Die cutter mechanism for automotive acoustic parts

A technology of acoustic components and slitting knives, which is applied in metal processing and other directions, can solve the problems of single manual handling, large mold size, multi-manual operation, etc., to achieve convenient handling, reduce punching force, and save energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

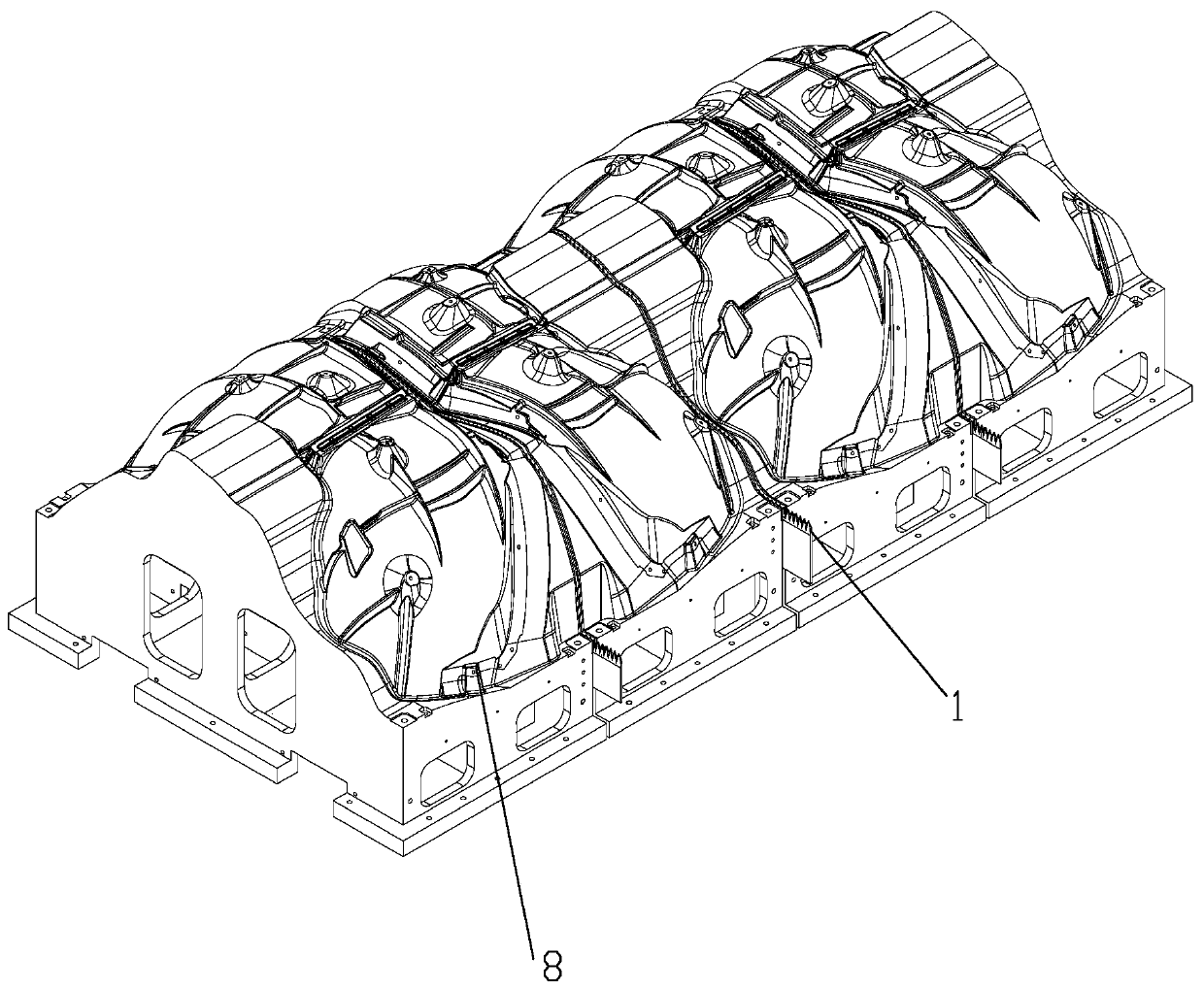

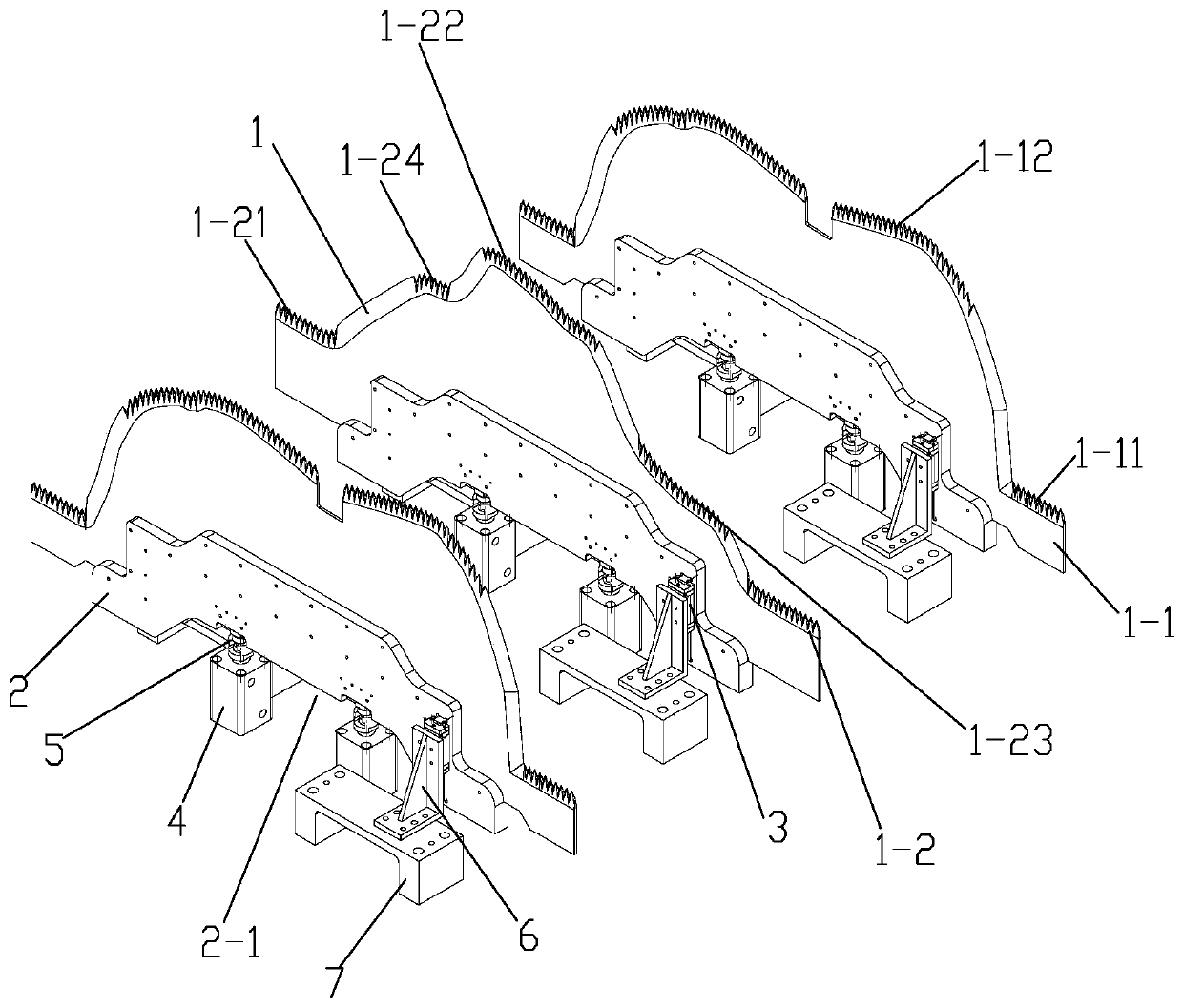

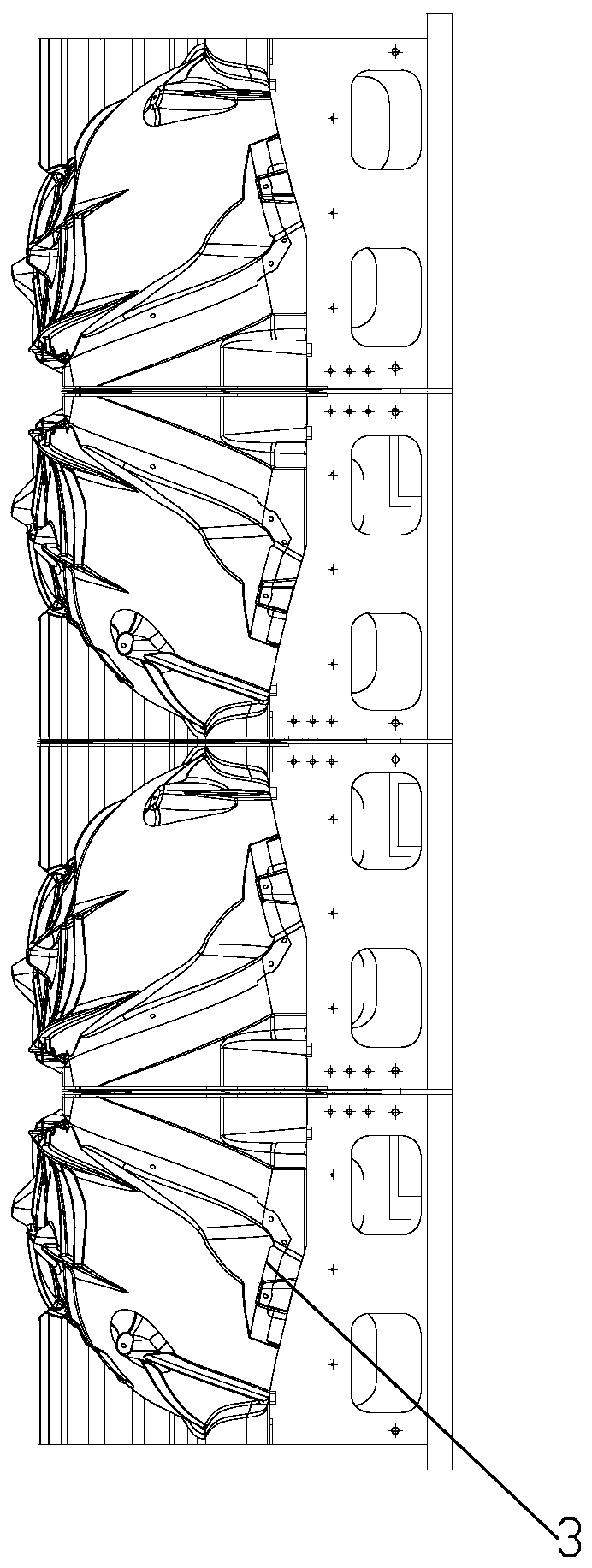

[0018] Figure 1~4 Among them, including slitting blade 1, end part cutting blade 1-1, end part cutting blade horizontal serrated edge 1-11, end part cutting blade top serrated edge 1-12, middle slitting blade 1-2, middle slitting blade Horizontal serrated edge 1-21, middle slitting blade top serrated edge 1-22, middle slitting blade first serrated edge 1-23, middle slitting blade second serrated edge 1-24, fixed plate 2, groove give way Space 2-1, guide rail combination device 3, oil cylinder 4, connecting block 5, support frame 6, slide rail fixing seat 7, mold body 8, etc.

[0019] Such as Figure 1~4 As shown, the present invention is a mold cutting knife mechanism for automobile acoustic parts, including three-component knife mechanism uniformly distributed along the length direction of the bottom plate, and each component knife mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com