Pulley block for hook bridge crane

A technology of bridge cranes and pulley blocks, which is applied in the direction of load hanging components, portable lifting devices, hoisting devices, etc., which can solve the problems of reducing the service life of steel cables, damage to steel cable friction, and tilting of pulley blocks, etc., to increase winding way, reduce position swing, reduce wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

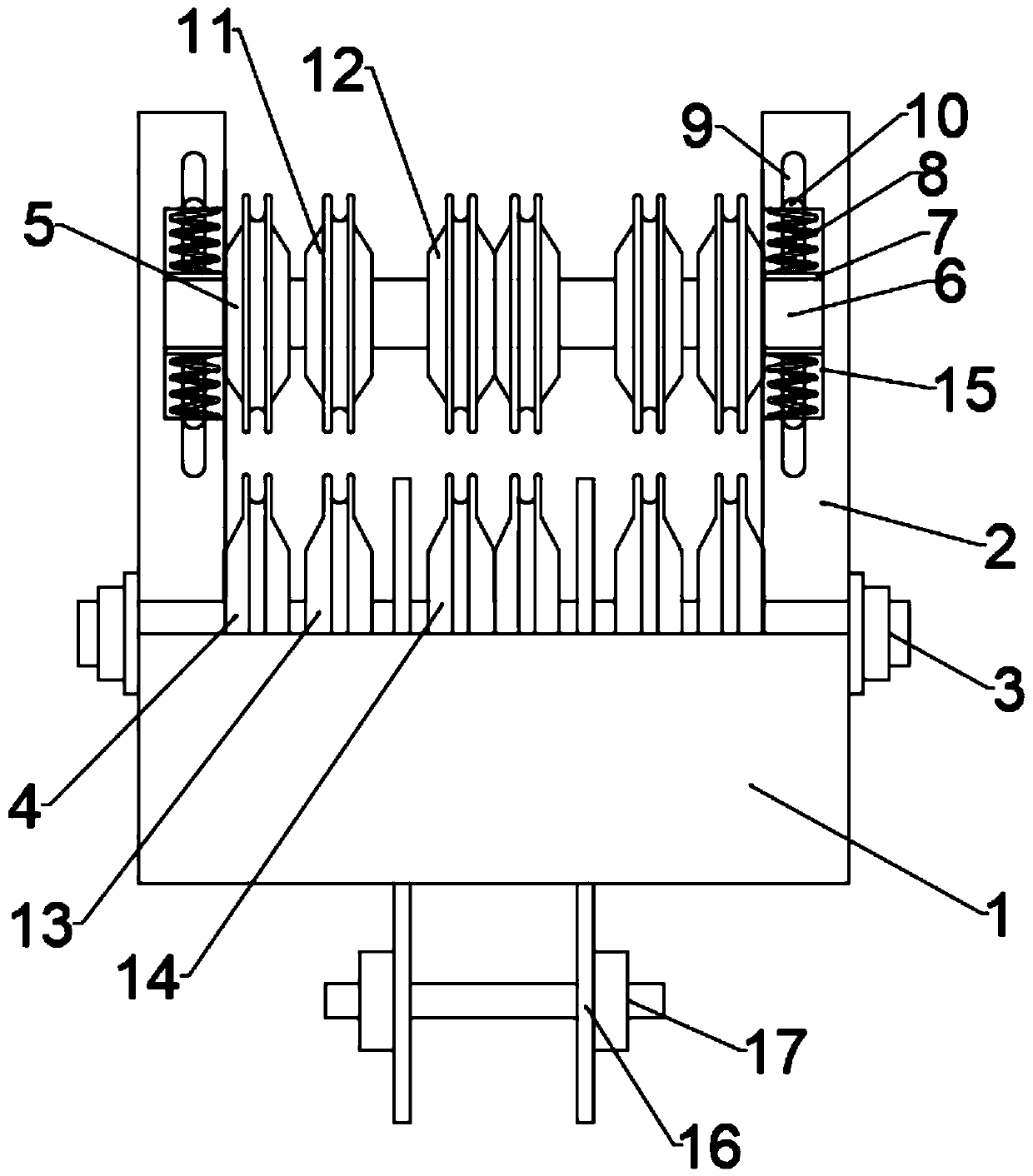

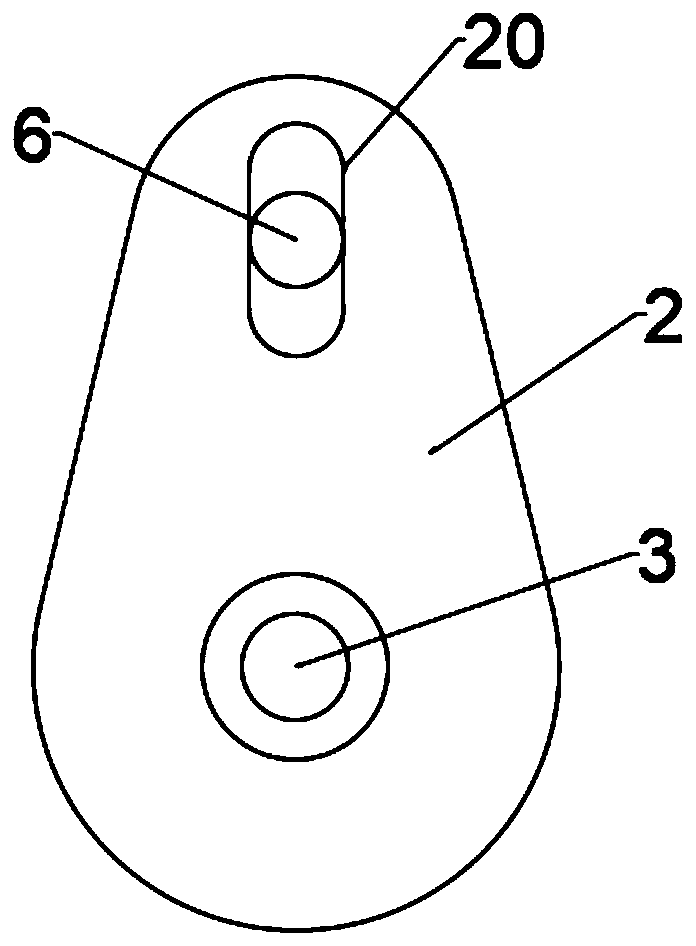

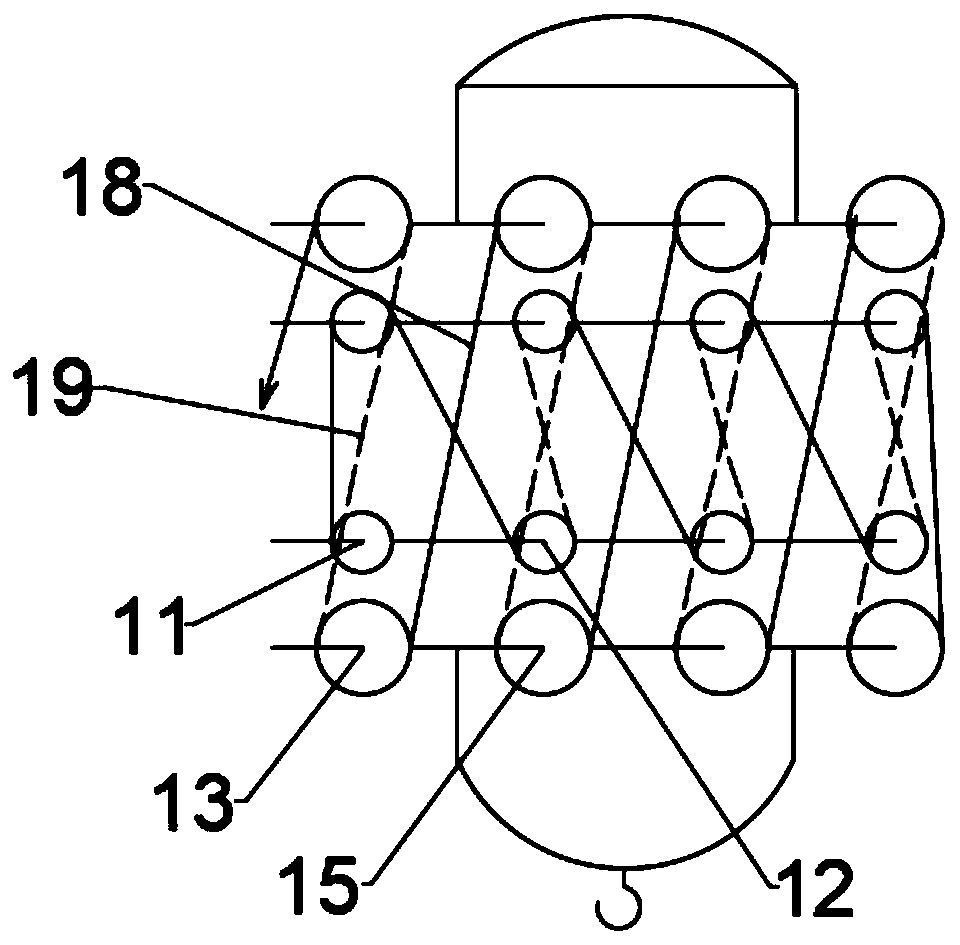

[0019] Such as figure 1 and figure 2 As shown, the present invention provides a pulley block for a hook bridge crane, comprising an outer casing 1 and a side wall 2, the semicircular outer casing 1 is set on the bottom of the side wall 2, and the side The outer wall at the top of the wall 2 is provided with a limiting groove 20, and the inner wall of the side wall 2 is provided with a rectangular elastic cavity 15, and the limiting groove 20 communicates with the elastic cavity 15, and the bottom and top of the side wall 2 The main shaft 3 and the secondary shaft 6 are installed horizontally in the middle, the main and auxiliary wheels 4 are installed at both ends of the main shaft 3, and the main line wheel C13 is installed on the inner side of the main line wheel 4, and the combination line is set on the inner side of the main line wheel C13. Wheel D14, hook side plates 16 are installed at both ends of the combined wire wheel, the hook side plates 16 longitudinally penetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com