Vacuum pumping side-pressing mechanism for manufacturing water-cooled clutch casing

A clutch housing and vacuum pumping technology, which is applied in the field of die-casting molds, can solve problems such as air leakage, reduce the strength of castings, and unfavorable high-efficiency production, so as to ensure the overall quality and avoid shrinkage cavities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

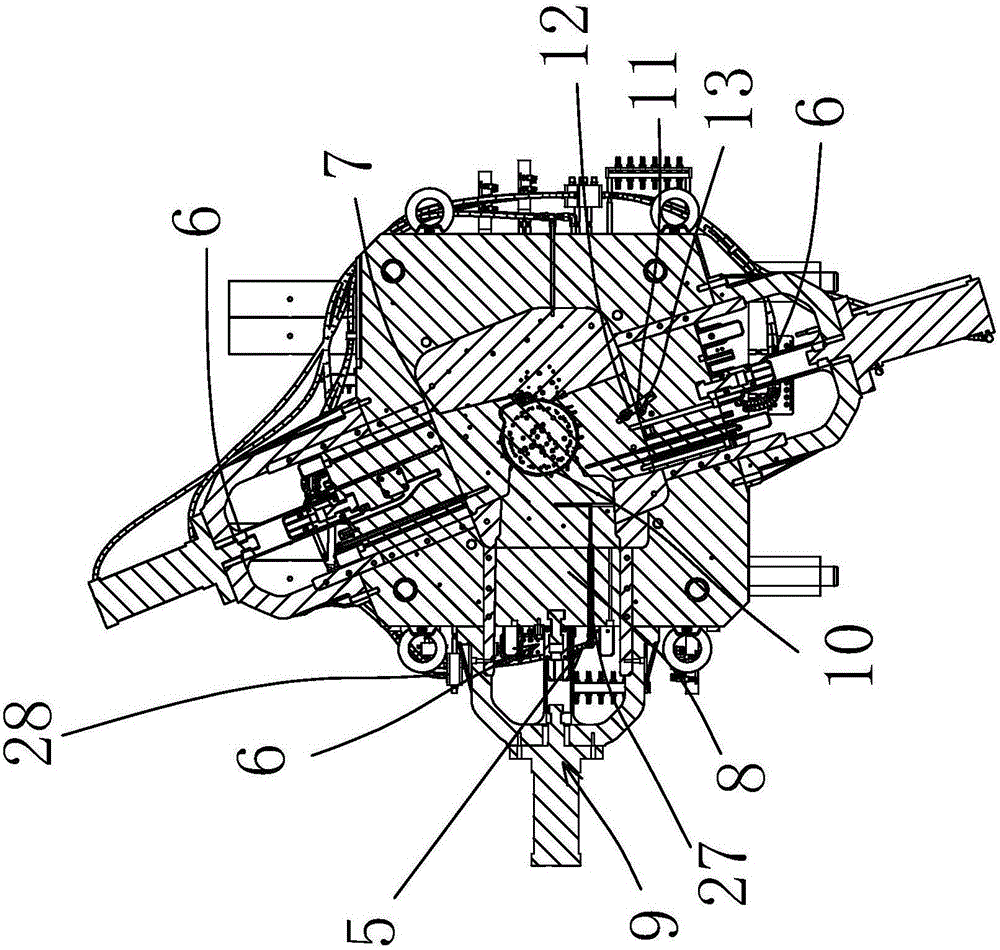

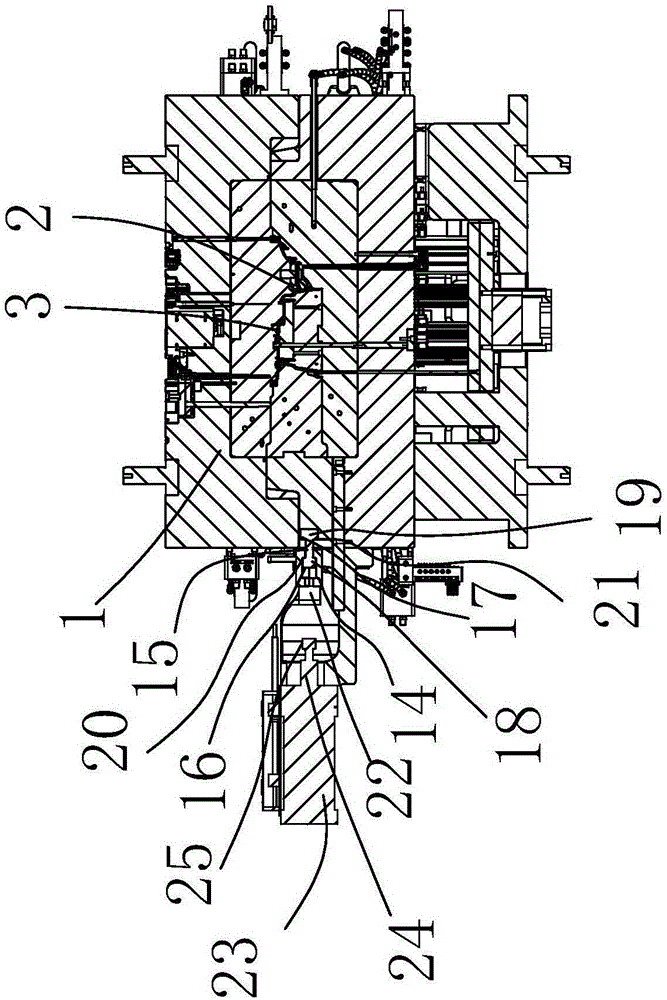

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

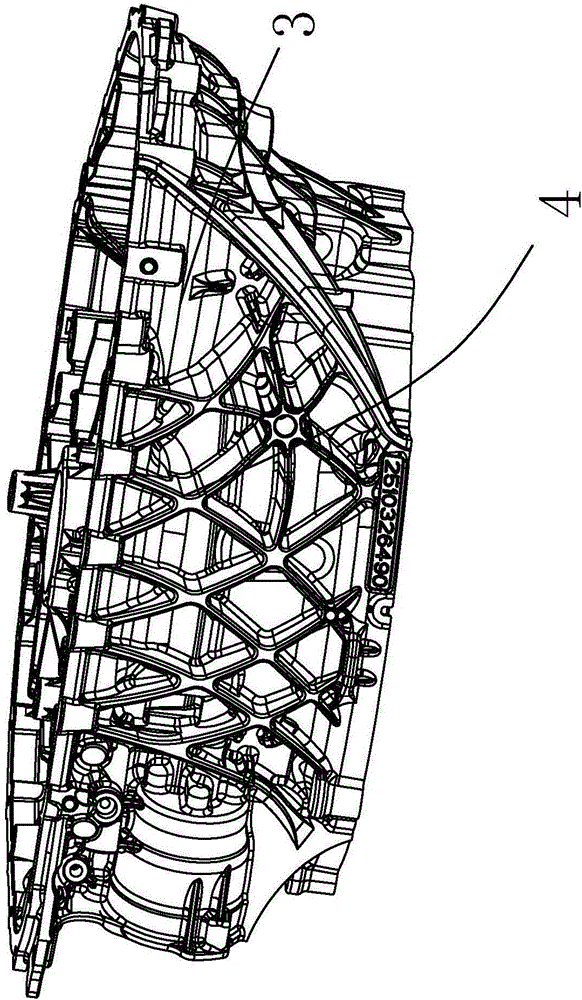

[0019] In the figure, die-casting mold 1; injection mold cavity 2; clutch housing 3; protruding position 4; valve type vacuum device 5; side pressure device 6; side pressure top block 7; side pressure auxiliary driving block 8; side pressure driving parts 9; side pressure plug 10; oblique fixed adjustment piece 11; first oblique adjustment groove 12; second oblique adjustment groove 13; hedging piece 14; hedging rod 15; main buckle groove 16; from buckle groove 17; first Set of chucks 18; second set of chucks 19; outer limiting convex edge 20; inner limiting convex edge 21; top pressure inlet groove 22; side pressure cylinder 23; side pressure air rod 24; raised step head 25; vacuum valve 26; Vacuum tube 27.

[0020] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com