Lifting mechanism of free dropping type forced ramming machine with hammer

A lifting mechanism and dynamic tamping machine technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of increased purchase cost, complex control system, high full load capacity, etc., to achieve reasonable cost, convenient use, and improved safety The effect of sex and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Regarding the structural composition, technical means and effect of the present invention, it will be illustrated as follows in conjunction with the drawings:

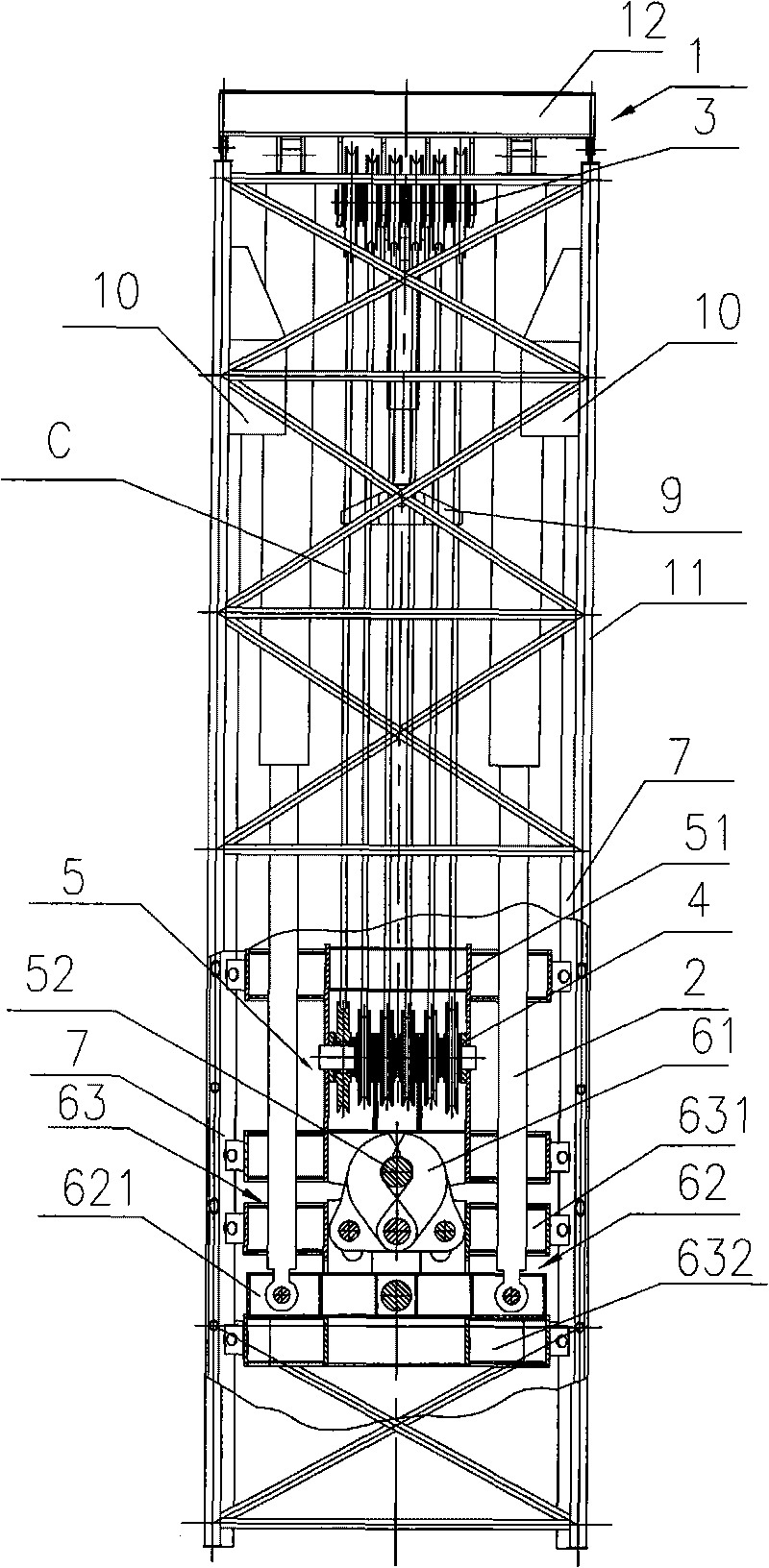

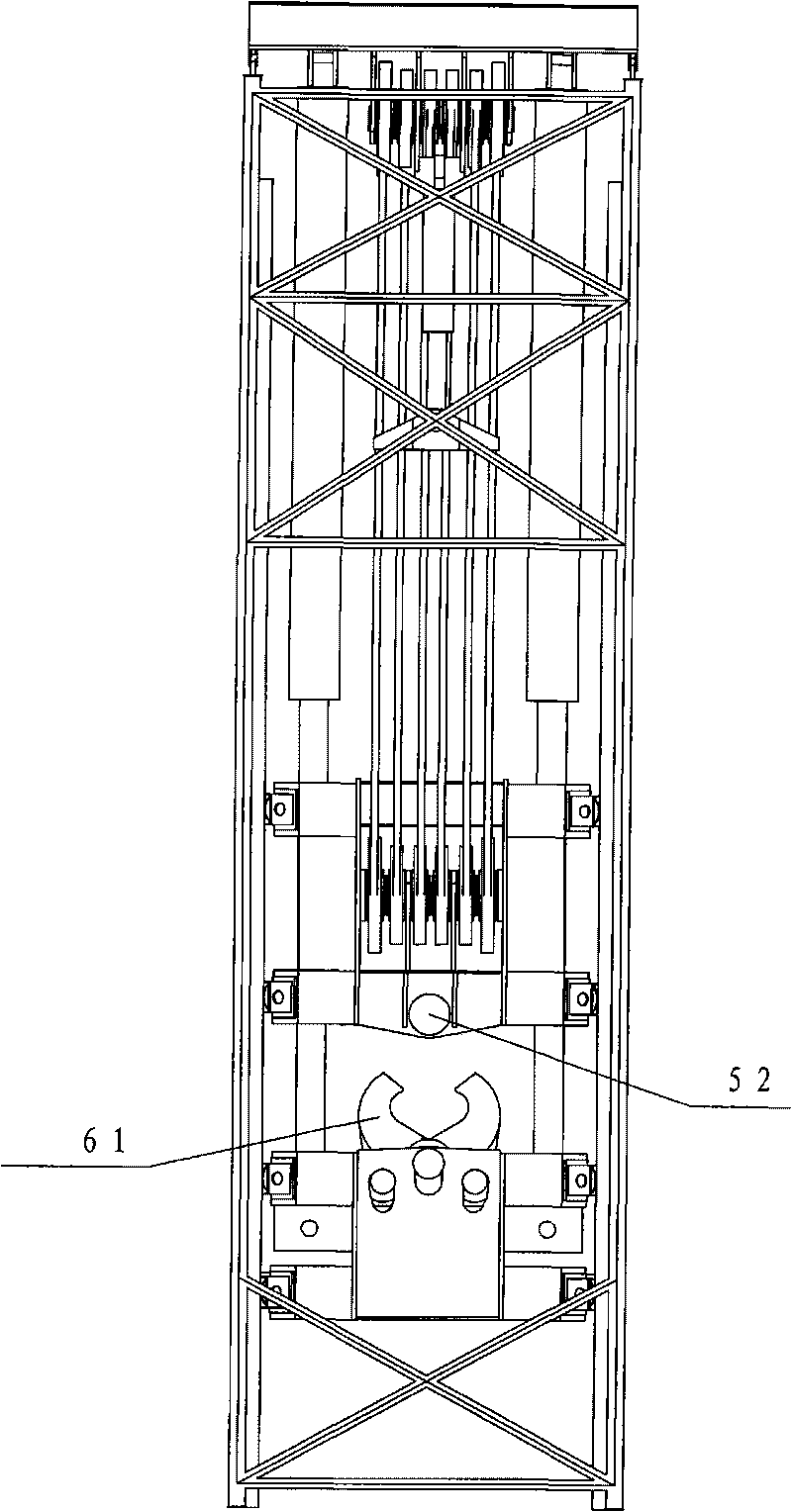

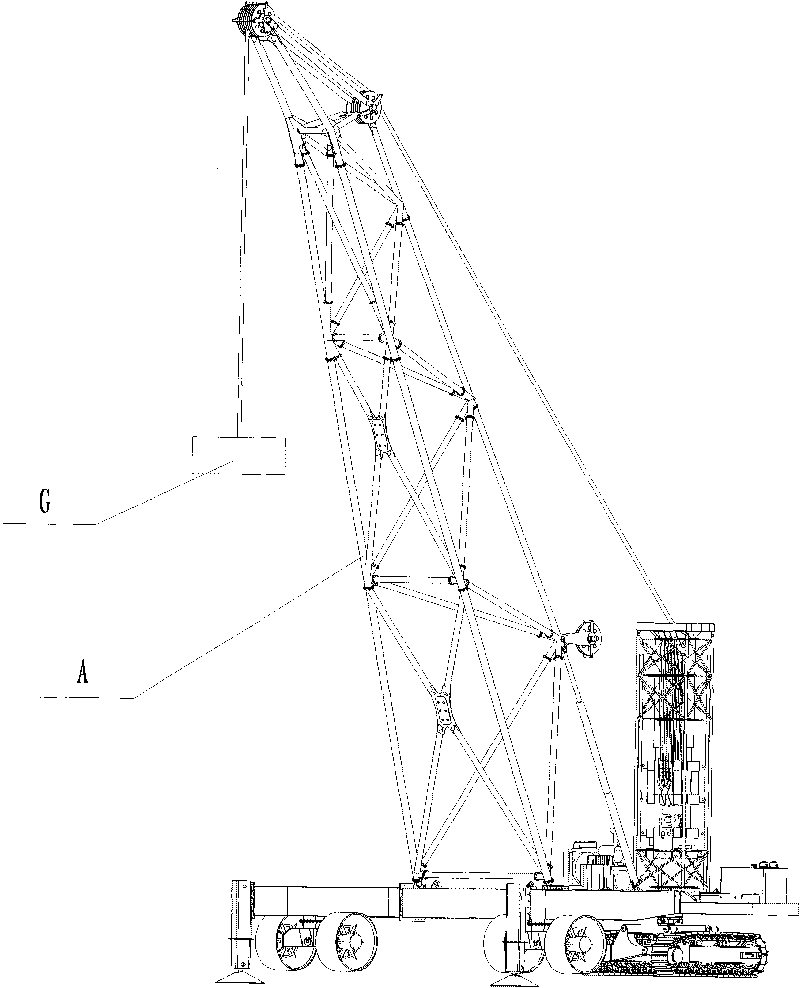

[0028] Such as figure 1 , Figure 1a and figure 2 As shown, it is a hoisting mechanism of a free-falling dynamic tamping machine with a hammer of the present invention, which includes: a hanging device 1, which is fixed with a hydraulic cylinder 2 and a fixed pulley block 3, and the fixed pulley block 3 passes through a steel wire rope C It is connected with the movable pulley block 4, the movable pulley block 4 is fixed on the sliding device 5, the piston rod of the hydraulic cylinder 2 is connected with the decoupling device 6, and the decoupling device 6 corresponds to the sliding device 4, and the decoupling device 6 selectively under the action of the hydraulic cylinder 2 It is connected or separated from the sliding device 5 of the movable pulley block 4 . The wire rope C of the lifting mechanism is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com