Building construction hanging basket

A technology of building construction and hanging basket, which is applied in the direction of construction, building structure, house structure support, etc. It can solve the problems that affect the work of the staff, affect the aesthetics of the wall, and the degree of inclination is serious, so as to improve stability and good protection , Improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

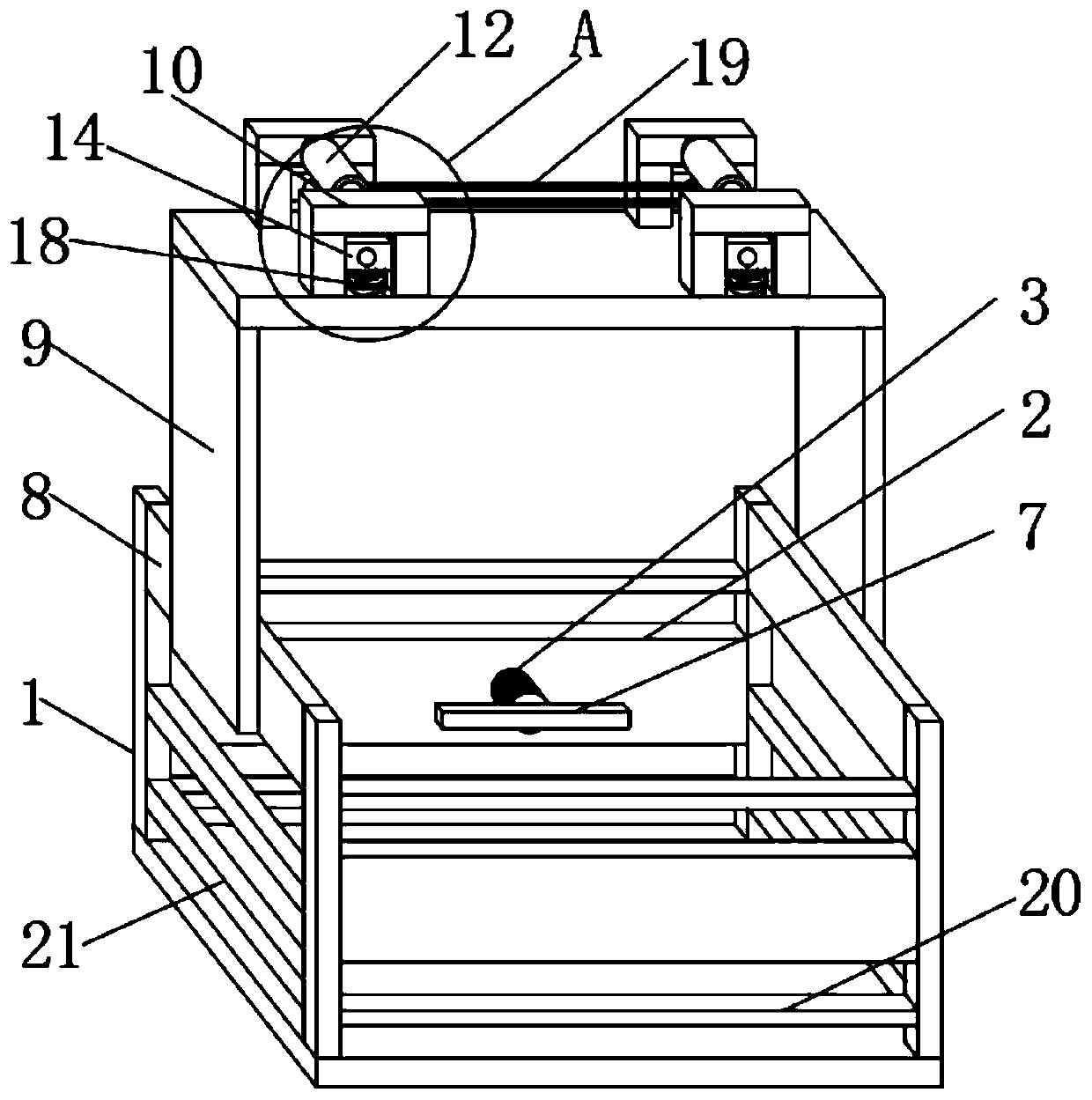

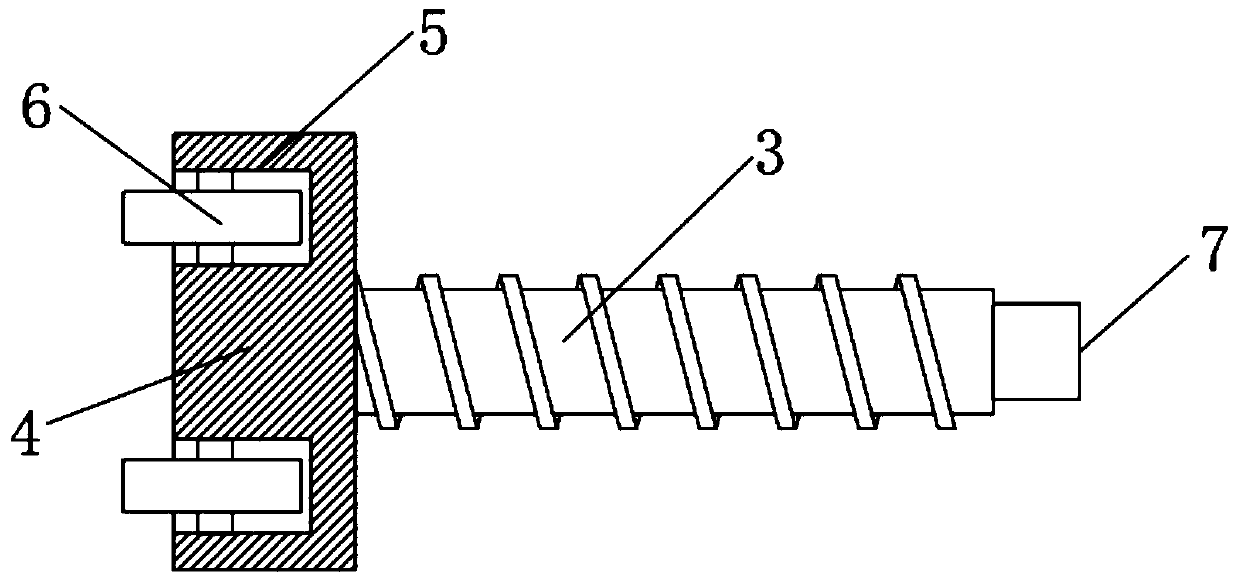

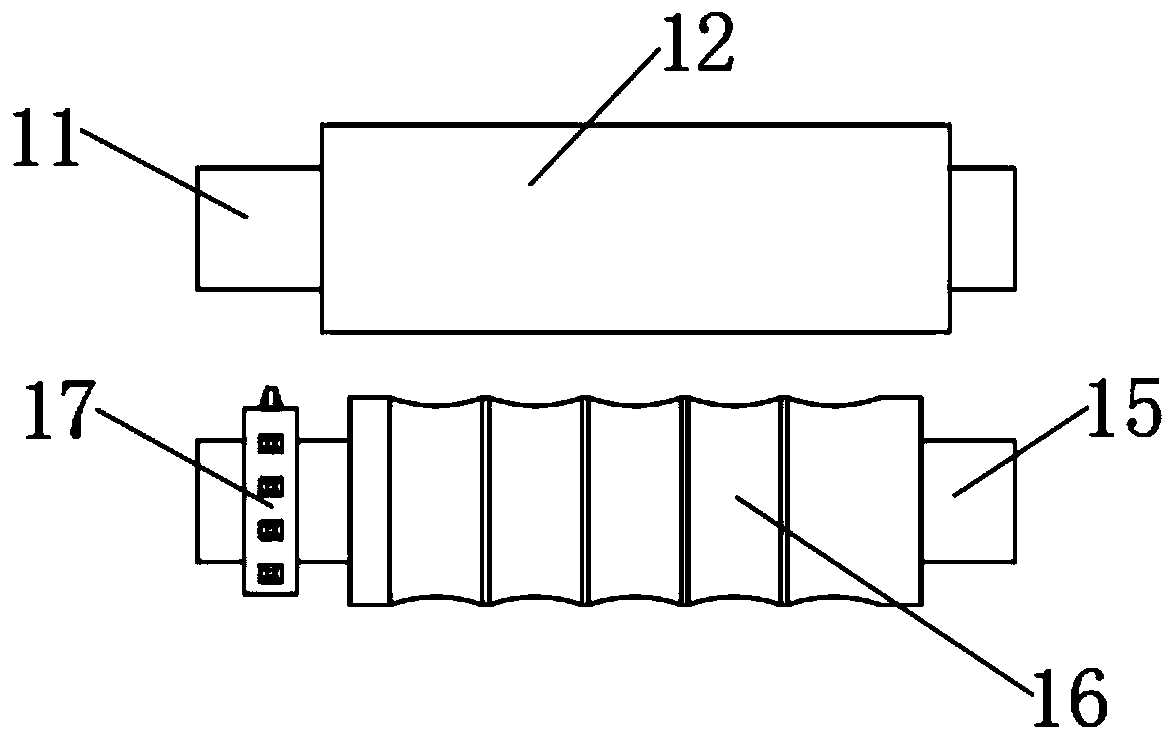

[0022] see Figure 1-4 , this embodiment provides a construction hanging basket, including a hanging basket body 1, the front end and the middle of the rear end of the hanging basket body 1 are fixedly connected with a first fixing plate 2, and one of the first fixing plates 2 is fixedly installed in the body of the hanging basket Screw column 3, one end of the screw column 3 is fixedly connected with a fixed frame 4, one end of the fixed frame 4 is provided with a mounting groove 5, and a supporting wheel 6 is rotatably connected in the mounting groove 5, and the upper ends of both sides of the hanging basket body 1 are fixedly connected with a second fixed frame. plate 8, one end of the second fixed plate 8 is fixedly connected with a U-shaped plate 9, two connecting frames 10 are fixedly connected on both sides of the top of the U-shaped plate 9, and a first fixed column 11 is fixedly connected between the two connecting frames 10, The side wall of the first fixed column 11...

Embodiment 2

[0025] see Figure 1-4 , made further improvement on the basis of embodiment 1: one end of screw column 3 is fixedly connected with rotating rod 7, and the length of rotating rod 7 is 20 centimeters; Rotating rod 7 can be rotated, thereby rotating rod 7 drives screw rod 3 to carry out Rotate, then make the screw column 3 drive the support wheel 6 under the situation of moving on the first fixed plate 2 to support on the body of wall. The side wall of the support cylinder 16 is set as a concavo-convex groove, and the support wheel 6 is made of rubber; 16 can preferably clamp and drive the wire rope. The side wall of the first fixed column 11 is fixedly connected with a bearing, and the first fixed column 11 is rotatably connected with the drum 12 through the bearing; The outer wall of the column 11 is rotated to ensure the performance of the rotation of the drum 12 . The inner side wall of the connecting frame 10 is provided with a sliding groove 13, and the sliding block 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com