Thrust-adjustable multistage pulse solid rocket engine

A rocket engine and pulse solid technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of complex structure, difficult dynamic sealing control, and inability to adjust the thrust of pulse solid rocket motor in real time, etc., to achieve structural Simple, easy-to-adjust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

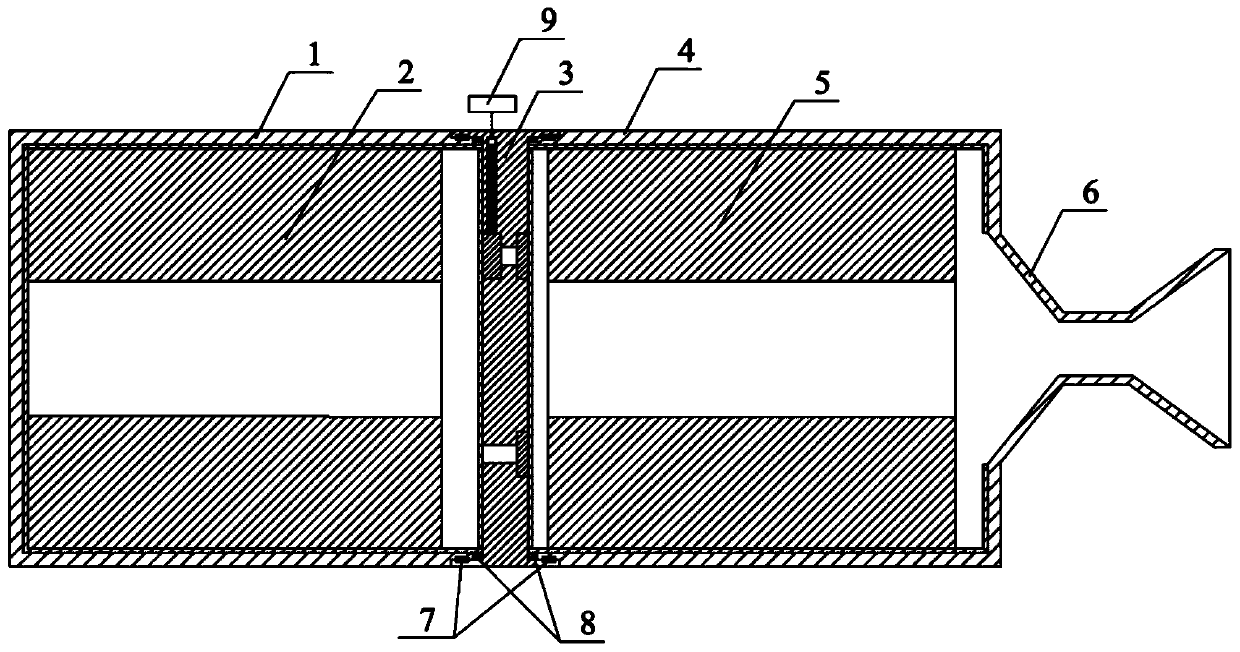

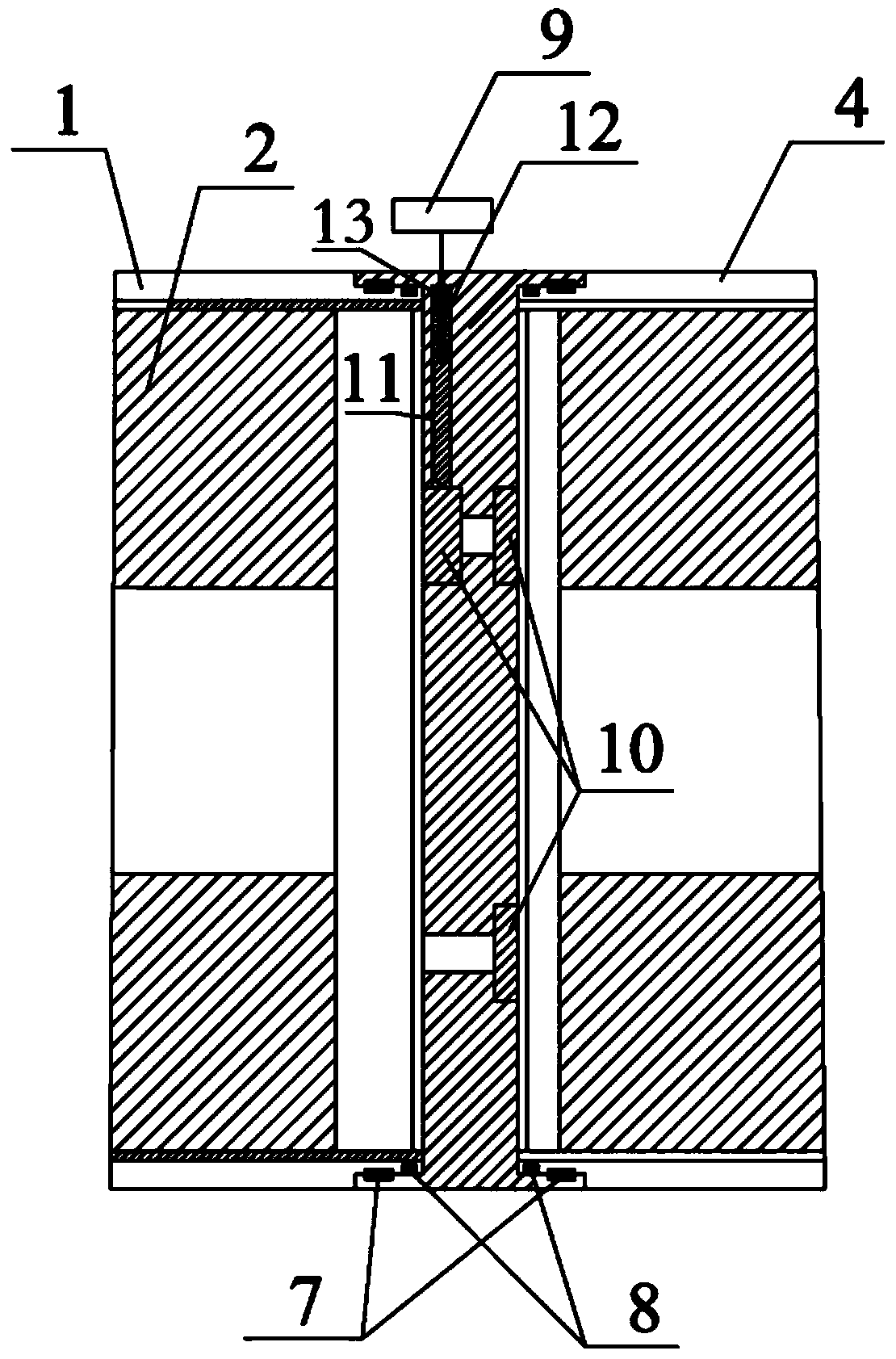

[0020] This embodiment provides a thrust-adjustable multi-stage pulse solid rocket motor. Active holes are added to the compartment of the multi-stage pulse solid rocket motor. The structure is simple, the adjustment and control are convenient, and the multi-stage pulse solid rocket motor can be adjusted according to engineering needs. thrust.

[0021] The multi-stage pulse solid rocket motor includes more than two pulse combustion chambers connected in sequence and a compartment 3 for connecting adjacent pulse combustion chambers. The compartment 3 is connected to two adjacent pulse combustion chambers through a connection card fast 7 , the connection is sealed by an O-ring 8.

[0022] Taking the two-stage pulse solid rocket motor as an example, the adjacent two pulse combustion chambers are the first pulse combustion chamber 4 and the second pulse combustion chamber 1, the first pulse combustion chamber 4 is equipped with a pulse charge 5, and the first pulse combustion cham...

Embodiment 2

[0029] On the basis of Embodiment 1, the blocking cover opening device includes: pin 11, spring 12, pyrotechnics and excitation device, the non-metallic blocking cover 10 outer circumference of the I-shaped through hole facing the second pulse combustion chamber 1 side along the radial direction Open the prefabricated hole, after the pin 11, the spring 12 and the pyrotechnic device are loaded into the prefabricated hole in sequence, the opening of the prefabricated hole is blocked from the outer periphery of the compartment 3, and a via hole is opened at the plugged place, and the excitation device passes through the via hole and connects with the pyrotechnic device. For the connection of the device, the two ends of the spring 12 are respectively in contact with the shoulder of the pin 11 and the pyrotechnic device. Before the pyrotechnic device moves, the spring 12 is in a compressed state, which is used to compress the pyrotechnic device to the blockage of the compartment 3 A...

Embodiment 3

[0031] On the basis of Embodiment 2, the pyrotechnic product is selected as the electric pyrotechnic device 13, and the excitation device is selected as the electric pyrotechnic device 9. Product 13 exploded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com