Tire burst safety guaranteeing auxiliary device applicable to four-driven unmanned mine truck

An auxiliary device and a safe technology, applied in the direction of vehicle cleaning equipment, etc., can solve the problems of high requirements on the manufacturing and processing precision of hydraulic components, not considering uneven load distribution, and not fully considering the danger of tires, etc., to achieve load transfer and movement. The law is easy to control, and the effect of increasing the lateral and longitudinal maximum tire force value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

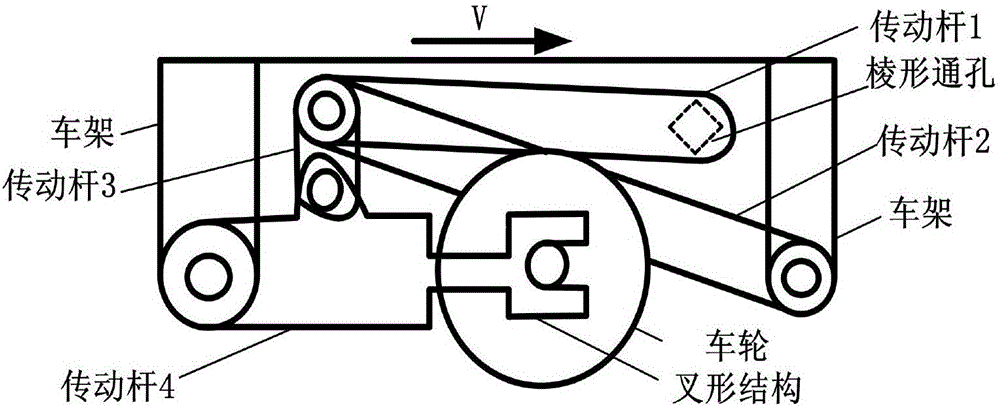

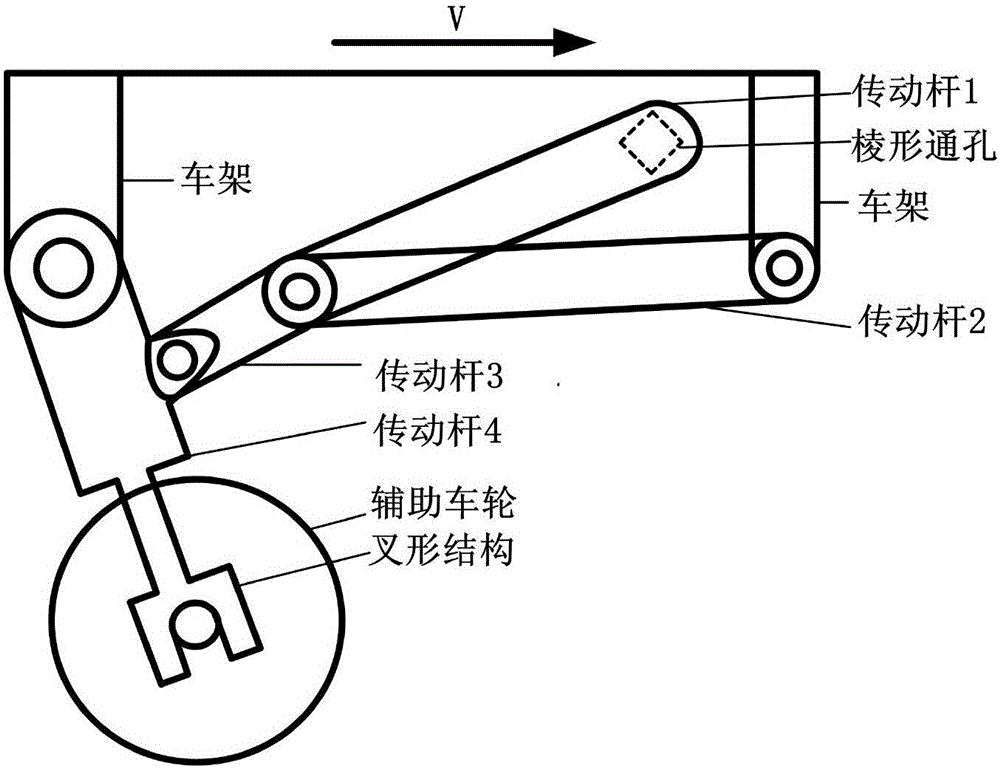

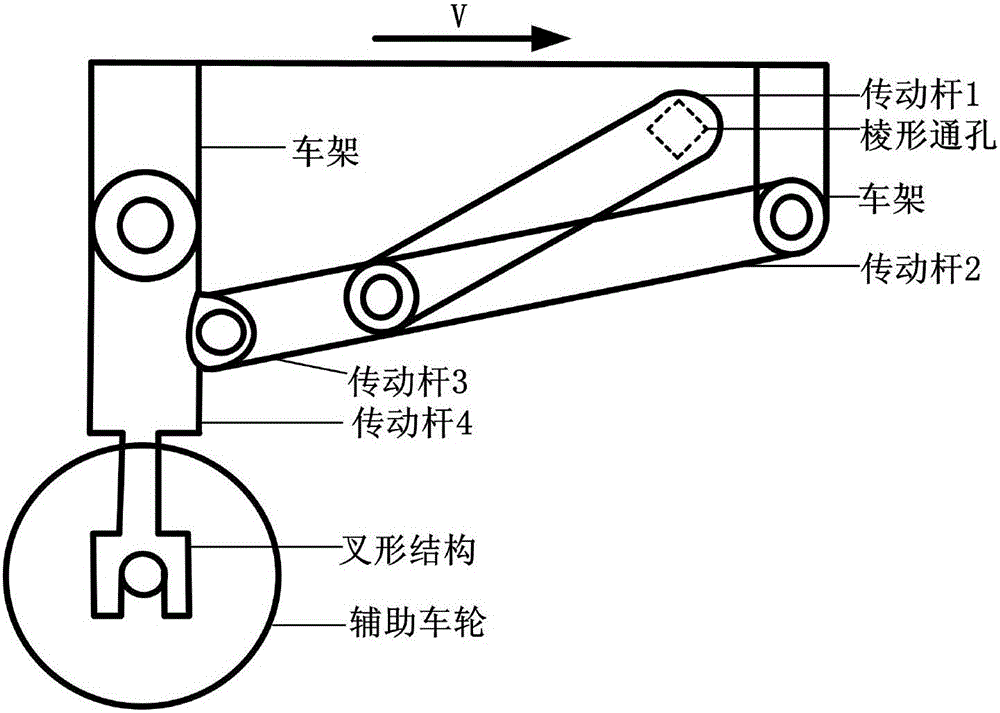

[0030] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] refer to figure 1 , the whole tire blowout safety auxiliary device includes a driving mechanism, a transmission mechanism, a connecting structure and auxiliary wheels. The driving mechanism adopts a motor, and the motor is installed and fixed on the chassis through bolts as the power source of the safety auxiliary device; the transmission mechanism adopts a rod system, including 4 transmission rods; the connection structure adopts a hinged structure, which is used for fixing the safety auxiliary device and various mechanisms The connection between them realizes the relative position change of the transmission rod system; the auxiliary wheel adopts the wheel equipped with the hub drive motor and is installed on the fork mechanism. The reverse rotation of the auxiliary wheel provides part of the braking force; the applicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com