Capacitive sensor without capacitor element

A capacitive sensor, a technology without capacitance, applied in the field of sensors, can solve the problems of individual error of capacitance value, unimprovable, long induction, etc., achieve good sensing accuracy, maintain consistency, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

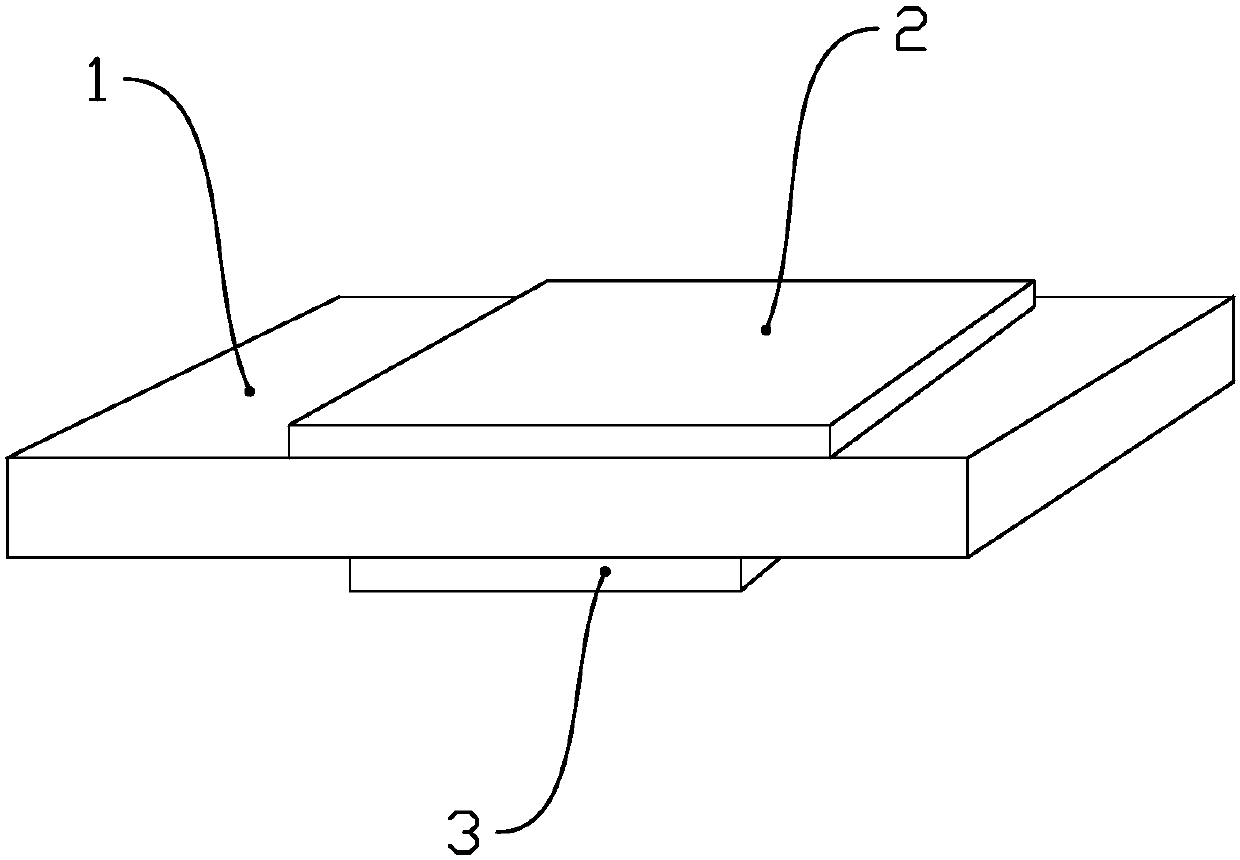

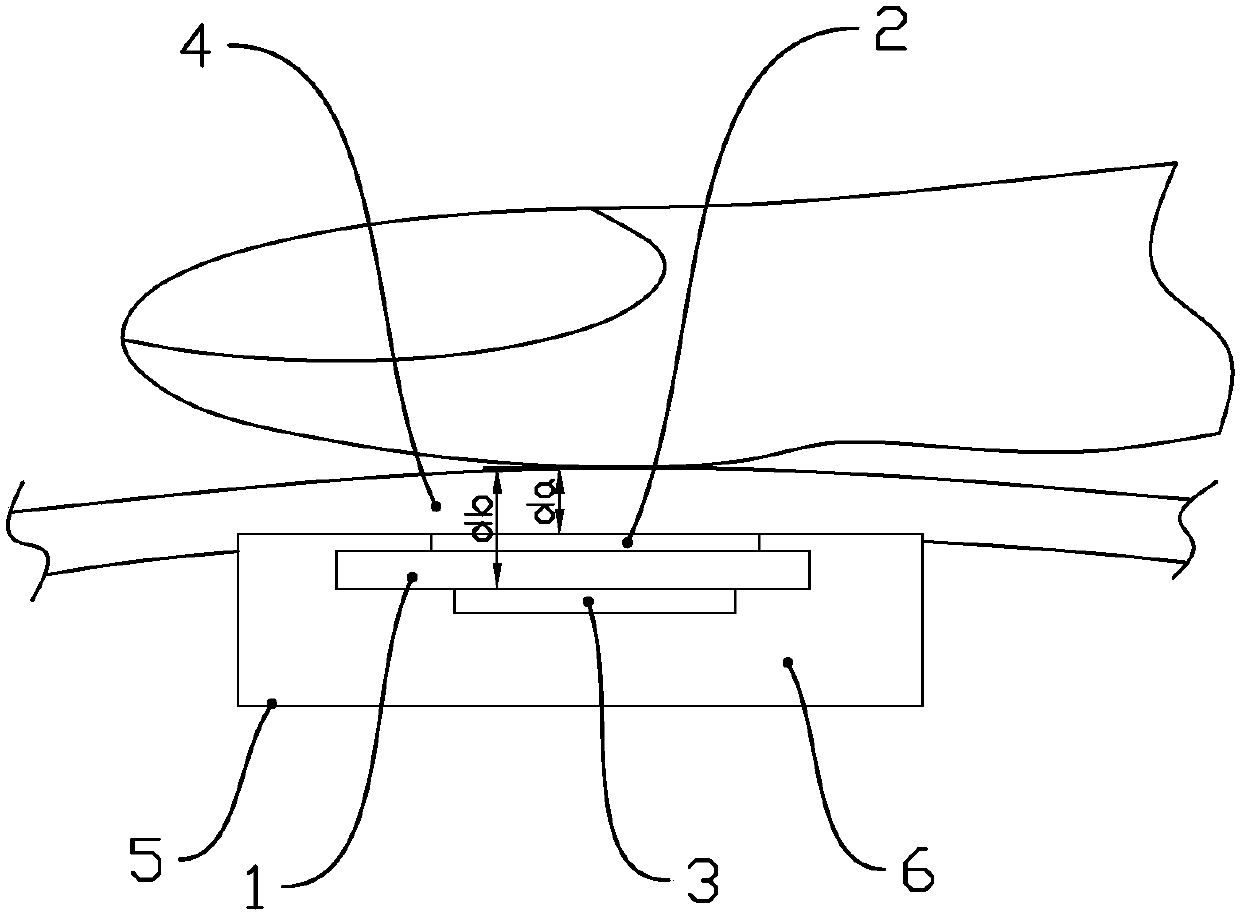

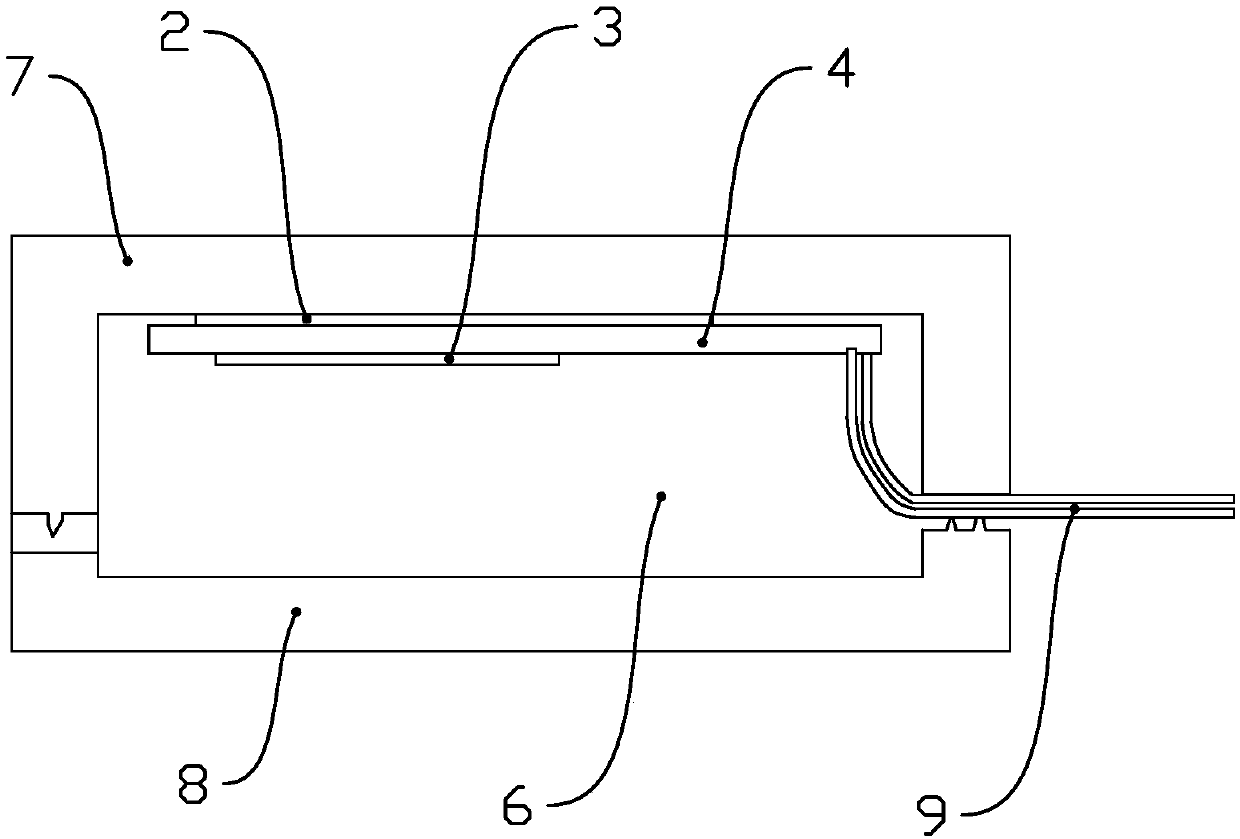

[0021] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —4:

[0022] The capacitive sensor without capacitive element comprises the first copper sheet 2 and the second copper sheet 3 which are fixed on the top surface and the bottom surface of the substrate 1 respectively, the volume of the first copper sheet 2 is greater than the volume of the second copper sheet 3, and the second copper sheet 3 The upper side of a copper sheet 2 is closely attached to the lower side of the non-conductor trigger 4, and further, the thickness of the first copper sheet 2 is the same as that of the second copper sheet 3, and the volume of the first copper sheet 2 is larger than that of the second copper sheet 3. The volume of the second copper sheet 3 . In this capacitive sensor, the top surface and the bottom surface of the first copper sheet 2 and the second copper sheet 3 are relatively speaking, as long as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com