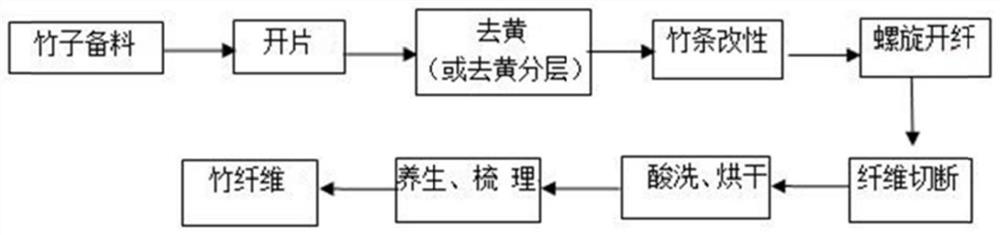

Equipment for spirally splitting bamboo strips and bamboo fiber obtaining method of equipment

A technology of bamboo strips and spirals, which is applied in the equipment of bamboo strips spiral fiber opening and the field of bamboo fiber acquisition, which can solve the problems of uncontrollable fiber fineness, achieve controllable fineness, avoid fiber structure damage and strong damage, and separation uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

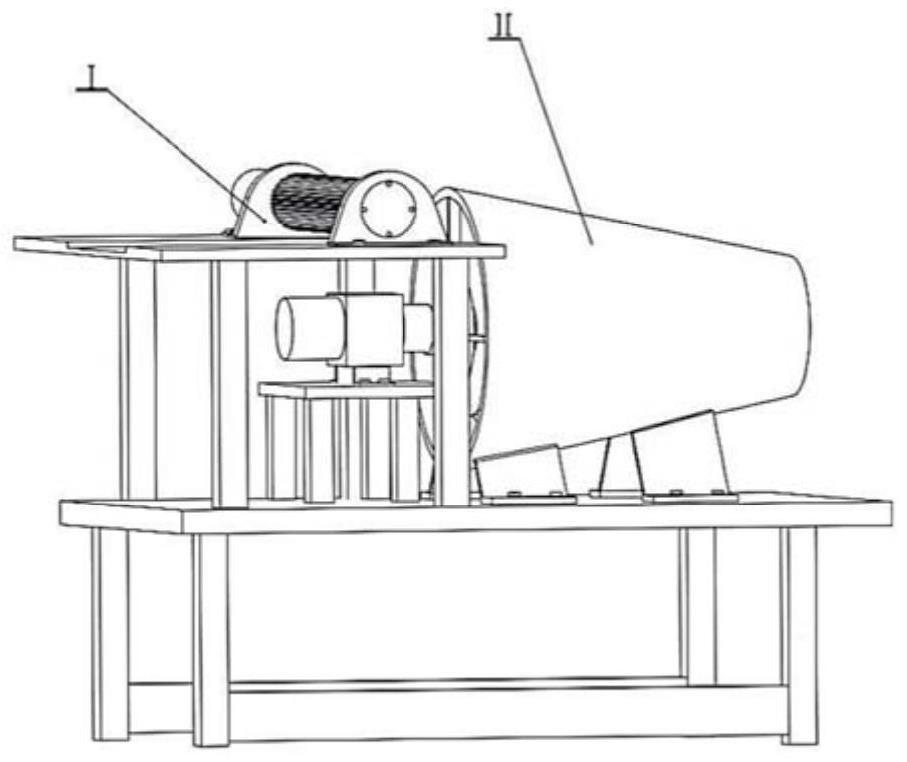

[0038] Such as figure 2 As shown, the present invention provides a device for spiral fiber opening of bamboo strips, which mainly includes feeding system I and spiral fiber opening system II.

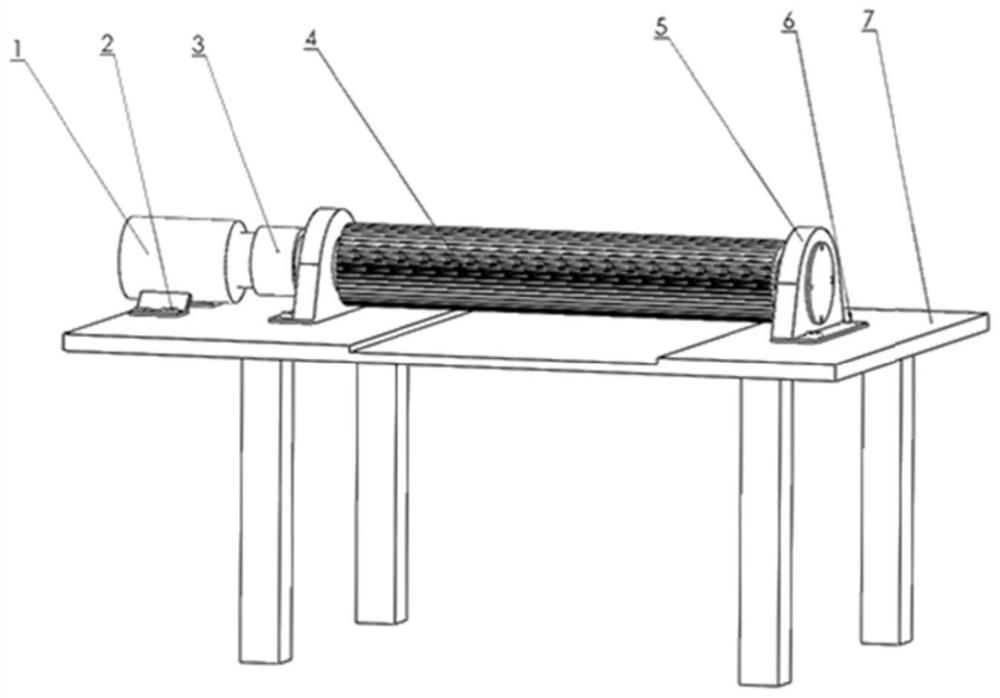

[0039] Such as image 3 As shown, the feeding system I is used for feeding and mainly includes the first frame 7 and the feeding roller 4 . The feed roller 4 is connected with the first motor 1, and the feed roller 4 can be driven to rotate by the first motor 1. The first frame 7 can adopt any structure that can play a supporting role to the feed roller 4, as long as there is a certain interval (i.e. the feeding space) between the rotating surface of the feed roller 4 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com