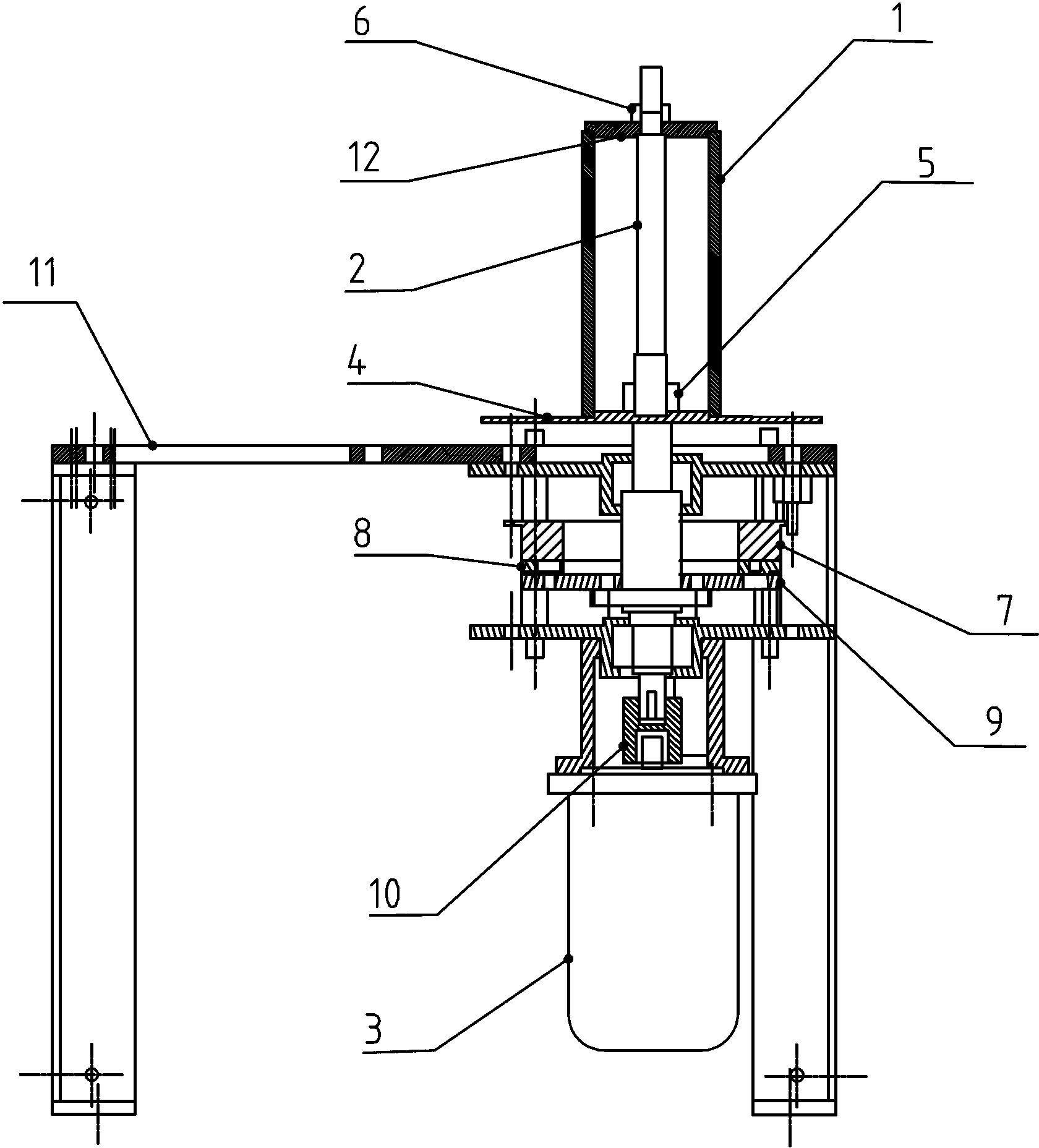

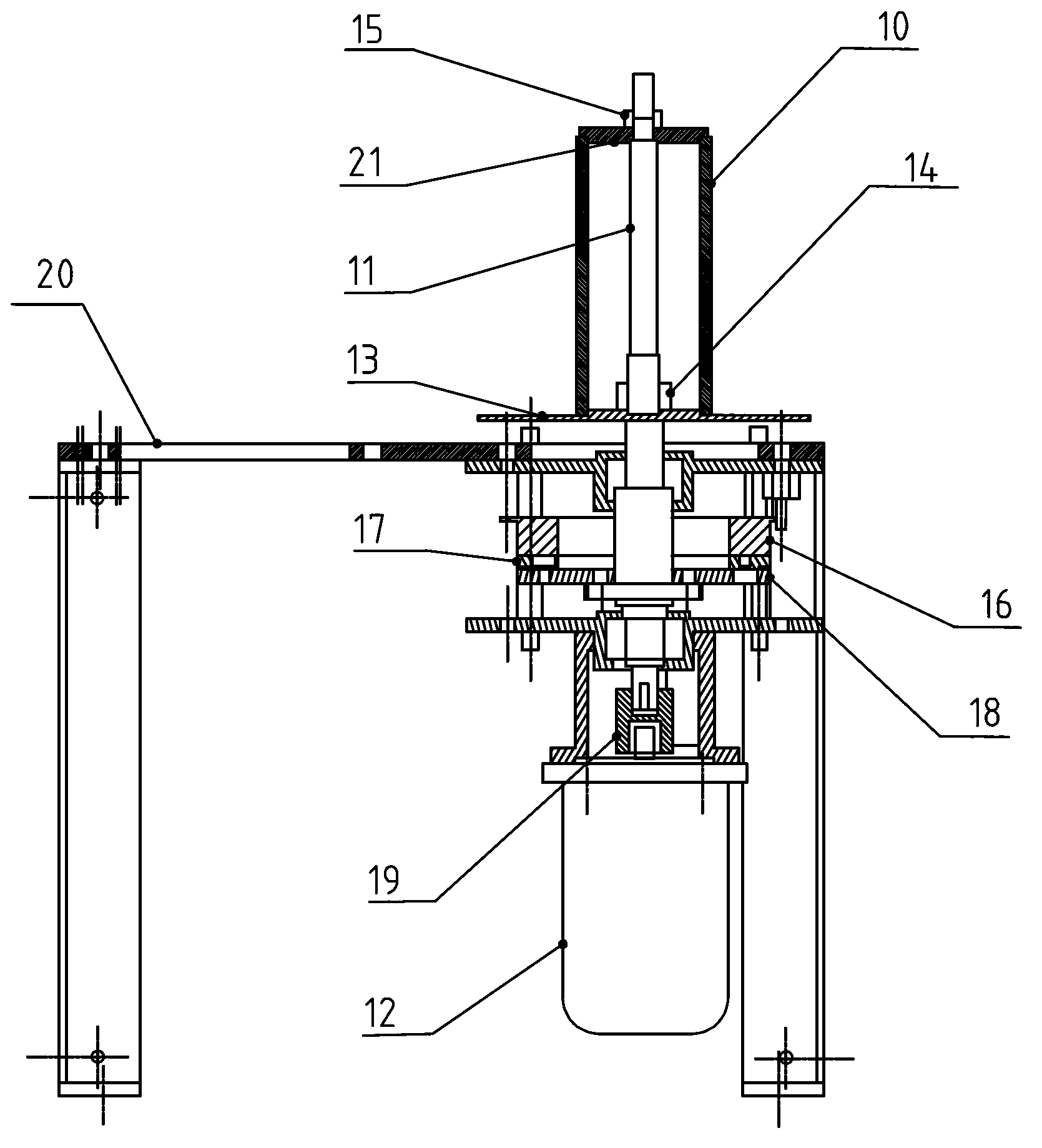

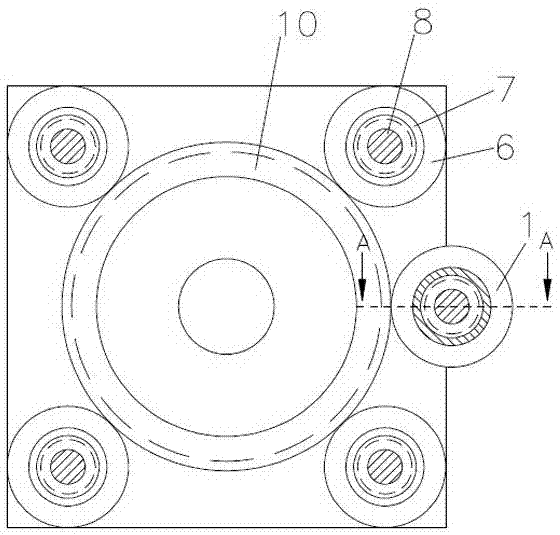

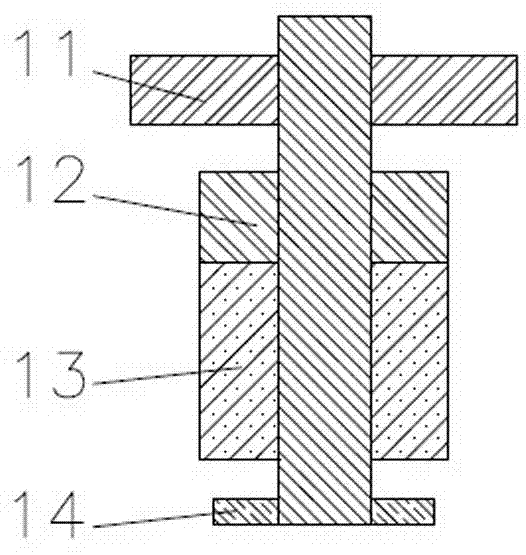

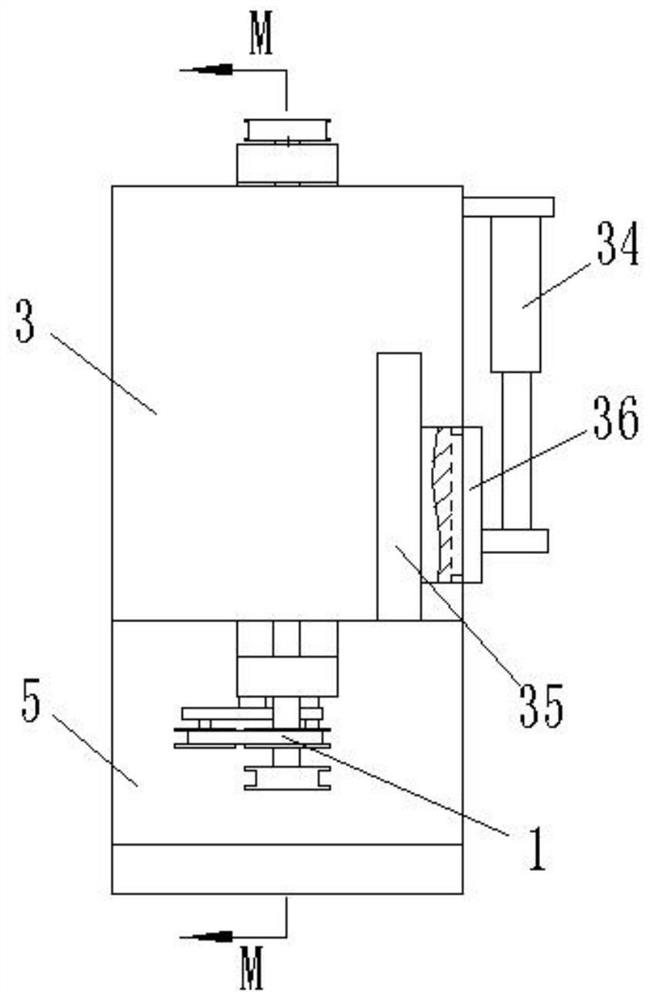

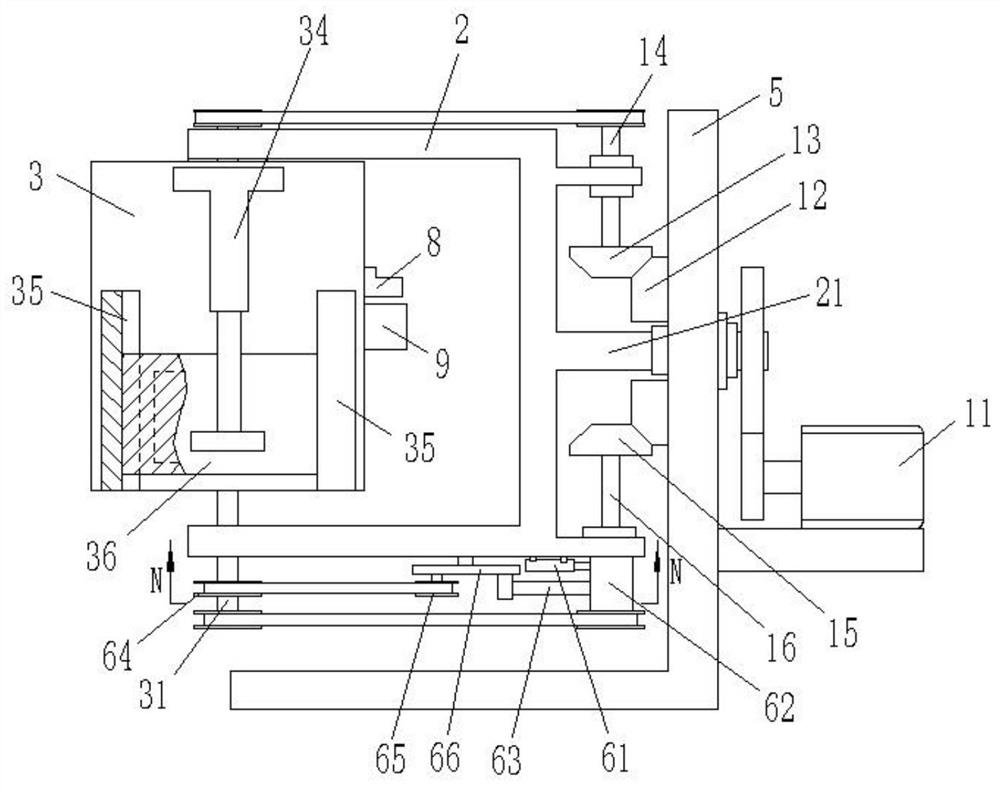

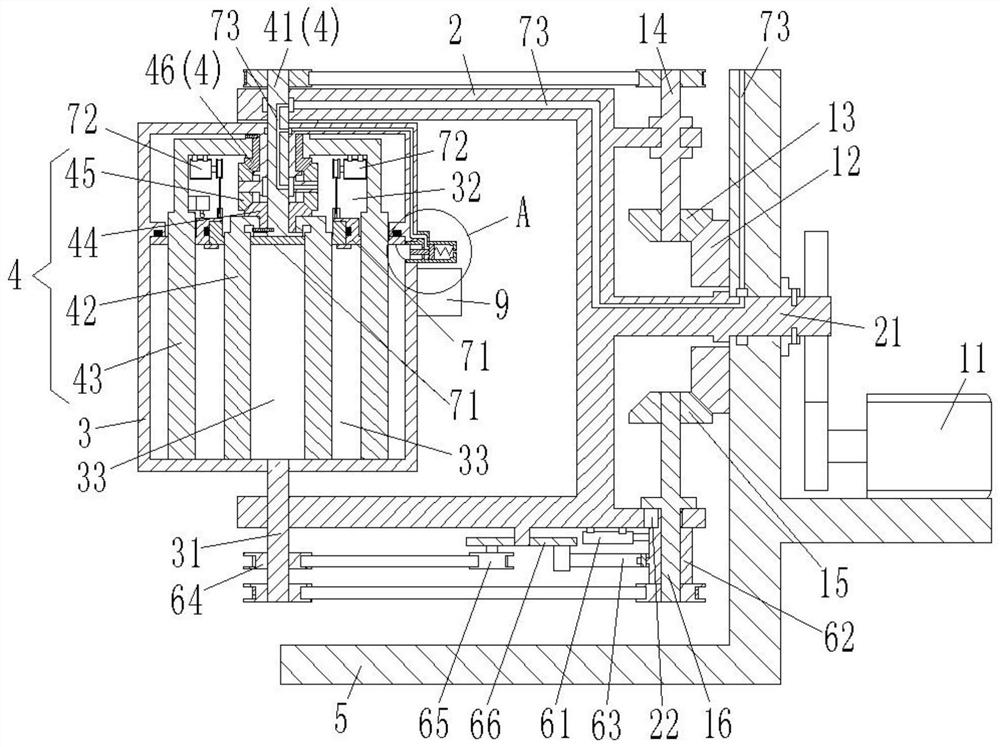

The invention discloses a full-automatic speaker magnetic circuit assembling machine which comprises a center rotary table. A plurality of fixed jigs are arranged on the circumference of the center rotary table; each fixed jig is provided with a movable jig; an automatic washer feeding apparatus, a washer pressing apparatus, a first glue injection apparatus, an automatic magnetic sheet feeding apparatus, a magnetic sheet pressing apparatus, a second glue injection apparatus, an automatic bracket feeding apparatus, a bracket pressing apparatus, a discharge apparatus and a movable jig placement apparatus are sequentially arranged around the periphery of the circumference of the center rotary table; a drying tunnel is formed between the discharge apparatus and the movable jig placement apparatus; a finished product separation apparatus for separating finished products from the movable jigs is arranged in front of the movable jig placement apparatus. After the technical scheme is adopted, compared with the prior art, the technical scheme has the following advantages that after the machine is available, complete automation can be achieved for assembling of a speaker magnetic circuit; labor cost is greatly lowered; labor intensity is reduced; meanwhile, product quality is improved and ensured.

Owner:佛山市南海科盈华电子有限公司

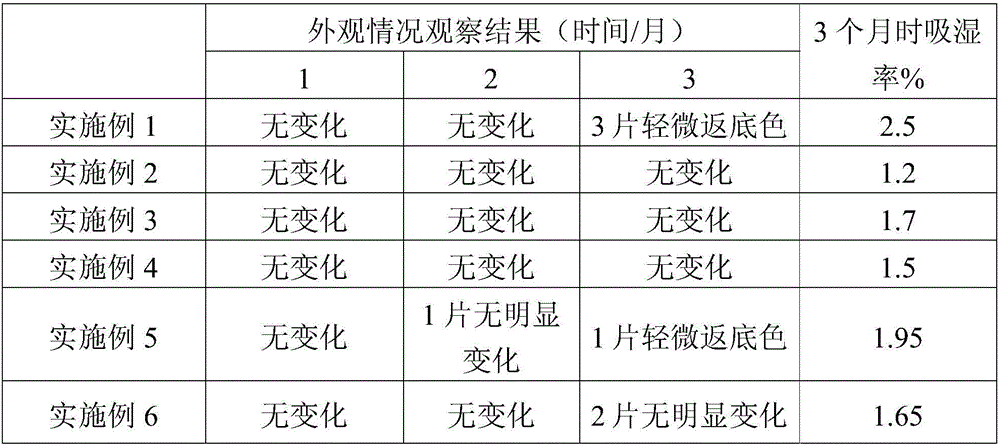

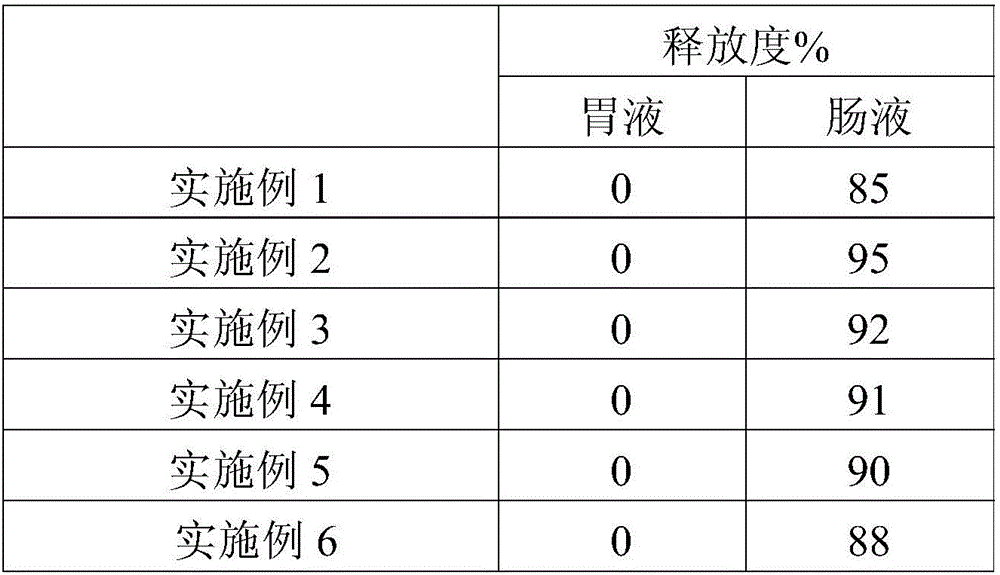

Aqueous enteric film coating premixed agent and preparation method thereof

ActiveCN105833281AOvercoming brittlenessOvercome the problem that the film coating is prone to damageOrganic active ingredientsInorganic non-active ingredientsSpray GranulationPlasticizer

The invention belongs to the technical field of medicines, and particularly relates to an aqueous enteric film coating premixed agent and a preparation method thereof. The aqueous enteric film coating premixed agent comprises the following components in percentage by weight: 45-65% of polyacrylic resin I, 9-19% of a plasticizer, 16-26% of an anti-sticking agent, 2-15% of a colorant, 0.8-2.5% of a surfactant and 2.6-4.7% of other additives. The preparation method of the premixed agent comprises the following steps: (1) crushing the polyacrylic resin I, the plasticizer, the anti-sticking agent, the colorant, the surfactant and the other additives, screening, and stirring in pure water so as to obtain suspension; (2) granulating the suspension of the step (1) by using a spraying granulation method; (3) crushing granules obtained in the step (2), and screening, thereby obtaining the premixed agent. A coating agent prepared from the premixed agent provided by the invention is good in stability and low in moisture absorption rate.

Owner:连云港万泰医药辅料技术有限公司

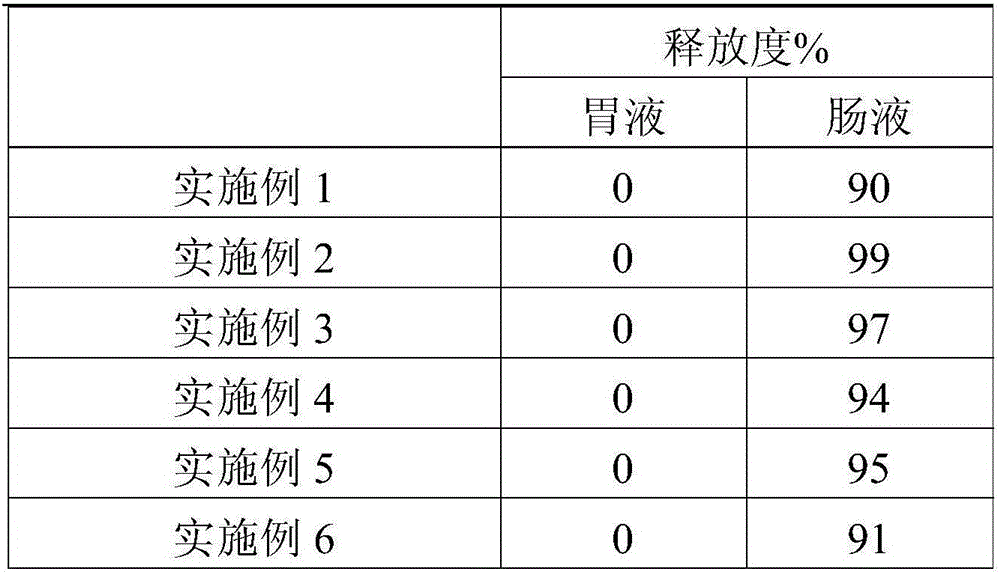

Large size pipe with glass being spread on internal lining and manufacturing method

InactiveCN1727743AGuarantee the overall qualityStrong bondCorrosion preventionPipe protection against corrosion/incrustationElectrostatic adsorptionSmooth surface

The present invention relates to a large-size glass lining pipe and its production method, belonging to the field of pipeline for transmission of media of petroleum, chemical material, natural gas and water source, etc. It is characterized by that the inner wall of steel pipe is lined with glass-glaze, so that said glass lining utilizes its firm binding capacity, smooth surface and good chemical stability free from electrostatic adsorption effect to effectively ensure smooth transmission of media of natural gas and water source, etc.

Owner:朱文华

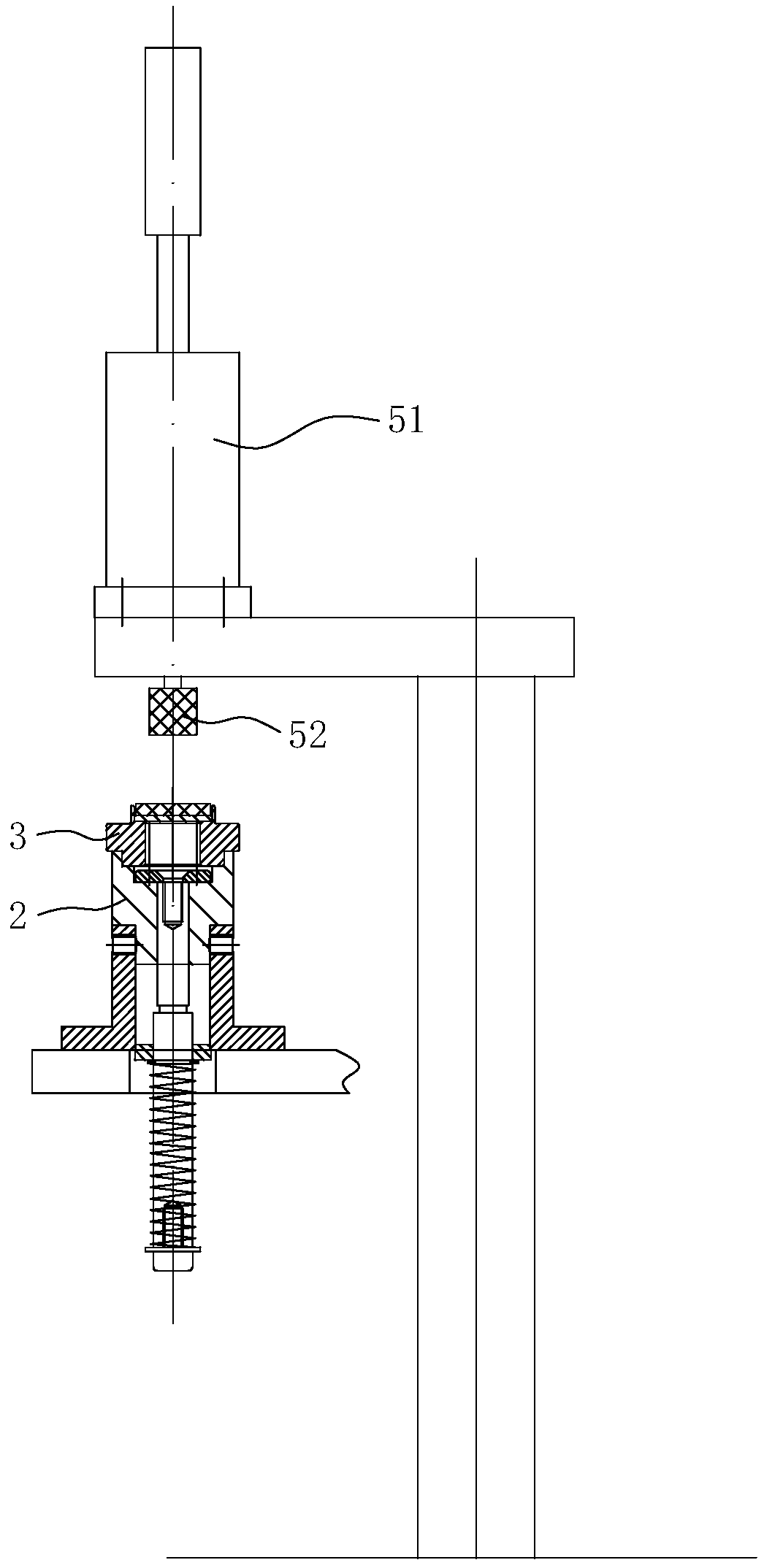

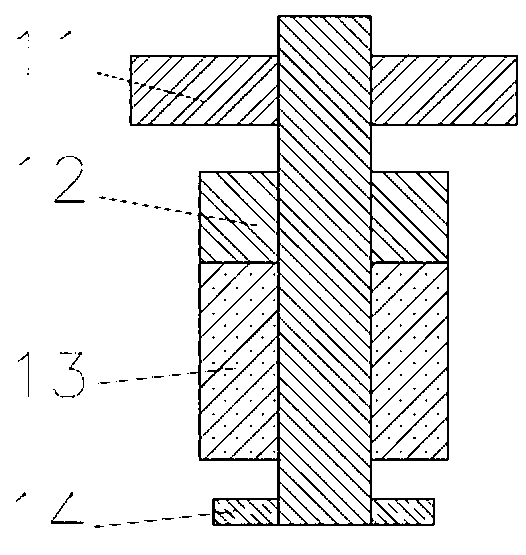

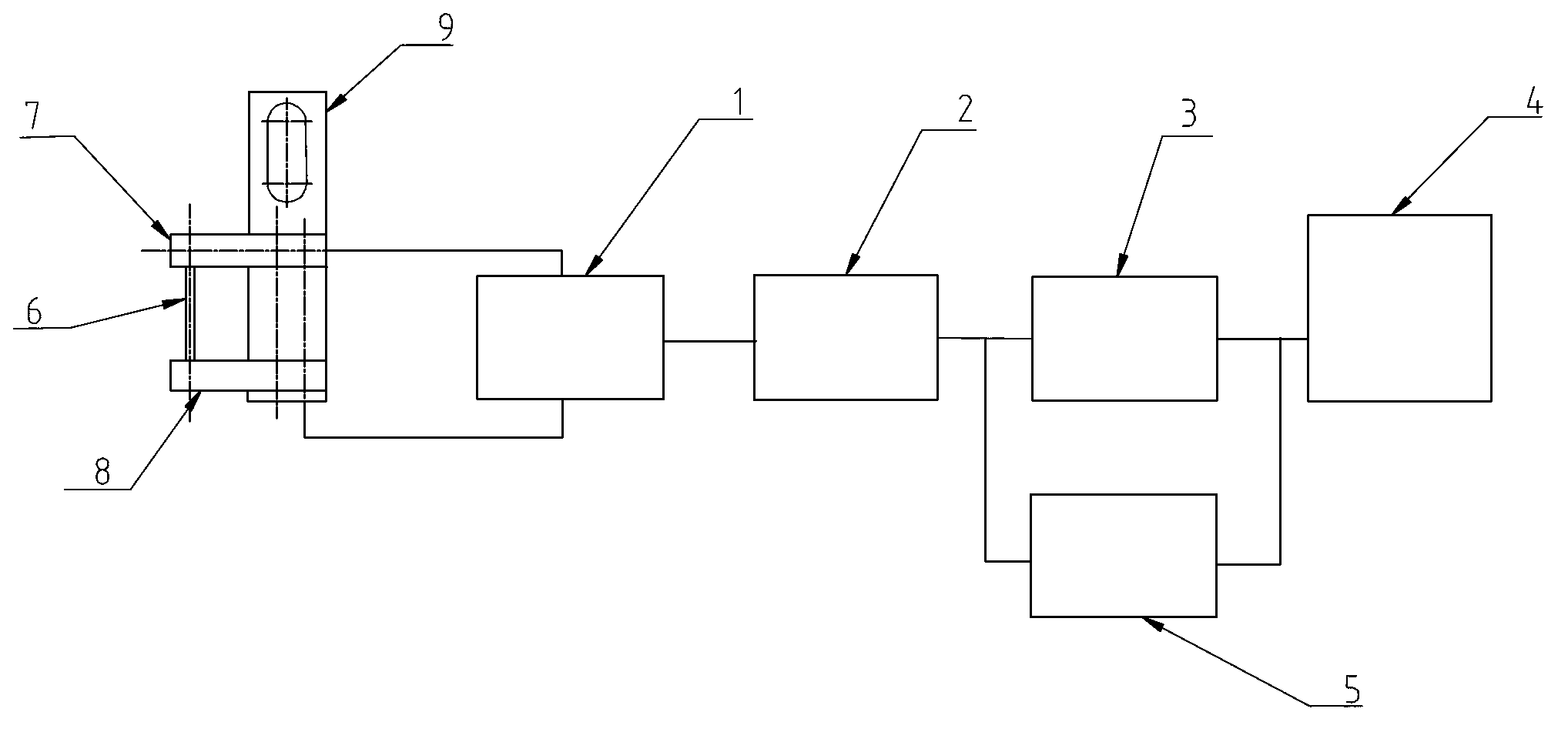

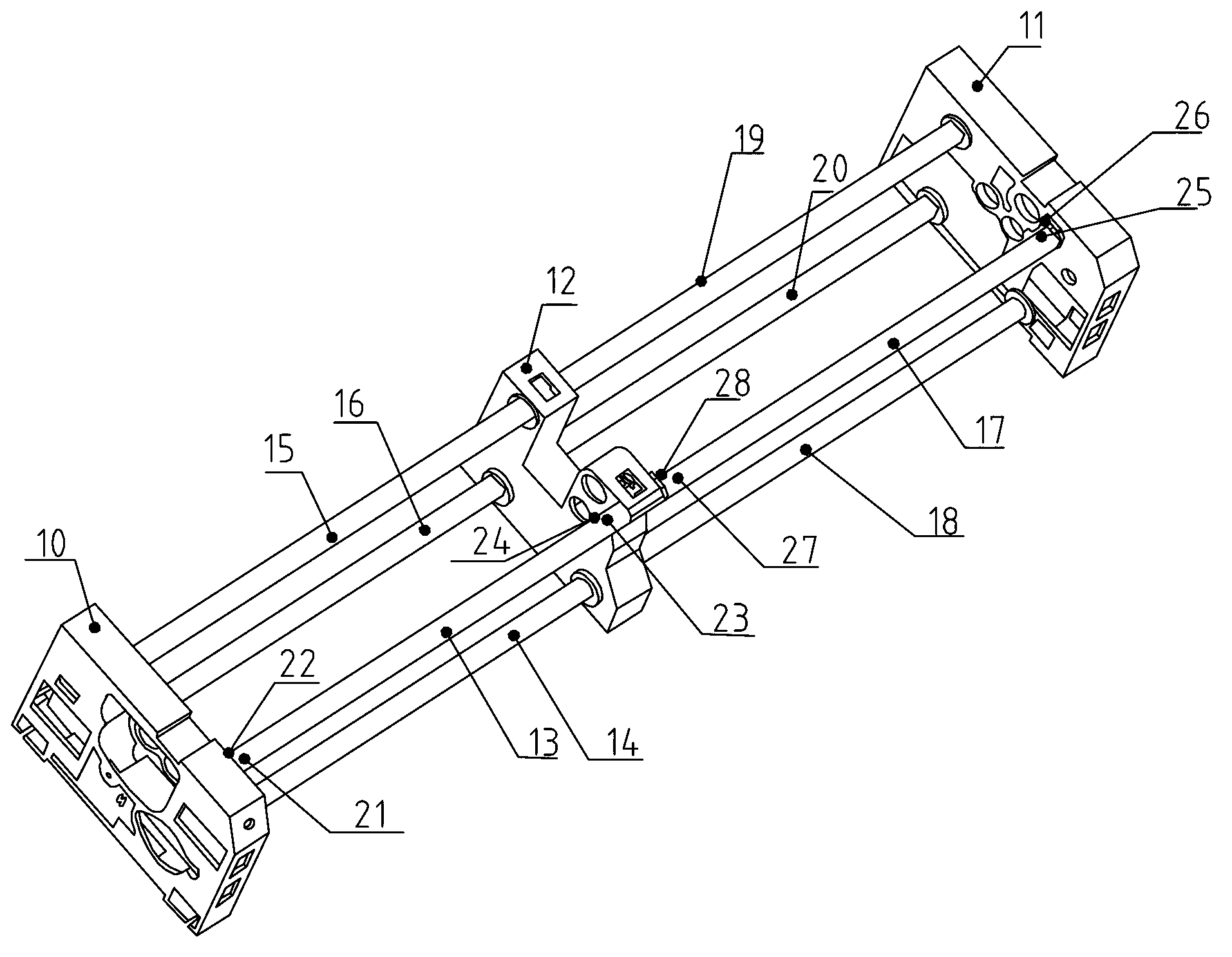

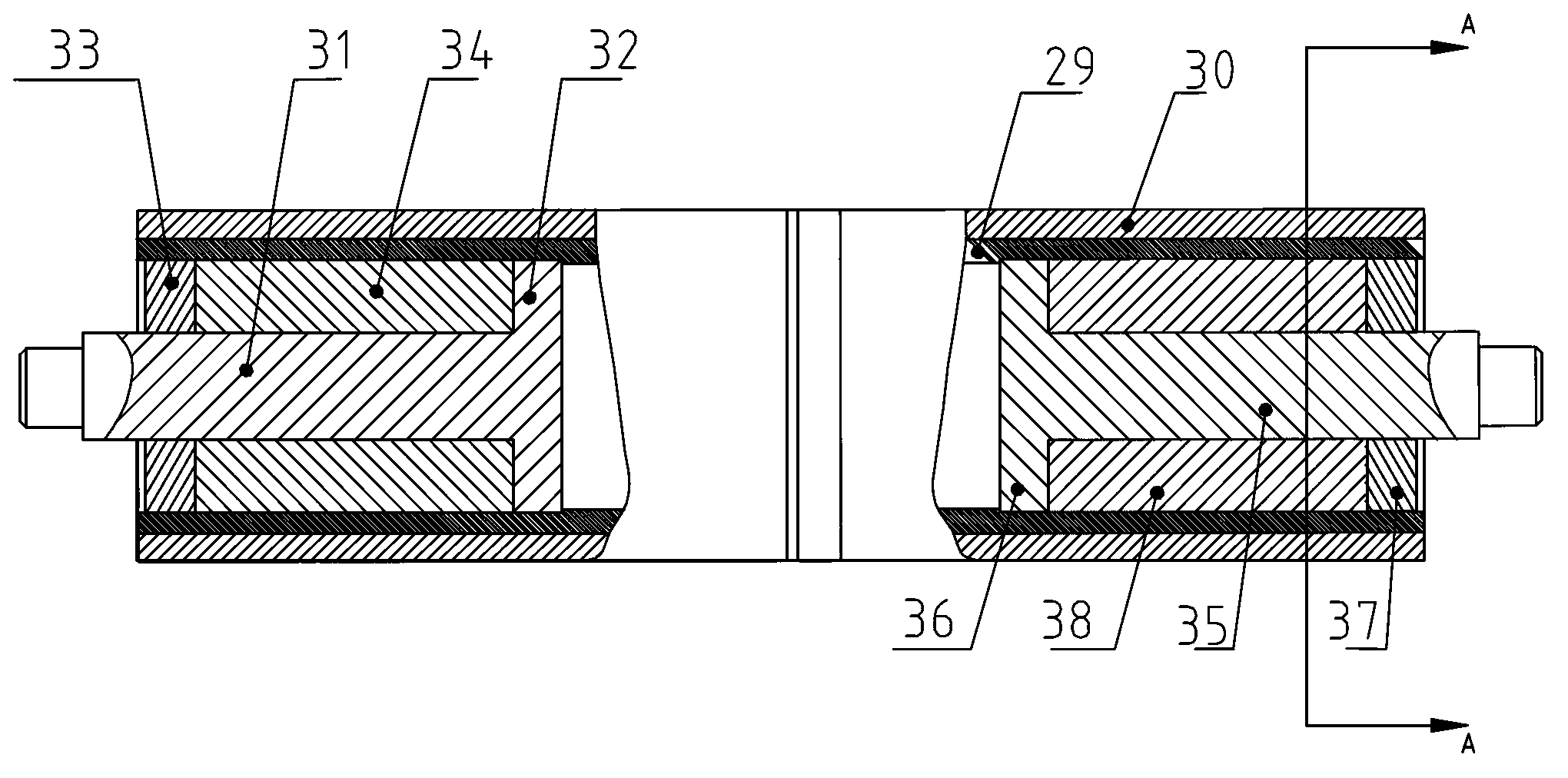

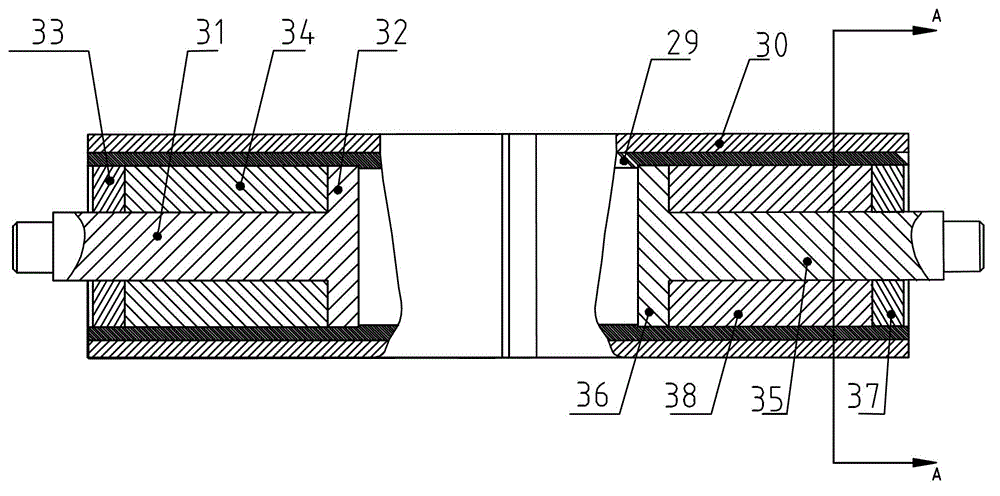

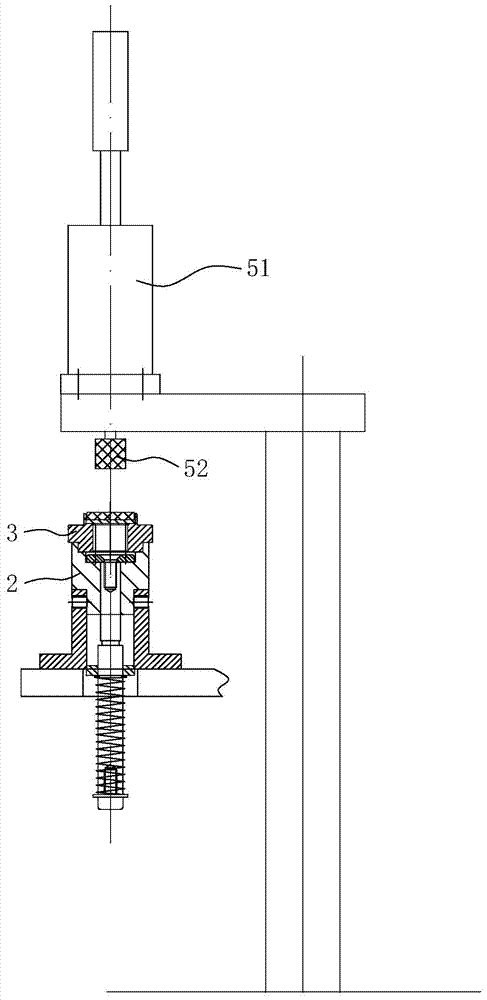

Die casting machine clamping force online adjusting device and adjusting algorithm

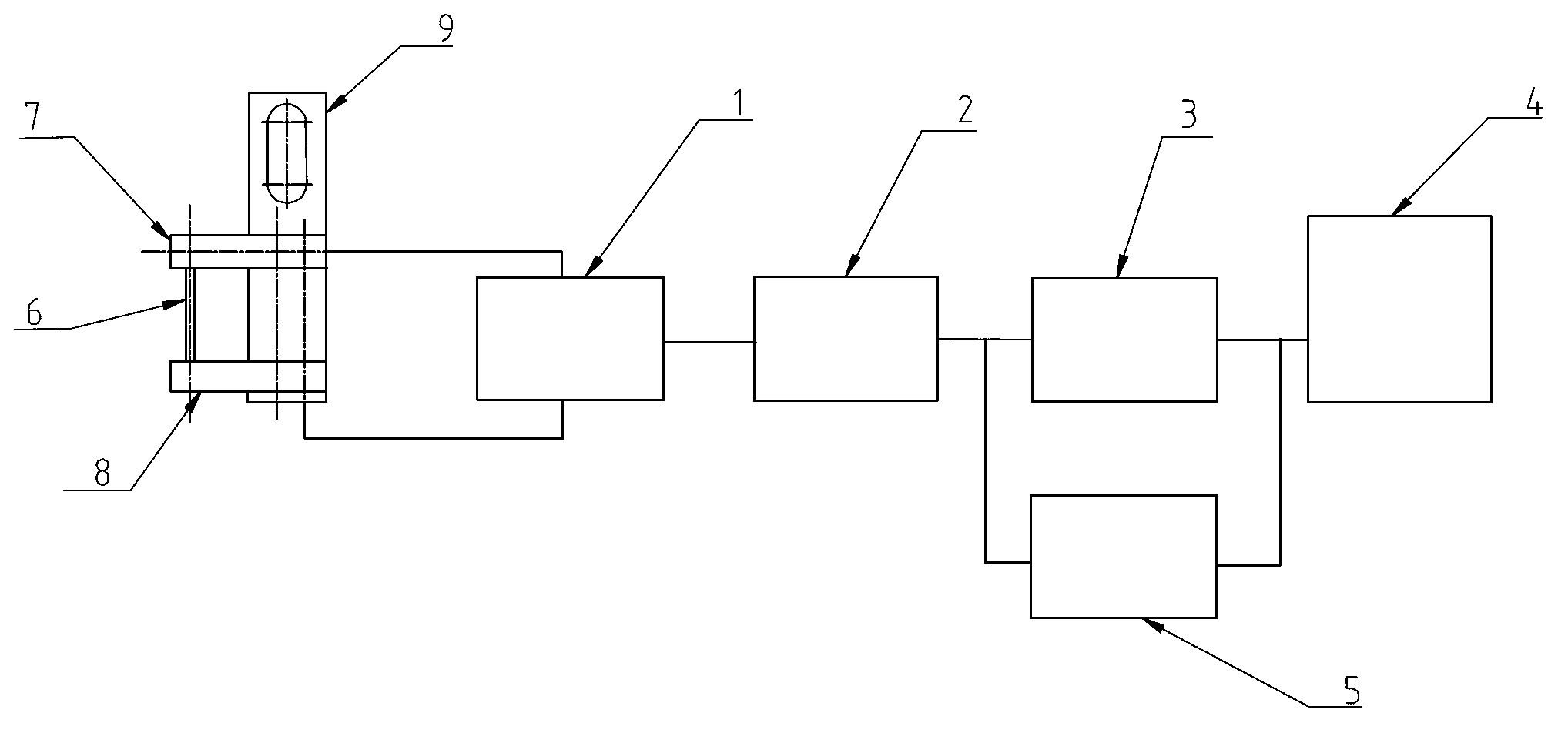

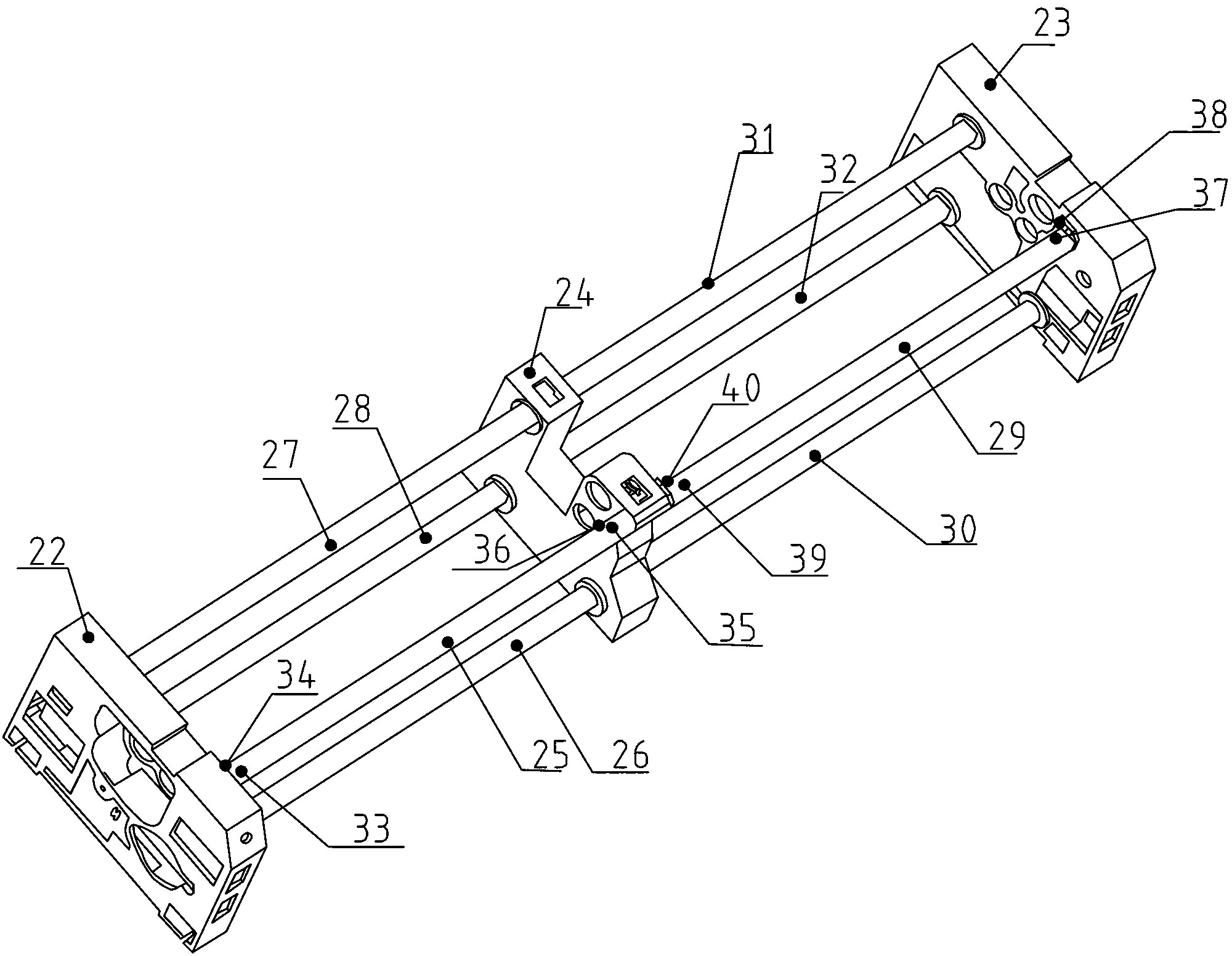

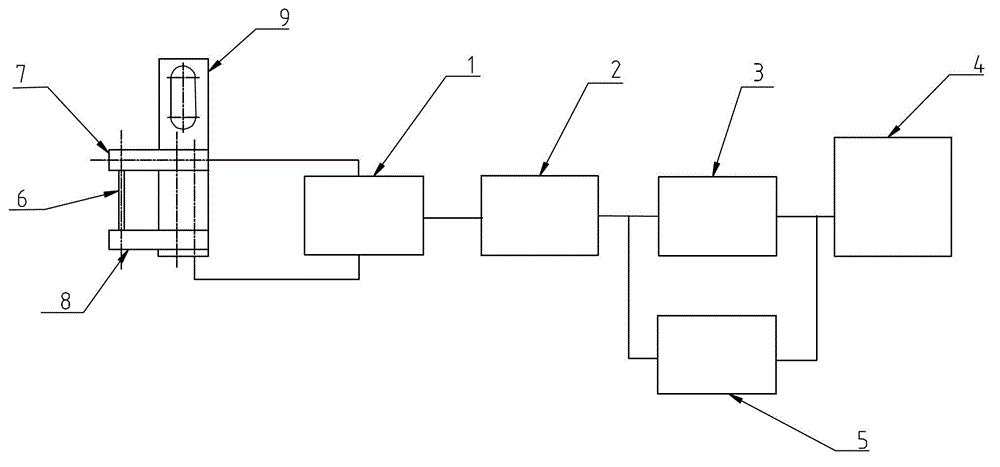

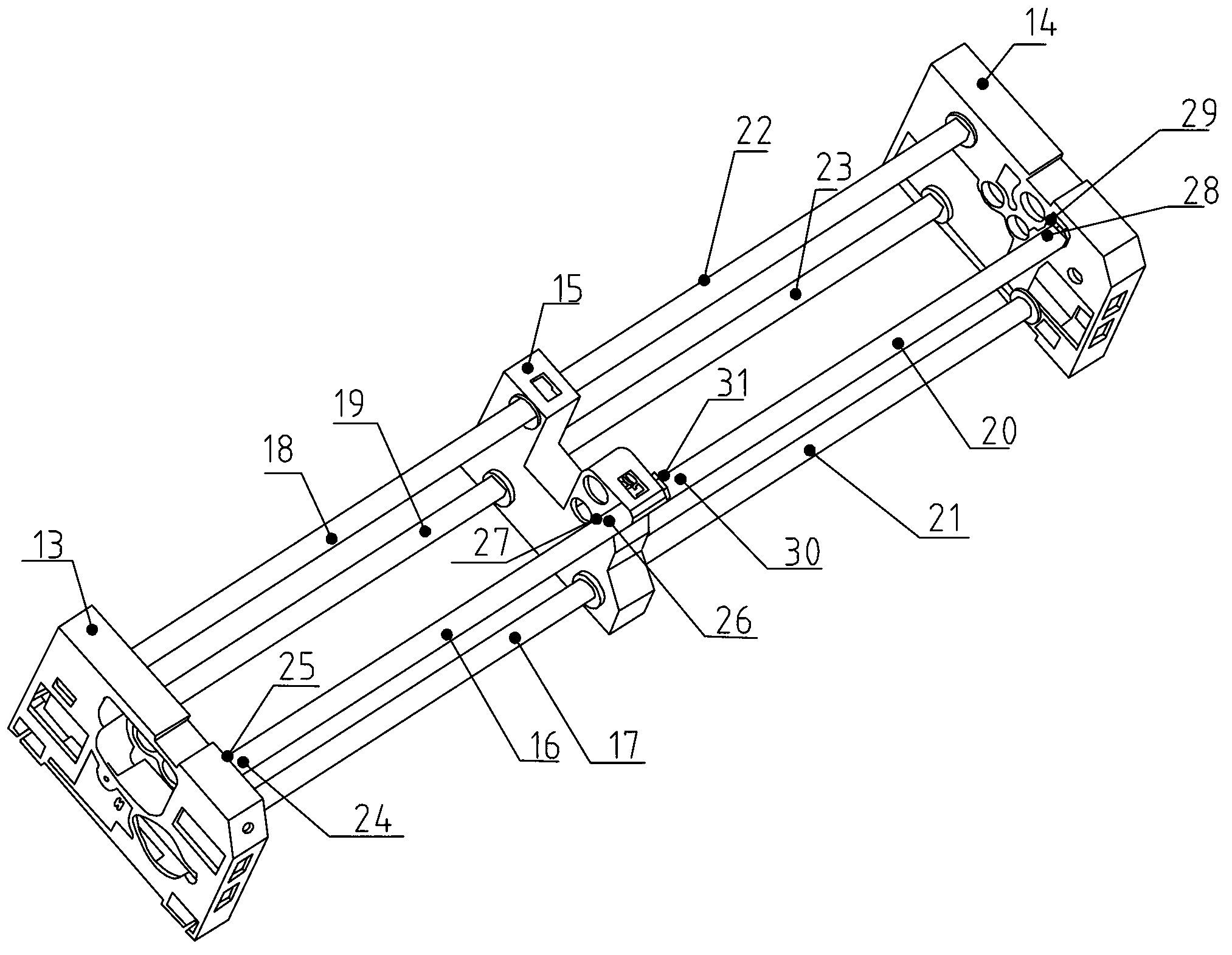

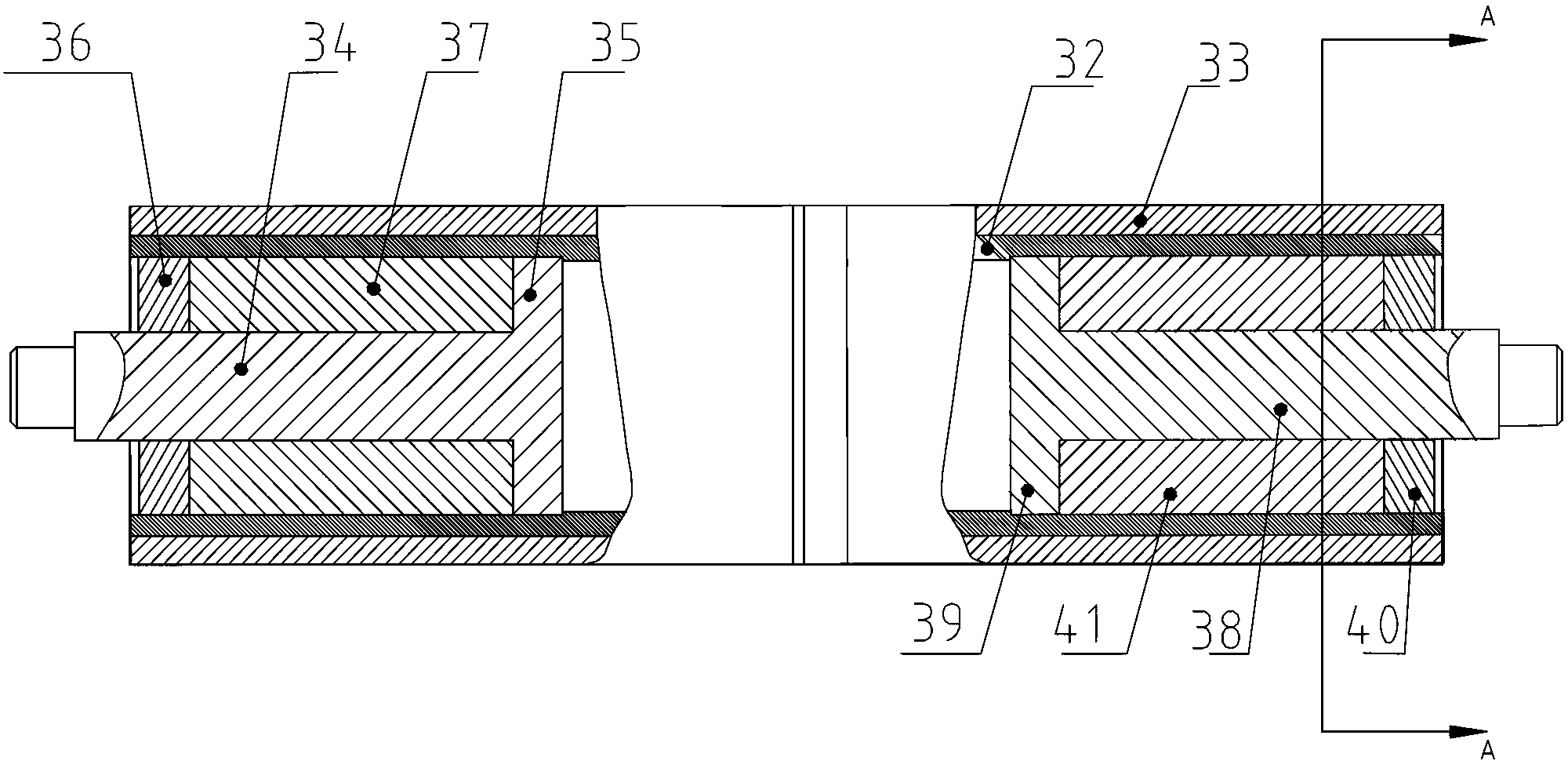

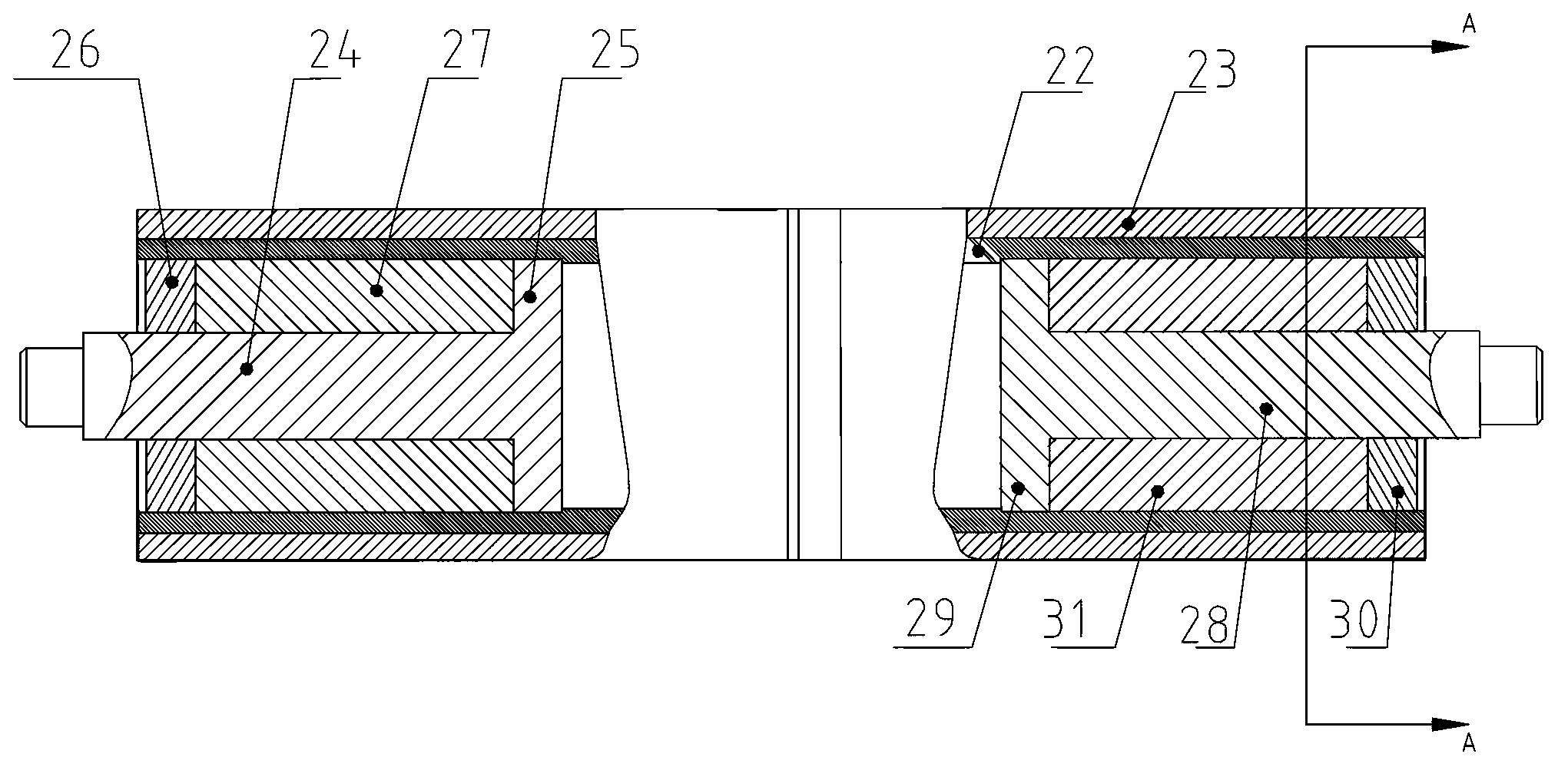

The utility model relates to a mechanics volume adjusting device and adjusting algorithm based on route micro adjusting, in particular to a die casting machine clamping force online adjusting device and adjusting algorithm. The object of the invention is to ensure the actual clamping force within the set value in the process of die casting from beginning to end, to improve the real-time detection and control level, and to improve the quality of die casting products. The die casting machine clamping force online adjusting device comprises a clamping force online detecting system, a feedback control system and a die-adjusting actuator mechanism. The clamping force online detecting system obtains clamping resultant force by arranging strain gauge force sensor on the one pull rod or four pull rod of the die-casting machine. The feedback control system comprises an encoder and a control program. The die-adjusting actuator mechanism comprises a hydraulic motor, major and minor die-adjusting gear and a die-adjusting nut. A die casting machine clamping force online adjusting algorithm is also provided. The die casting machine clamping force online adjusting device and adjusting algorithm has the advantages of utilizing feedback signals to start hydraulic motor and driving the die-adjusting nut to rotate so as to adjust the clamping force within the set value, thereby ensuring the quality of the products.

Owner:SIJIN INTELLIGENT FORMING EQUIP CO LTD

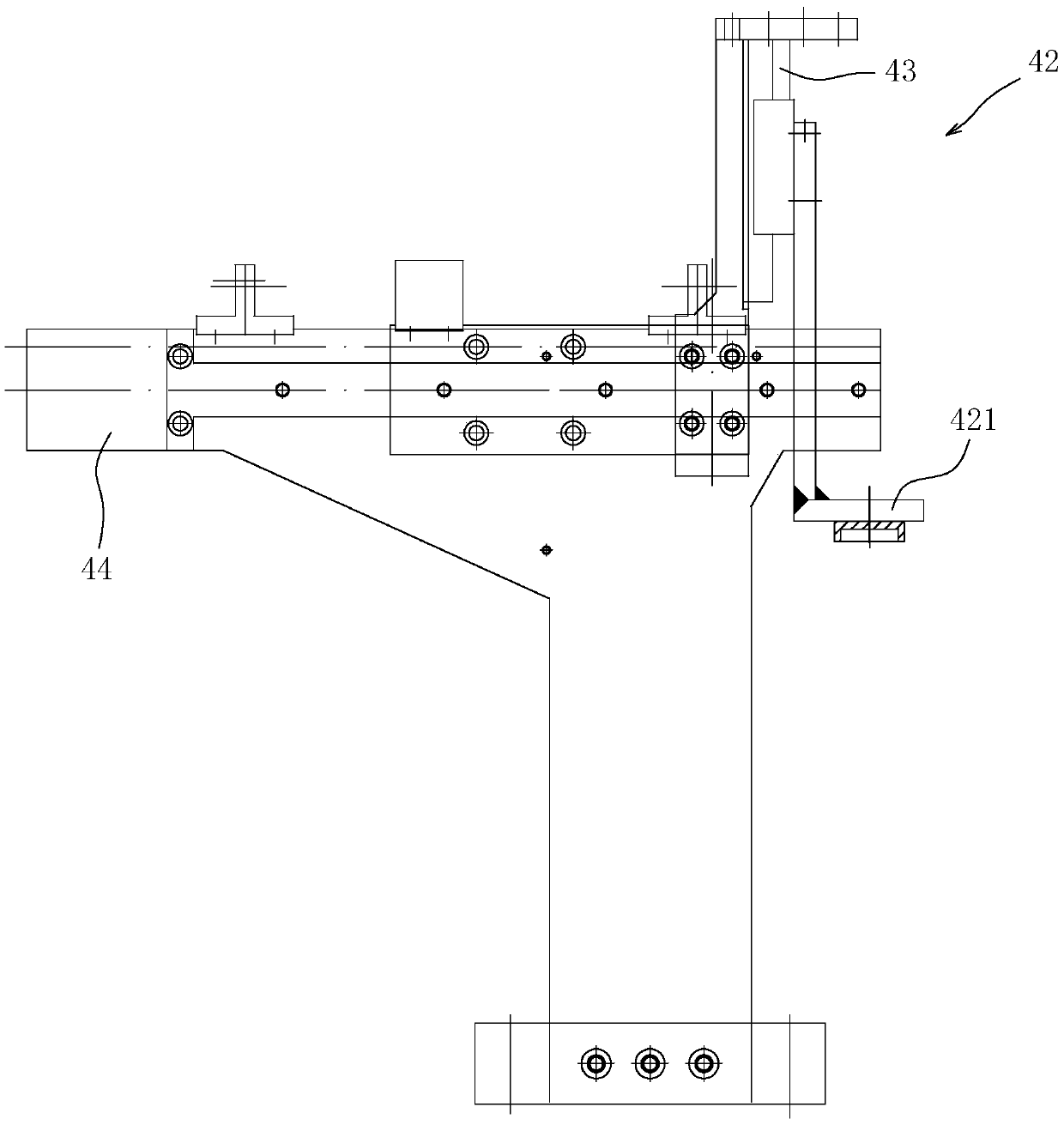

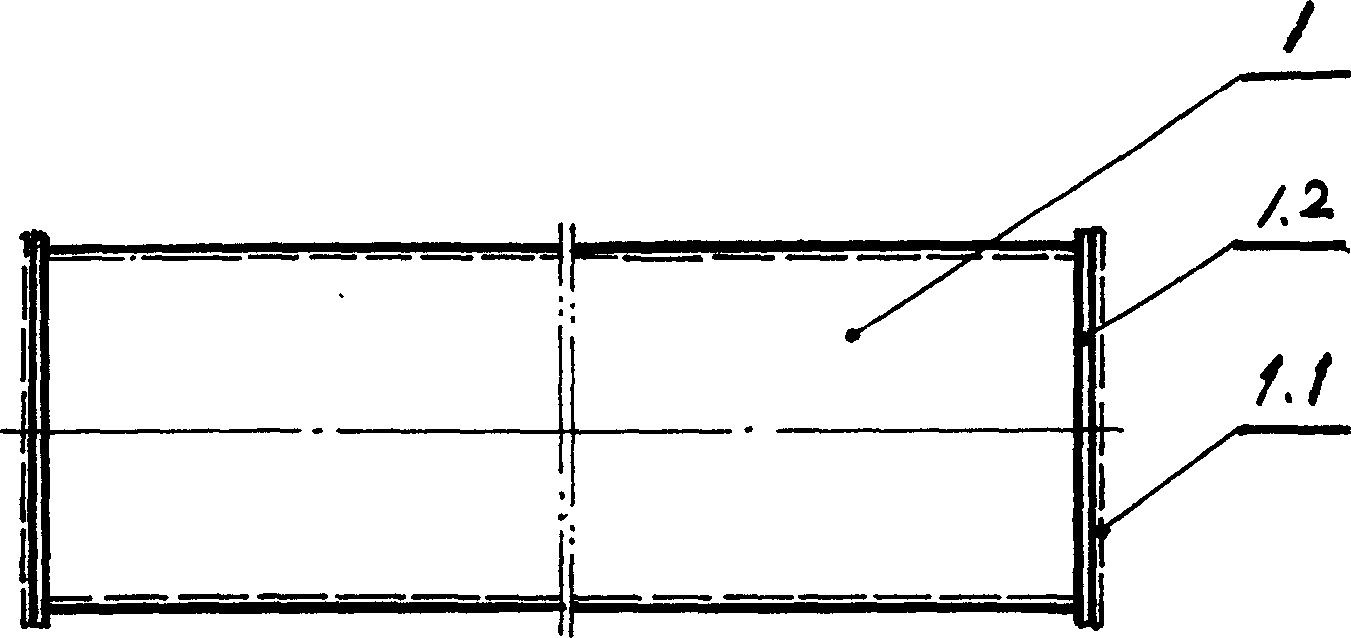

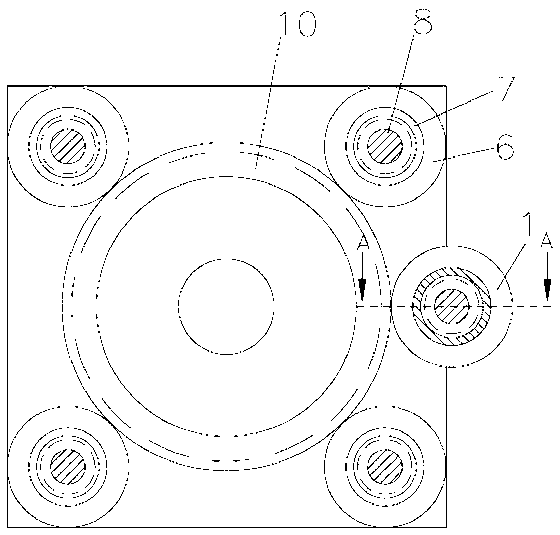

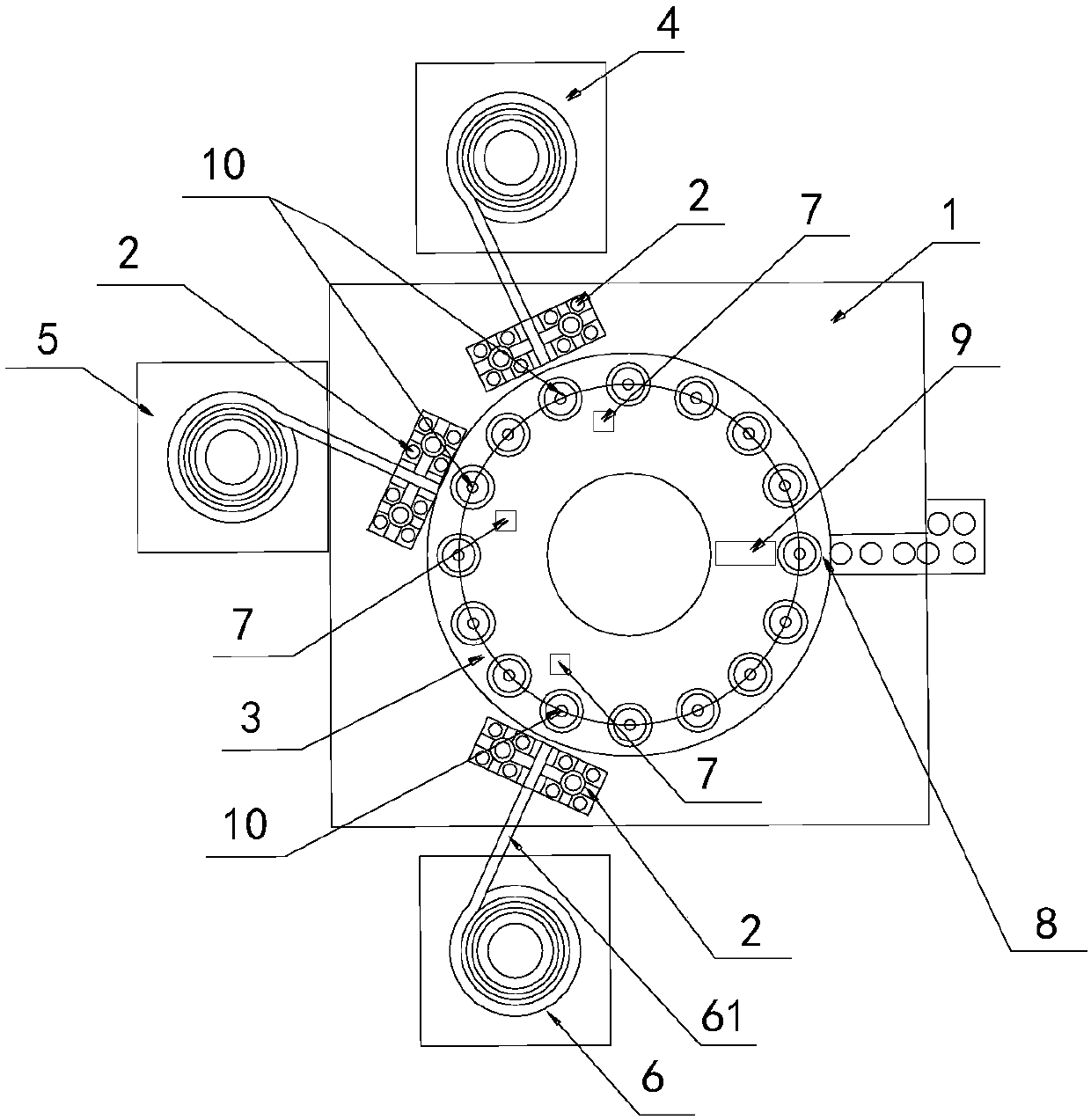

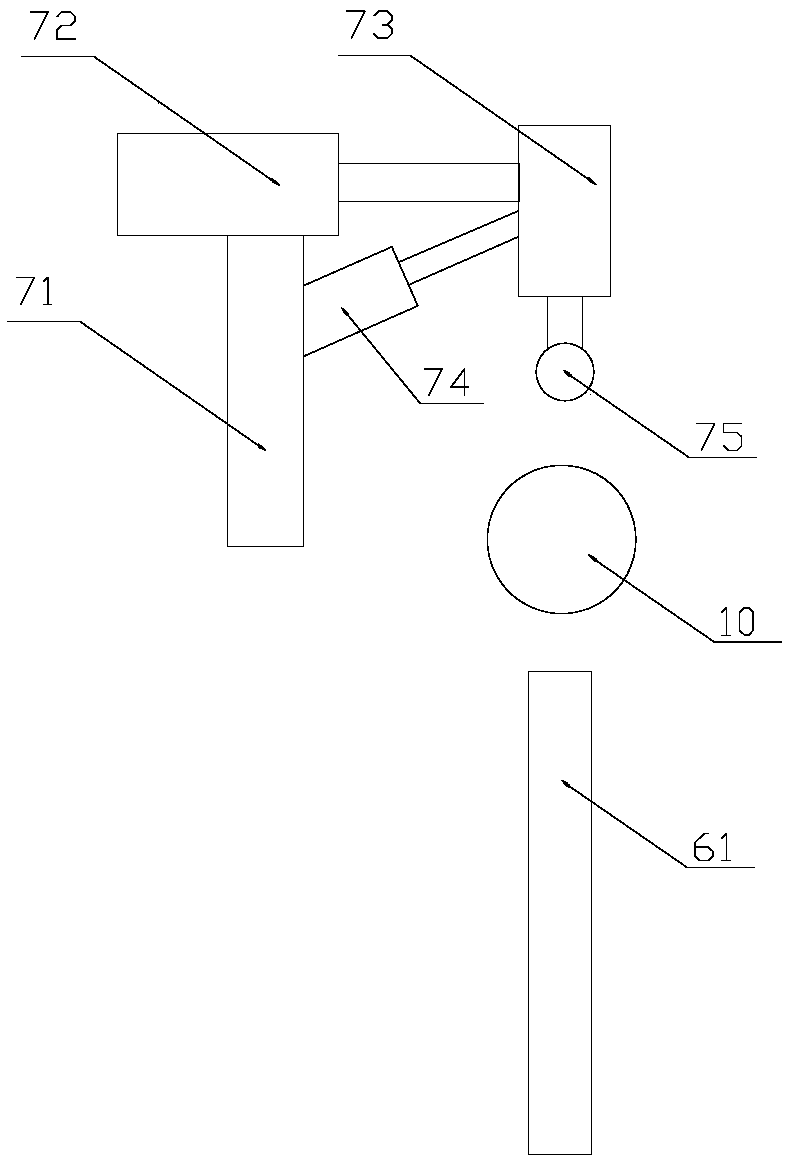

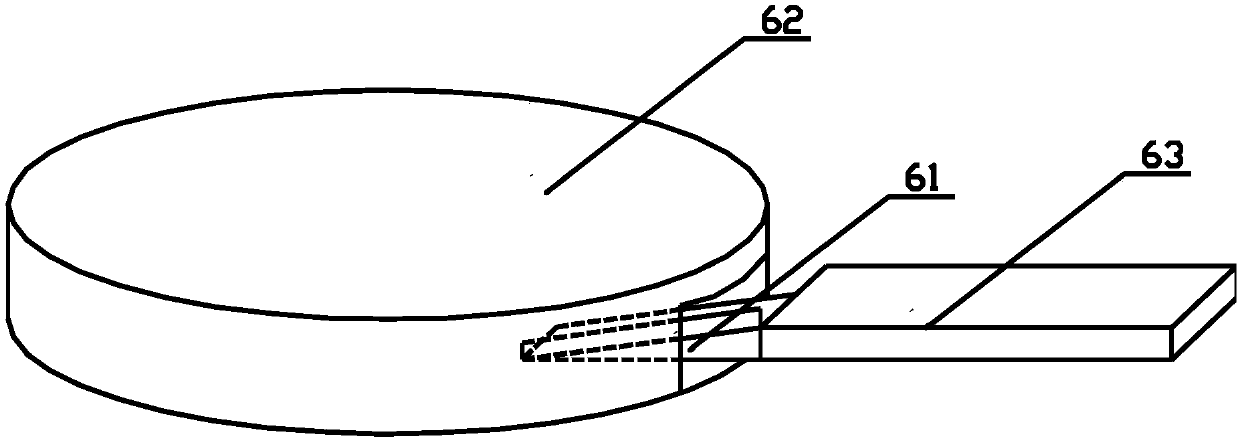

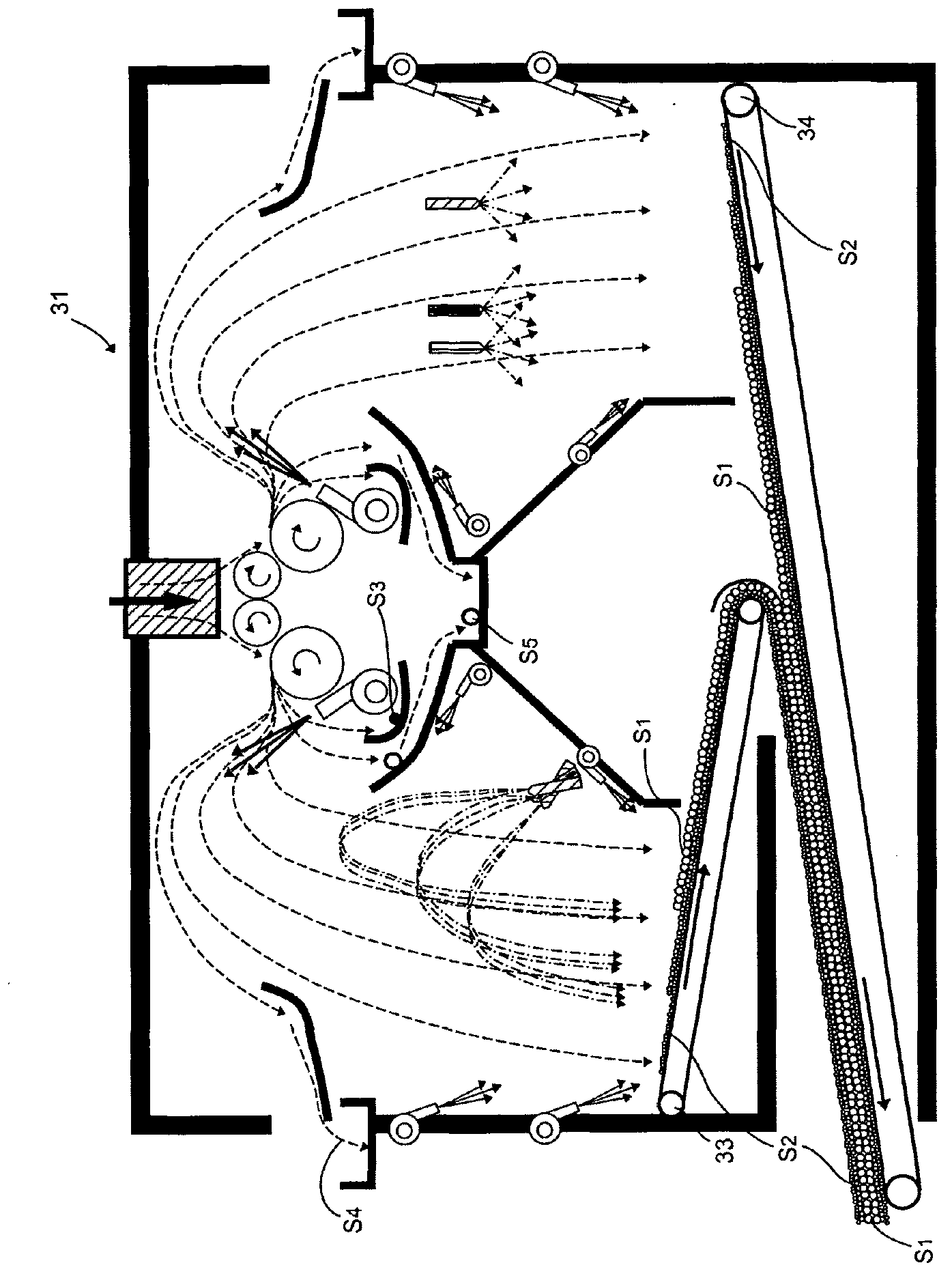

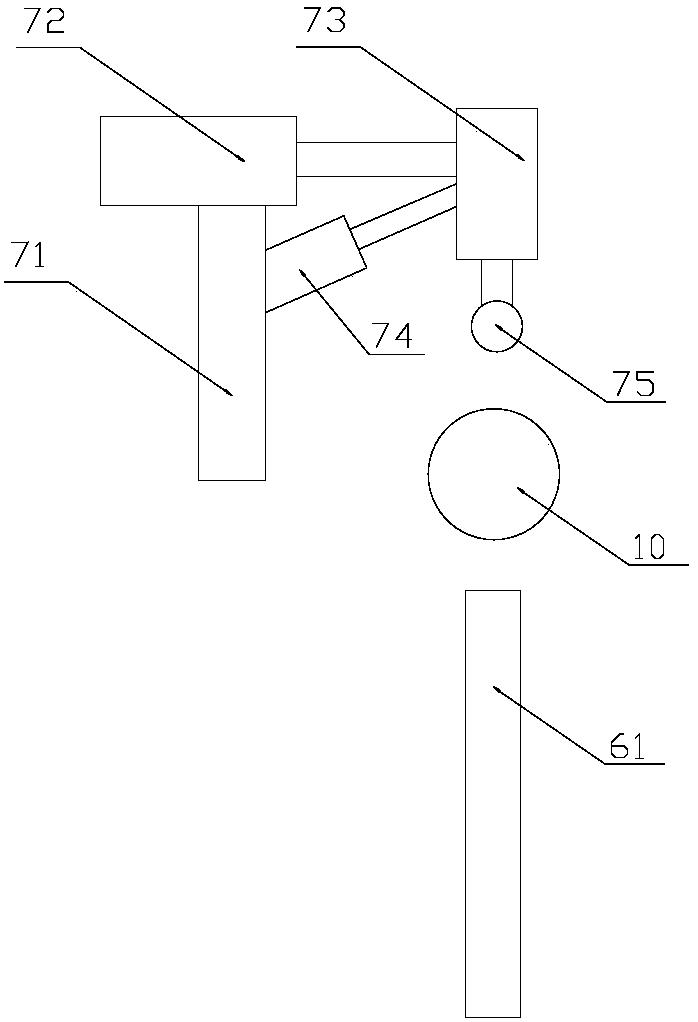

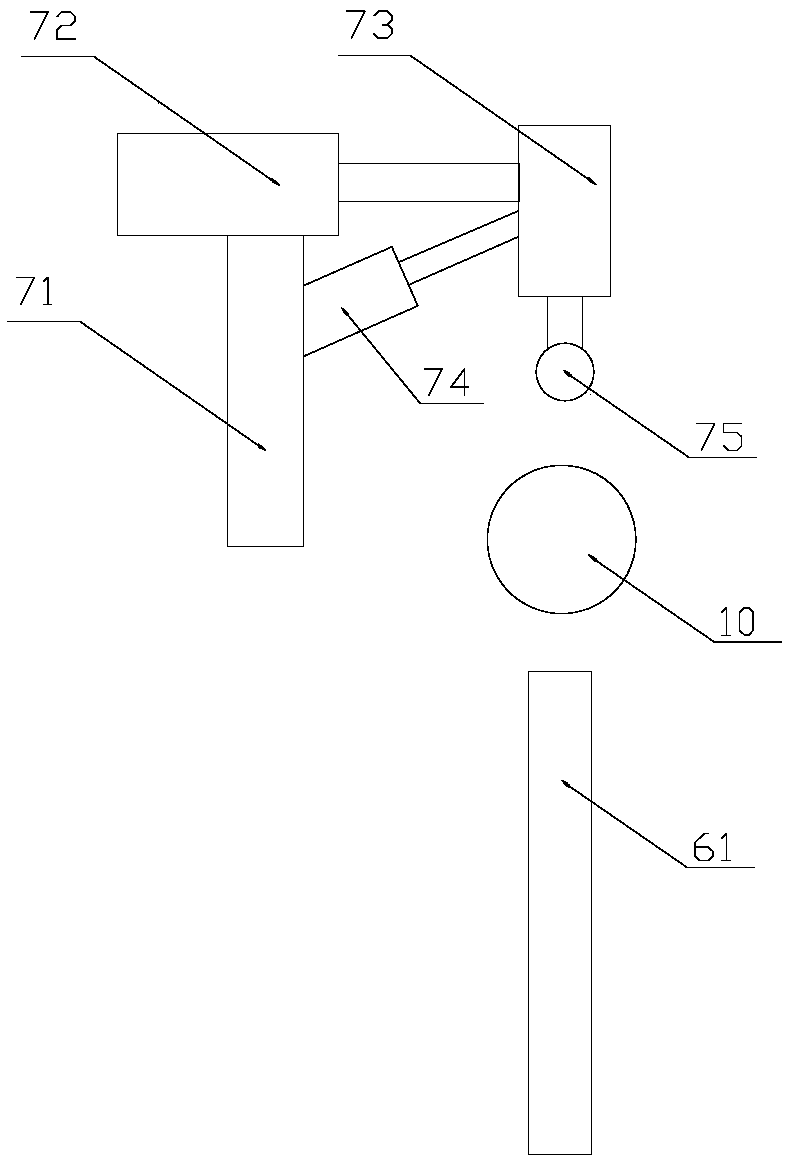

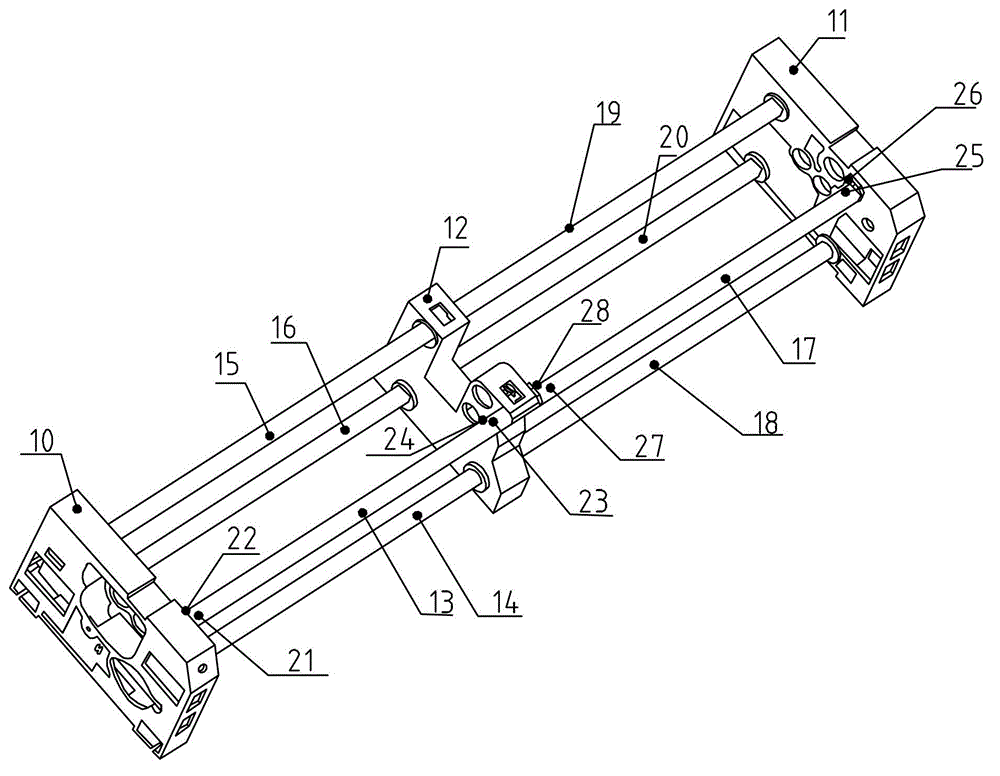

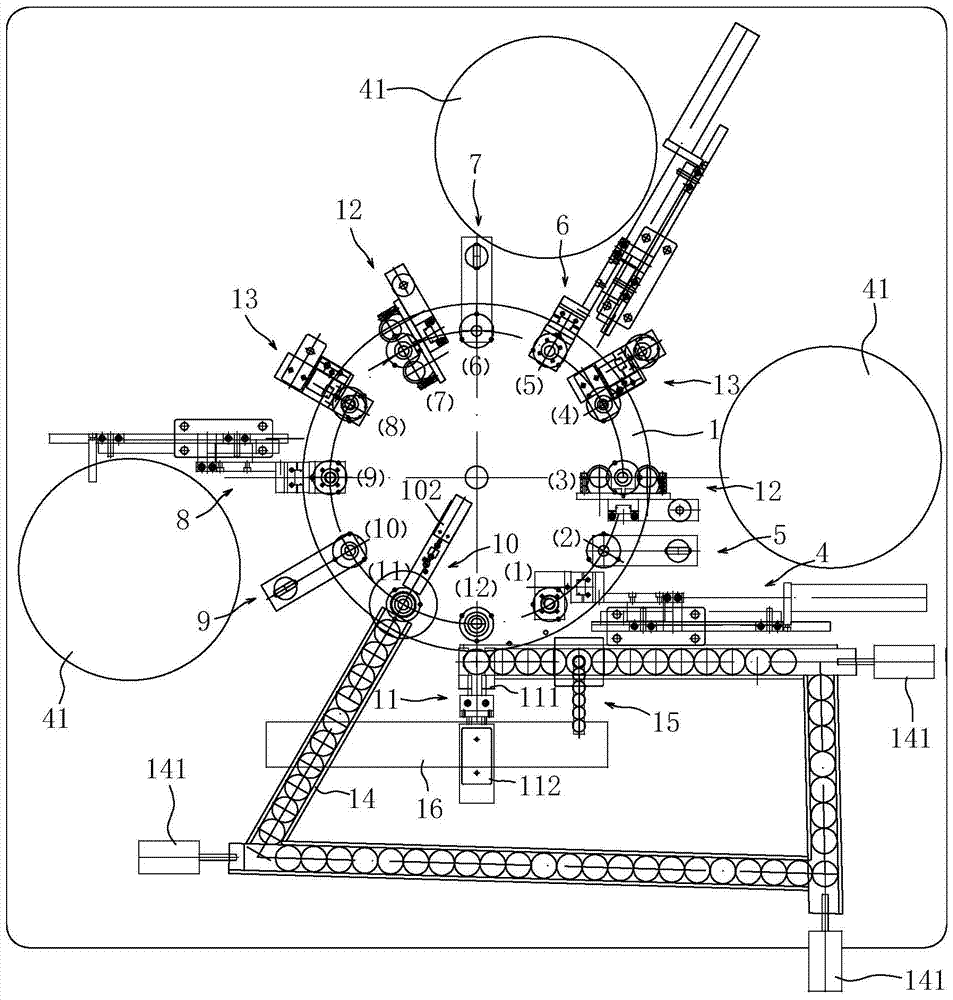

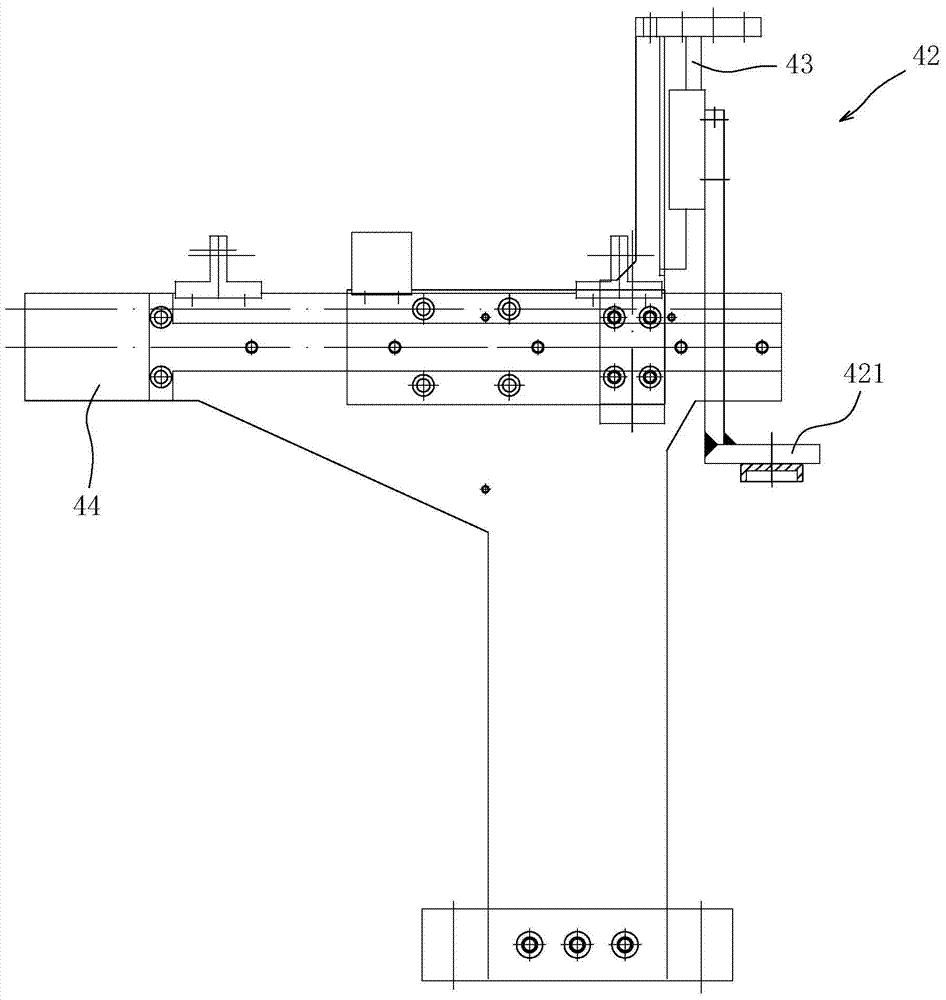

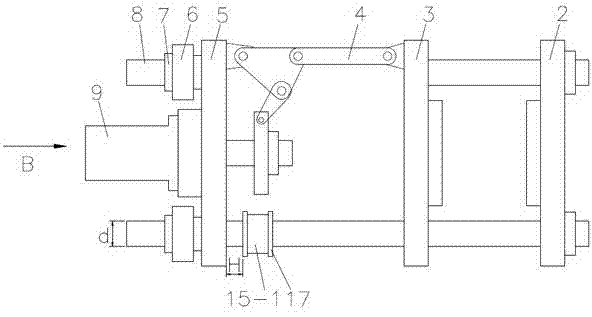

Loudspeaker internal magnetic circuit assembling machine with reverse installation prevention function

InactiveCN107708057AGuaranteed concentricityGuaranteed forward transferElectrical transducersConveyor beltLoudspeaker

The invention discloses a loudspeaker internal magnetic circuit assembling machine with a reverse installation prevention function. The assembling machine includes a bracket automatic feeding platform, a magnet automatic feeding platform, a washer automatic feeding platform, dispensers, an indexing plate, dragging devices, and a discharge channel. Operation areas are set on the circumference of the indexing plate. One dispenser and one dragging device are arranged beside each operation area. The bracket automatic feeding platform, the magnet automatic feeding platform and the washer automaticfeeding platform are respectively connected to the peripheries of the corresponding operation areas. The discharge channel is connected to the periphery of the indexing plate. The bracket automatic feeding platform, the magnet automatic feeding platform and the washer automatic feeding platform are of the same structure. Each platform includes a connecting track, a vibration plate and a conveyor belt, wherein the vibration plate has an opening, the connecting track passes through the opening, the connecting track is at least partially disposed in the vibration plate, and the connecting track inclines. By using the loudspeaker internal magnetic circuit assembling machine, full-automatic loudspeaker internal magnetic circuit assembling is realized, the labor cost is greatly saved, and the labor intensity is reduced. The loudspeaker internal magnetic circuit assembling machine can ensure that the automatic feeding platforms carry out feeding forwardly and prevent reverse installation.

Owner:PENGMEI ELECTRIC AUDIO APPLIANCES DONGTAI CITY

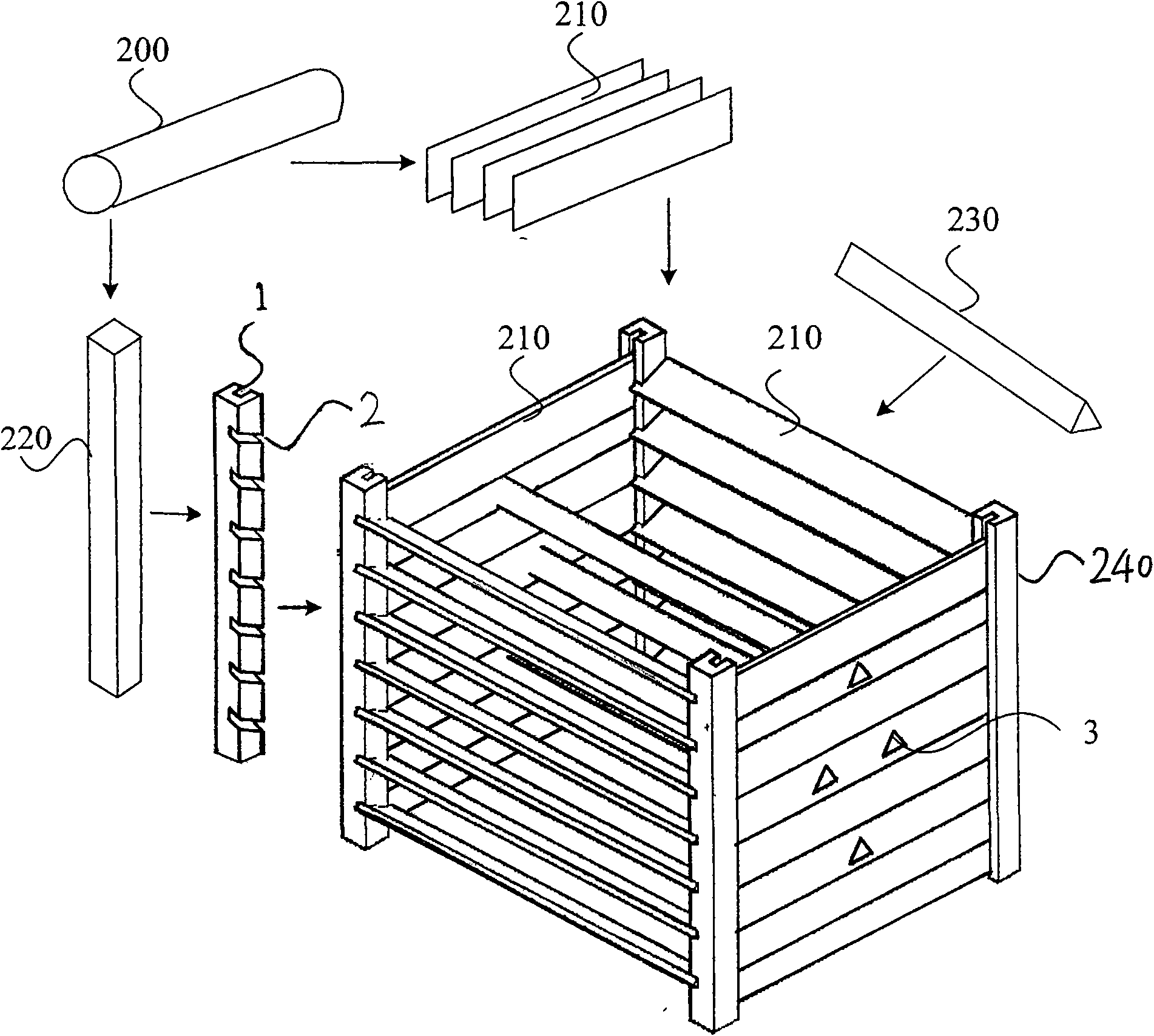

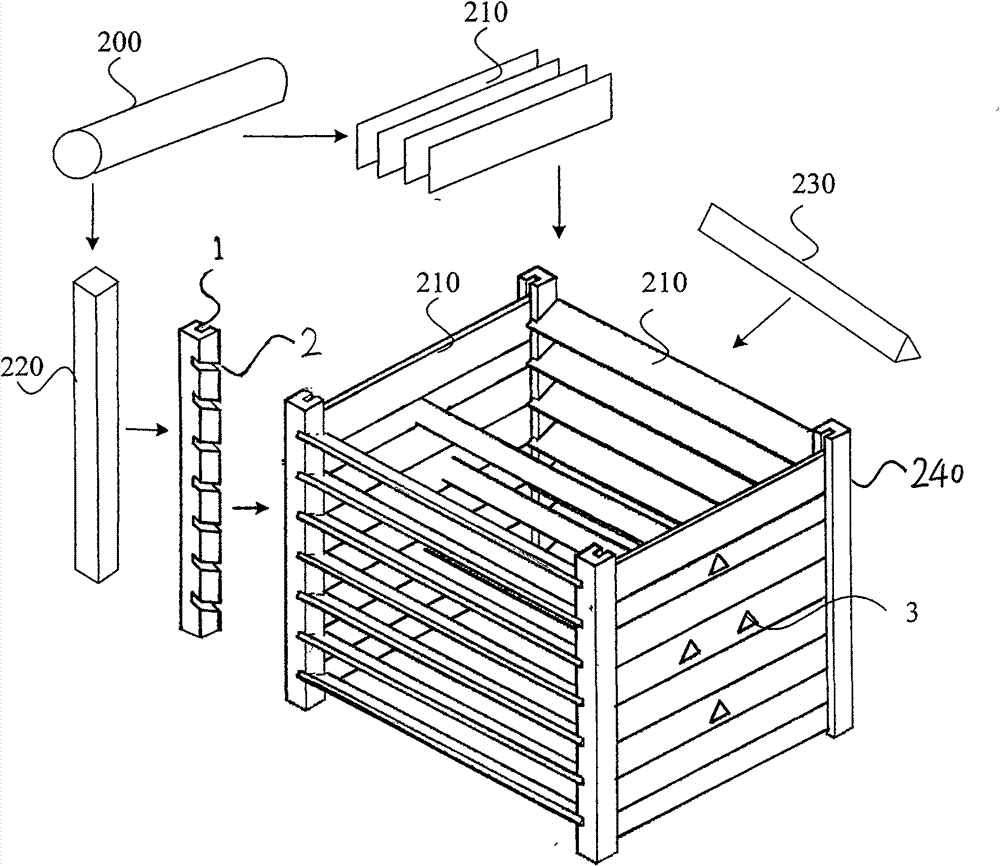

Device and method for elutriating and gluing wood chips

ActiveCN103282171AEvenly distributedSave glueGas current separationFlow mixersChip sizeEmbedded system

The invention relates to a device and method for elutriating and gluing wood chips. According to the invention, at least one elutriating apparatus is provided in order to fractionate the wood chips into at least one coarse chip fraction and one fine chip fraction, wherein the elutriating apparatus comprises a fall duct and is designed in such a way that the chip fractions pass through different gluing regions provided in the fall duct. Furthermore, at least one gluing apparatus is provided in order to glue the chip fractions in the gluing regions. Thus the chip fractions can be glued in a common apparatus specifically with a glue amount adapted to the particular average chip size.

Owner:利格朗木业技术公司

Loudspeaker internal magnetic circuit assembling machine

InactiveCN107708058AGuaranteed concentricityReduce labor costsElectrical transducersEngineeringLoudspeaker

The invention discloses a loudspeaker internal magnetic circuit assembling machine which includes a bracket automatic feeding platform, a magnet automatic feeding platform, a washer automatic feedingplatform, dispensers, an indexing plate, and dragging devices. Operation areas are set on the circumference of the indexing plate. One dispenser and one dragging device are arranged beside each operation area. The bracket automatic feeding platform, the magnet automatic feeding platform and the washer automatic feeding platform are respectively connected to the peripheries of the corresponding operation areas. By using the loudspeaker internal magnetic circuit assembling machine, full-automatic loudspeaker internal magnetic circuit assembling is realized, the labor cost is greatly saved, and the labor intensity is reduced.

Owner:PENGMEI ELECTRIC AUDIO APPLIANCES DONGTAI CITY

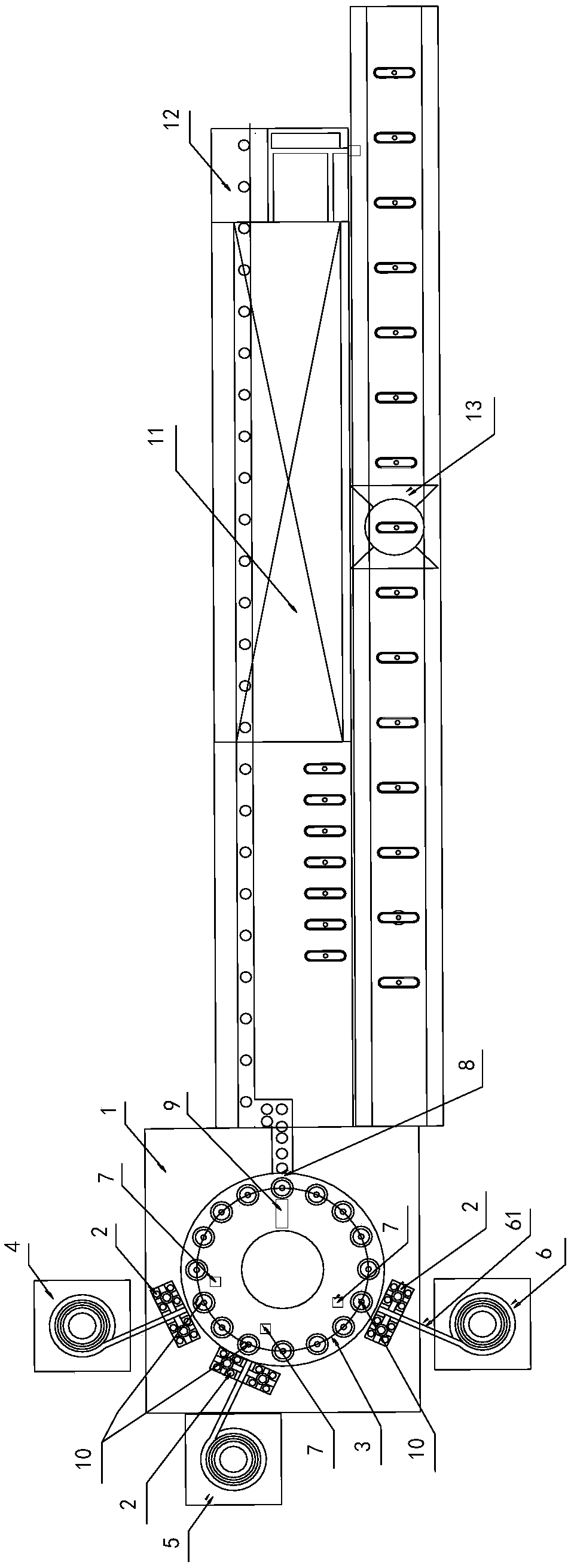

Full-automatic horn internal magnetic circuit assembly molding device

InactiveCN107896360AGuaranteed concentricityGuaranteed forward transferElectrical transducersAutonomationAutomation

The invention discloses an automatic horn internal magnetic circuit assembly molding device. The device comprises a support automatic loading table, a magnetic automatic loading table, a washer automatic loading table, glue dispensers, an indexing plate, dragging devices, an oven, an automatic turnover line and a magnetizer. Operating areas are arranged at the circumference of the indexing plate,the sides of the operating areas are provided with the glue dispensers and the dragging devices, the support automatic loading table, the magnetic automatic loading table and the washer automatic loading table are connected with the peripheries of respective operating areas, the automatic turnover line is connected with the periphery of the indexing plate, the automatic turnover line is provided with the oven and the magnetizer, and the oven is disposed at the upstream end of the magnetizer. By use of the device provided by the invention, full-automation of the assembling of a horn internal magnetic circuit can be realized, the labor cost is greatly saved, and the labor intensity is reduced.

Owner:PENGMEI ELECTRIC AUDIO APPLIANCES DONGTAI CITY

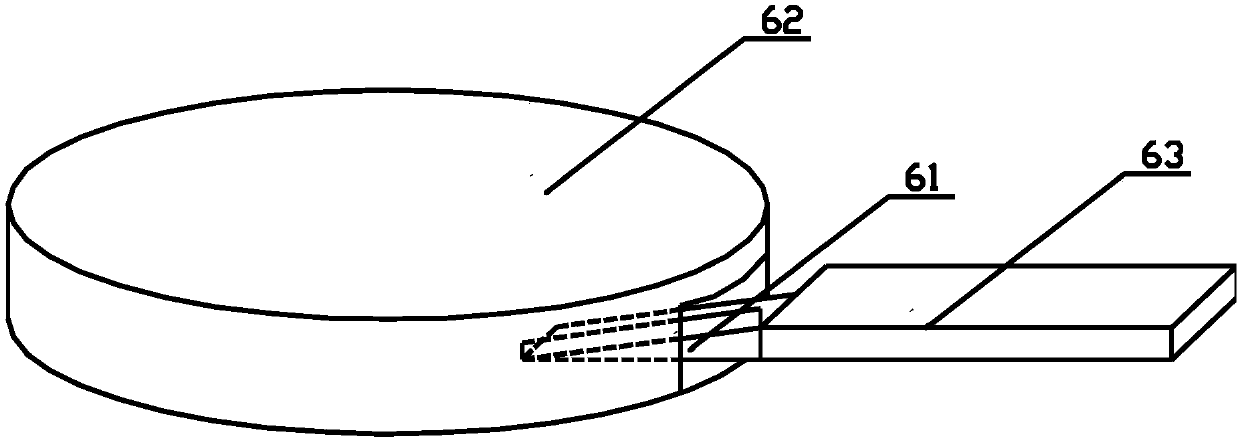

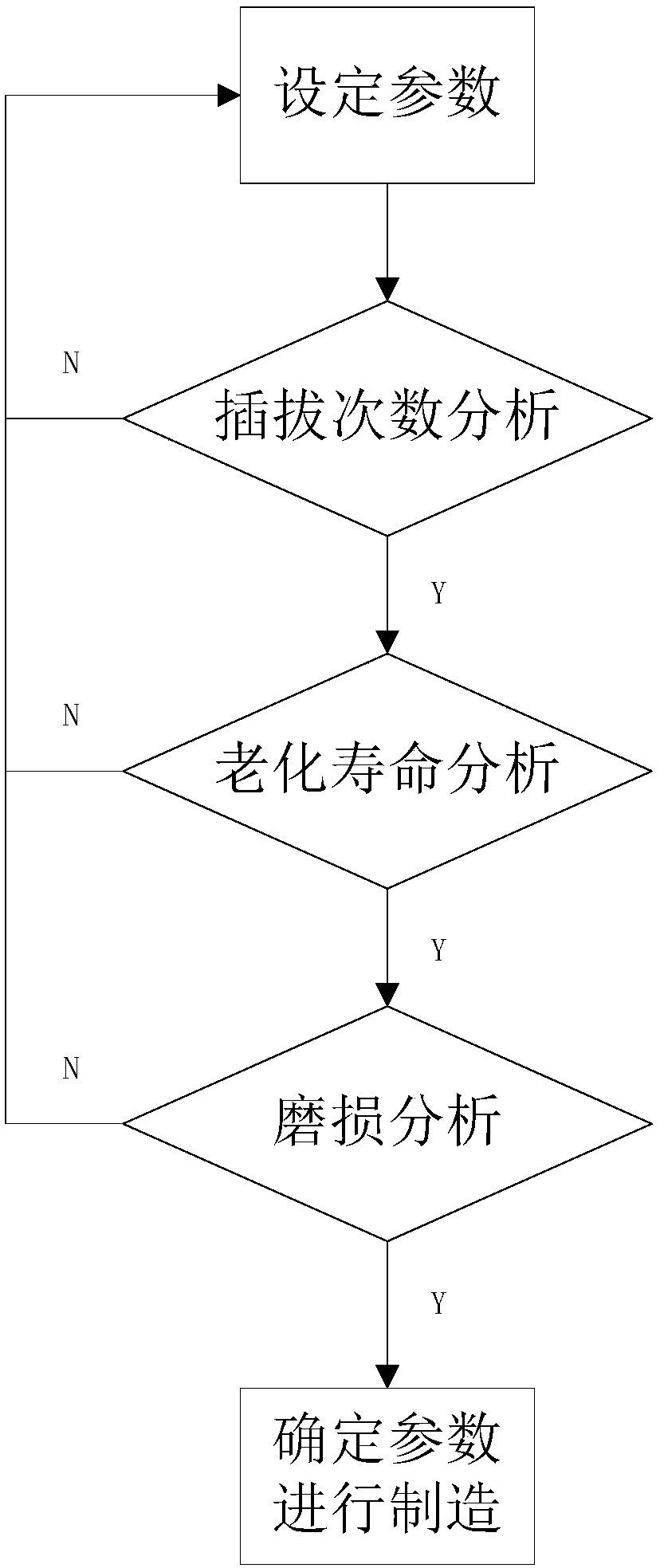

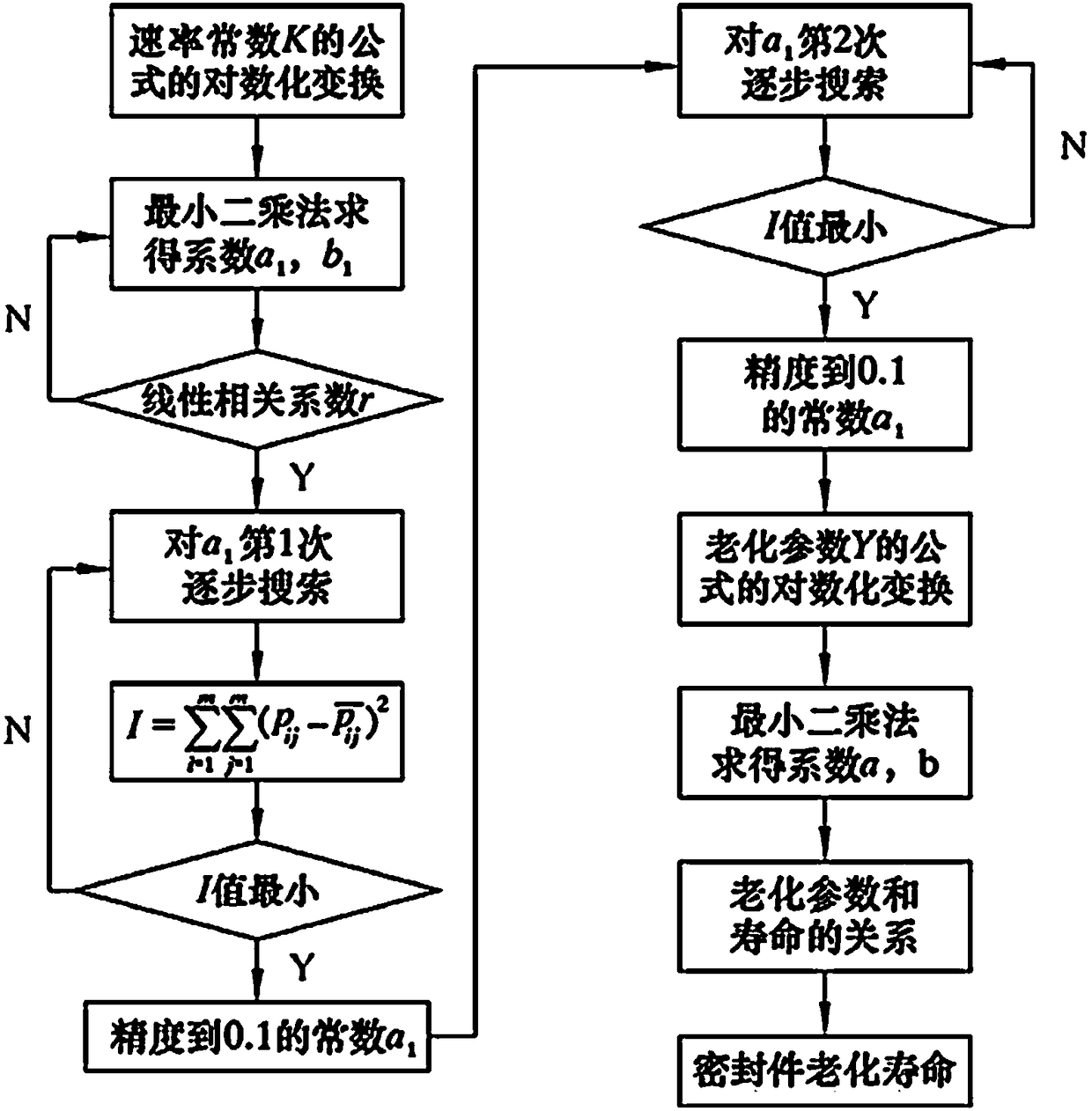

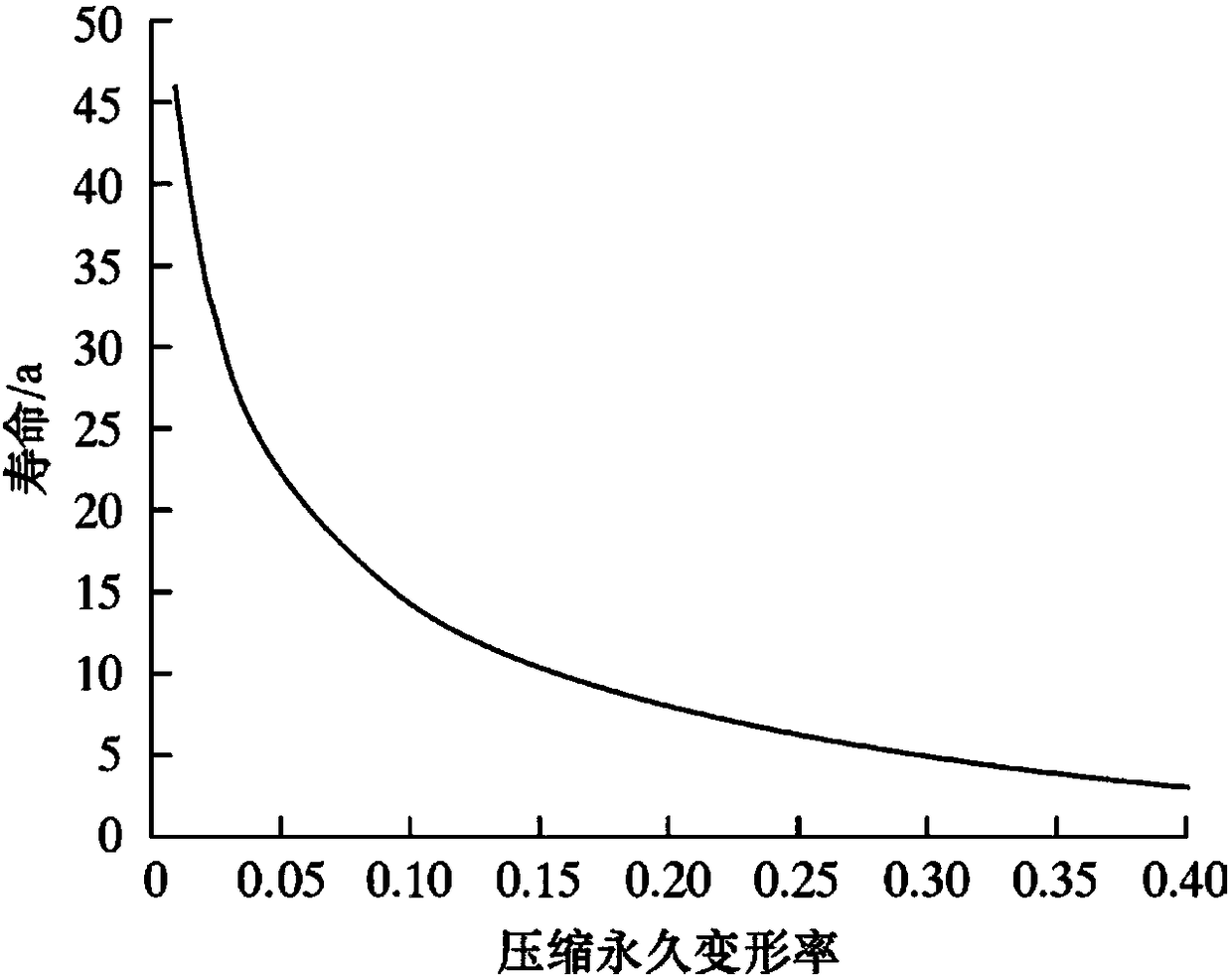

Design method for underwater wet type sealing ring for electrical general connecting head

The invention relates to a design method for an underwater wet type sealing ring for an electrical general connecting head. The design method is used for guaranteeing that the designed and manufactured sealing ring for the electrical general connecting head meets design needs. The design method comprises the following steps of: S1, determining parameters of the underwater wet type electrical general connecting head according to design requirements; S2, performing sealing ring insertion and extraction time test; S3, performing sealing ring temperature ageing test; S4, performing sealing ring abrasion test; and S5, determining final parameters of the underwater wet type electrical general connecting head, and producing and manufacturing based on the final parameters. The design method can beused for performing quantitative analysis on sealing ring insertion and extraction times, sealing ring temperature ageing and sealing ring abrasion, so that the analyzed results are more accurate, and the conclusion is clearer, and therefore, quality of practical products is favorably improved and guaranteed.

Owner:CSSC SYST ENG RES INST

Metal plate strip rolling process based on liquid carbon dioxide cooling and lubrication

InactiveCN110665966AImprove and ensure thicknessImprove and ensure qualityFurnace typesWork cooling devicesLiquid carbonLubrication

The invention discloses a metal plate strip rolling process based on liquid carbon dioxide cooling and lubrication. The metal plate strip rolling process based on the liquid carbon dioxide cooling andlubrication comprises the following steps: S1, a metal plate strip blank is put into a roller mill for rough rolling, and a cooling lubricant is sprayed on the blank; S2, the metal plate strip blanksubjected to rough rolling in the S1 is fed into a three-roller cold rolling mill for repeated finish rolling, and the cooling lubricant is sprayed at the same time; and S3, the process of the metal plate strip blank preparation, the adjustment of a deformation rolling tool and the preparation process of lubricating coolant need to be carried out again every two passes of rolling, and then the thickness deviation adjustment of the metal plate strip blank in the corresponding passes is carried out until a finished product meeting the requirements is rolled out. According to the metal plate strip rolling process based on the liquid carbon dioxide cooling and lubrication, the sectional cold rolling process is adopted in the rolling process, the strength of the metal plate strip blank can be improved by controlling the cooling speeds of different temperature sections, and the contradiction between the hardness and the strength, the wear resistance, the toughness and the fatigue resistanceof the metal plate strip blank can be better solved.

Owner:OKUMTEC TECH WENZHOU CO LTD

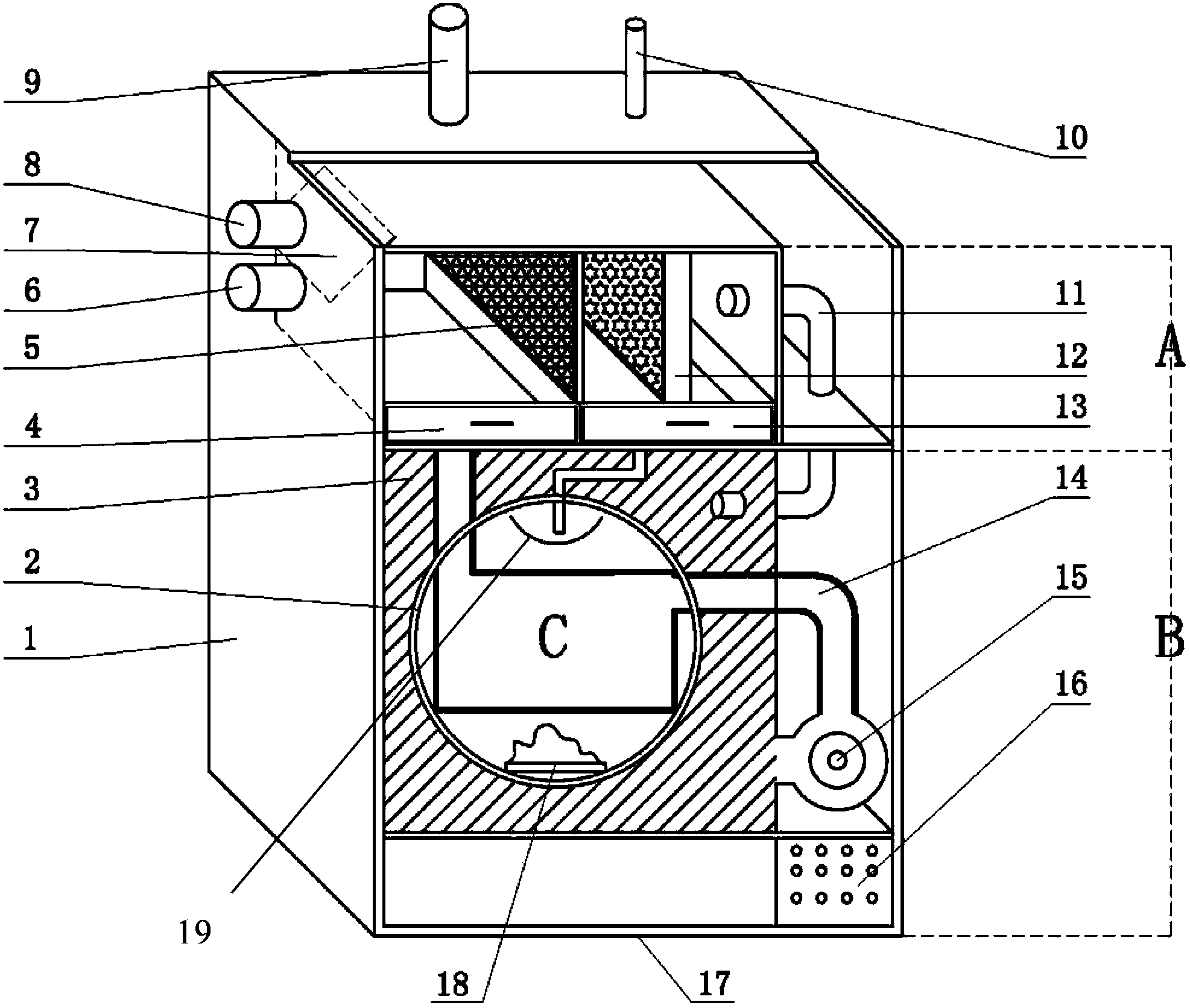

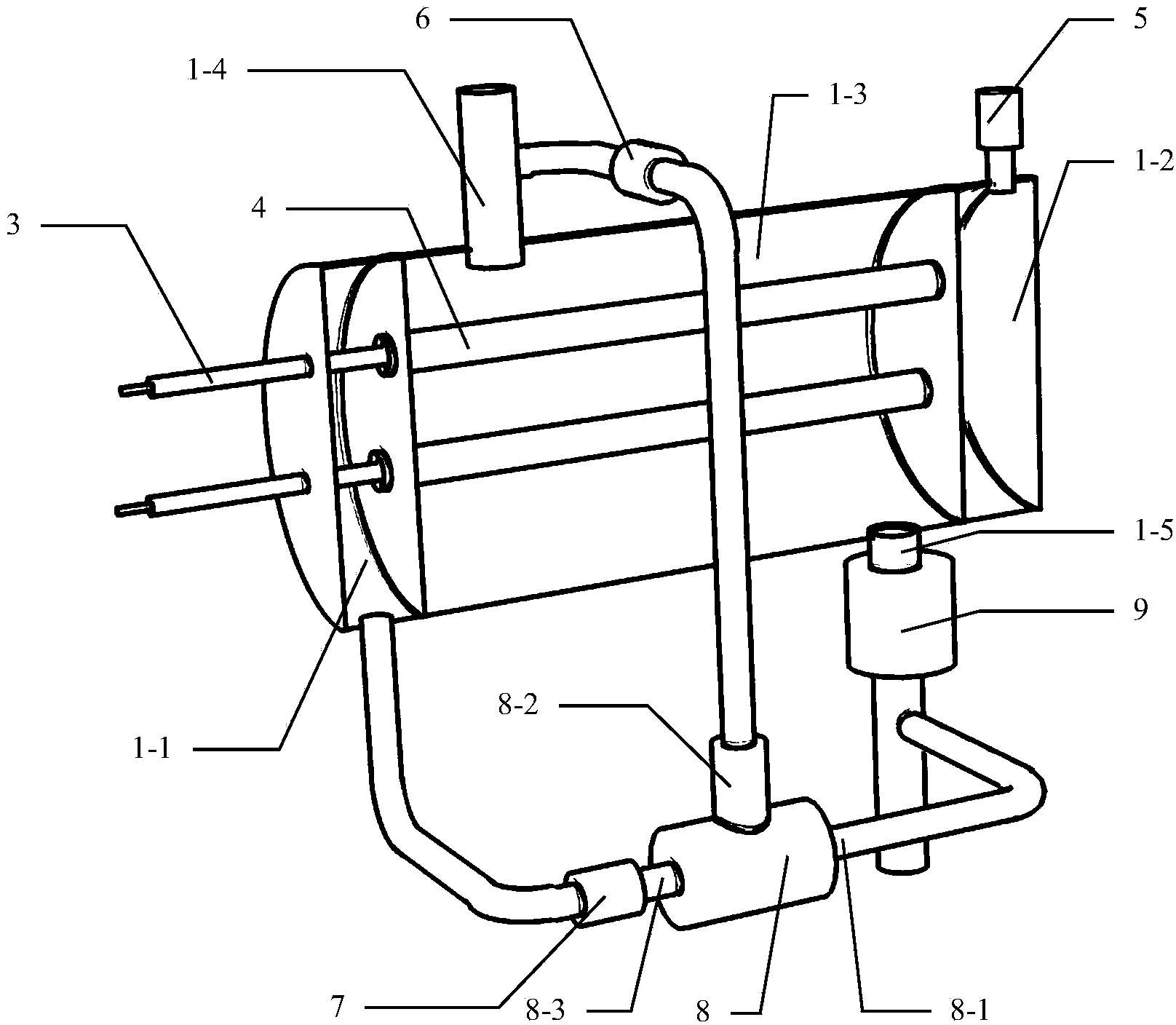

Method and device for recirculating disinfection of drinking water using waste ozone

ActiveCN104163466BSmall footprintLow running costWater/sewage treatment by irradiationWater/sewage treatment by oxidationAtmospheric airUltraviolet

The invention relates to a method and device for re-circulating disinfection of drinking water by using waste ozone. The method comprises six steps of disinfecting with ultraviolet rays; continuously mixing, dissolving and decomposing a gas-water mixed flow in the drinking water; and disinfecting a tank body, the drinking water in the tank body and air in the tank body. The device comprises the tank body, a plurality of ultraviolet lamps, a plurality of quartz socket tubes, a water ejector, and a high pressure water pump. The tank body comprises a first cavity, a second cavity communicated with air and a water cavity; the quartz socket tubes sealingly penetrate through the left and right walls of the water cavity and open in the first cavity and second cavity; the ultraviolet lamps sealingly penetrate through the first cavity and are disposed in the quartz socket tubes; a pressure water inlet of the water ejector is communicated with a high pressure water outlet of the high pressure water pump; a nozzle of the water ejector is communicated with the water cavity; and a gas inlet of the water ejector is communicated with the first cavity. The method and device take full use of conventional equipment and waste ozone byproducts, carry out ozone deep disinfection on the drinking water again, and save energy.

Owner:科泷(重庆)环保科技有限公司

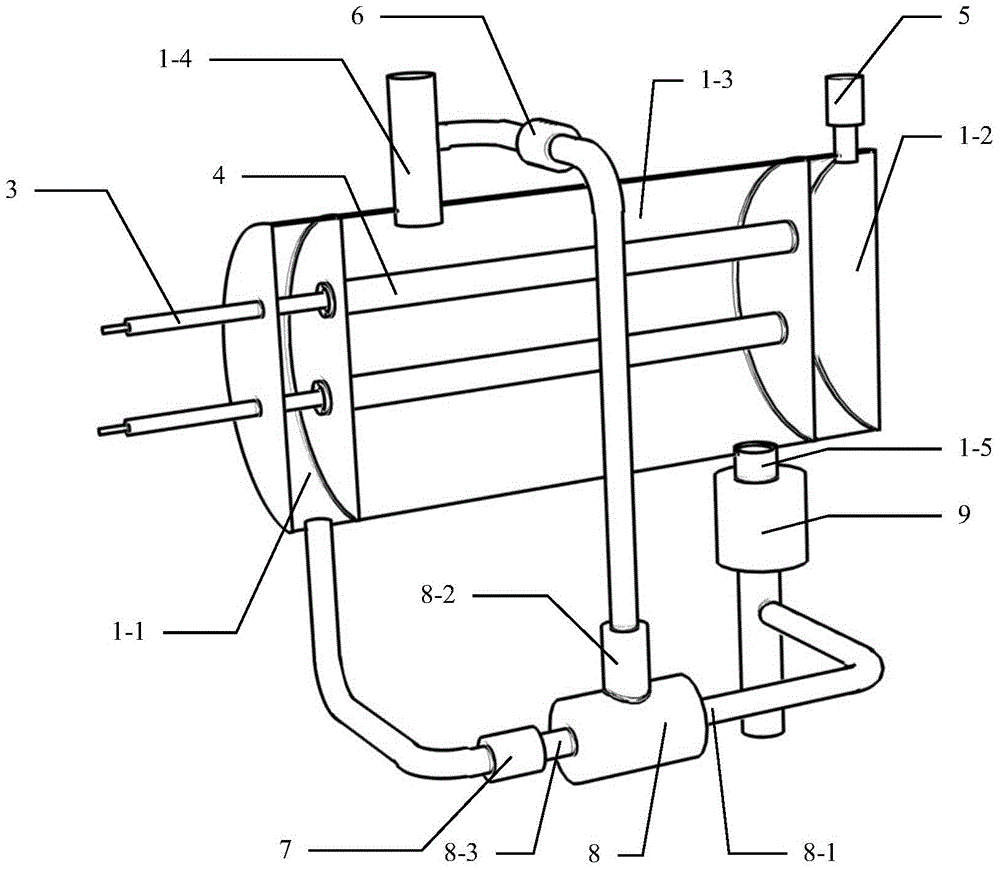

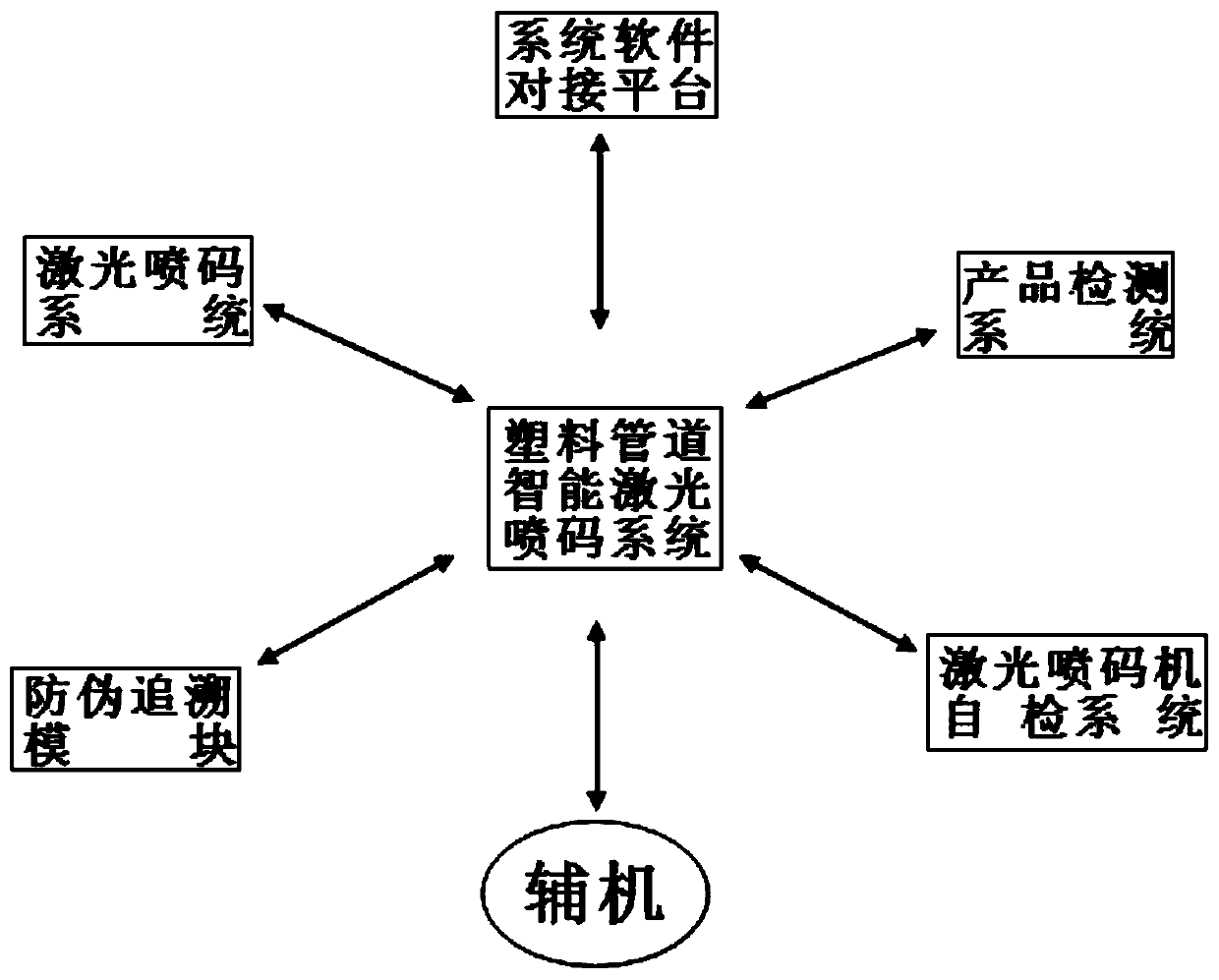

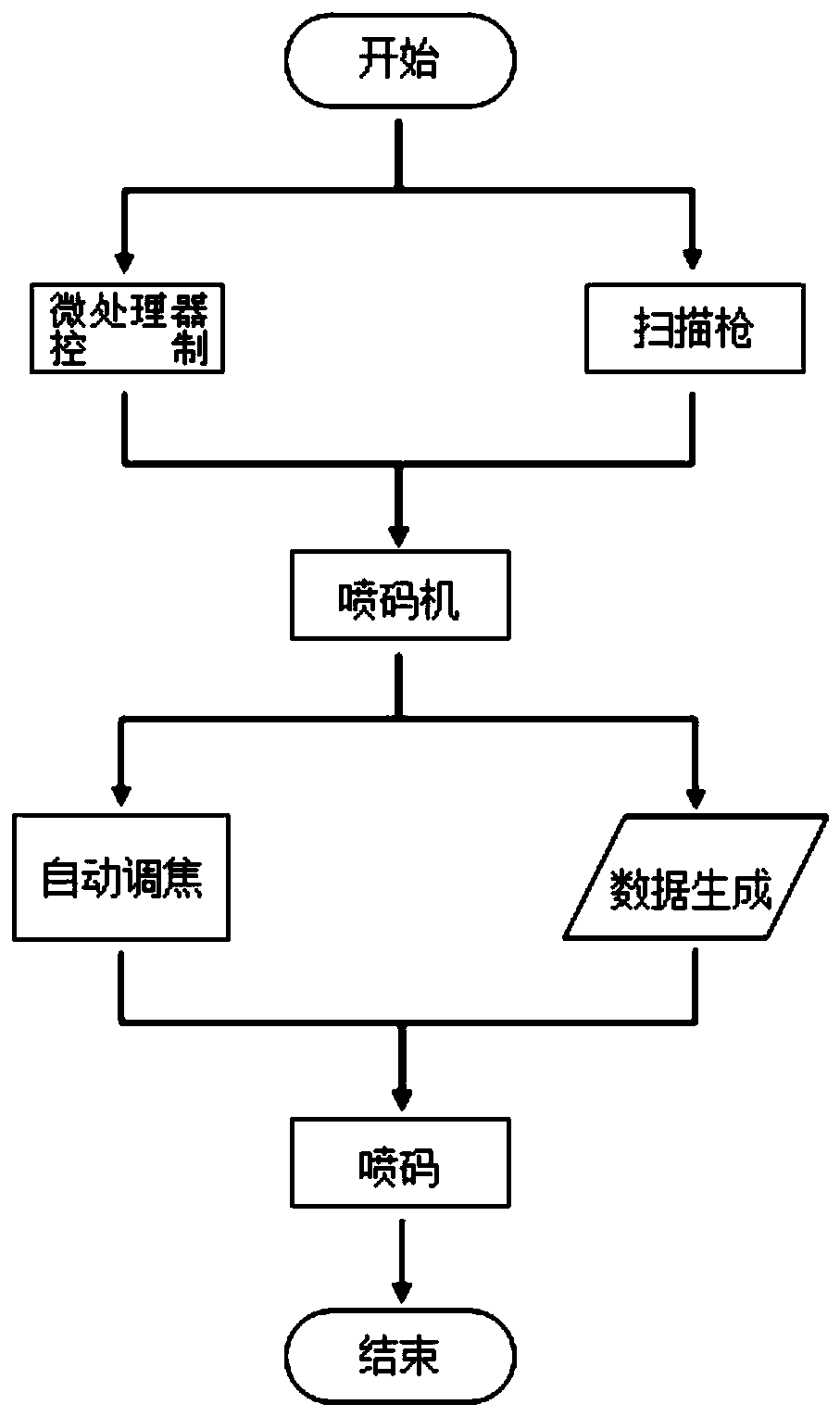

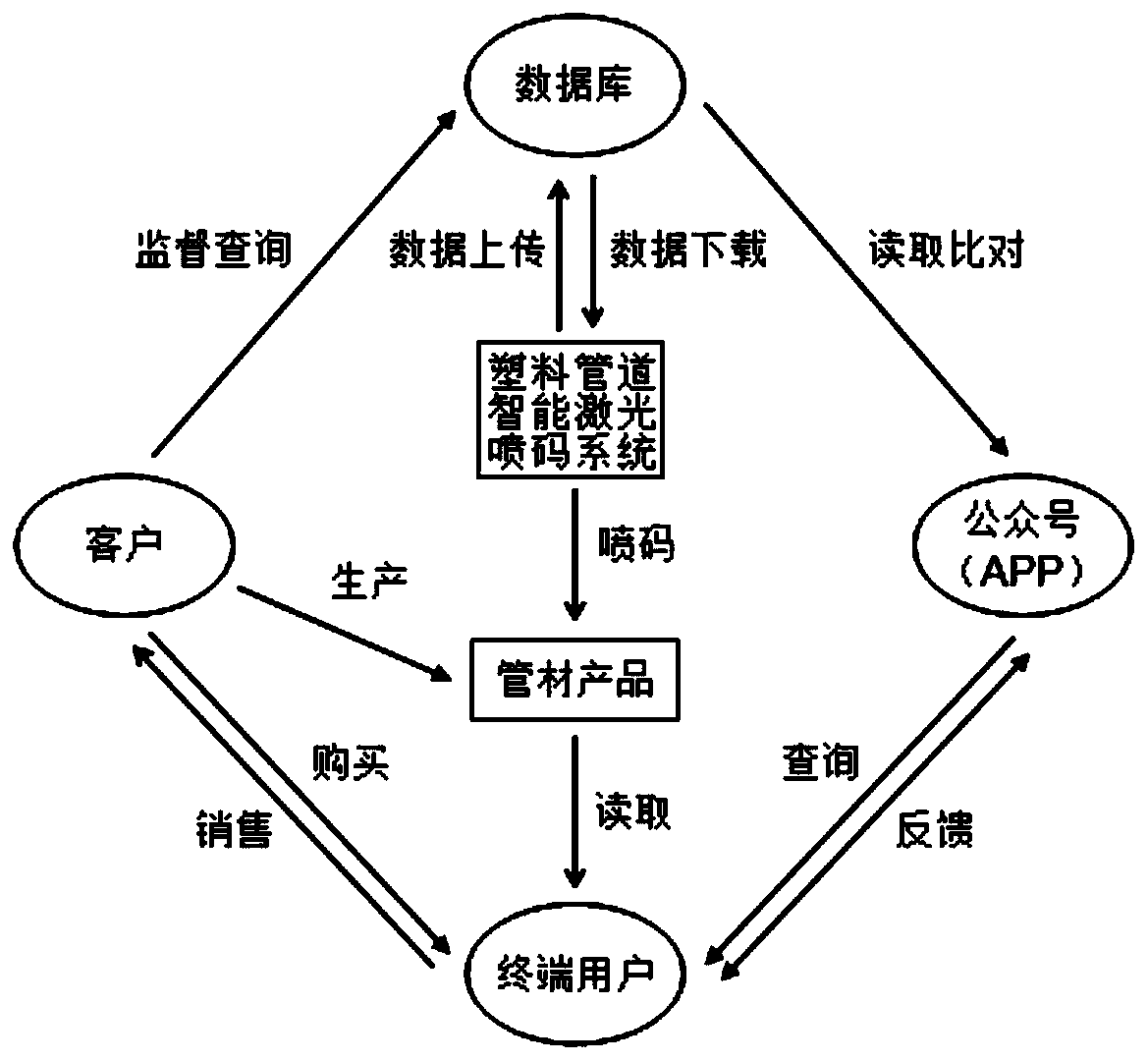

A control method of an intelligent laser coding system for plastic pipes

ActiveCN109774315BRealize automatic laser printingAchieve traceabilityTypewritersOther printing apparatusUltrasonic thickness measurementPlastic pipework

Owner:苏州大楚智能激光喷码设备有限公司

Plain-weave plastic braiding machine

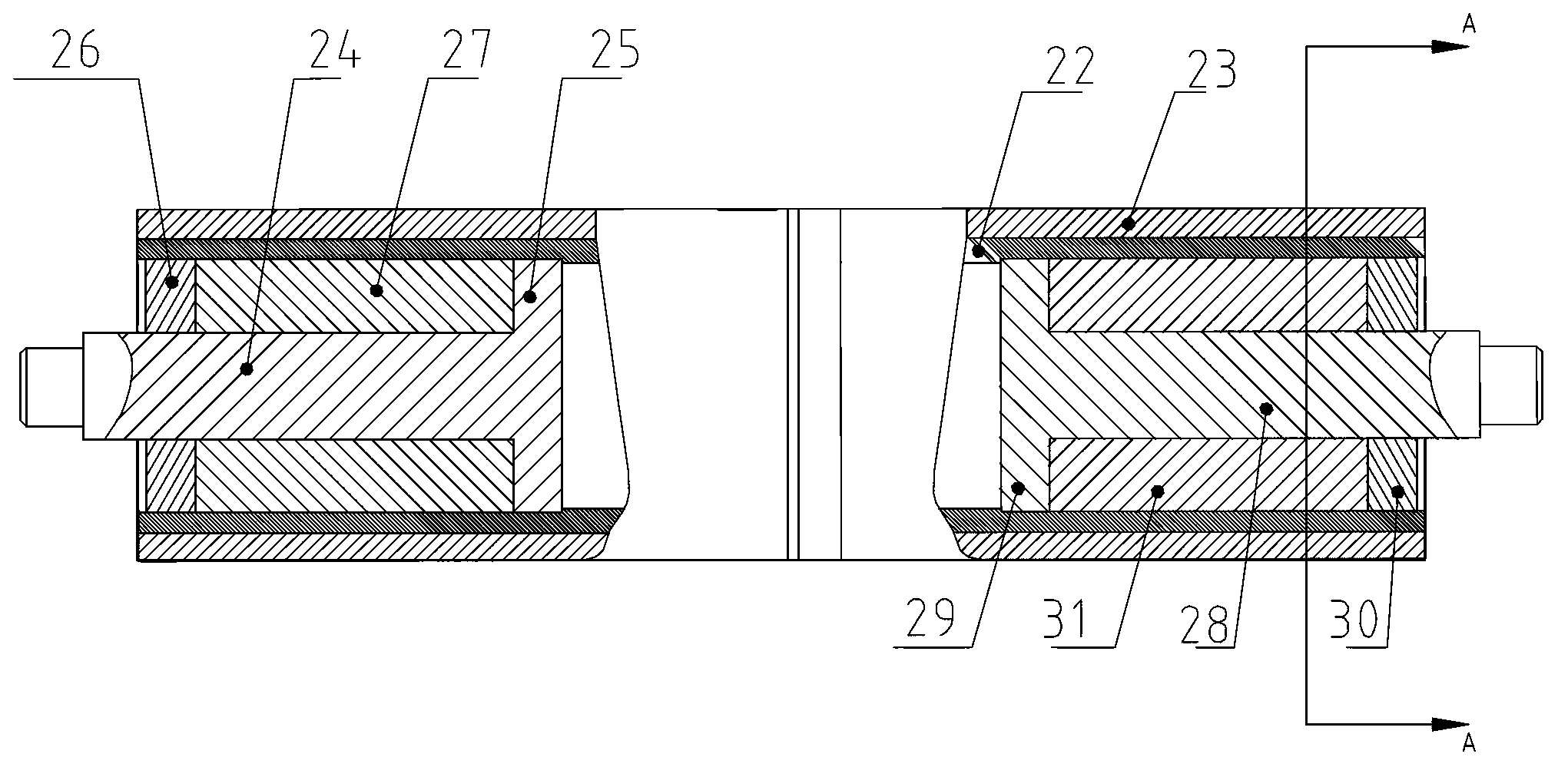

The invention discloses a plain-weave plastic braiding machine which is characterized by comprising a shedding mechanism, a water jet weft insertion mechanism, a weft beating-up mechanism, a let-off mechanism, a take-up mechanism and an auxiliary mechanism; the take-up mechanism comprises a wringing roller, the wringing roller comprises a rubber roller inner barrel and a coating layer arranged on the outer barrel wall of the rubber roller inner barrel, a spindle nose is arranged at the two ends of the roller tube inner barrel respectively, each spindle nose is fixedly arranged on the inner barrel wall of the rubber roller inner barrel through a spindle nose inner support disc and a spindle nose outer support disc, a plurality of radial reinforcing ribs are arranged between the spindle nose inner support disc and the spindle nose outer support disc, one end of each reinforcing rib is fixedly arranged on one spindle nose, the other end of each reinforcing rib is fixedly arranged on the inner barrel wall of the rubber roller inner barrel, in the length range of being 350-450 mm from the each end part of the coating layer, the diameter of the coating layer is reduced gradually from the middle part to the end parts, and the diameter of the end part is smaller than the diameter of the middle part by 1-1.5 mm. The plain-weave plastic braiding machine is suitable for weaving wide and heavy fabric and is also beneficial to further improving and guaranteeing the quality of plastic fabric.

Owner:青岛东佳机械制造有限公司

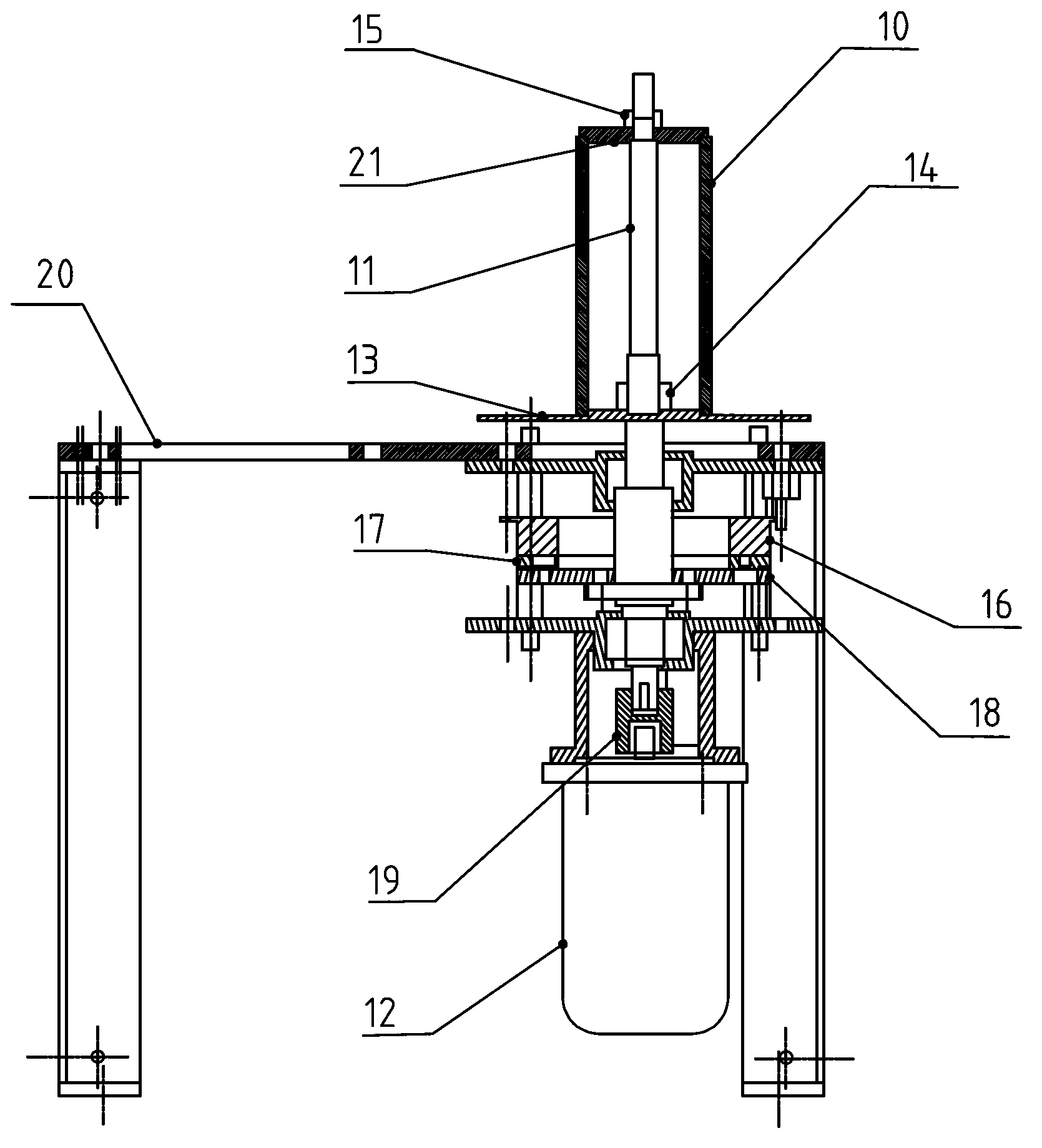

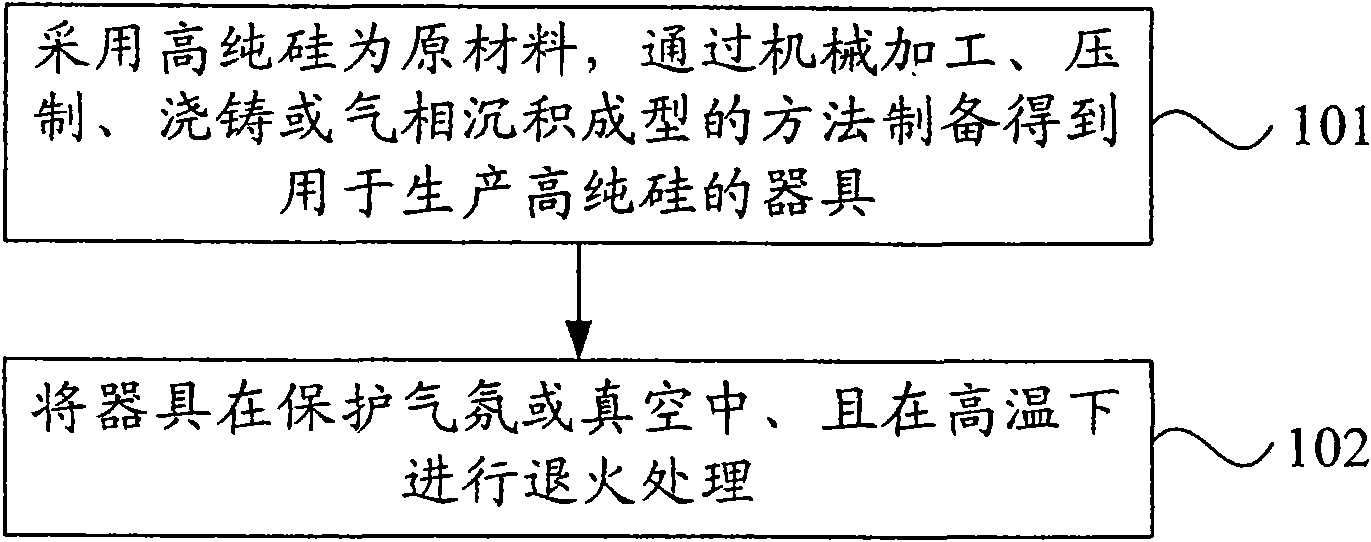

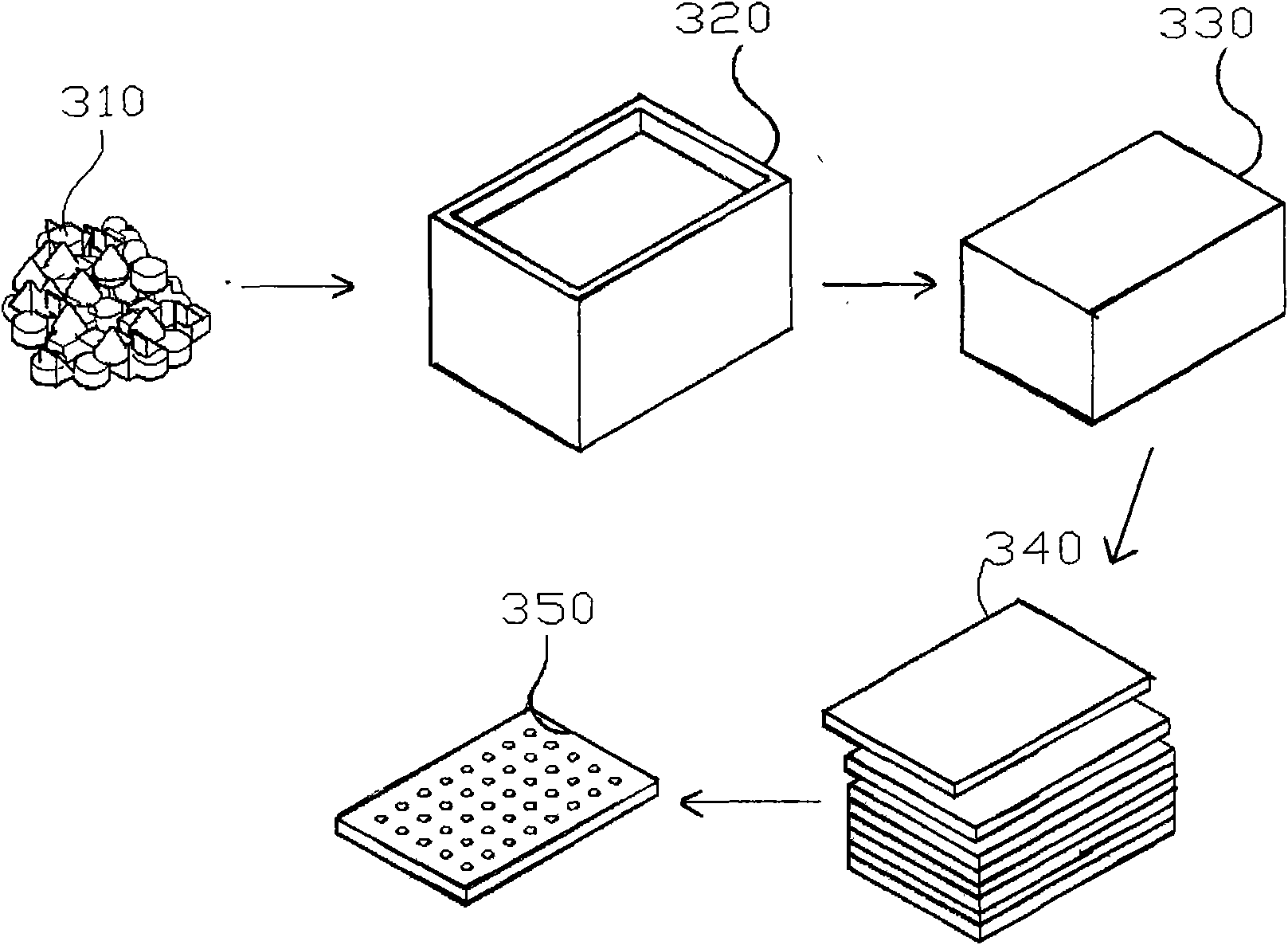

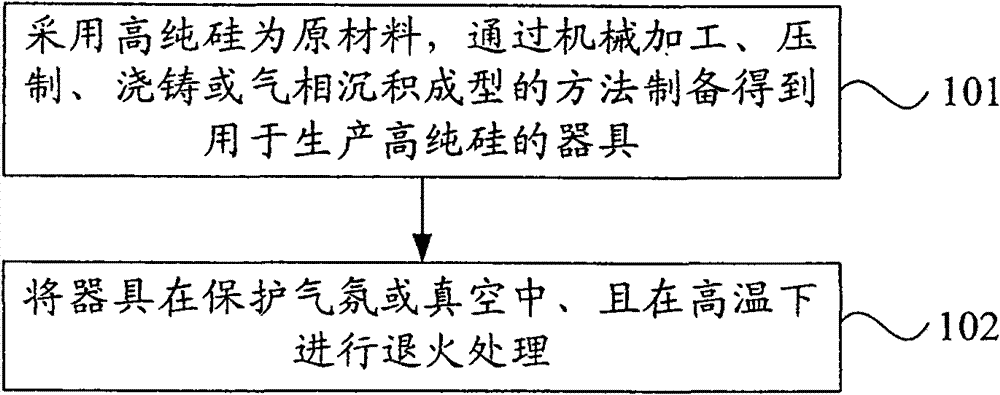

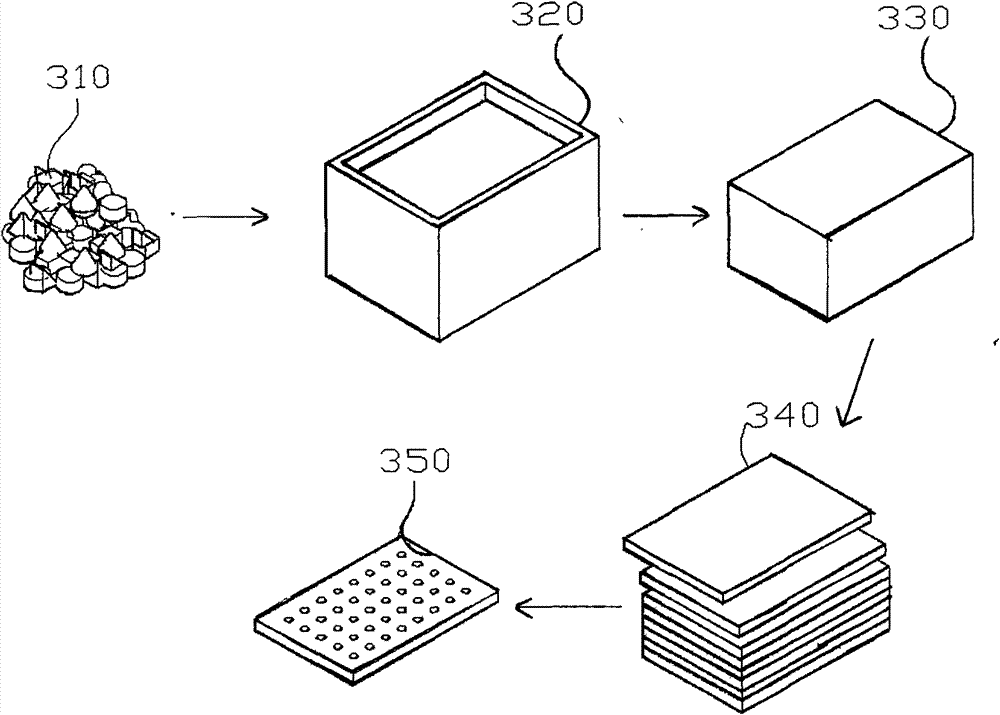

High purity silicon production device and preparation method thereof

ActiveCN101671021AAvoid pollutionImprove and ensure qualitySilicon compoundsGas phaseInternal stress

The invention provides a high purity silicon production device and a preparation method thereof. The method comprises the following steps: adopting high purity silicon as raw material to perform machining, pressing and casting or vapor depositing and obtain the device for producing high purity silicon and finally annealing at high temperature under protective atmosphere or vacuum. The high puritysilicon production device and the preparation method thereof provided by the invention adopts high purity silicon as raw material to process high purity silicon with different shapes by machining, pressing and casting or vapor depositing, prepares the device for producing high purity silicon and performs annealing treatment of the device under protective atmosphere or vacuum to remove residual internal stress of the device; the device is used to produce high purity silicon, which can avoid the pollution to high purity silicon, increase and guarantee the quality of high purity silicon and reduce the production cost of high purity silicon.

Owner:储晞

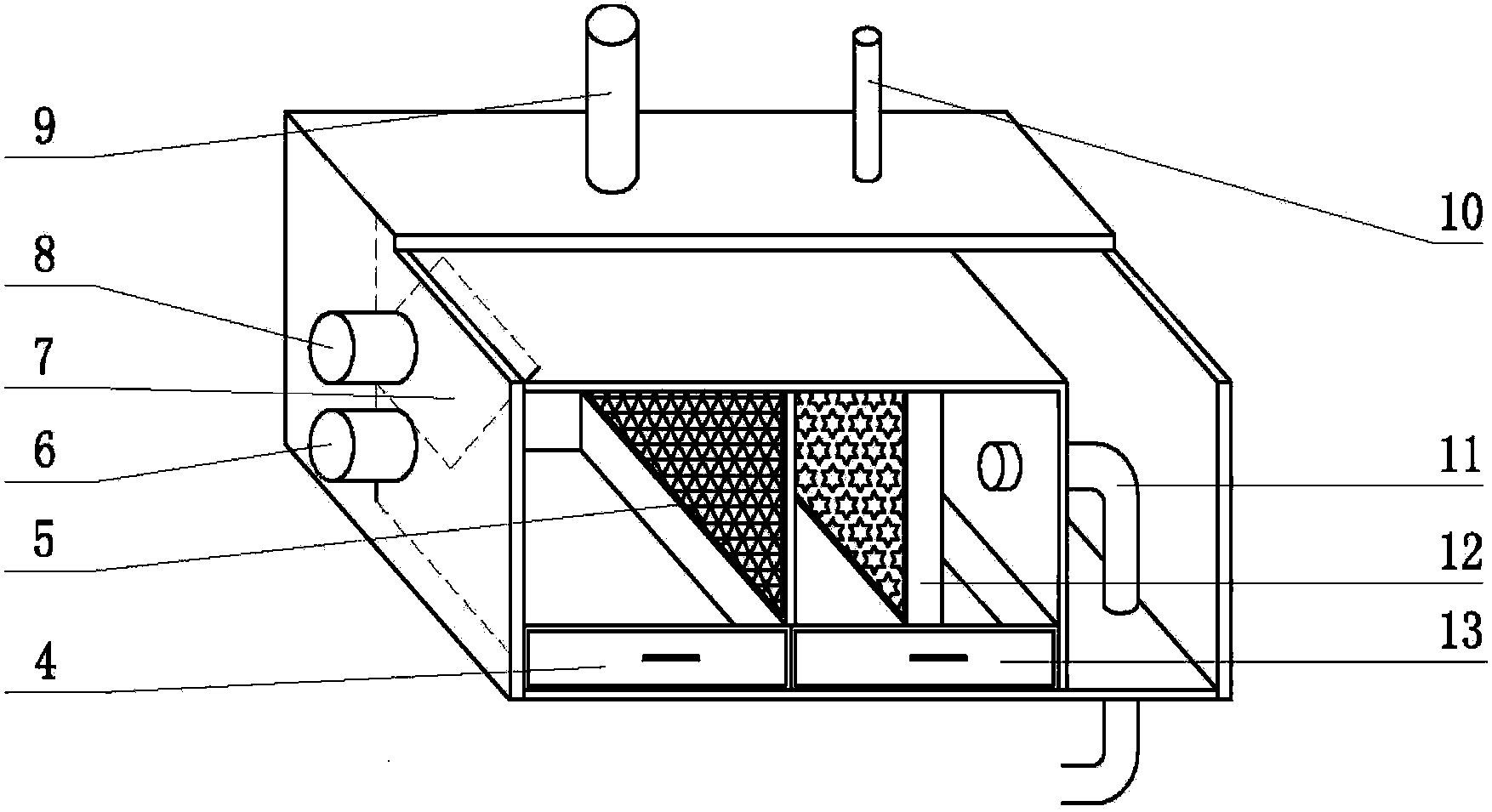

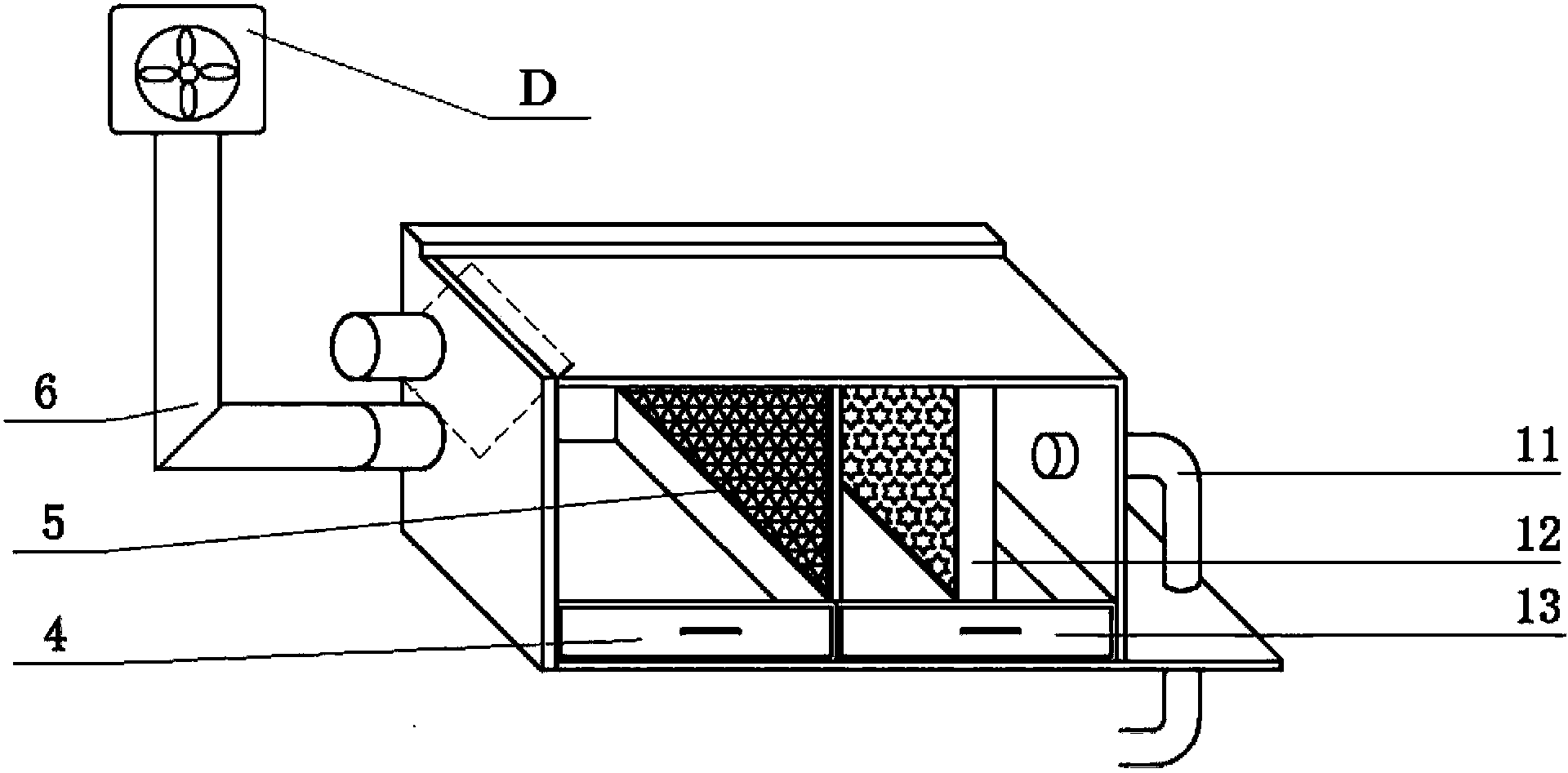

Directly-heated type air conditioning device capable of purifying gas by double circulation of indoor and outdoor air

ActiveCN102721100BSimple structureEmission reductionLighting and heating apparatusSpace heating and ventilation detailsCombustion chamberAir cleaning

A directly-heated type air conditioning device capable of purifying gas by double circulation of indoor and outdoor air comprises an indoor air input pipe, an outdoor air input pipe, and an indoor and outdoor double-circulation purifier and a gas-air heater of an air purifying device, wherein the gas-air heater comprises a spherical combustion chamber which is arranged in a shell and is provided with a smoke discharging tube, an air curtain between the shell and a combustor is connected with the double-circulation purifier by a pipeline, and sends air to a heating pipe in the combustion chamber by a fan, and the heating pipe is heated by a gas device in the spherical combustion chamber and conveys hot air into a room. The directly-heated type air conditioning device has a simple structure, is low in cost, convenient to use and obvious in heating effect, is not limited by power supply and water supply and has the effect of purifying air. The directly-heated type air conditioning device utilizes air as heat conduction medium so as to be high in conduction efficiency, overcomes the defect of closing and single circulation in the prior art, has obvious heating and sterilizing effects, can be widely applied to heating, ventilating and disinfecting of houses, schools, hospitals, offices and hotels for the old, and also can be applied to planting greenhouses, cultivation greenhouses, warehouse storage or field places.

Owner:刘明生

Plastic knitting machine

InactiveCN102839490AIncrease widthAdapt to weaving requirementsLoomsElectrical resistance and conductancePower flow

The invention discloses a plastic knitting machine, which is characterized by including a shedding mechanism, a water jet weft insertion mechanism, a beating-up mechanism, a let-off mechanism, a winding mechanism and an auxiliary mechanism. The auxiliary mechanism includes a frame mechanism and an electronic weft cutter. The electronic weft cutter comprises a main controller, a current relay, a current transformer, a first copper terminal, a second copper terminal and a resistance wire for thermally cutting off a weft yarn; the main controller is connected with the current relay; the current relay is connected with the current transformer; the current transformer is connected with the first copper terminal and the second copper terminal; and the resistance wire has one end connected with the first copper terminal and the other end connected with the second copper terminal. The frame mechanism includes a left wall plate, a right wall plate and spacers; a middle wall plate is arranged between the left and the right wall plate; the left wall plate is connected with the middle wall plate through a first spacer group; and the right wall plate is connected with the middle wall plate through a second spacer group. The plastic knitting machine is not only suitable for knitting wide and heavy fabrics, but also in favor of further improvement and guarantee on the quality of plastic fabrics.

Owner:青岛东佳纺机(集团)有限公司 +1

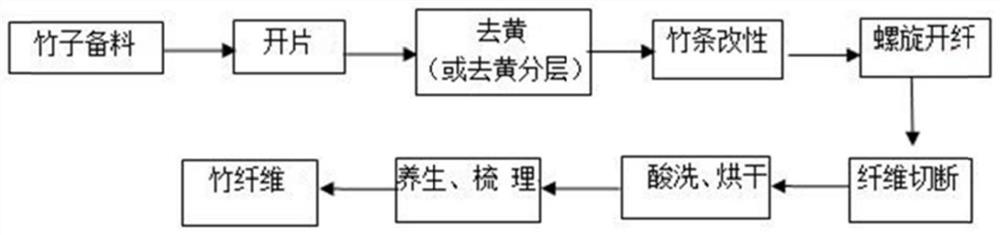

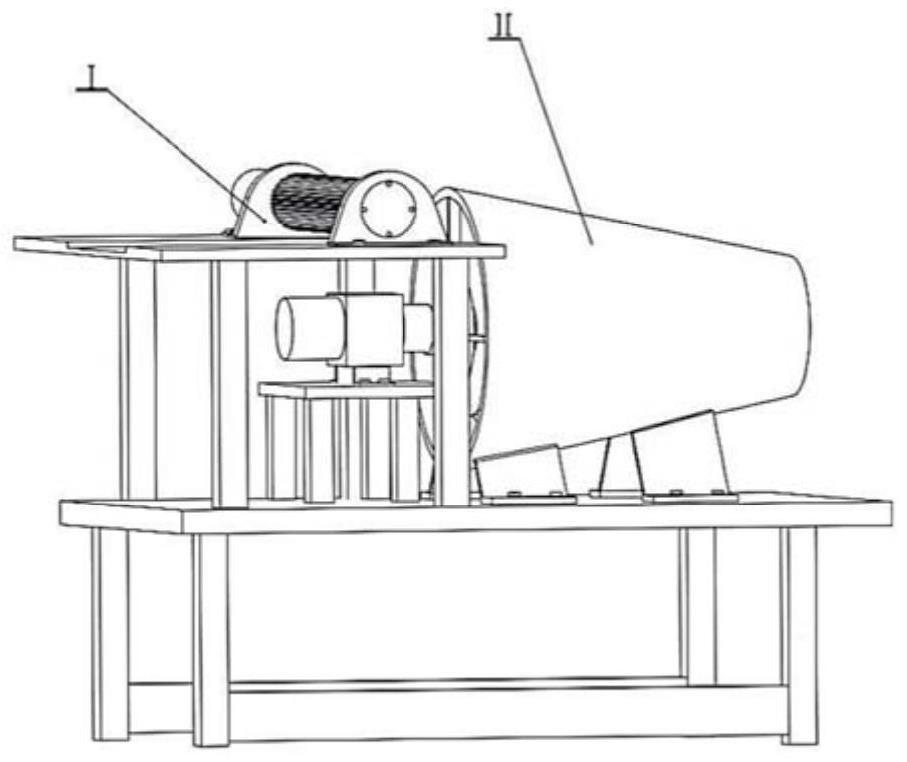

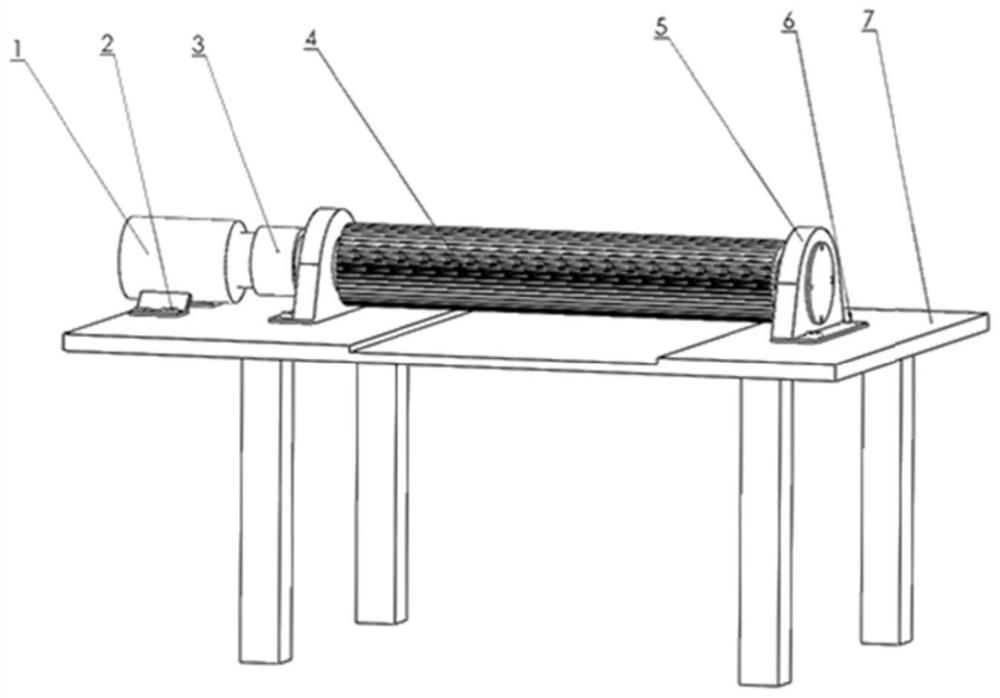

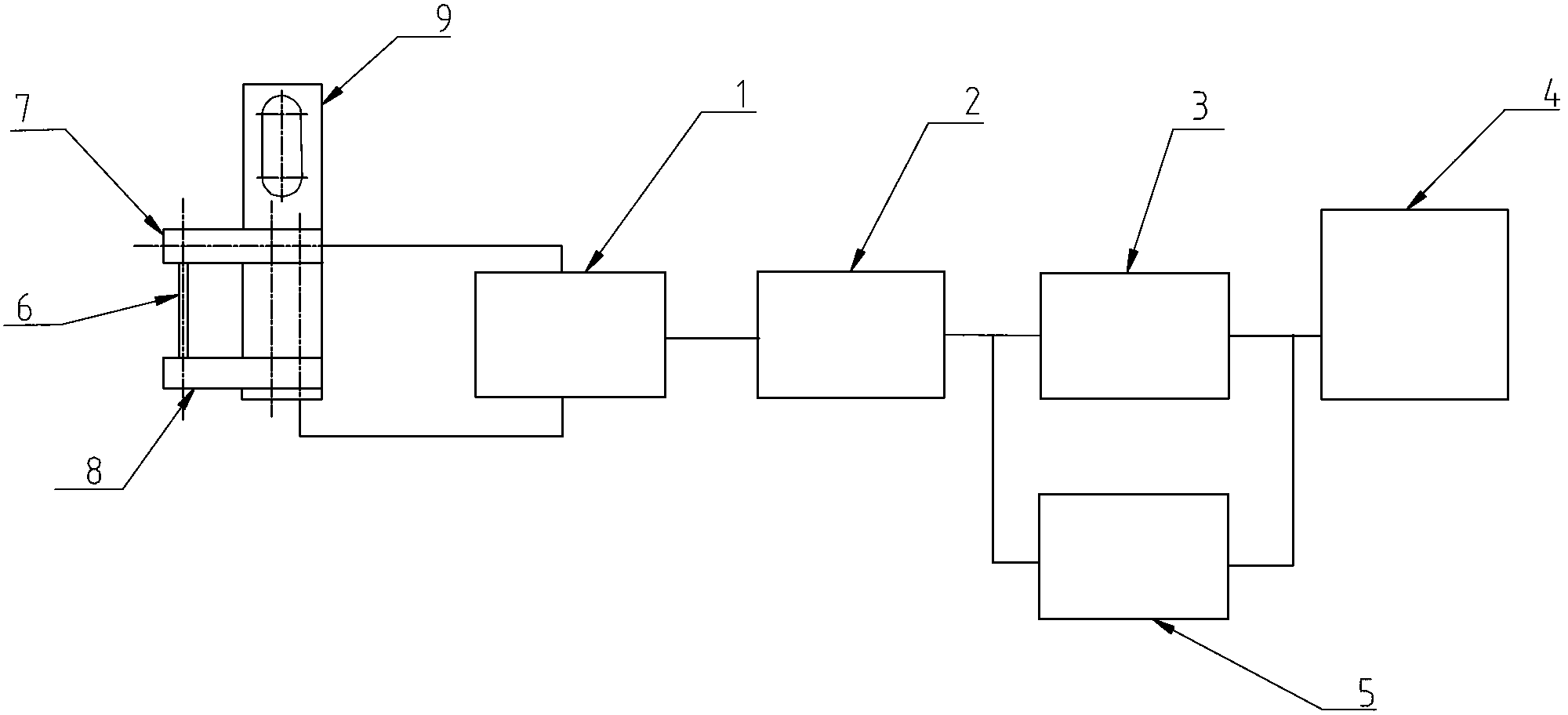

Equipment for spirally splitting bamboo strips and bamboo fiber obtaining method of equipment

PendingCN113815076AAvoid damageIntegrity guaranteedWood treatment detailsCane mechanical workingFiber bundleSpiral blade

The invention discloses equipment for spirally splitting bamboo strips and a bamboo fiber obtaining method of the equipment. The equipment comprises a feeding system and a spiral splitting system. The spiral splitting system comprises a main shaft and an outer cylinder which are conical and have cross sections gradually reduced along the feeding direction; the main shaft is connected with a second motor, and double spiral blades are axially arranged on the outer surface; two spiral blades of the double spiral blades have the same spiral direction and are symmetrically arranged in the axial direction, and the screw pitch of the double spiral blades is gradually reduced in the feeding direction; the outer cylinder is coaxially sleeved outside the main shaft, the inner wall of the cylinder does not influence the rotation of the double spiral blades, and the cylinder, the double spiral blades and the main shaft jointly form a splitting channel capable of enabling bamboo strips to move spirally; and bamboo strips to be treated can enter an inlet of the splitting channel after being fed by the feeding system. In the bamboo splitting process through the equipment, the integrity of fiber tissue can be kept to the maximum extent, fiber structure damage and strength damage are avoided, and lossless separation between fiber bundles is achieved.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

Plain weave plastic loom

The invention discloses a plain weave plastic loom, which comprises an open mechanism, a water jet weft insertion mechanism, a weft beating-up mechanism, a warp feeding mechanism, a take-up mechanism and an auxiliary mechanism. The loom is characterized in that the auxiliary mechanism comprises a frame mechanism, an electronic weft-yarn cutter device and an electronic weft feeding device; the electronic weft-yarn cutter device comprises a main controller, a current relay, a current transformer, a No.1 copper terminal, a No.2 copper terminal and a resistance wire for burning off weft yarns; the electronic weft feeding device comprises a weft-yarn table component, a weft-yarn tube, a vertical drive shaft, a weft feeding motor and an electromagnetic brake component; a tray driven by the drive shaft is arranged at the upper part of a tabletop; the weft-yarn tube is placed on the tray and rotates together along with the tray; the electromagnetic brake component comprises a brake fixed tray and a friction disk; and the fixed tray is fixed at the bottom of the tabletop; the friction disk is positioned under the fixed tray and is fixedly connected with the drive shaft. The plain weave plastic loom can be not only suitable for weaving wide heavy fabrics, but also favorable for further improving and ensuring the quality of plastic fabrics.

Owner:青岛东佳机械制造有限公司

Plastic knitting machine

The invention discloses a plastic knitting machine, which is characterized by including a shedding mechanism, a water jet weft insertion mechanism, a beating-up mechanism, a let-off mechanism, a winding mechanism and an auxiliary mechanism. The auxiliary mechanism includes a frame mechanism and an electronic weft cutter. The electronic weft cutter comprises a main controller, a current relay, a current transformer, a first copper terminal, a second copper terminal and a resistance wire for thermally cutting off a weft yarn; the main controller is connected with the current relay; the current relay is connected with the current transformer; the current transformer is connected with the first copper terminal and the second copper terminal; and the resistance wire has one end connected with the first copper terminal and the other end connected with the second copper terminal. The frame mechanism includes a left wall plate, a right wall plate and spacers; a middle wall plate is arranged between the left and the right wall plate; the left wall plate is connected with the middle wall plate through a first spacer group; and the right wall plate is connected with the middle wall plate through a second spacer group. The plastic knitting machine is not only suitable for knitting wide and heavy fabrics, but also in favor of further improvement and guarantee on the quality of plastic fabrics.

Owner:青岛东佳纺机(集团)有限公司 +1

A kind of direct oral decoction piece production process

InactiveCN103271949BImprove cleanlinessImprove the efficacy of the drugPlant ingredientsBiochemical engineeringPollution

The invention discloses a production process of a directly-oral medicinal slice, and the production process comprises the following steps of: picking, washing, wetting, slicing, drying, sterilization, crushing, internal packing and external packing; the whole production process is carried out in a sterile clean room; sterile cleanness of the production environment is retained all the time; flowing type sterilization of ozone gas is adopted so as to ensure no residue pollution as well as effective sterilization; the sterilized traditional Chinese medicines are crushed until the crushing fineness is 80-120 meshes; the powdery traditional Chinese medicinal slice is packed in unit dosage at sterile and vacuum condition, so that no secondary pollution is caused in storage and transportation. The traditional Chinese medicinal slice prepared by the process disclosed by the invention has a cleanness to meet the condition that the slice can be orally taken directly, can be effectively absorbed by a human body due to a high crushing fineness, saves a process of weighing and boiling, saves time and labor, and has high medicine effect utilization rate.

Owner:SICHUAN SHENGLE PHARMA CO LTD

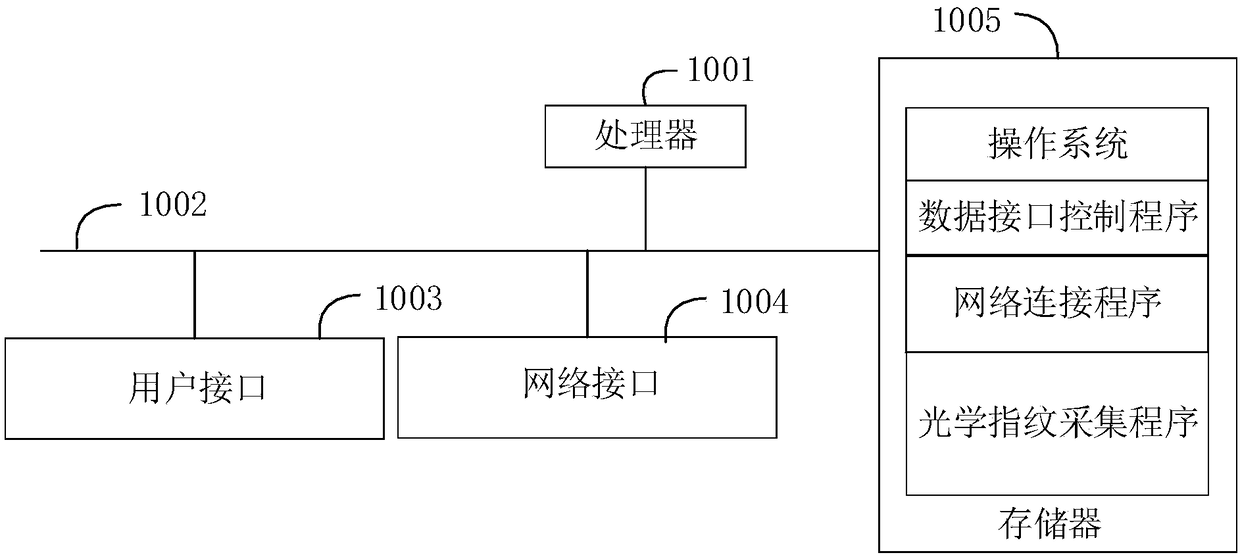

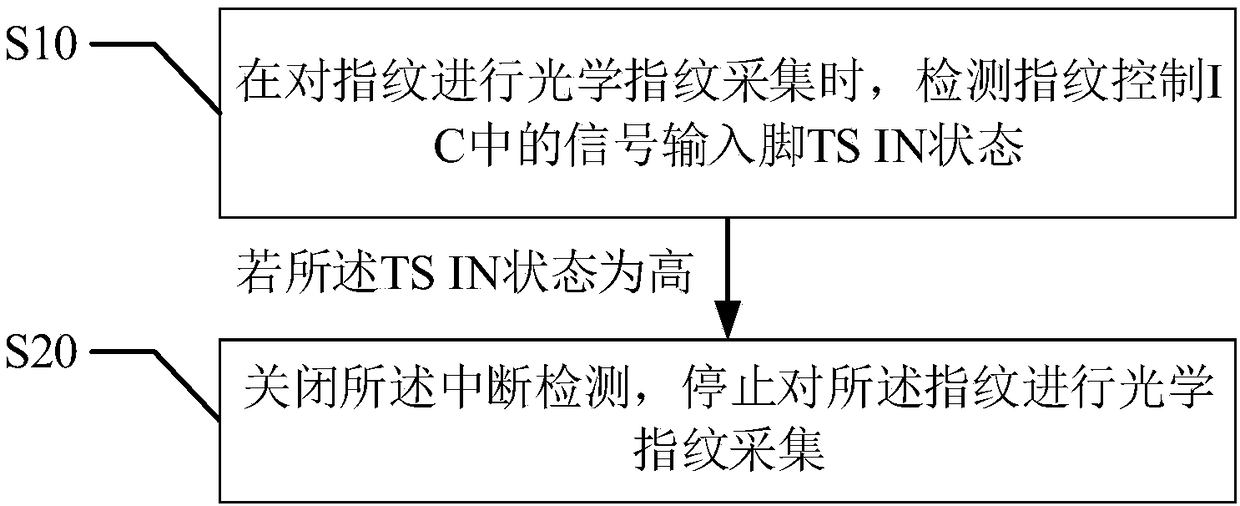

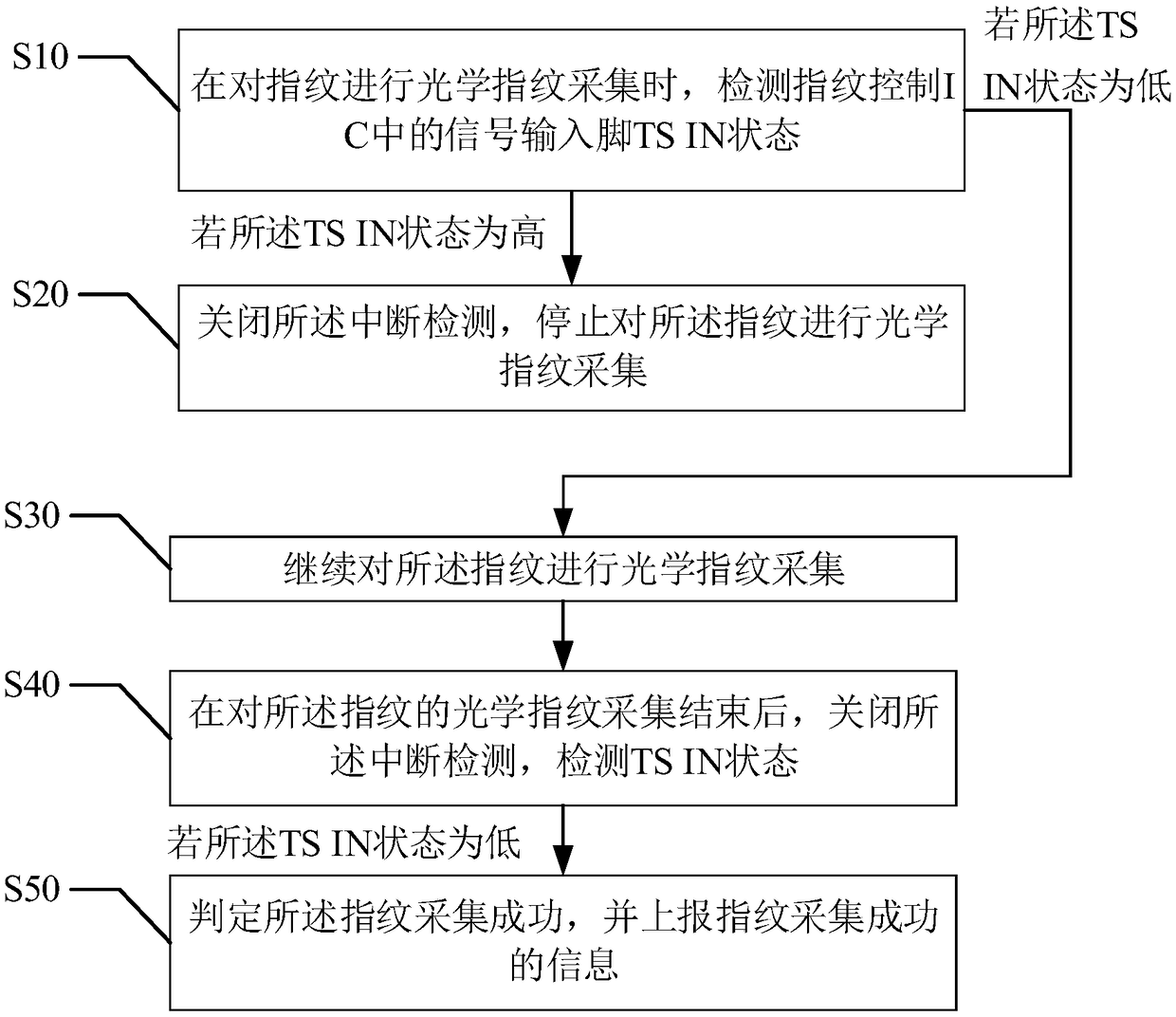

Optical fingerprint acquisition method, device and user terminal

InactiveCN108573239AImprove and ensure qualityImprove accuracyCharacter and pattern recognitionComputer hardwareFingerprint image

The invention provides an optical fingerprint acquisition method, device and a user terminal. The method comprises steps: when optical fingerprint acquisition is carried out on a fingerprint, the TS IN state of a signal input pin in a fingerprint control IC is detected, wherein the TS IN state comprises a high state or a low state; and if the TS IN state is high, interrupted detection is closed, and optical fingerprint acquisition on the fingerprint is stopped. Whether a finger leaves already is monitored through the hardware TS IN state, the finger can be constantly kept in a fingerprint acquisition range during a fingerprint acquisition process, the quality of a fingerprint image in the case of fingerprint acquisition is greatly enhanced and ensured, the fingerprint acquisition accuracyand the fingerprint acquisition efficiency are improved, and convenience is provided for optical fingerprint acquisition.

Owner:ONEPLUS TECH SHENZHEN

High purity silicon production device and preparation method thereof

ActiveCN101671021BAvoid pollutionImprove and ensure qualitySilicon compoundsManufactured materialMachining

The invention provides a high purity silicon production device and a preparation method thereof. The method comprises the following steps: adopting high purity silicon as raw material to perform machining, pressing and casting or vapor depositing and obtain the device for producing high purity silicon and finally annealing at high temperature under protective atmosphere or vacuum. The high puritysilicon production device and the preparation method thereof provided by the invention adopts high purity silicon as raw material to process high purity silicon with different shapes by machining, pressing and casting or vapor depositing, prepares the device for producing high purity silicon and performs annealing treatment of the device under protective atmosphere or vacuum to remove residual internal stress of the device; the device is used to produce high purity silicon, which can avoid the pollution to high purity silicon, increase and guarantee the quality of high purity silicon and reduce the production cost of high purity silicon.

Owner:储晞

Device and method for elutriating and gluing wood chips

ActiveCN103282171BEvenly distributedSave glueGas current separationFlow mixersChip sizeEmbedded system

A device and method for elutriating and gluing wood chips. At least one elutriating apparatus is used to fractionate the wood chips into at least one coarse chip fraction and one fine chip fraction. The elutriating apparatus has a fall duct and is designed so that the chip fractions pass through different gluing regions in the fall duct. At least one gluing apparatus is provided in order to glue the chip fractions in the gluing regions. Thus, the chip fractions can be glued in a common apparatus specifically with a glue amount adapted to a particular average chip size.

Owner:利格朗木业技术公司

A fully automatic speaker magnetic circuit assembly machine

The invention discloses a full-automatic speaker magnetic circuit assembling machine which comprises a center rotary table. A plurality of fixed jigs are arranged on the circumference of the center rotary table; each fixed jig is provided with a movable jig; an automatic washer feeding apparatus, a washer pressing apparatus, a first glue injection apparatus, an automatic magnetic sheet feeding apparatus, a magnetic sheet pressing apparatus, a second glue injection apparatus, an automatic bracket feeding apparatus, a bracket pressing apparatus, a discharge apparatus and a movable jig placement apparatus are sequentially arranged around the periphery of the circumference of the center rotary table; a drying tunnel is formed between the discharge apparatus and the movable jig placement apparatus; a finished product separation apparatus for separating finished products from the movable jigs is arranged in front of the movable jig placement apparatus. After the technical scheme is adopted, compared with the prior art, the technical scheme has the following advantages that after the machine is available, complete automation can be achieved for assembling of a speaker magnetic circuit; labor cost is greatly lowered; labor intensity is reduced; meanwhile, product quality is improved and ensured.

Owner:佛山市南海科盈华电子有限公司

Plastic knitting machine

The invention discloses a plastic knitting machine, which is characterized by including a shedding mechanism, a water jet weft insertion mechanism, a beating-up mechanism, a let-off mechanism, a winding mechanism and an auxiliary mechanism. The auxiliary mechanism comprises a frame mechanism and an electronic weft feeder. The electronic weft feeder comprises a weft table assembly, weft drums, a vertical transmission shaft, a weft feeding motor and an electromagnetic brake assembly. The frame mechanism comprises a left wall plate, a right wall plate, a middle wall plate, and first and second spacer groups; the left wall plate is connected with the middle wall plate through the first spacer group; and the right wall plate is connected with the middle wall plate through the second spacer group. The winding mechanism comprises a water squeezing roller; the water squeezing roller includes a rubber roller inner cylinder, and a kiss-coating layer disposed at the outer cylinder wall of the rubber roller inner cylinder; each of two ends of the rubber roller inner cylinder is provided with an axle head; and each axle head is fixed on the inner cylinder wall of the rubber roller inner cylinder through an axle head internal support disc and an axle head external support disc. The plastic knitting machine is not only suitable for knitting wide and heavy fabrics, but also in favor of further improvement and guarantee on the quality of plastic fabrics.

Owner:青岛东佳纺机(集团)有限公司 +1

Method and device for re-circulating disinfection of drinking water by using waste ozone

ActiveCN104163466ASmall footprintLow running costWater/sewage treatment by irradiationWater/sewage treatment by oxidationAtmospheric airUltraviolet

The invention relates to a method and device for re-circulating disinfection of drinking water by using waste ozone. The method comprises six steps of disinfecting with ultraviolet rays; continuously mixing, dissolving and decomposing a gas-water mixed flow in the drinking water; and disinfecting a tank body, the drinking water in the tank body and air in the tank body. The device comprises the tank body, a plurality of ultraviolet lamps, a plurality of quartz socket tubes, a water ejector, and a high pressure water pump. The tank body comprises a first cavity, a second cavity communicated with air and a water cavity; the quartz socket tubes sealingly penetrate through the left and right walls of the water cavity and open in the first cavity and second cavity; the ultraviolet lamps sealingly penetrate through the first cavity and are disposed in the quartz socket tubes; a pressure water inlet of the water ejector is communicated with a high pressure water outlet of the high pressure water pump; a nozzle of the water ejector is communicated with the water cavity; and a gas inlet of the water ejector is communicated with the first cavity. The method and device take full use of conventional equipment and waste ozone byproducts, carry out ozone deep disinfection on the drinking water again, and save energy.

Owner:科泷(重庆)环保科技有限公司

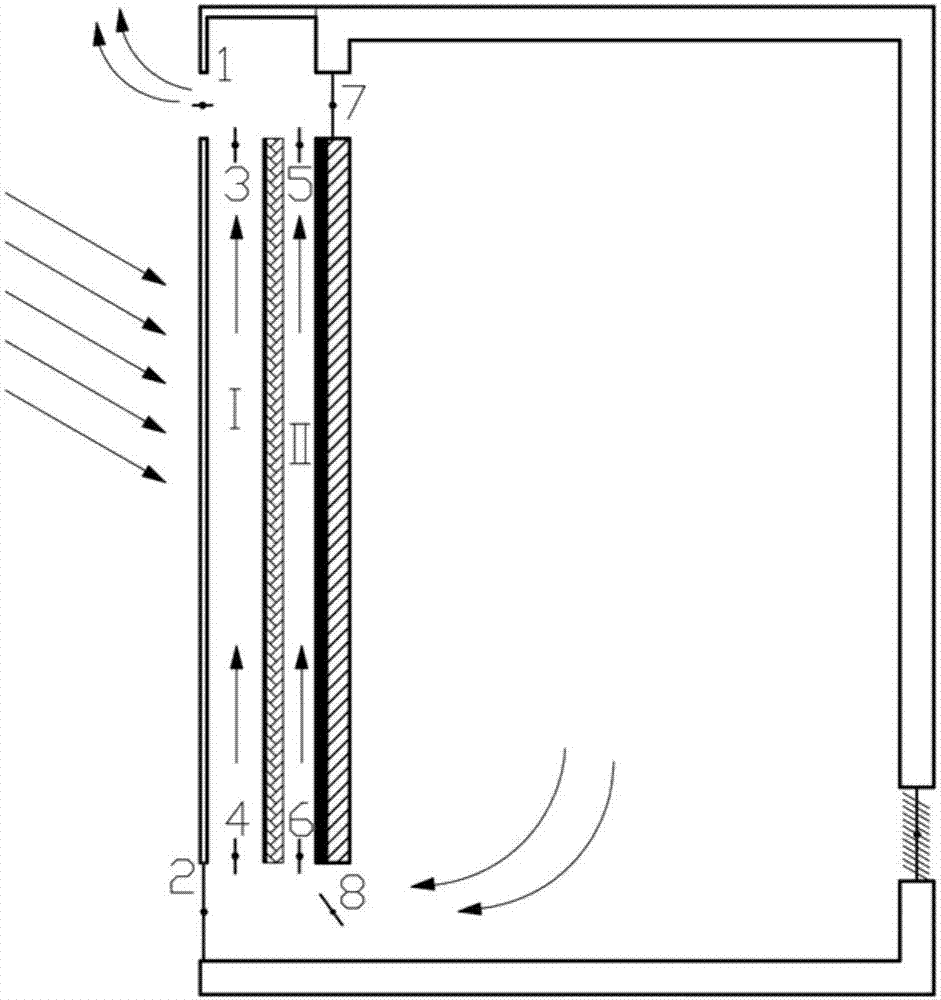

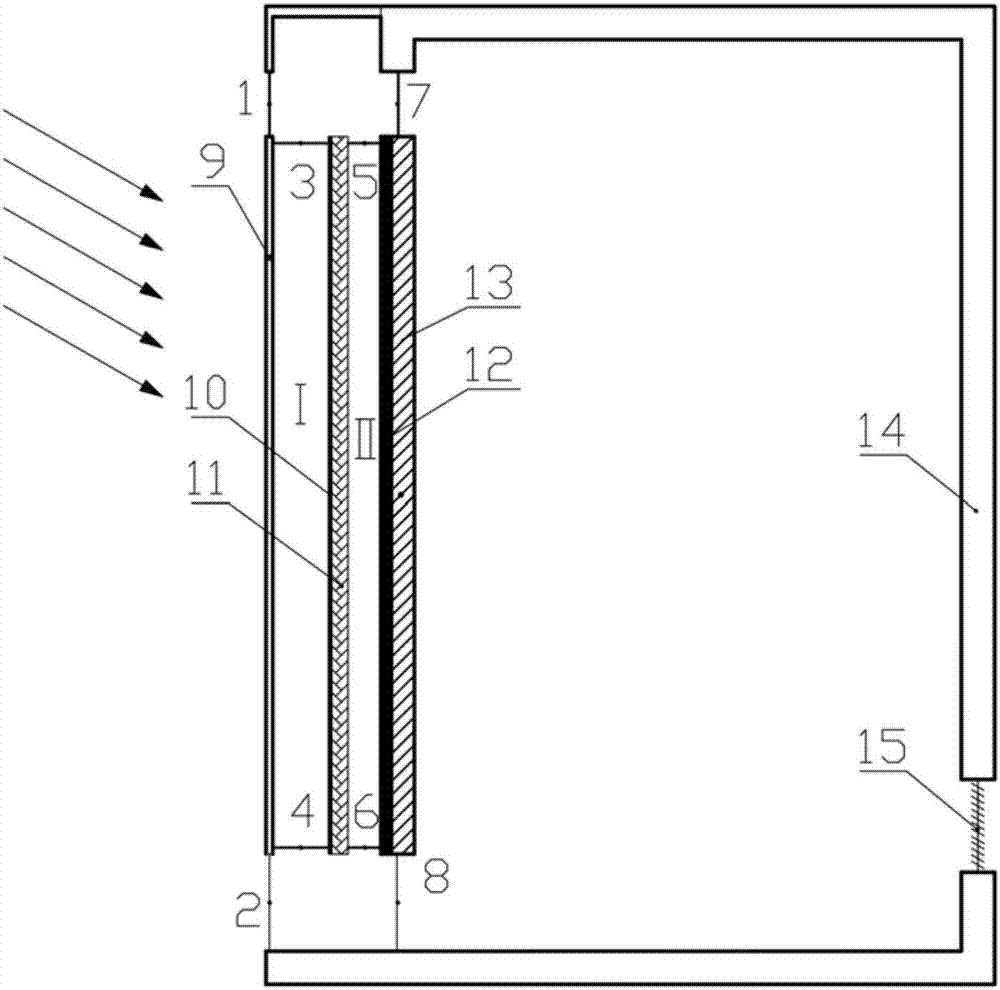

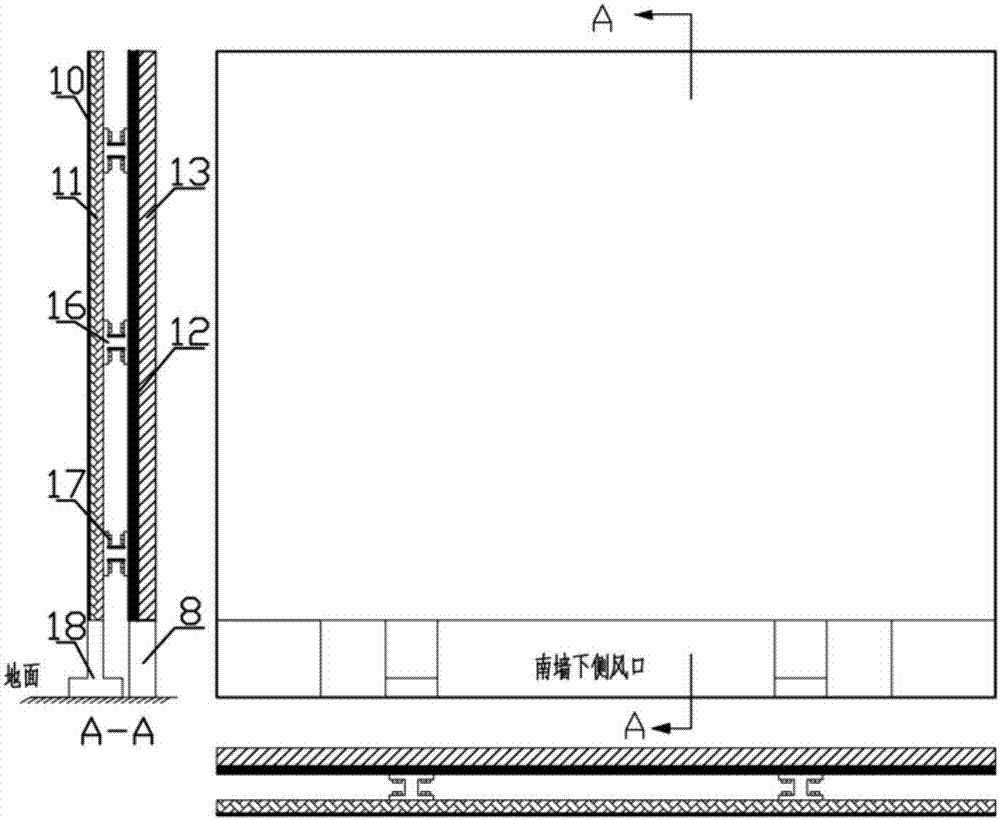

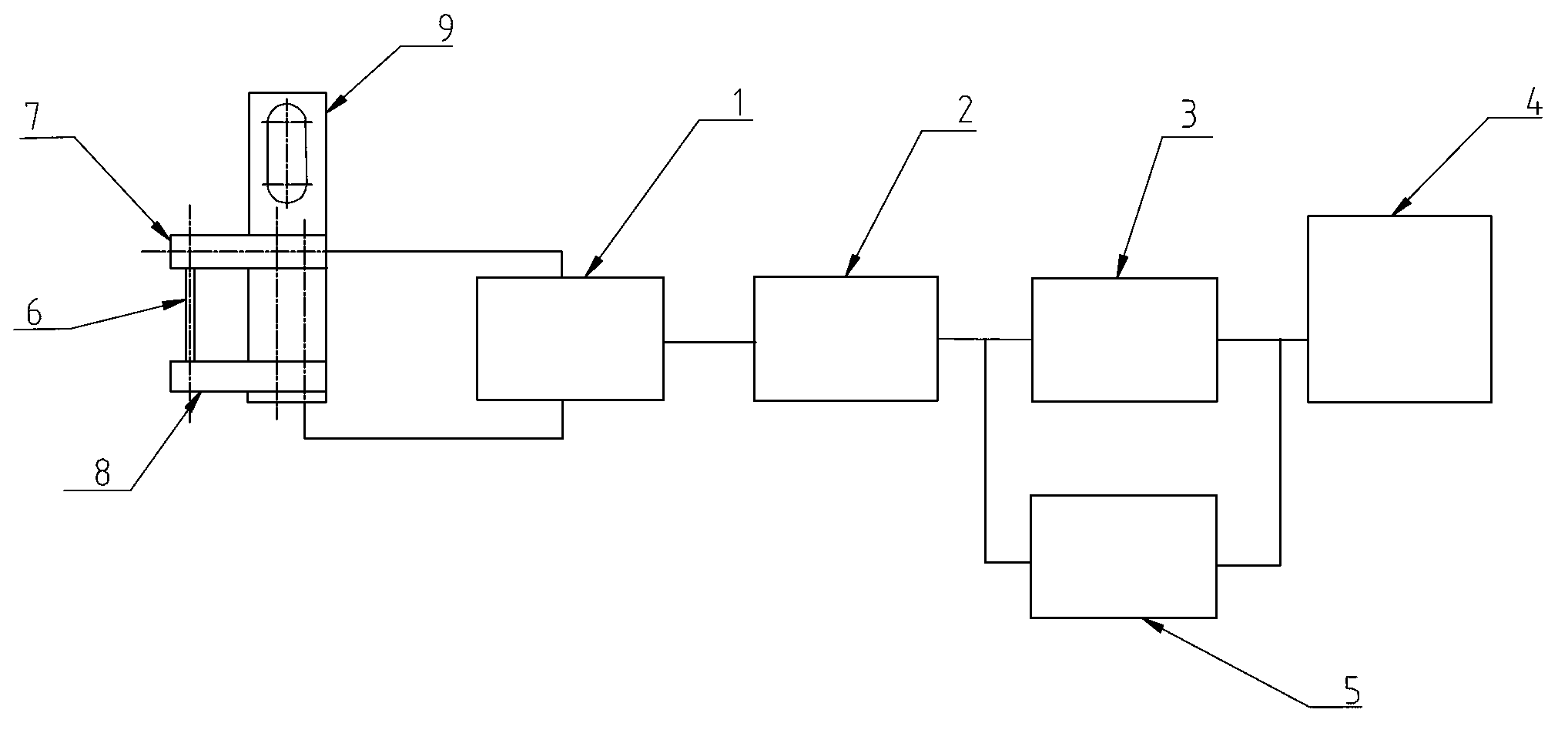

A thermal storage type controllable dual-channel ventilation insulation wall system and its operation method

ActiveCN105735516BImprove adjustabilityImprove adaptabilityMechanical apparatusLighting and heating apparatusGlass coverEngineering

The invention provides a heat storage type controllable double-channel ventilation heat preservation wall system and an operation method thereof, and belongs to the technical field of passive building energy conservation. The heat storage type controllable double-channel ventilation heat preservation wall system and the operation method thereof are characterized in that double air channels with a phase change heat storage function are arranged, controllable air valves are arranged on the upper sides and the lower sides of the channels, and flexible conversion between a ventilation wall and an air heat preservation wall is completed by controlling the air valves, so that ventilation and heat preservation functions of a building are achieved. The heat storage type controllable double-channel ventilation heat preservation wall system comprises a glass cover plate, the two channels, a heat-absorbing material layer, a phase change heat storage material layer and the multiple controllable air valves, and the heat-absorbing material layer and the phase change heat storage material layer are arranged between the two channels. When the controllable air valves on the upper sides and the lower sides of the channels are opened, the natural ventilation wall is formed. When the controllable air valves on the upper sides and the lower sides of the channels are closed, the air heat preservation wall is formed. The controllable air valves are controlled according to the indoor and outdoor temperature and humidity parameters and the change of solar radiation, and conversion between the air heat preservation wall and the natural ventilation wall is achieved, so that coordinated operation of the heat storage type controllable double-channel ventilation heat preservation wall system and the operation method thereof, the building structure and the outdoor climate is achieved.

Owner:TAIYUAN UNIV OF TECH

Plain-weave plastic braiding machine

The invention discloses a plain-weave plastic braiding machine which is characterized by comprising a shedding mechanism, a water jet weft insertion mechanism, a weft beating-up mechanism, a let-off mechanism, a take-up mechanism and an auxiliary mechanism; the take-up mechanism comprises a wringing roller, the wringing roller comprises a rubber roller inner barrel and a coating layer arranged onthe outer barrel wall of the rubber roller inner barrel, a spindle nose is arranged at the two ends of the roller tube inner barrel respectively, each spindle nose is fixedly arranged on the inner barrel wall of the rubber roller inner barrel through a spindle nose inner support disc and a spindle nose outer support disc, a plurality of radial reinforcing ribs are arranged between the spindle nose inner support disc and the spindle nose outer support disc, one end of each reinforcing rib is fixedly arranged on one spindle nose, the other end of each reinforcing rib is fixedly arranged on the inner barrel wall of the rubber roller inner barrel, in the length range of being 350-450 mm from the each end part of the coating layer, the diameter of the coating layer is reduced gradually from the middle part to the end parts, and the diameter of the end part is smaller than the diameter of the middle part by 1-1.5 mm. The plain-weave plastic braiding machine is suitable for weaving wide and heavy fabric and is also beneficial to further improving and guaranteeing the quality of plastic fabric.

Owner:青岛东佳机械制造有限公司

Die casting machine clamping force online adjusting device and adjusting algorithm

The utility model relates to a mechanics volume adjusting device and adjusting algorithm based on route micro adjusting, in particular to a die casting machine clamping force online adjusting device and adjusting algorithm. The object of the invention is to ensure the actual clamping force within the set value in the process of die casting from beginning to end, to improve the real-time detection and control level, and to improve the quality of die casting products. The die casting machine clamping force online adjusting device comprises a clamping force online detecting system, a feedback control system and a die-adjusting actuator mechanism. The clamping force online detecting system obtains clamping resultant force by arranging strain gauge force sensor on the one pull rod or four pull rod of the die-casting machine. The feedback control system comprises an encoder and a control program. The die-adjusting actuator mechanism comprises a hydraulic motor, major and minor die-adjusting gear and a die-adjusting nut. A die casting machine clamping force online adjusting algorithm is also provided. The die casting machine clamping force online adjusting device and adjusting algorithm has the advantages of utilizing feedback signals to start hydraulic motor and driving the die-adjusting nut to rotate so as to adjust the clamping force within the set value, thereby ensuring the quality of the products.

Owner:SIJIN INTELLIGENT FORMING EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com