Device and method for elutriating and gluing wood chips

A technology of gluing and winnowing, applied in the direction of chemical instruments and methods, adhesives, applications, etc., can solve problems such as uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

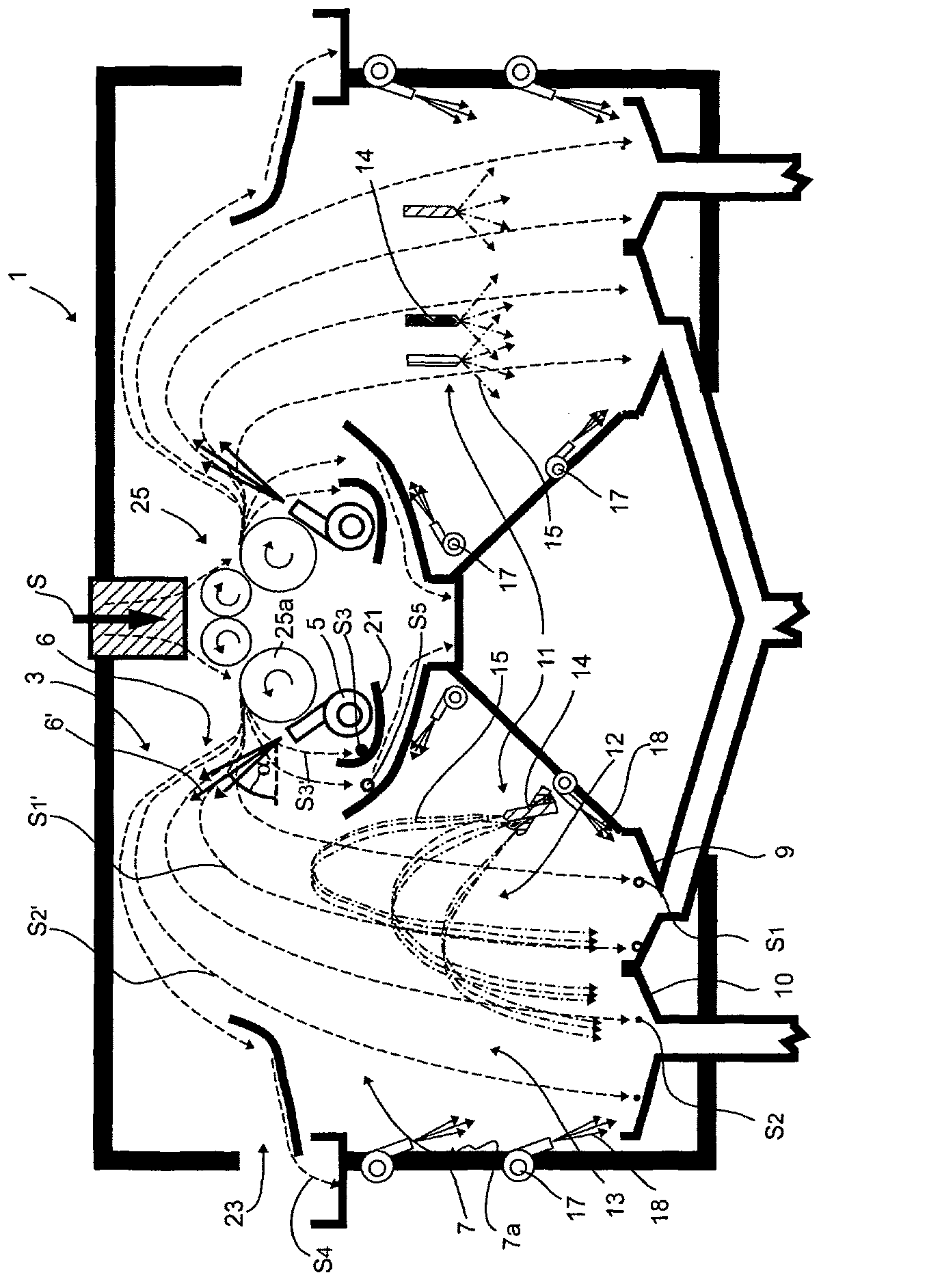

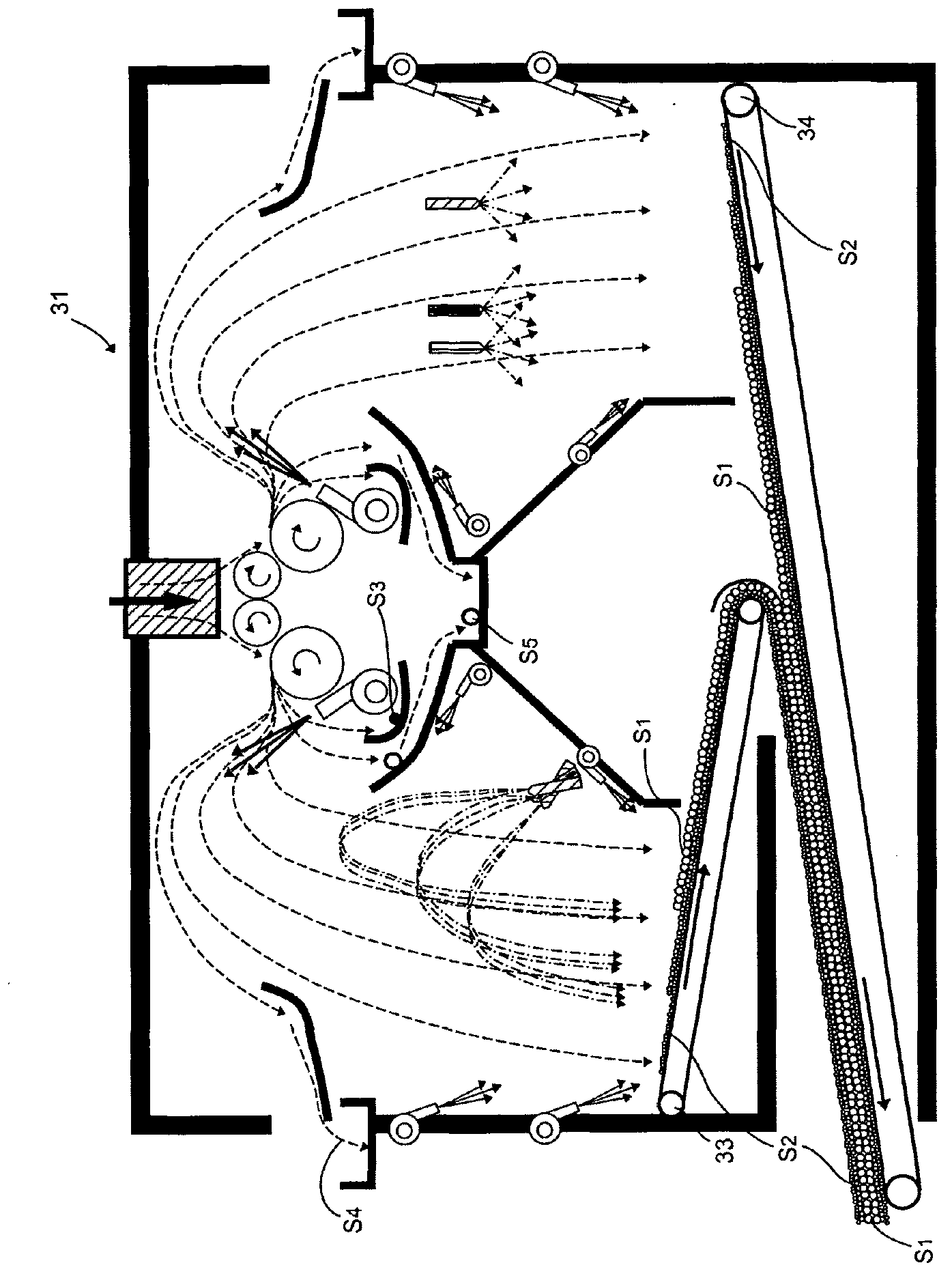

[0026] as in figure 1 As can be seen in the figure, a first embodiment 1 of the plant for winnowing and gluing wood chips S etc. And the winnowing device 3 of S2.

[0027]The winnowing device 3 comprises a blowing device 5 which generates an obliquely upwardly directed deflection flow 6 for laterally deflecting the chips S; and a drop channel 7 in which the deflected particles can be optimized according to the size of the chips Different parabolic falls are followed in order to spatially separate the coarser chips S1 from the finer chips S2. The chips S1 , S2 descending successively substantially along the associated screening tracks S1 ′, S2 ′ are accumulated by a first collection device 9 for coarse wood chips and a second collection device 10 for fine wood chips to for reprocessing.

[0028] Furthermore, the device 1 according to the invention comprises, in the region of the drop channel 7 , a gluing device 11 with a spray device 14 for generating at least one aerosol 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com