System for sensing shifting of drive ring, compressor and gas turbine

A sensing system and gas turbine technology, applied in the direction of engine components, engine functions, machines/engines, etc., can solve the problems of complicated installation of the sensing mechanism, affecting the sensing accuracy of the sensing mechanism 14, and high cost, so as to achieve high power generation efficiency, The effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

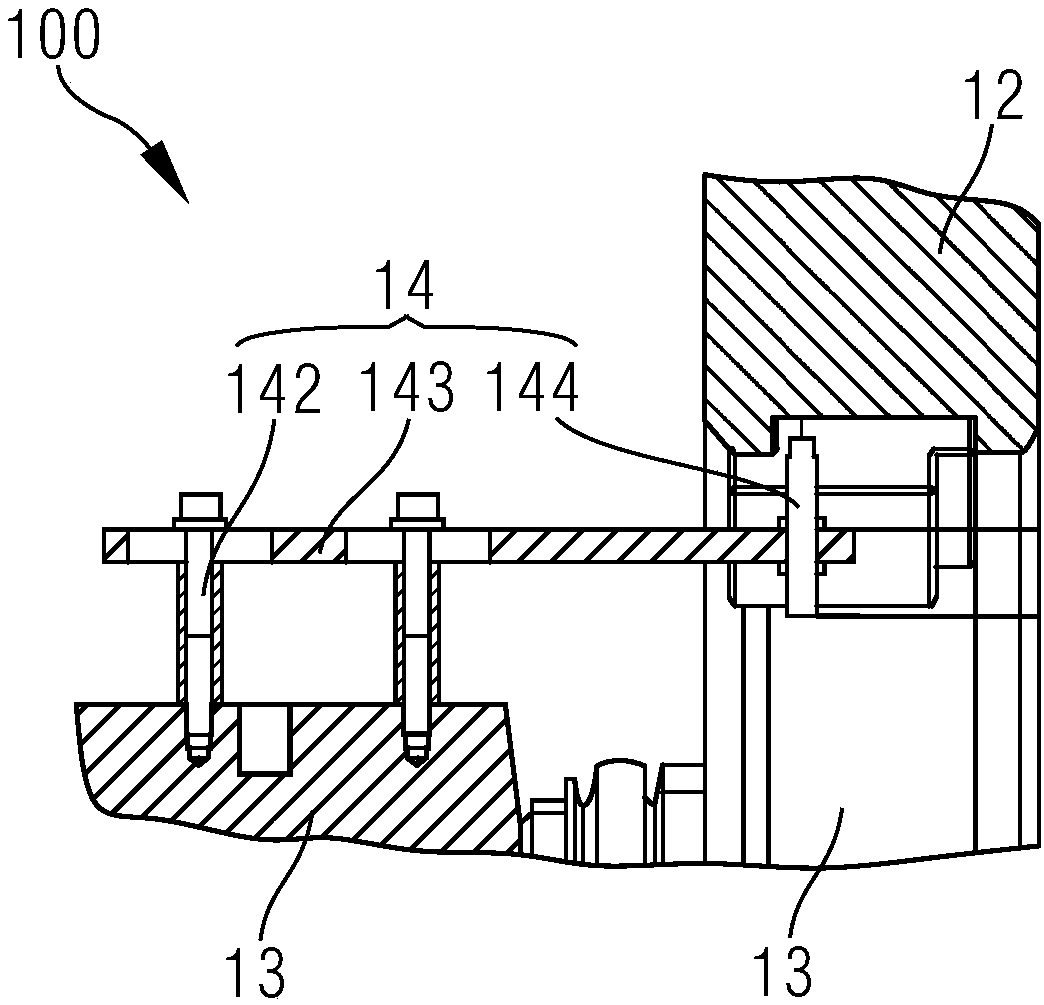

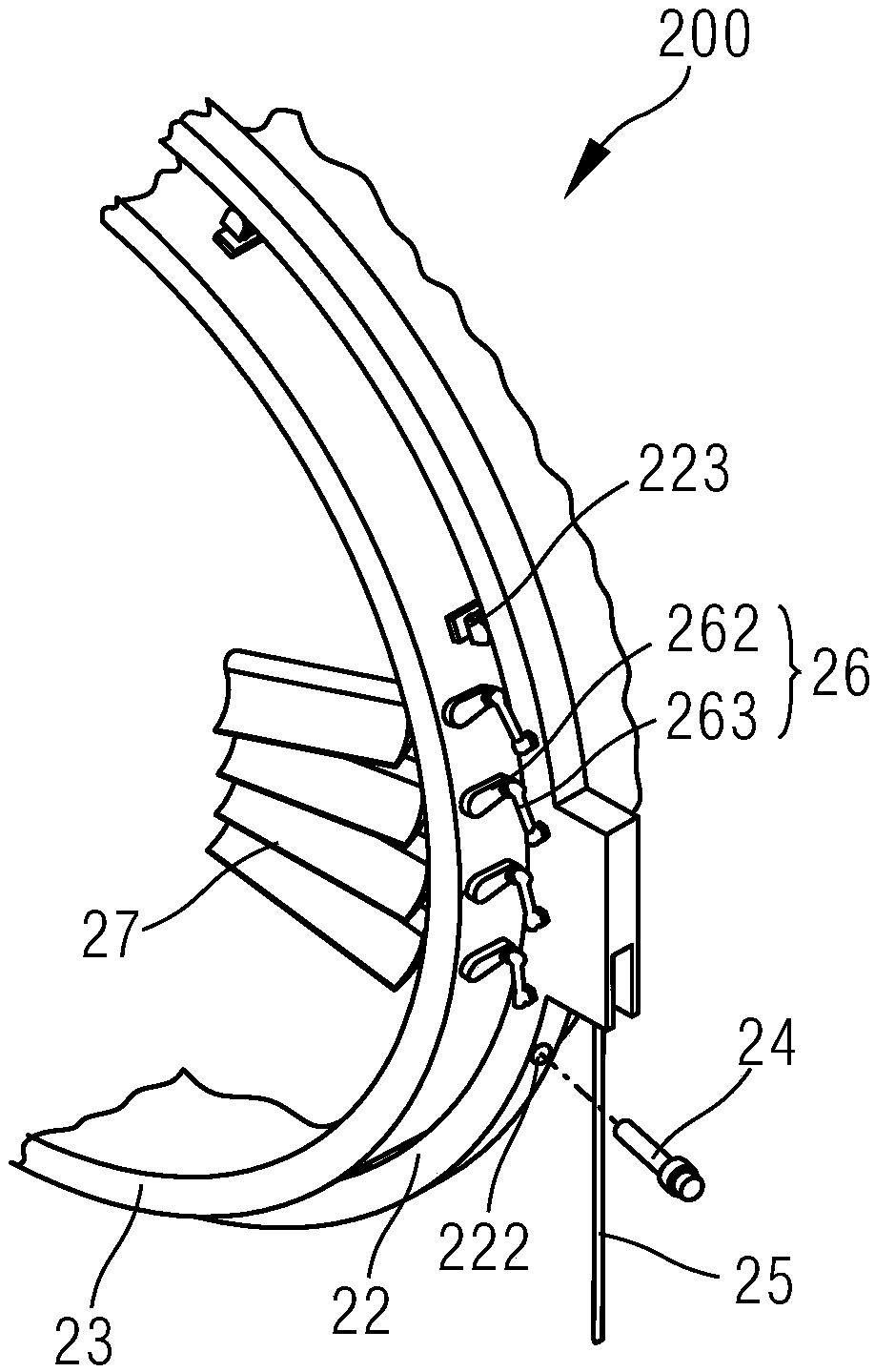

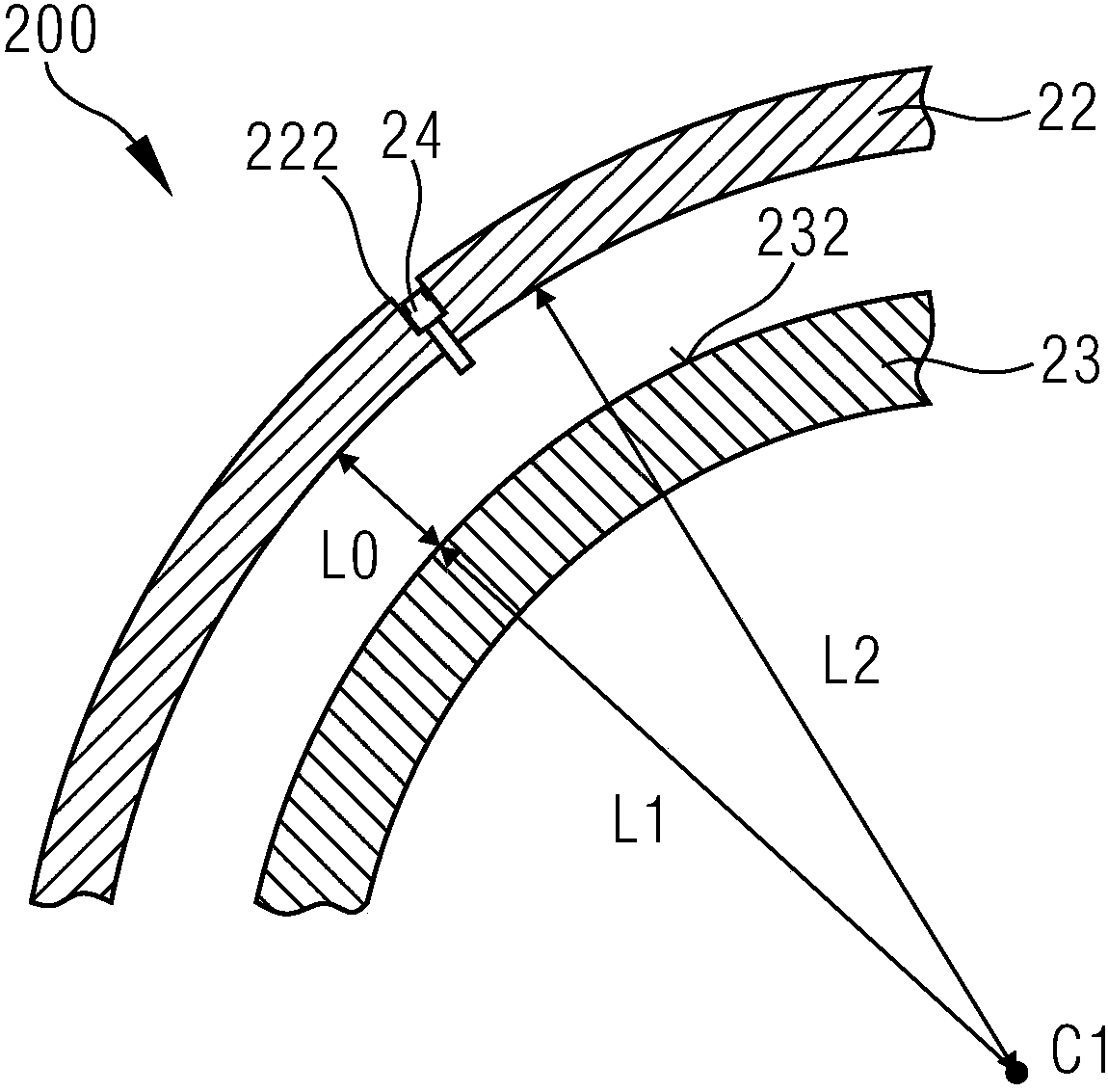

[0052] figure 2 It is a structural schematic diagram of an air compressor according to an embodiment of the present invention. image 3 for figure 2 A schematic cross-sectional view of the drive ring offset sensing system of the compressor shown. See figure 2 and image 3In this embodiment, the compressor includes a drive ring offset sensing system 200 , at least one push rod 25 , multiple linkage mechanisms 26 and multiple guide vanes 27 . The drive ring offset sensing system 200 includes at least one drive ring 22, a compressor housing 23, and at least one sensor 24. The drive ring 22 can be installed on the compressor housing 23, and is spaced apart from the compressor housing 23, namely The drive ring 22 is sheathed on the compressor housing 23 , and when the drive ring 22 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com