Upper die for press-fitting of fan rotor and motor shaft

A fan rotor and motor shaft technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems affecting the overall quality of the fan, large noise, etc., to achieve time-saving and convenient operation, ensure the overall quality, and not easy to move The effect of moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

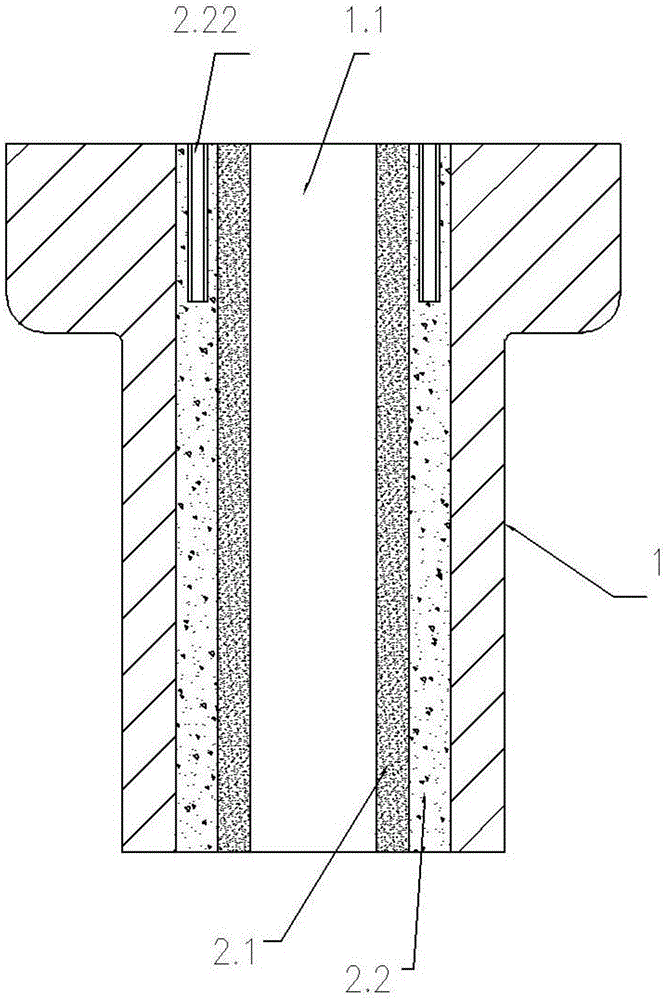

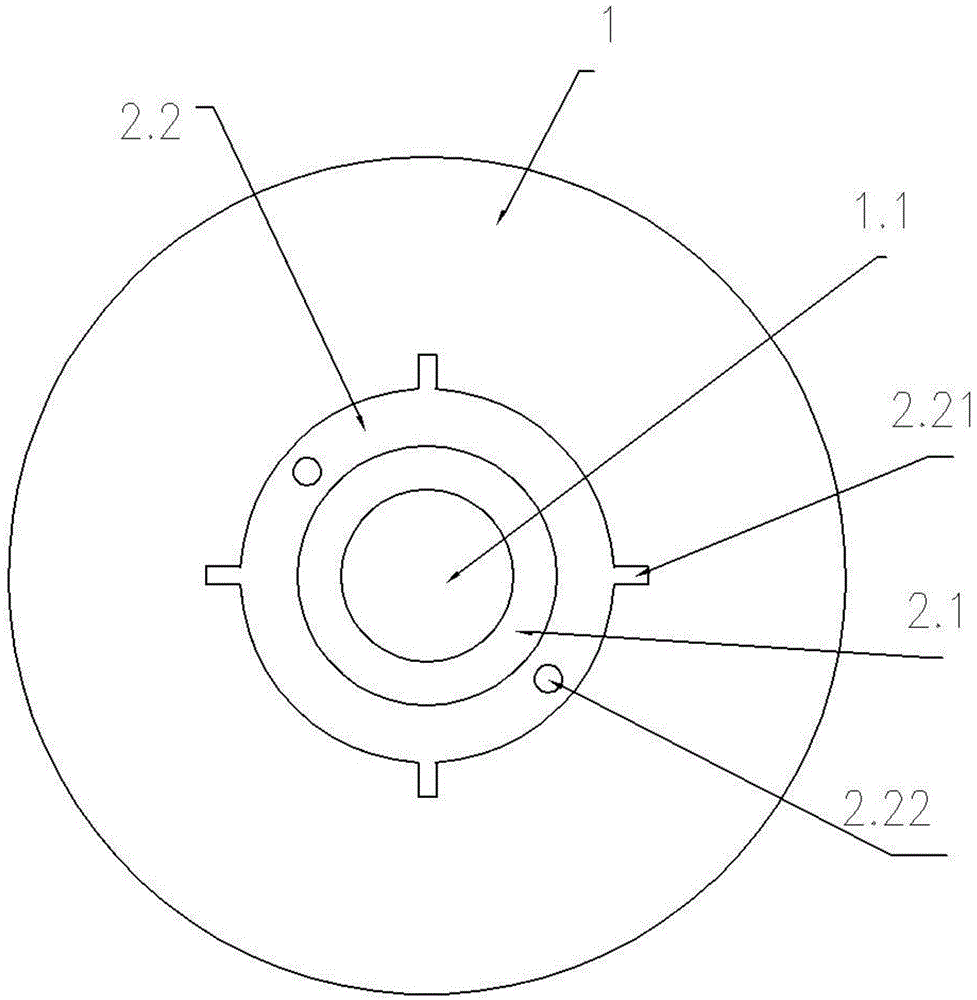

[0016] As shown in the figure, the upper mold for press-fitting the fan rotor and the motor shaft of the present invention includes a steel upper mold body 1, and the upper mold body 1 is provided with an axial through hole 1.1.

[0017] The inner sleeve of the axial through hole 1.1 is provided with a combined rubber tube, and the combined rubber tube consists of an inner soft rubber tube 2.1 and an outer hard rubber tube 2.2. The inner layer of soft rubber tube 2.1 and the outer layer of hard rubber tube 2.2 are formed by injection molding through an injection mold. The outer wall of the outer hard rubber tube 2.2 is provided with a plurality of axial ribs 2.21 distributed along the circumferential direction, and the inner wall of the axial through hole 1.1 of the upper mold body 1 is provided with a plurality of axial ribs 2.21. One card matching card slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com