Loudspeaker internal magnetic circuit assembling machine

A technology of internal magnetic circuit and assembly machine, applied in the direction of electrical components, sensors, etc., can solve the problems of low assembly efficiency, high cost, and high labor intensity of workers, and achieve the effects of reducing labor intensity, ensuring quality, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

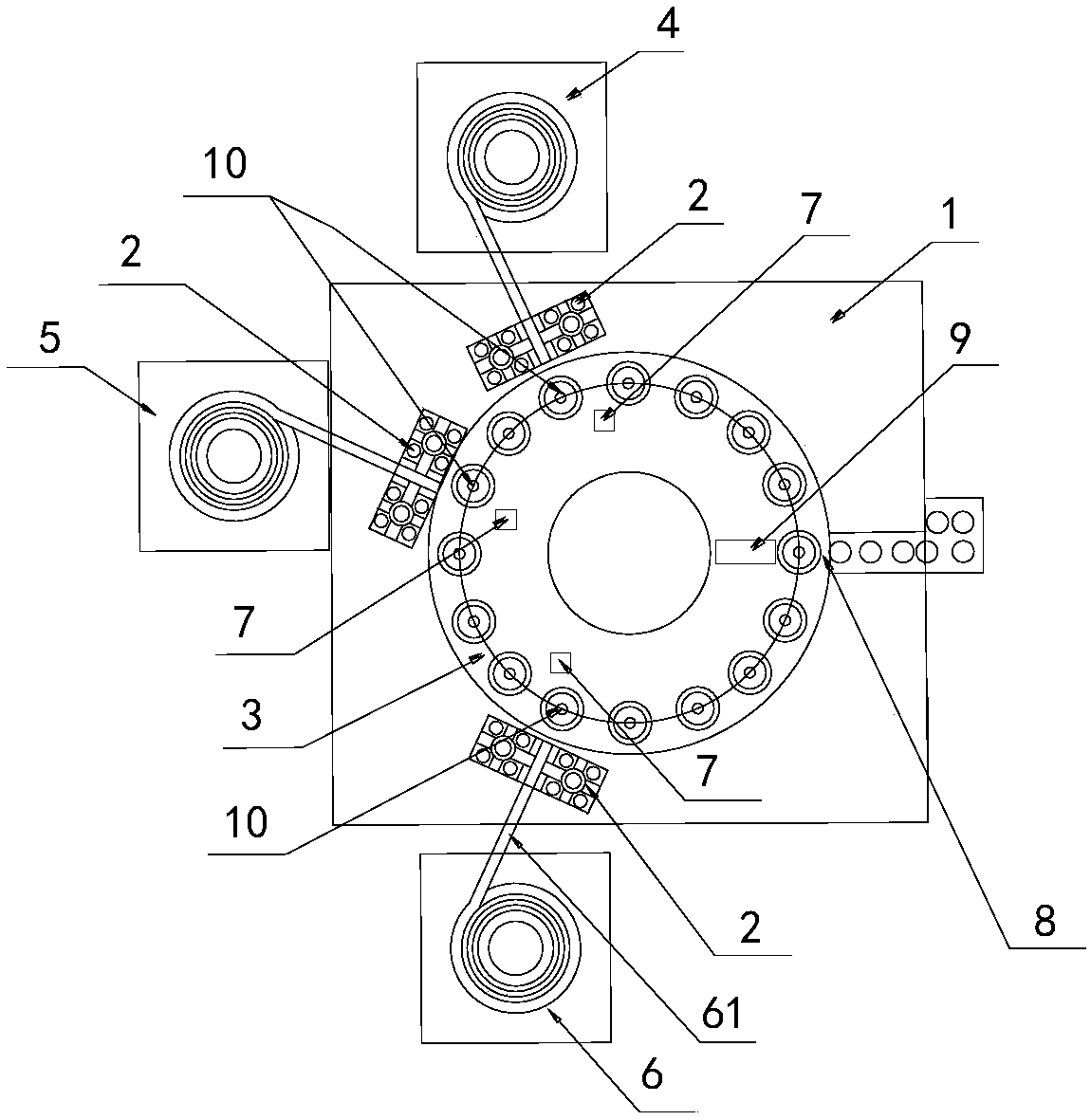

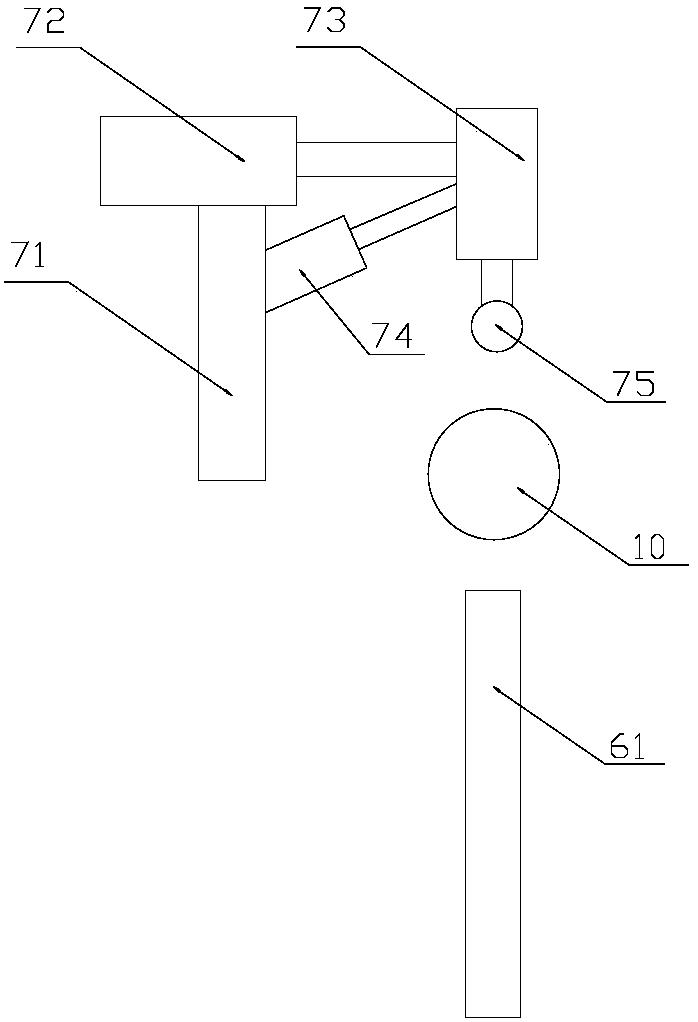

[0014] Such as figure 1 As shown, the speaker internal magnetic circuit assembly machine of the present invention includes a base 1, a bracket automatic feeding table 4, a magnet automatic feeding table 5, a washer automatic feeding table 6, a glue dispenser 2, an indexing plate 3 and a drag device 7. Both the glue dispenser 2 and the indexing plate 3 are installed on the base 1, and there are three operating areas 10 on the circumference of the indexing plate 3. Correspondingly, there are three glue dispensers 2 and the dragging device 7, The glue dispensing machine 2 and the dragging device 7 correspond to three operating areas 10 respectively, each operating area is provided with a sensor, each operating area 10 is provided with a disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com