Photoelectric single-spindle monitoring device and detection method

A monitoring device and photoelectric technology, applied in the field of spinning, can solve the problems of uncontrollable ring spinning, low efficiency of spinning frame, and inability to effectively improve yarn productivity and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

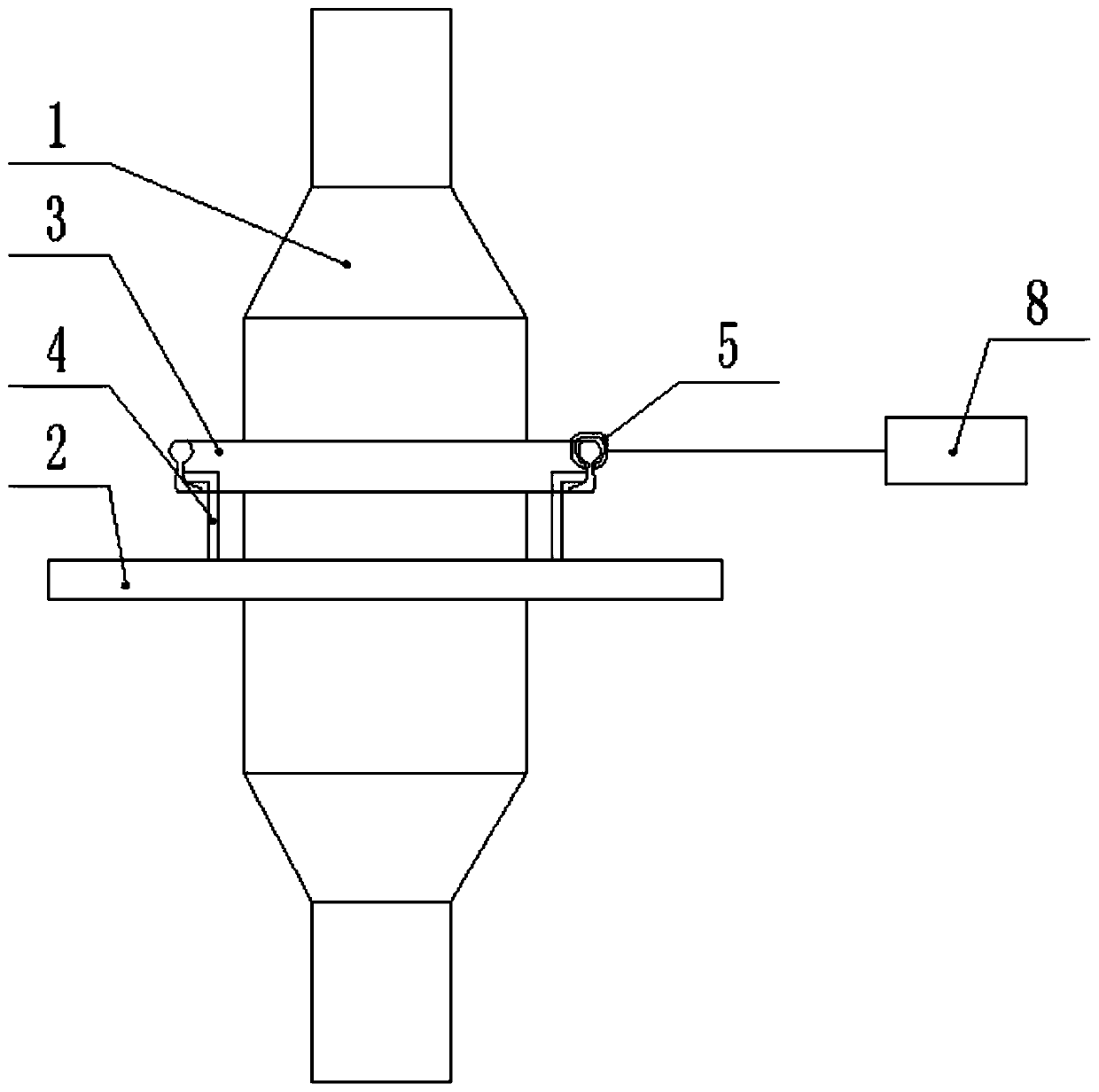

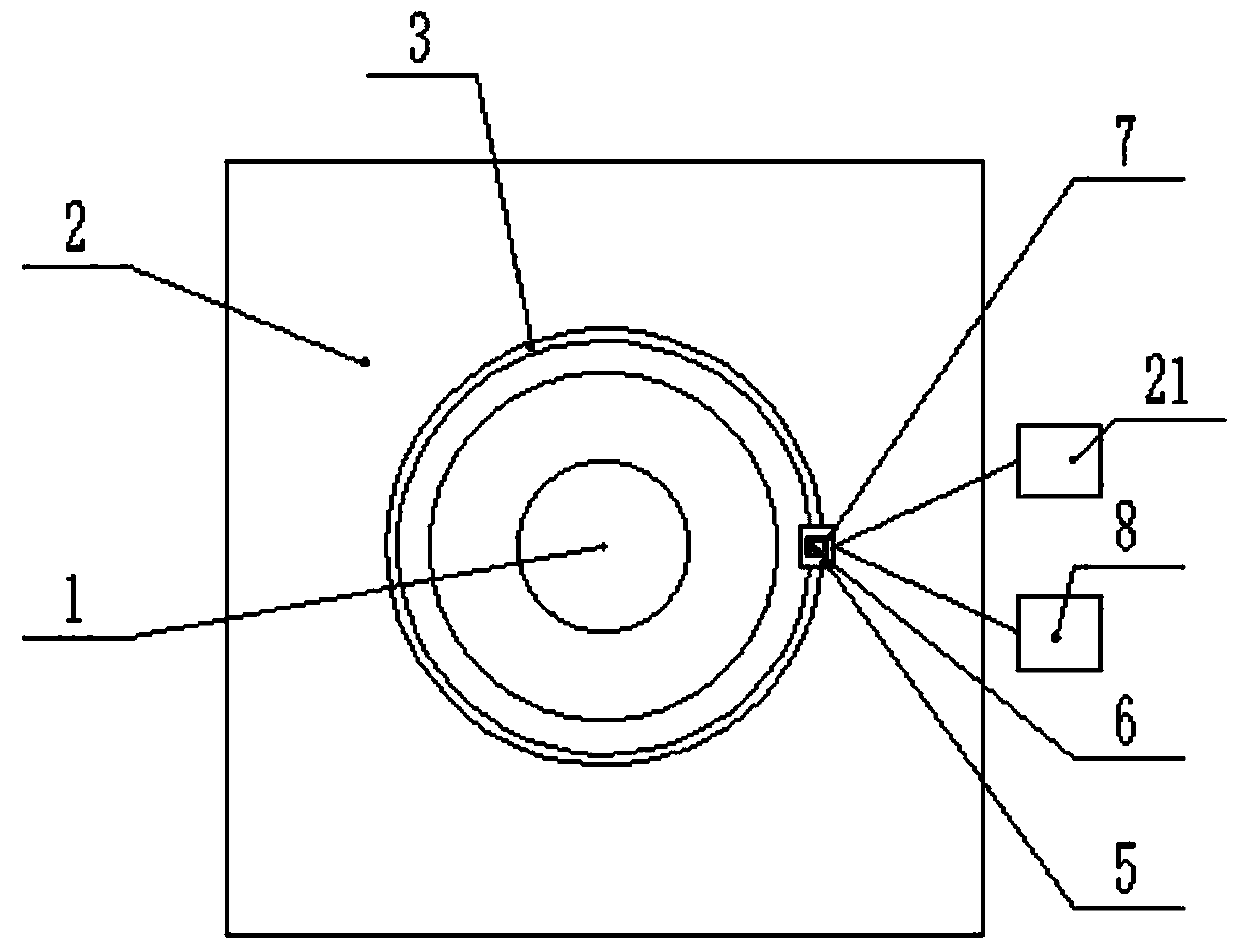

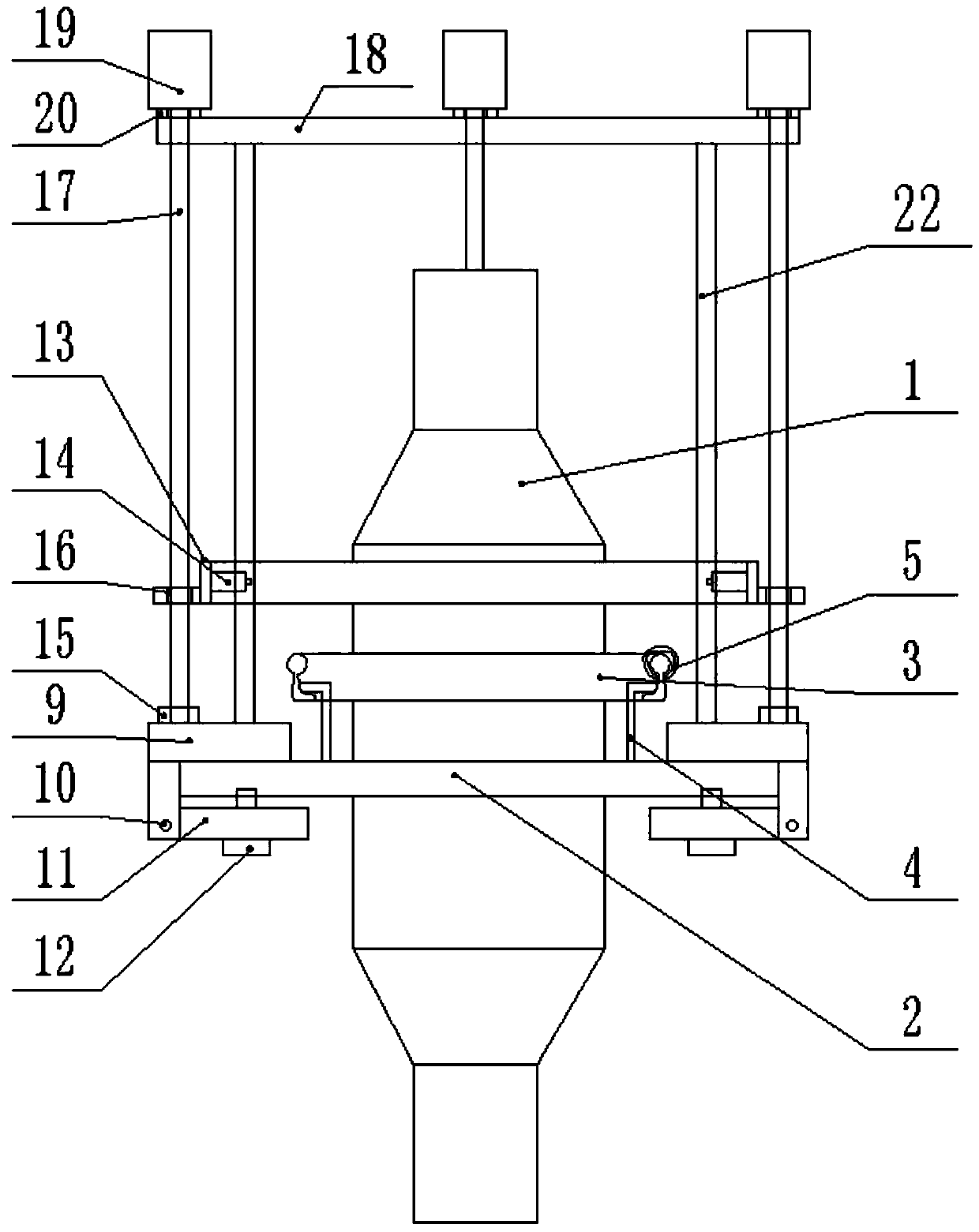

[0038] refer to Figure 1-6, a photoelectric single-spindle monitoring device, including a support plate 2, the support plate 2 includes a first plate body 201, and the center of the first plate body 201 is provided with a first installation hole 202 for passing through the bobbin 1, The periphery of the first installation hole 202 at the upper end of the first plate body 201 is fixed with a steel ring 3 through the support seat 4, a steel ring 5 is installed on the steel ring 3, and an infrared emitter 8 is installed on one side of the support plate 2 and an infrared receiver 21, a concentric detection device is detachably installed on the support plate 2, and the concentric detection device includes a fixed plate 9, and a plurality of support rods 22 are fixed on the upper end of the fixed plate 9, and the upper ends of the support rods 22 A mounting plate 18 is fixed, a stepper motor 19 is installed on the upper end of the mounting plate 18, the output shaft of the stepping...

Embodiment 2

[0040] refer to Figure 1-6 , a photoelectric single-spindle monitoring device, including a support plate 2, the support plate 2 includes a first plate body 201, and the center of the first plate body 201 is provided with a first installation hole 202 for passing through the bobbin 1, The periphery of the first installation hole 202 at the upper end of the first plate body 201 is fixed with a steel ring 3 through the support seat 4, a steel ring 5 is installed on the steel ring 3, and an infrared emitter 8 is installed on one side of the support plate 2 and an infrared receiver 21, a concentric detection device is detachably installed on the support plate 2, and the concentric detection device includes a fixed plate 9, and a plurality of support rods 22 are fixed on the upper end of the fixed plate 9, and the upper ends of the support rods 22 A mounting plate 18 is fixed, a stepper motor 19 is installed on the upper end of the mounting plate 18, the output shaft of the steppin...

Embodiment 3

[0043] refer to Figure 1-6 , a photoelectric single-spindle monitoring device, including a support plate 2, the support plate 2 includes a first plate body 201, and the center of the first plate body 201 is provided with a first installation hole 202 for passing through the bobbin 1, The periphery of the first installation hole 202 at the upper end of the first plate body 201 is fixed with a steel ring 3 through the support seat 4, a steel ring 5 is installed on the steel ring 3, and an infrared emitter 8 is installed on one side of the support plate 2 and an infrared receiver 21, a concentric detection device is detachably installed on the support plate 2, and the concentric detection device includes a fixed plate 9, and a plurality of support rods 22 are fixed on the upper end of the fixed plate 9, and the upper ends of the support rods 22 A mounting plate 18 is fixed, a stepper motor 19 is installed on the upper end of the mounting plate 18, the output shaft of the steppin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com