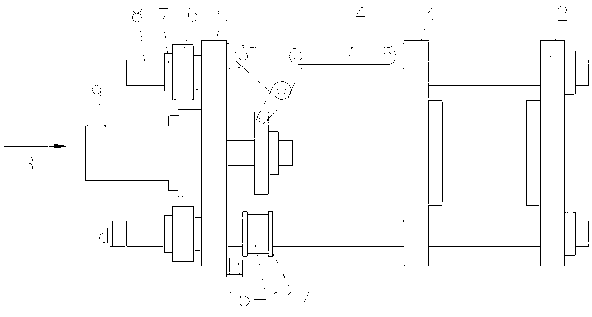

Die casting machine clamping force online adjusting device and adjusting algorithm

An adjustment device and clamping force technology, which is applied in the field of online adjustment device and adjustment algorithm for die-casting machine clamping force, can solve the problems of personal danger, affecting the performance and life of molds and die-casting machines, and affecting the quality of die-casting parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

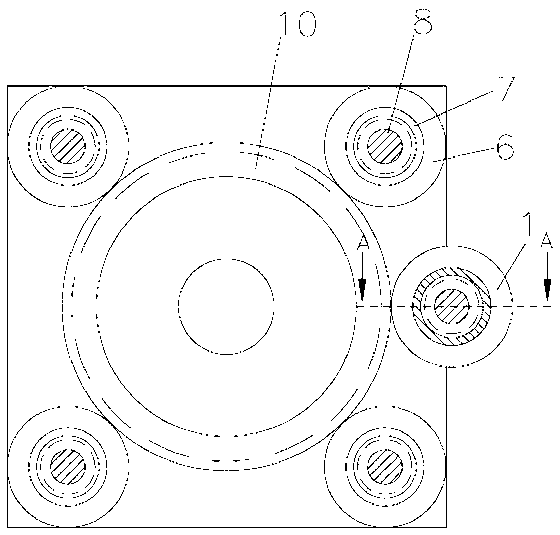

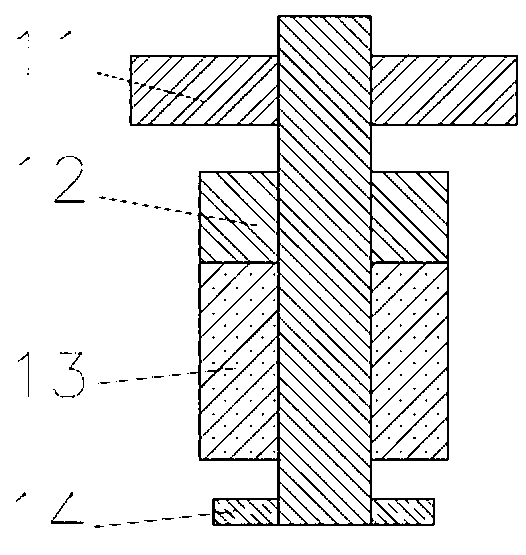

[0106] An online adjusting device and algorithm for clamping force of a die-casting machine provided in this embodiment, its general structure is consistent with that of Embodiment 1, the difference is that in the online adjusting algorithm for clamping force of a die-casting machine provided in this embodiment, each tie rod 8 is controlled by Under the assumption that the force is the same, only the measurement of the pulling force of one pull rod 8 is used as the measurement of the clamping force, which specifically includes the following steps:

[0107] a) Establish the relationship between the tensile force F received by the tie rod 8 of the mold clamping mechanism of the die-casting machine and the strain ε produced by the tie rod 8, the above relationship is related to the diameter d or cross-sectional area A of the tie rod 8 itself (A=πd 2 / 4), the elastic modulus E of the material used is related to:

[0108] The specific relationship is: ε=F / EA=4F / Eπd 2 or F=εEA=Eπd ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com