Crawler tractor production-used track anti-slip performance detection device

A technology of anti-skid performance and detection device, which is applied in the direction of vehicle trackless testing, etc., can solve the problems of personnel injury, lack of comparison of test results of track anti-skid performance, loss of control of tractors, etc., to achieve the effect of protecting safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

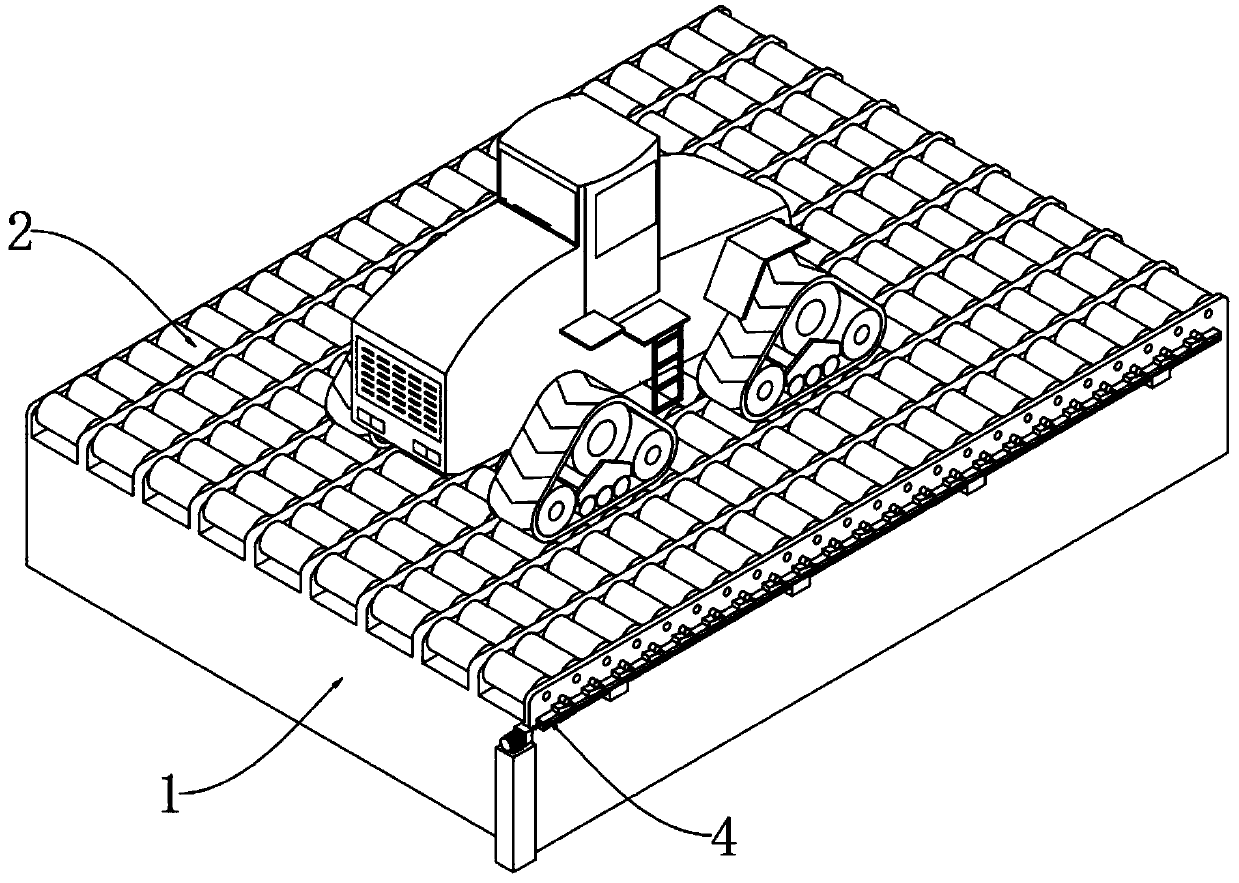

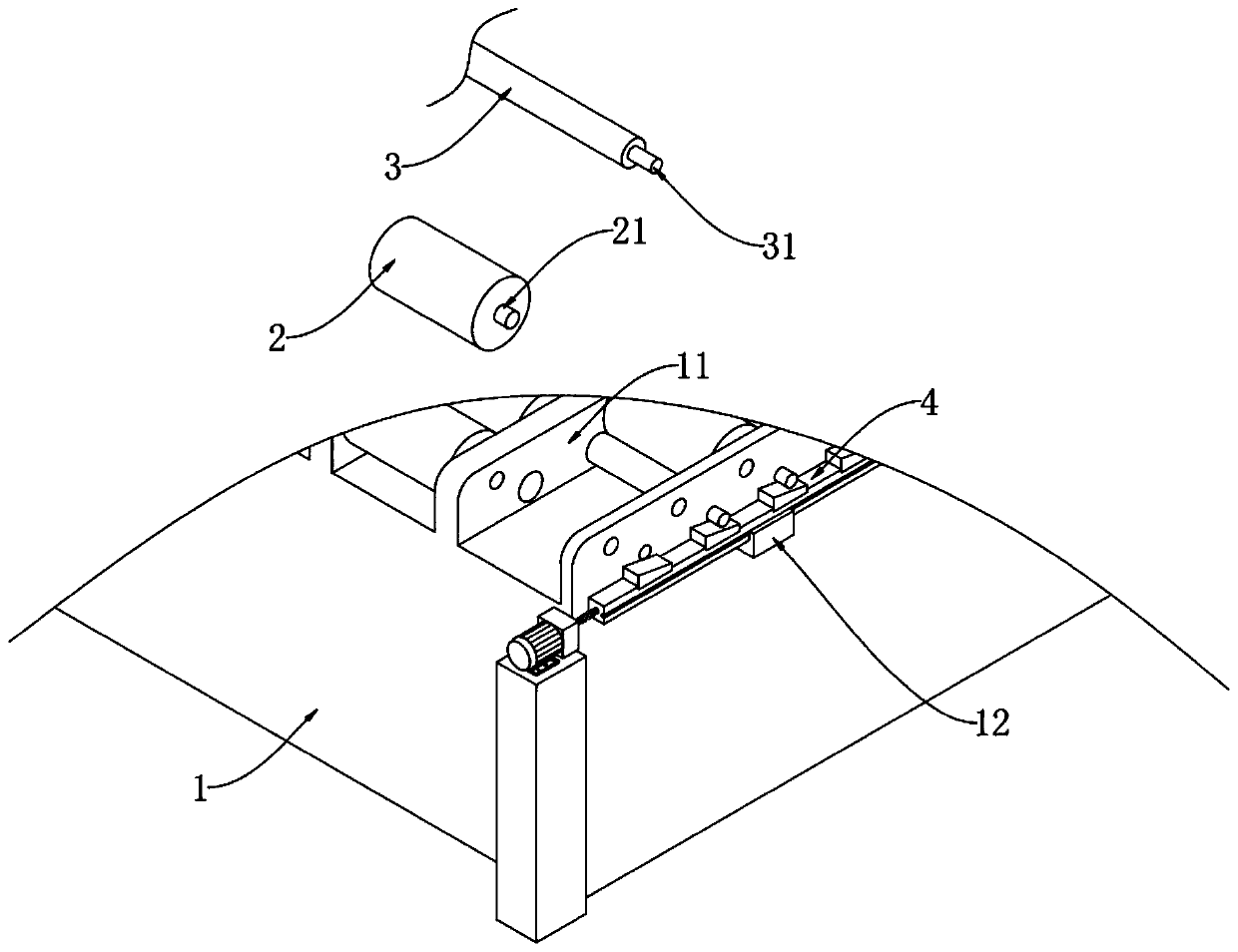

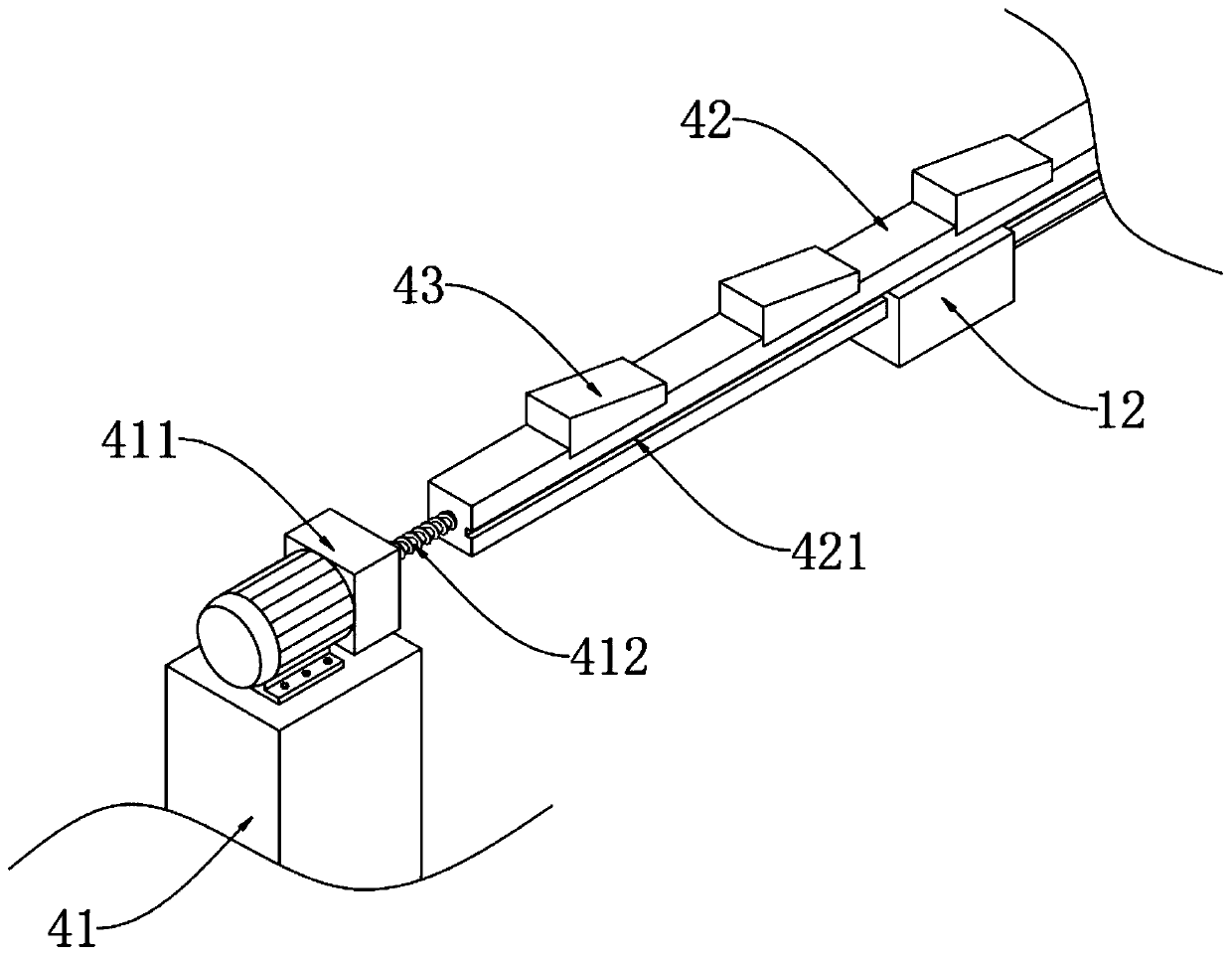

[0028] This embodiment provides a crawler tractor production track anti-skid performance detection device, such as Figure 1-Figure 3 As shown, including the test bench 1, the top of the test bench 1 is tightly welded with several rows of bearing bosses 11 arranged at equal intervals, and several rows of rollers 2 are rotatably connected between the adjacent two columns of bearing bosses 11. The supporting column 3 is arranged between two adjacent rows of rollers 2. The right end of the supporting column 3 is tightly welded with a rotating shaft 31, and the rotating shaft 31 protrudes from the side end surface of the rightmost bearing boss 11. A control device 4 is arranged at the place, and the control device 4 includes a base 41 tightly welded at the corner of the test bench 1, a sliding post 42 installed on the right end of the test bench 1 and slidingly connected with the test bench 1, and a sliding post 42 mounted on the sliding post 42 by bolts. Some stop blocks 43 at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com