Quick replacement method of steel cables of crane

A replacement method and wire rope technology, applied in the direction of spring mechanism, hoisting device, etc., can solve the problems of long time, unsafe, heavy wire rope replacement length and weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

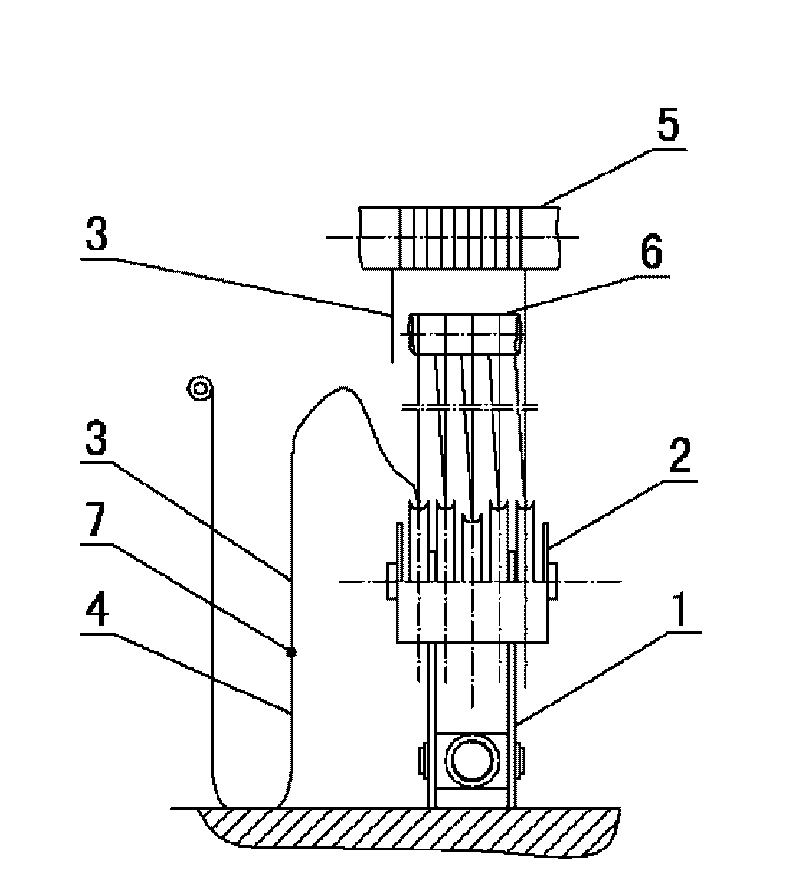

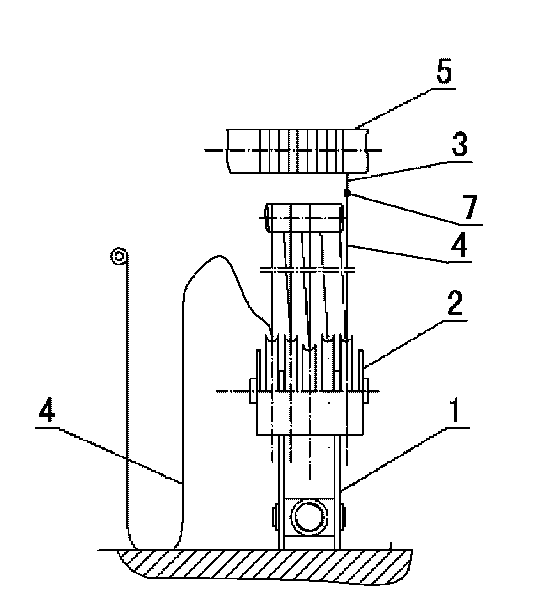

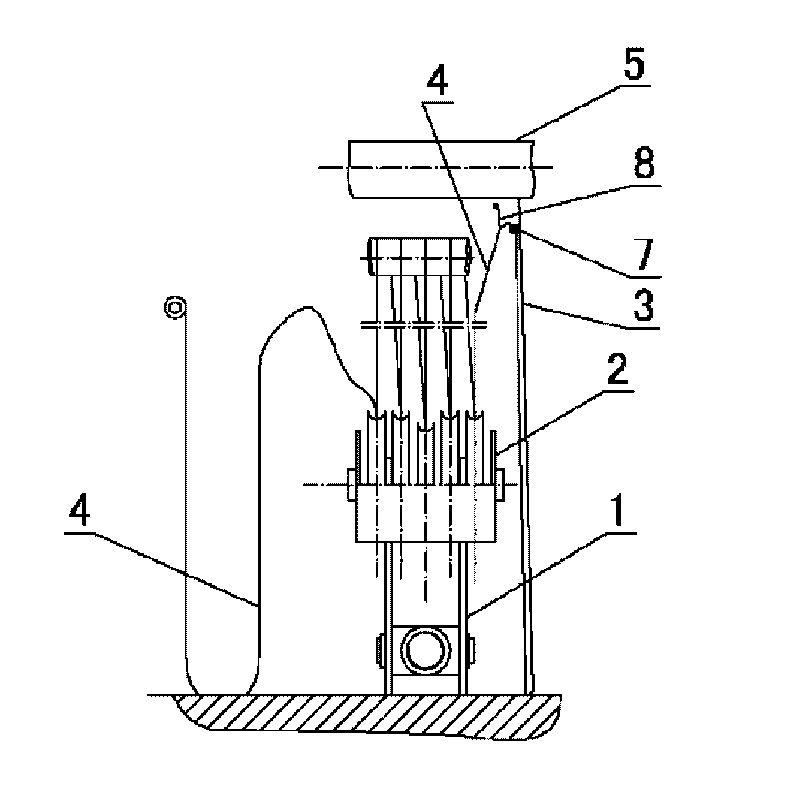

Image

Examples

Embodiment 2

[0027] like Figure 2a ~ Figure 2b As shown, Embodiment 2 of the present invention is a method for replacing the hook head and wire rope of a bridge crane, comprising the following steps

[0028] like Figure 2a As shown, put the new hook head 11 on the ground, then start the crane to drop the rope and drop the old hook head 10 close to the new hook head 11 and keep it still; cut off each of the old hook head 10 from A by electric welding The old wire rope 13 on both sides on the moving pulley 12 makes the old wire rope be separated into the old wire rope section 131 that is wound on each corresponding moving pulley piece 12 and the old wire rope section 132 that is still suspended on the drum on the crane.

[0029] like Figure 2b As shown, each old wire rope segment 131 wrapped around the movable pulley piece 12 of each old hook head 10 is taken off and then inserted into each pulley piece 14 of the new hook head 11, except for one of the outermost old wire rope segments. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com