Finished yarn storage device for textile machinery

A technology of textile machinery and storage devices, applied in the field of finished yarn storage devices, which can solve the problems of inconvenient placement and retrieval of yarns, and achieve the effects of ingenious structure, reduced friction, and increased structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

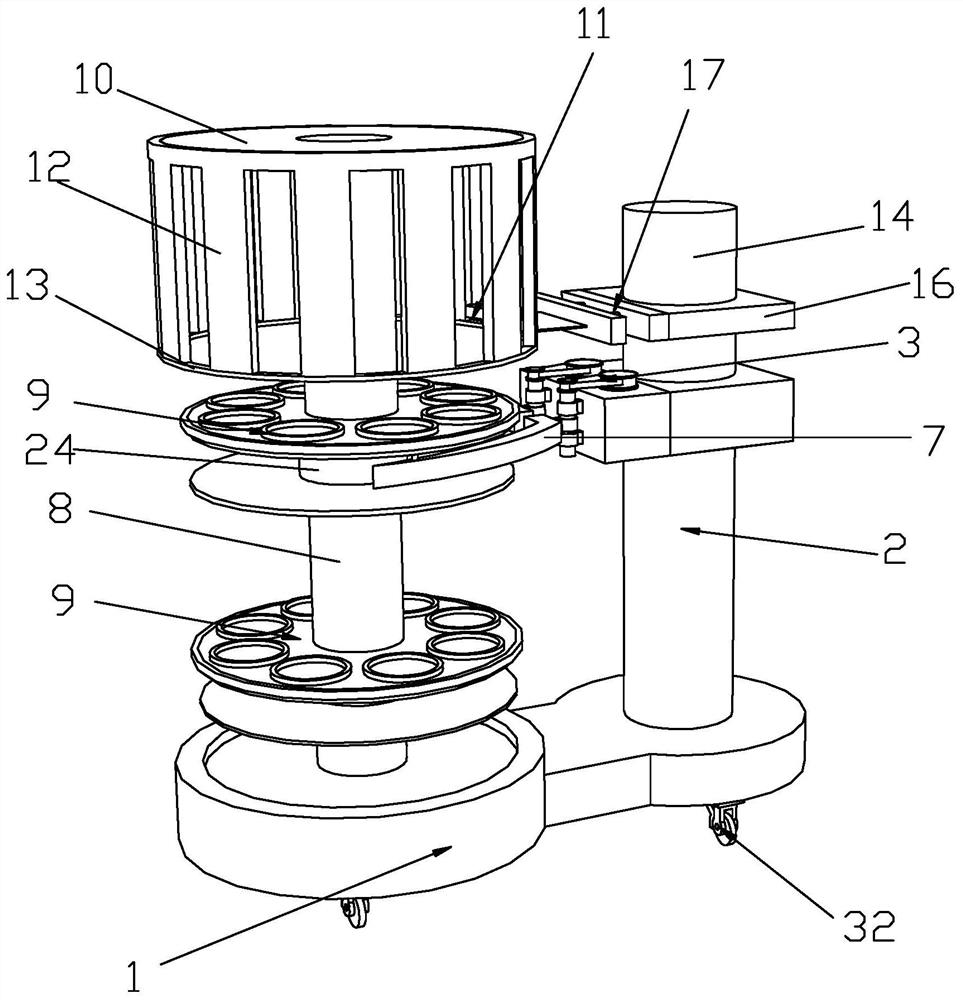

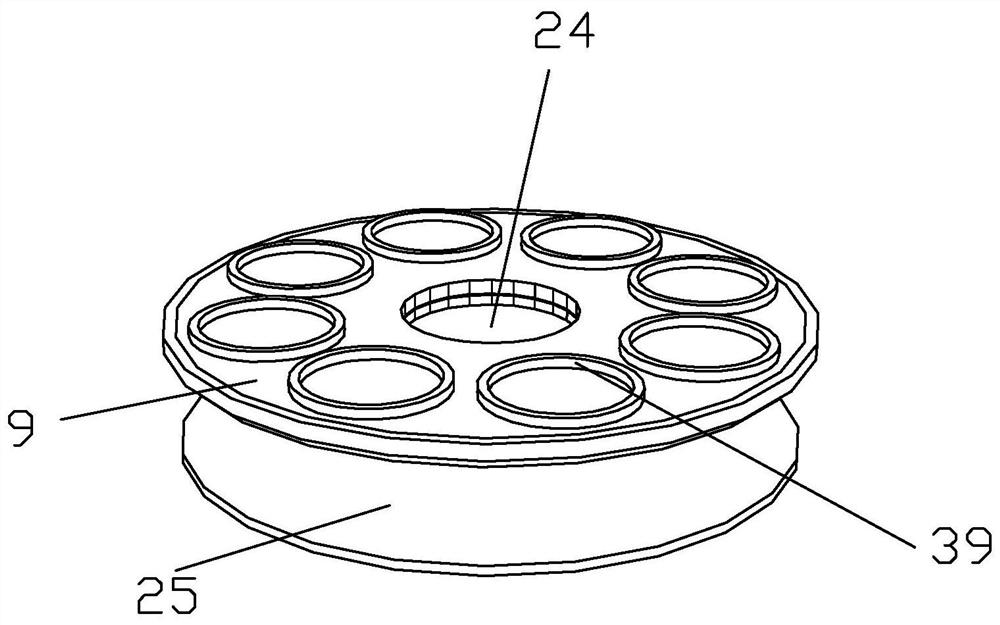

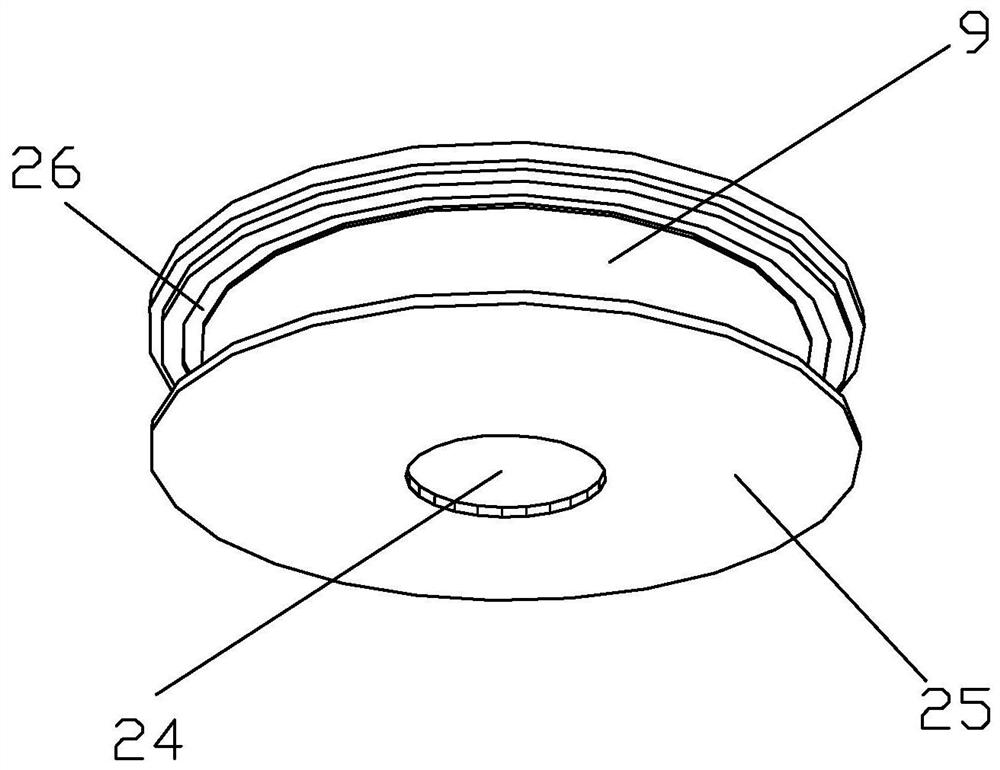

[0028] Such as Figure 1 to Figure 6 Shown is a finished yarn storage device for textile machinery according to the present invention, which includes a storage rack 1 and a lifting mechanism 2, and the storage rack 1 functions as a supporting and stabilizing device. Lifting mechanism 2 is provided with first fixed ring 4, and first fixed ring 4 is provided with fixed shaft 5, and first fixed ring 4 is connected with fixed shaft 5 in rotation, and fixed shaft 5 is provided with second fixed ring 6, and second fixed ring 6 It is fixedly connected with the fixed shaft 5. The second fixed ring 6 is provided with a rotating arm 7. The rotating arm 7 and the second fixed ring 6 are integrally formed. The end of the fixed shaft 5 is provided with a rotating mechanism 3. The rotating mechanism 3 and the lifting Mechanism 2 is connected, and storage rack 1 is provided with support column 8, and support column 8 plays the effect of fixed support. The support column 8 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com