Large size pipe with glass being spread on internal lining and manufacturing method

A manufacturing method, glass-lined technology, applied in pipeline protection, pipeline anticorrosion/rust protection, pipes/pipe joints/pipe fittings, etc., to achieve excellent non-static adsorption effect, ensure overall quality, ensure overall quality and circulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

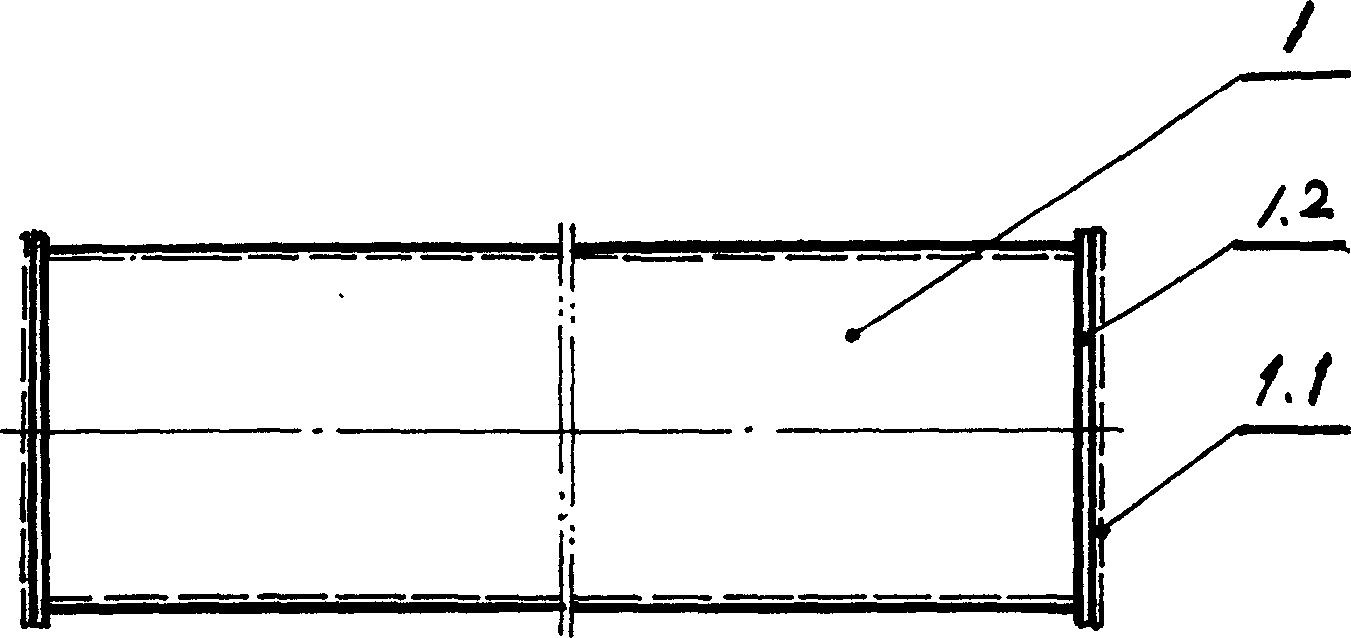

[0010] See figure 1 , the pipe (1) is a steel pipe body, including the inner wall re-lined with glass-lined glaze (1.1) and the flange surface (1.2) with through holes around it, according to the glass-lined process flow, the inner wall of the pipe (1) is sprayed Dry after spraying glass-lined (1.1) glaze slurry.

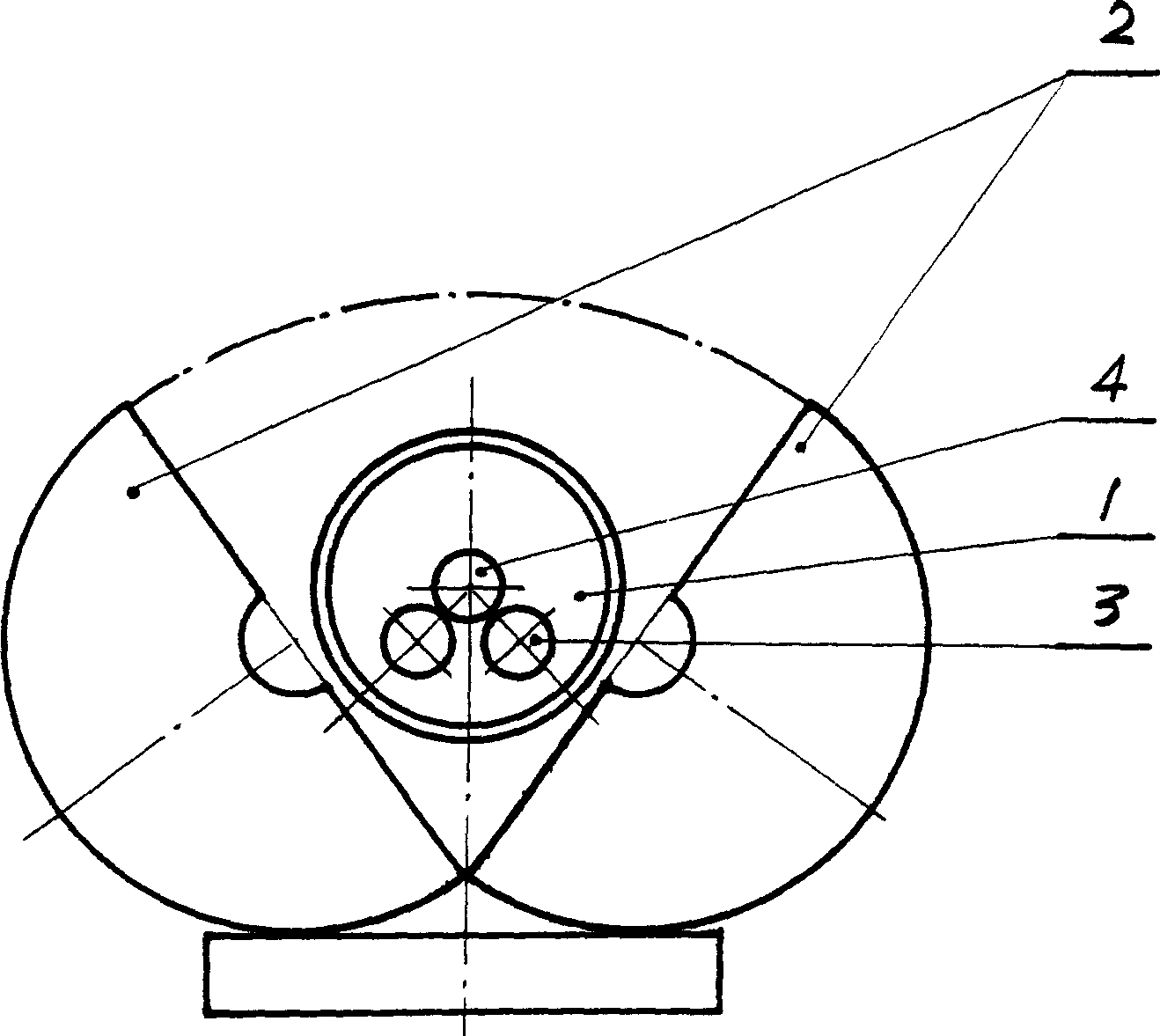

[0011] See figure 2 After spraying the glass-lined (1.1) glaze slurry and drying the pipe (1), after connecting its two ends with a special burning rack (4), hoist it into a new type of horizontal electric heating furnace that can be opened and closed by a mechanical crane ( In 2), it is positioned on the mechanical device (3) that can be rotated at both ends, and the glass-lined glaze is sintered while being rotated and heated, a new technology manufacturing method, and a large-scale glass-lined lined pipeline is manufactured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com