Design method for underwater wet type sealing ring for electrical general connecting head

A design method and technology of sealing rings, which are applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of quantitative analysis of sealing ring wear, sealing ring temperature aging, etc. The effect of reducing calculation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

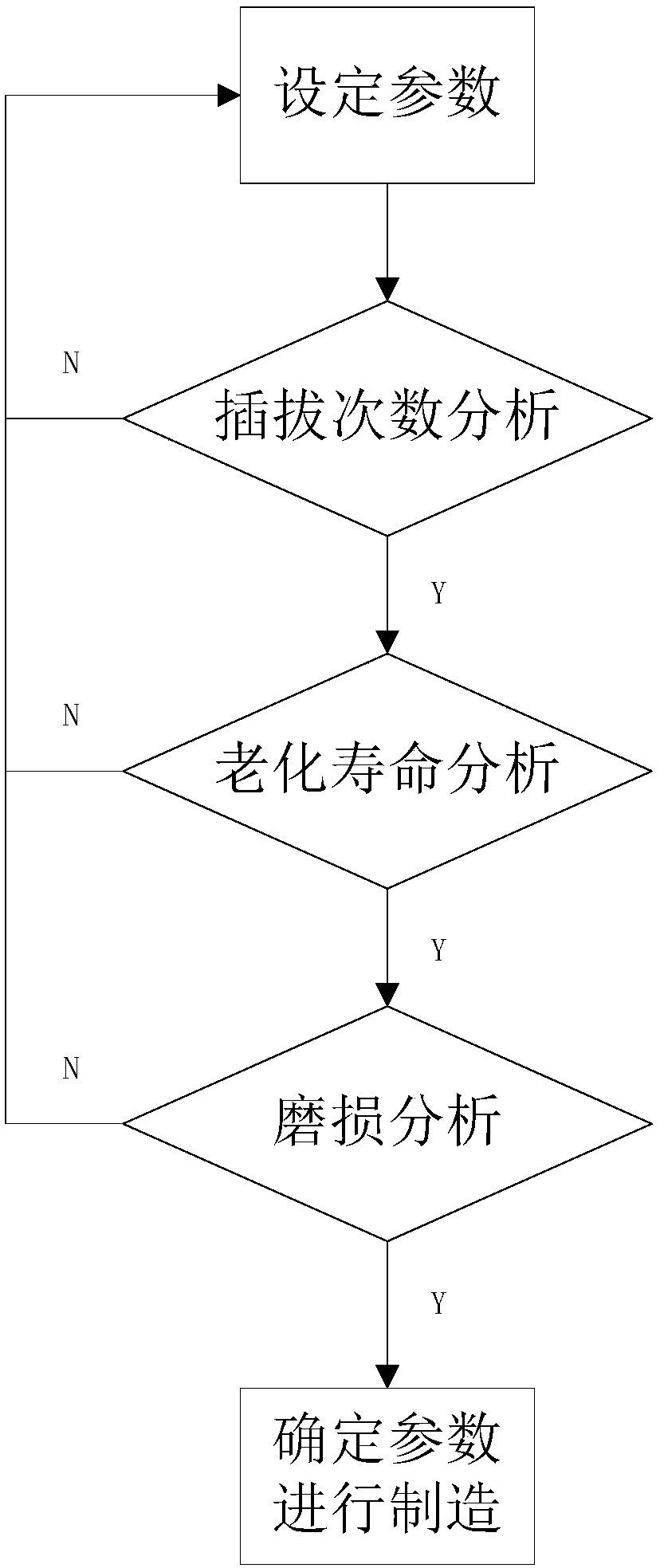

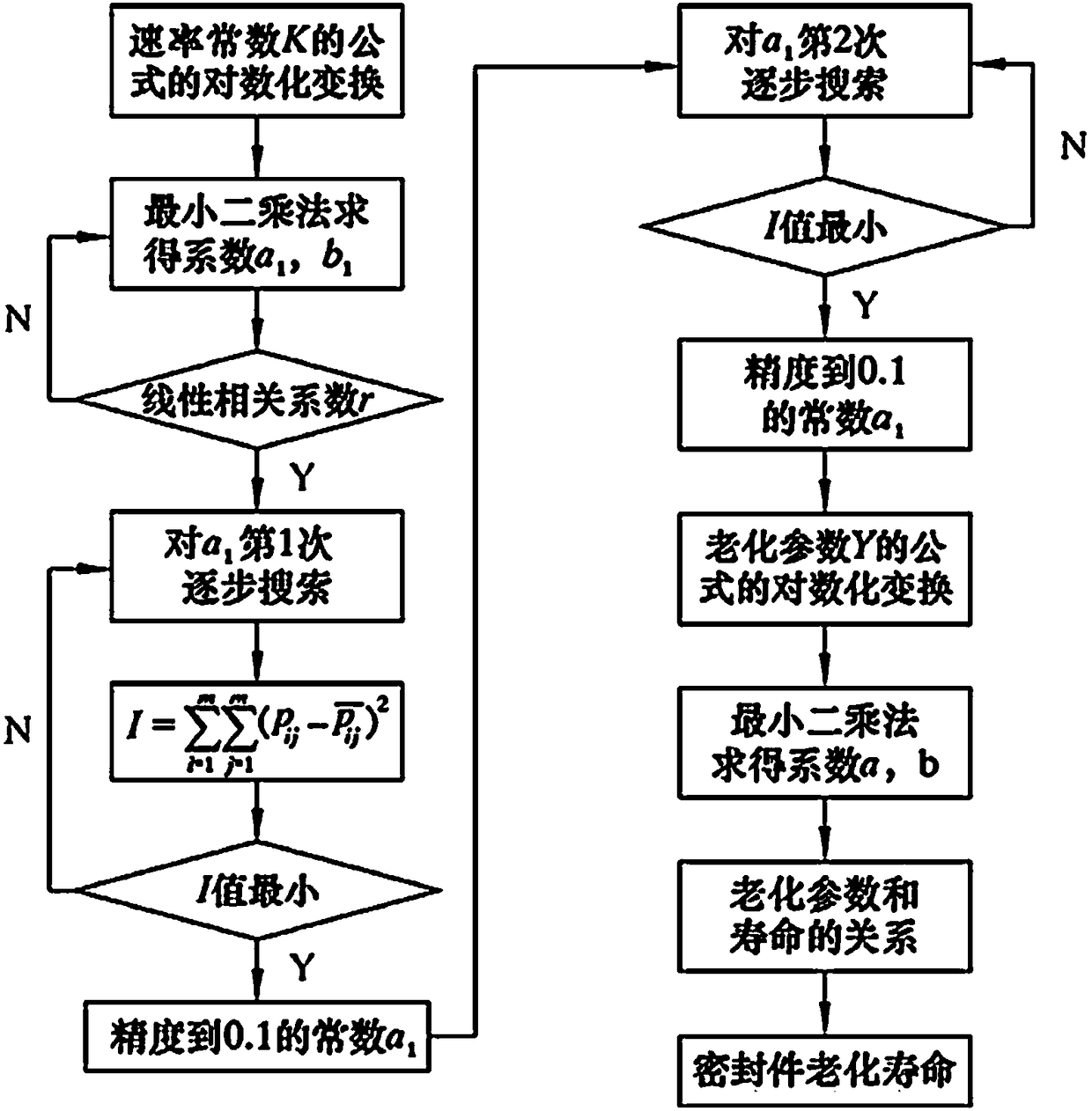

Method used

Image

Examples

Embodiment

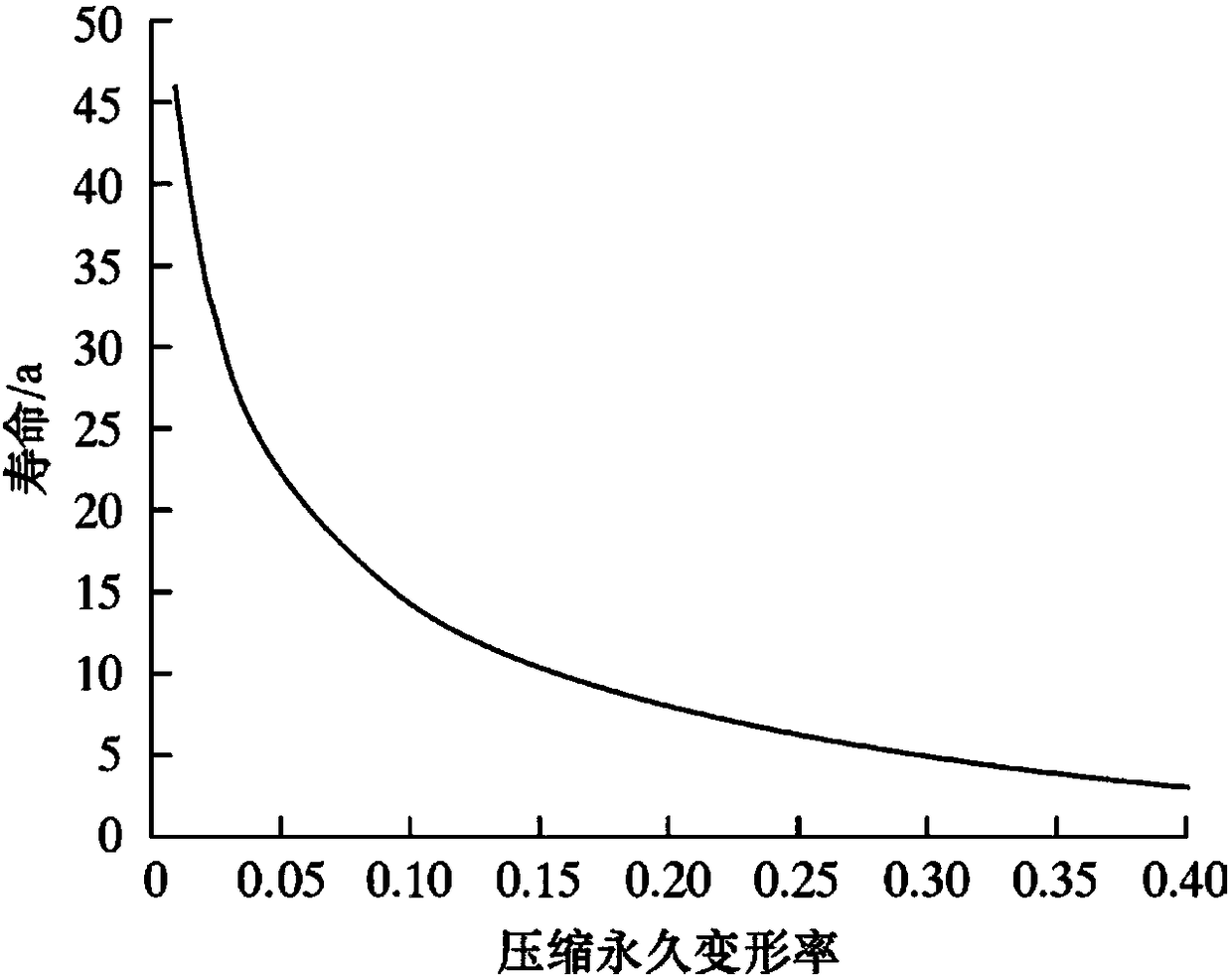

[0098] Design the sealing ring of a certain type of underwater wet electrical general connector

[0099] S1. According to the design requirements, all relevant parameters of the sealing ring of this type of connector can be determined;

[0100]S2. According to the relationship between the leakage amount G of the pin of the underwater wet electrical universal connector during the process of plugging and unplugging once

[0101] In the formula, K is the coefficient K=2.1×10 -4 , D is the inner diameter of the sealing ring D=0.00235m, S is the stroke length of the sealing surface when the pin is reciprocated once inserted and pulled out S=2πD, L is the contact width of the sealing surface L=0.01m, p is the pressure difference between seawater and hydraulic oil p = 50bar, generally 0bar ~ 50bar, v is the moving speed of the sealed surface v = 0.1m / s, generally 0m / s ~ 0.1m / s, R a is the surface roughness parameter R a =3.2×10 -6 m, η is the dynamic viscosity of the medium η=1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com