A dual-axis vibrating mirror

A shaft vibration and bearing technology, applied in the laser field, can solve the problems of reduced life of the galvanometer, low stiffness of the torsion beam, and the influence of the vibration of the galvanometer, and achieve the effect of increasing the range of the rotation angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

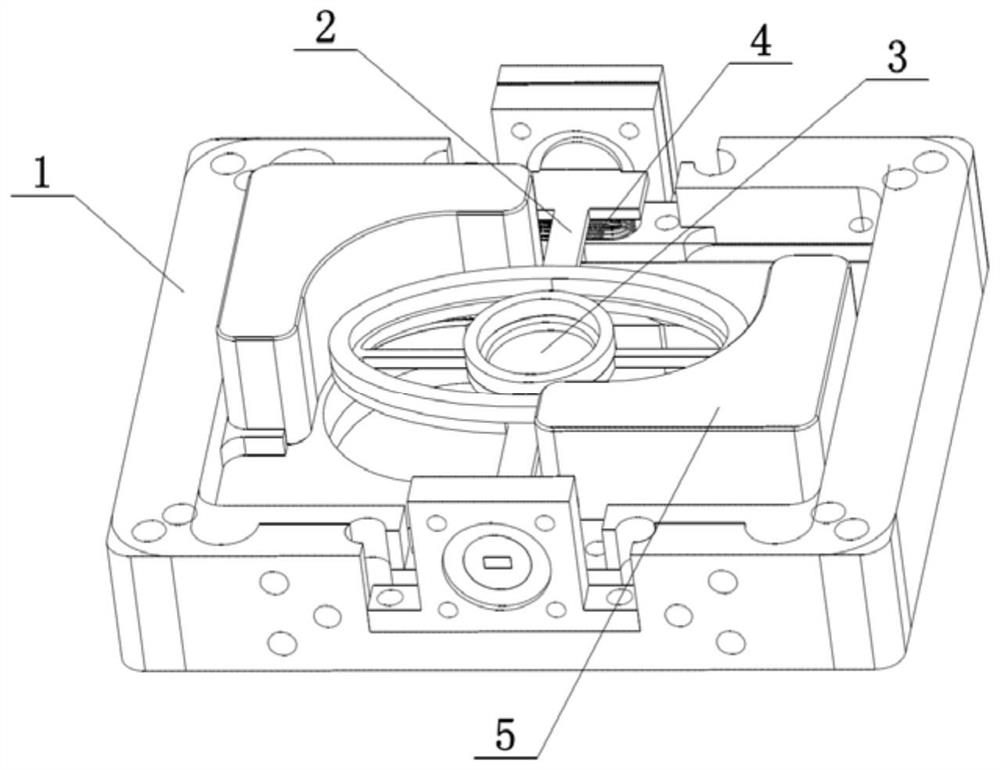

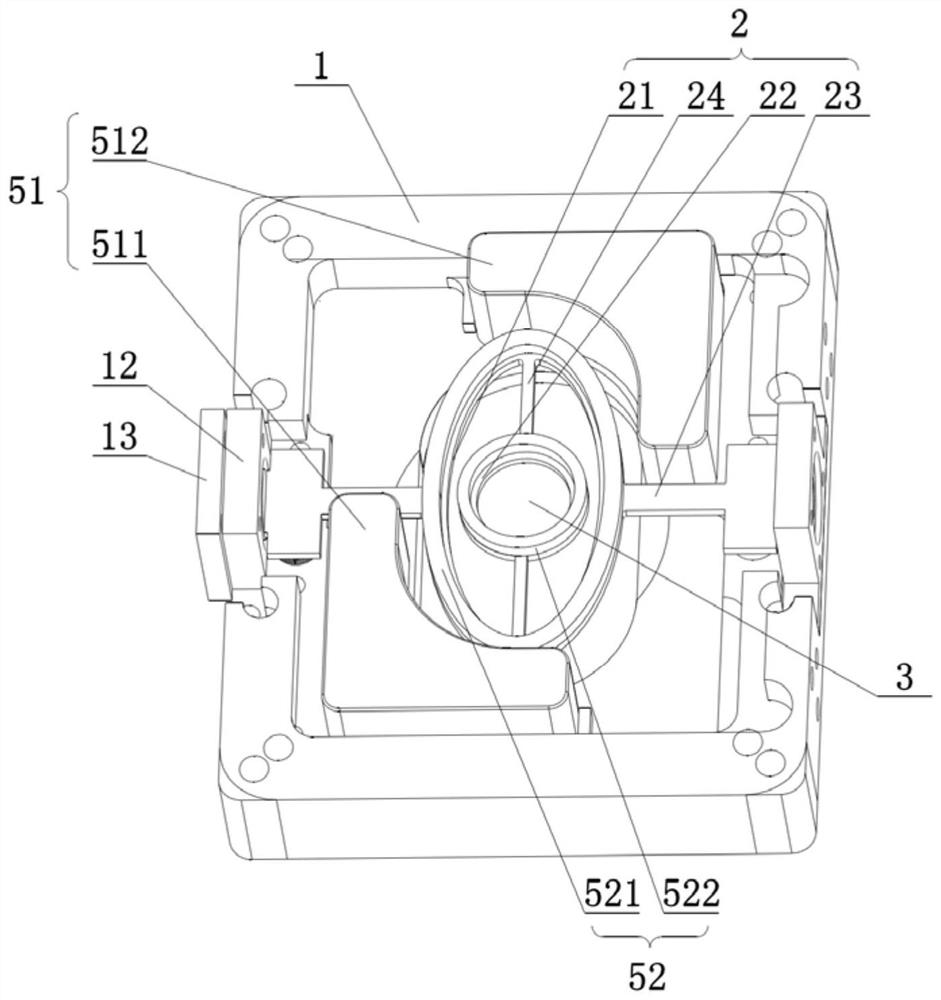

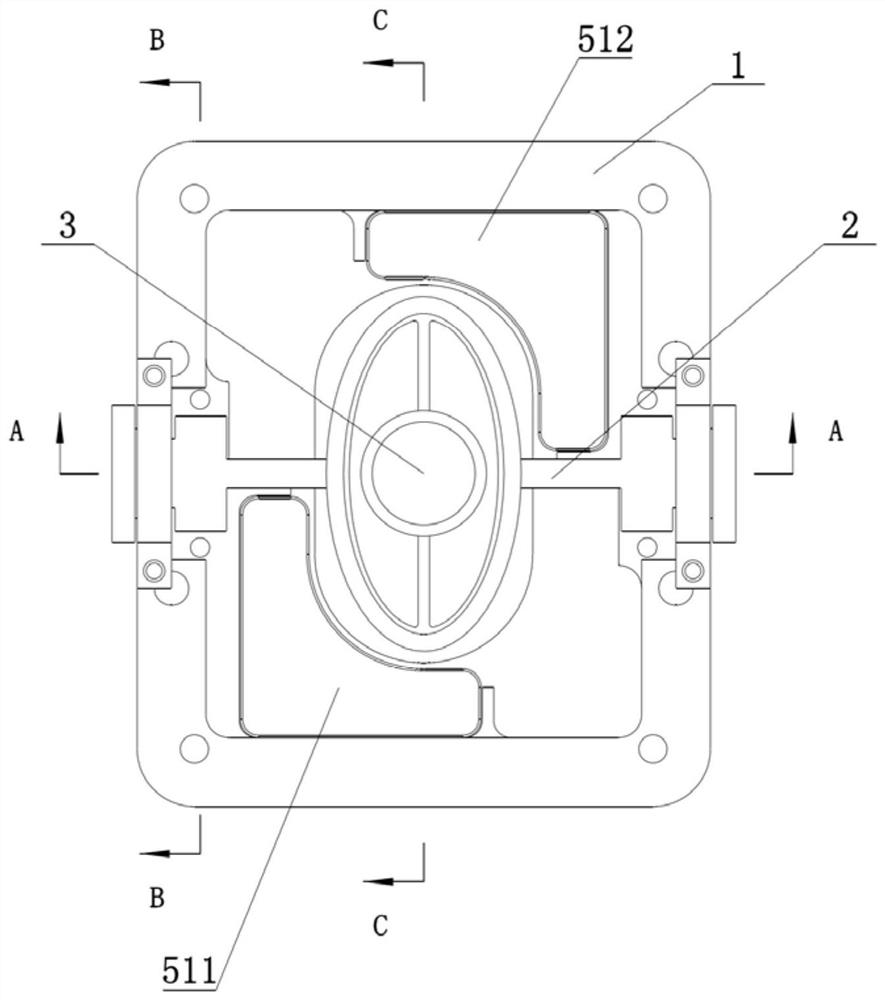

[0045] Such as Figure 1-Figure 6 As shown, this embodiment provides a two-axis vibrating mirror, including a fixing seat 1 , a support frame 2 , a mirror 3 , a reset device 4 and a driving device 5 . Wherein, the support frame 2 includes an outer frame 21, an inner frame 22, an outer support beam 23 and an inner support beam 24, the outer support beam 23 and the inner support beam 24 are perpendicular to each other, the outer frame 21 is connected to the outer support beam 23, and the outer support beam 23 Rotationally connected to the fixed seat 1, the inner frame 22 is connected to the outer frame 21 through the inner support beam 24, the reflector 3 is installed on the inner frame 22, the reset device 4 is respectively connected to the fixed seat 1 and the outer support beam 23, and the driving device 5 is set On the fixed seat 1 and the support frame 2, the support frame 2 and the reflector 3 can be driven to rotate on the axis of the outer support beam 23, and the inner ...

Embodiment 2

[0060] Such as Figure 7-Figure 10 As shown, this embodiment provides a dual-axis galvanometer. For the sake of brevity, only the differences between the present embodiment and the first embodiment are described below. In this embodiment, the reset device 4 is a reset elastic piece, both ends of the reset elastic piece are connected to the fixing base 1, and the outer support beam 23 is connected to the middle part of the reset elastic piece.

[0061] Specifically, the extension direction of the reset elastic piece is perpendicular to the outer support beam 23, and the extension lengths on both sides are symmetrical with respect to the shaft seat 12. The fixed block 15 is arranged on the fixed seat 1, and the two ends of the reset elastic piece are fixed on the fixed side by screws. Between the block 15 and the fixed seat 1.

[0062] More specifically, each section of the outer supporting beam 23 is correspondingly connected with a reset elastic piece, and each reset elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com