A fully automatic speaker magnetic circuit assembly machine

A horn magnetic circuit and assembly machine technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency, large workshop space, and high labor intensity of workers, so as to ensure quality, reduce labor intensity, The effect of saving artifacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technology will be further described below in conjunction with the accompanying drawings.

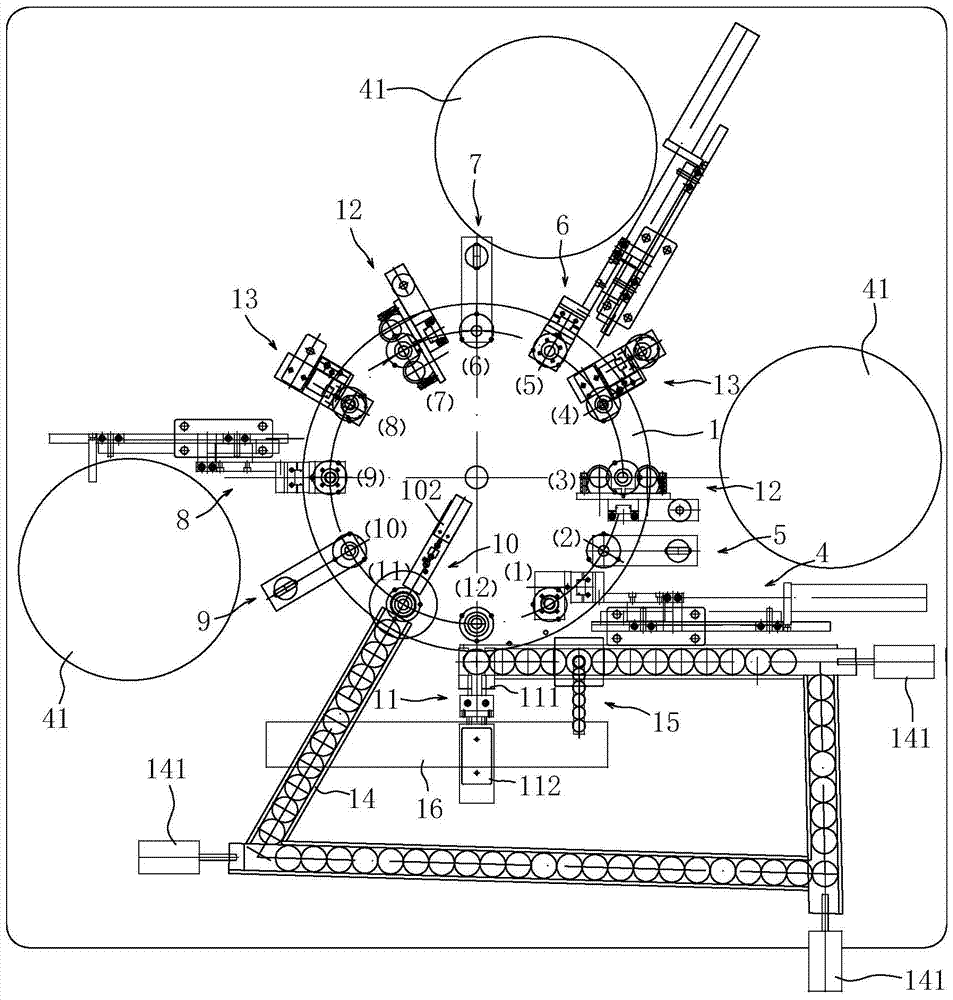

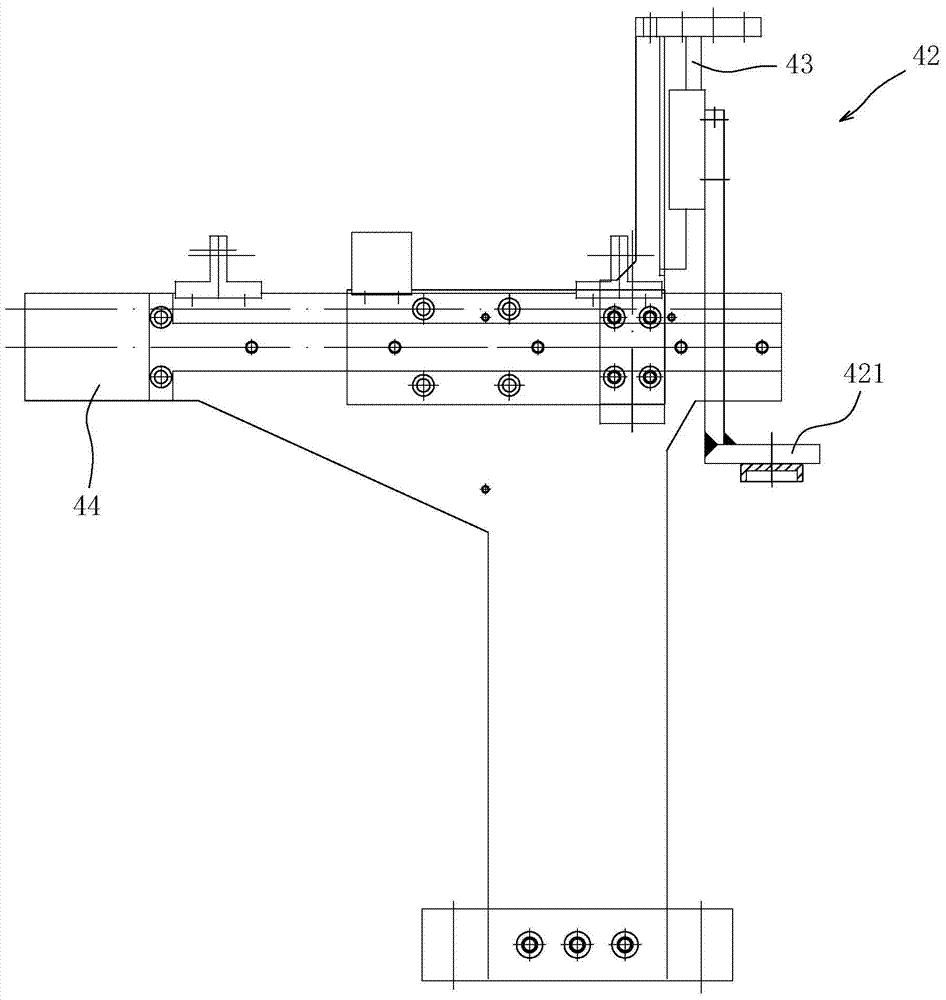

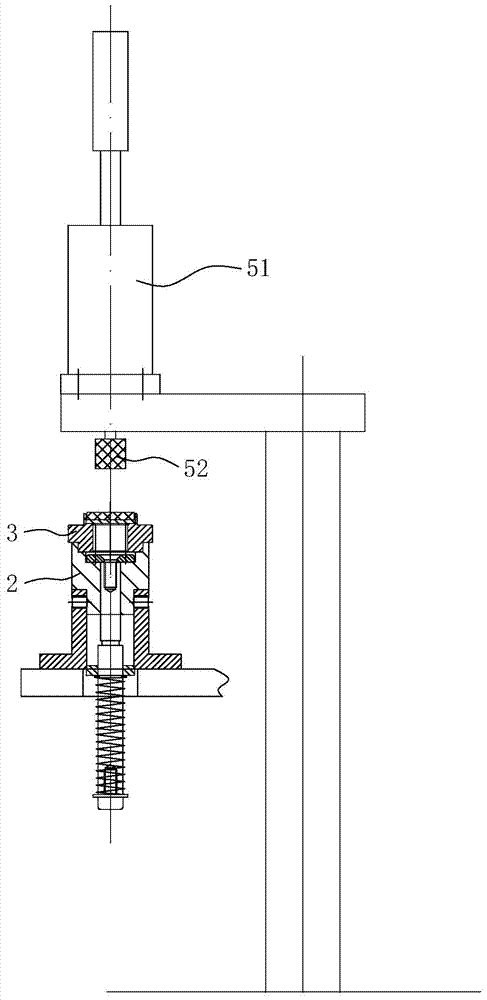

[0025] The full-automatic loudspeaker magnetic circuit assembling machine of the present embodiment includes a central turntable 1, on which 12 fixed jigs 2 are evenly arranged along the circumference, and a movable jig 3 is placed on each fixed jig, around the center The periphery of the turntable 1 is sequentially provided with an automatic washer device 4, a washer device 5, a first glue injection device, an automatic magnetic sheet loading device 6, a magnetic sheet pressing device 7, a second glue injection device, and an automatic upper bracket device 8. The support device 9, the unloading device 10 and the movable jig placement device 11. The first glue injection device and the second glue injection device have the same structure and are composed of two stations. The front station is the glue injection mechanism 12, and the rear station is the glue injection mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com