Vehicle-mounted movable hose tidying trolley capable of automatically tidying water hose

An automatic sorting and mobile technology, which is applied in thin material handling, folding thin material, fire rescue, etc., can solve the problems of physical loss, low efficiency, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described in conjunction with the following examples.

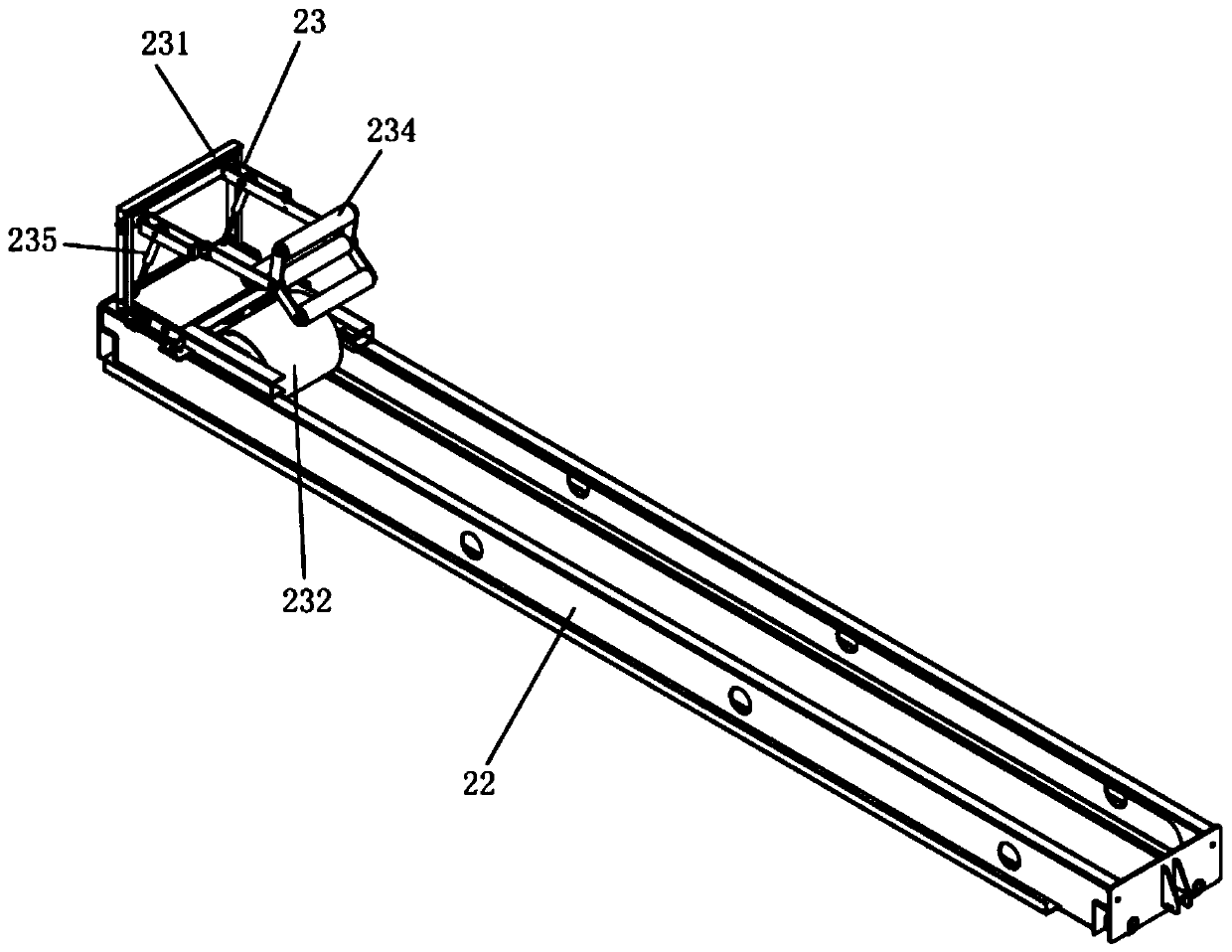

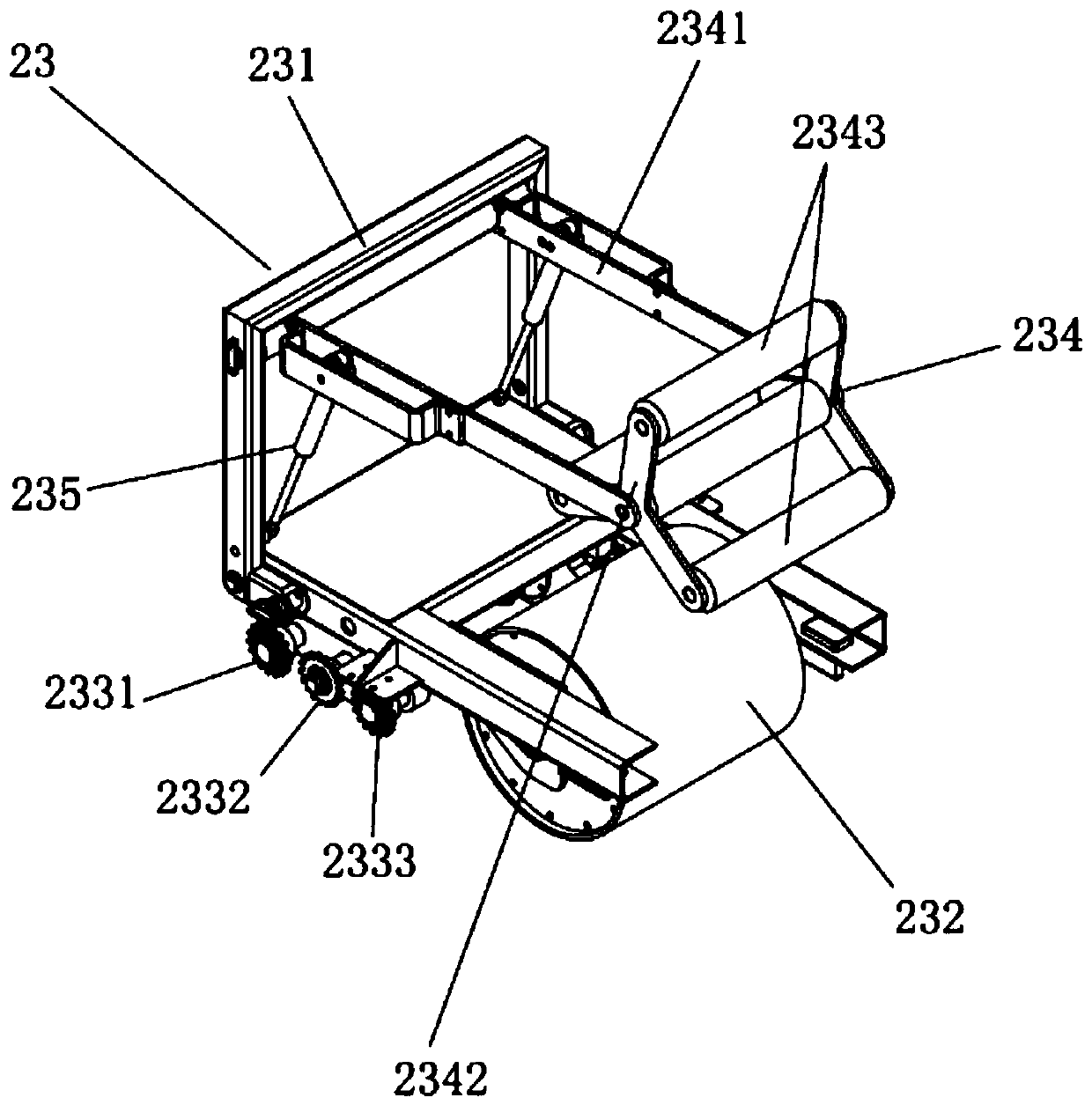

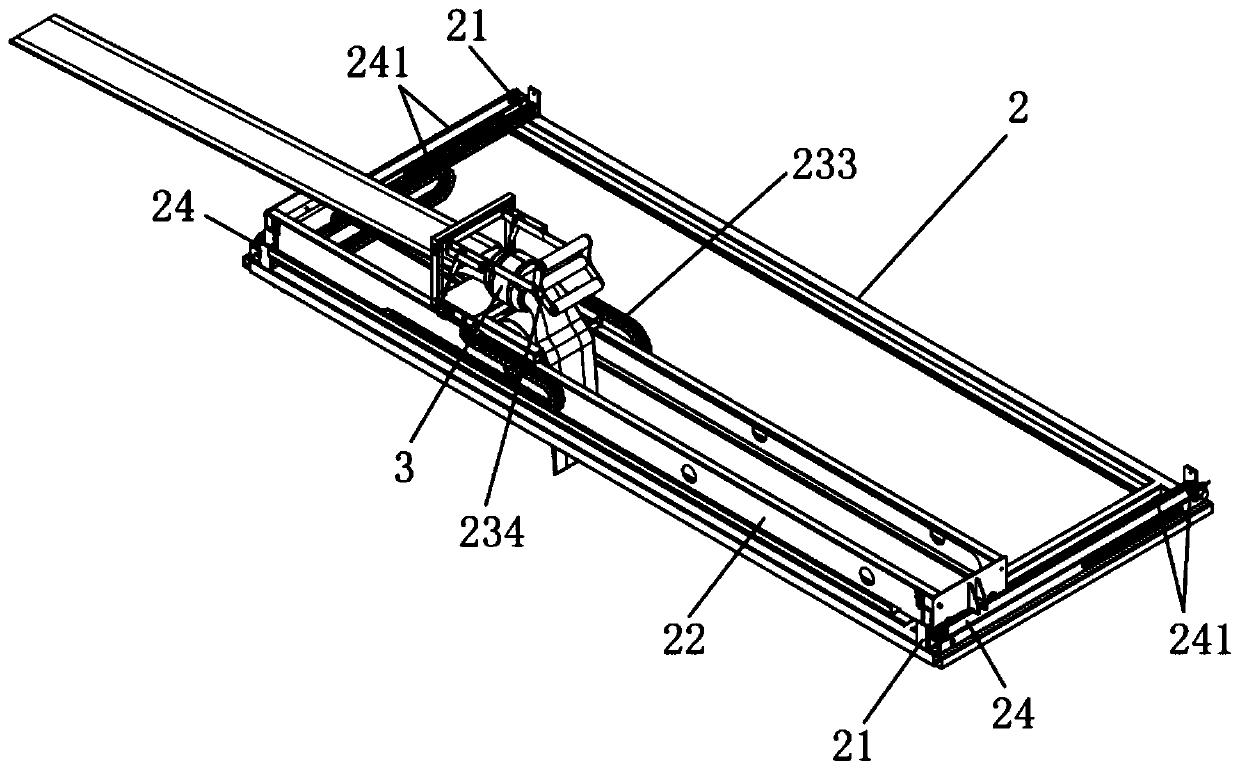

[0029] A kind of vehicle-mounted mobile belt unscrambling trolley that can automatically arrange water belts in this embodiment, such as Figure 1 to Figure 3 As shown, it includes a belt arrangement trolley 23 and a moving longitudinal beam 22 for the belt arrangement trolley 23 to slide back and forth. The moving sprocket transmission mechanism 233, the rotary obstacle avoidance mechanism 234 used to compress the hose and enable the hose connector 3 to pass through, and the cylinder 235 to drive the rotary obstacle avoidance mechanism 234 up and down, the moving longitudinal beam 22 is located at two longitudinal Both sides are provided with track grooves that cooperate with the sprocket drive mechanism 233 .

[0030] Specifically, the rotary obstacle avoidance mechanism 234 includes a support frame 2341, a triangular roller frame 2342, and small rollers 2343 respectively mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com