Vehicle-mounted anti-shake deploying and controlling ball

An anti-shake and motor control technology, applied to vehicle parts, TVs, color TV parts, etc., can solve problems such as inability to solve vehicle equipment shakes, image shakes, and difficulty in capturing license plate targets, etc., to achieve mechanical anti-shake Shake function, improved image stabilization accuracy, and good anti-shake performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

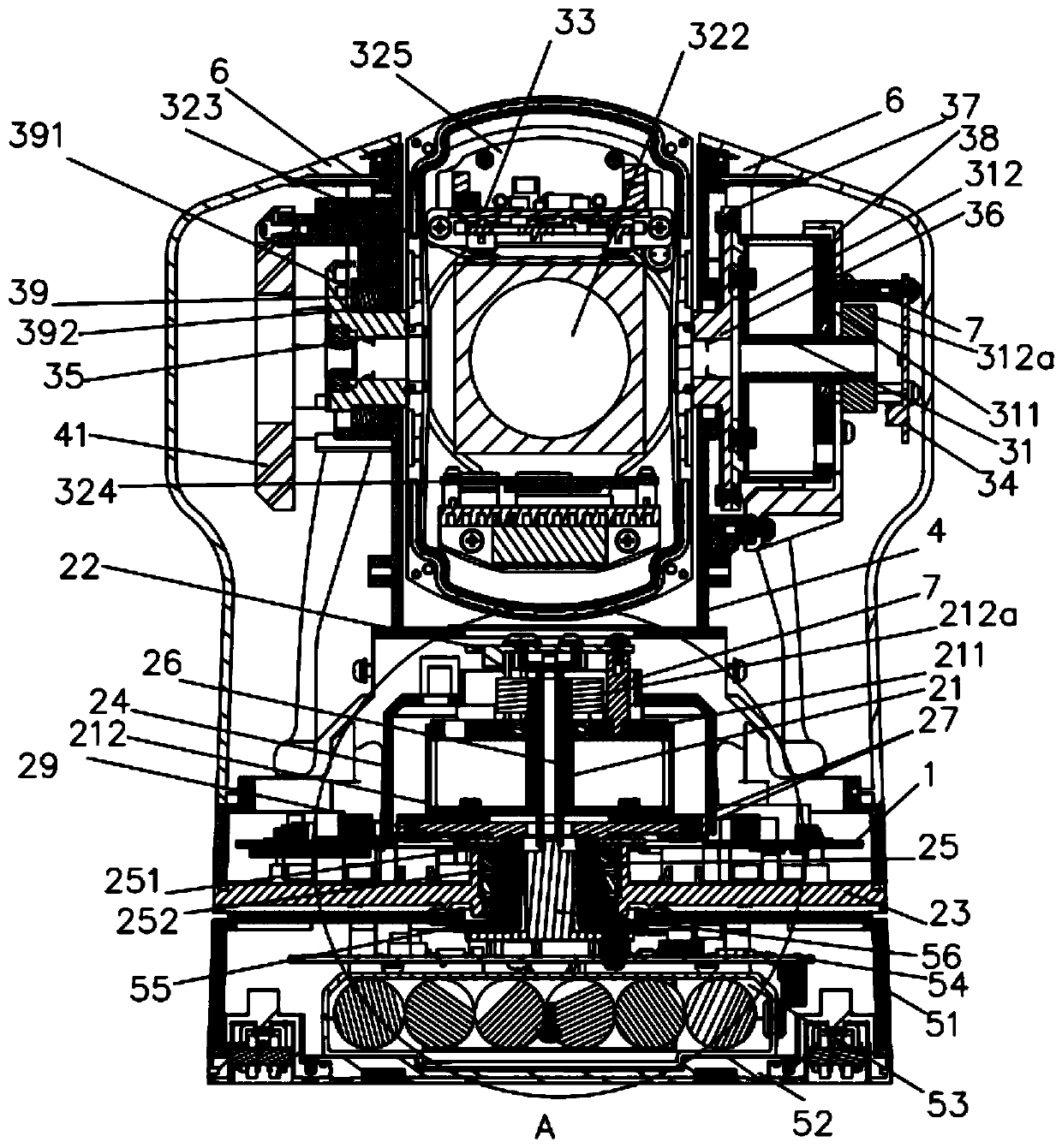

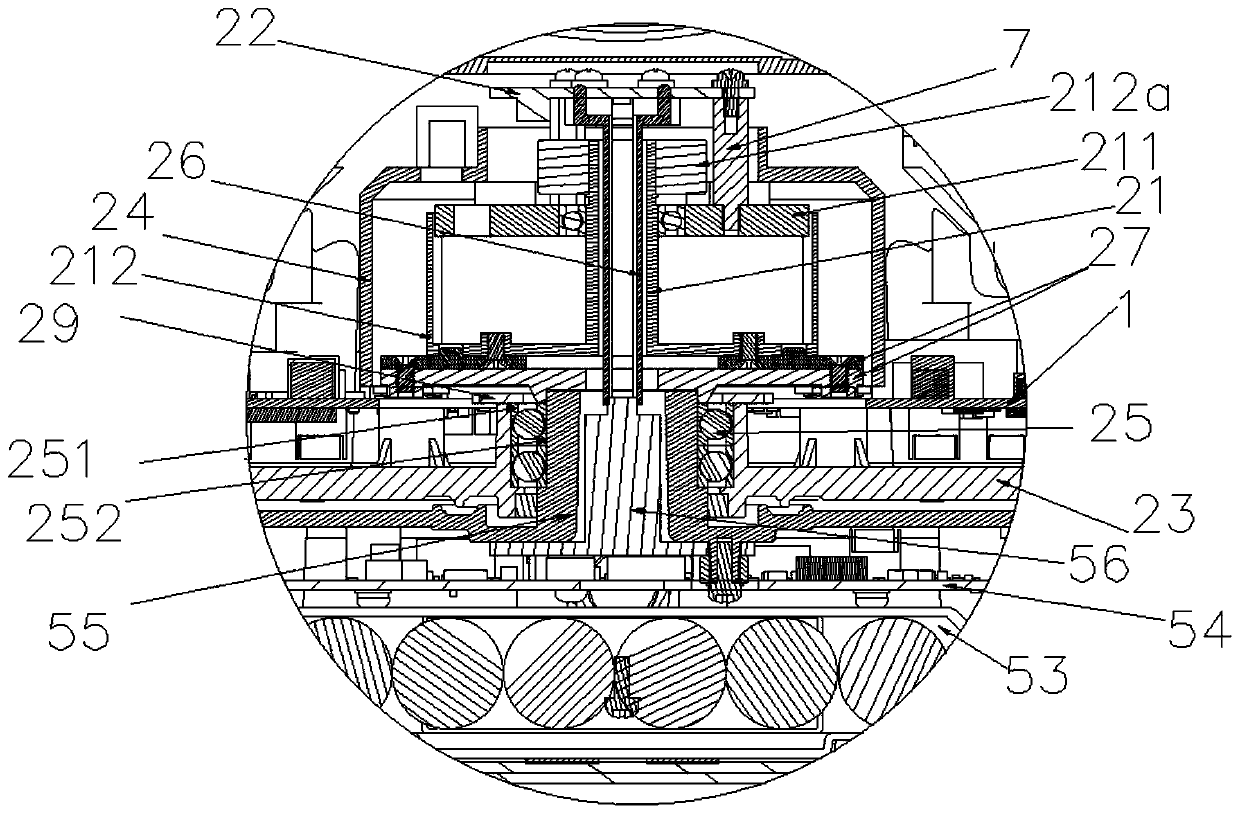

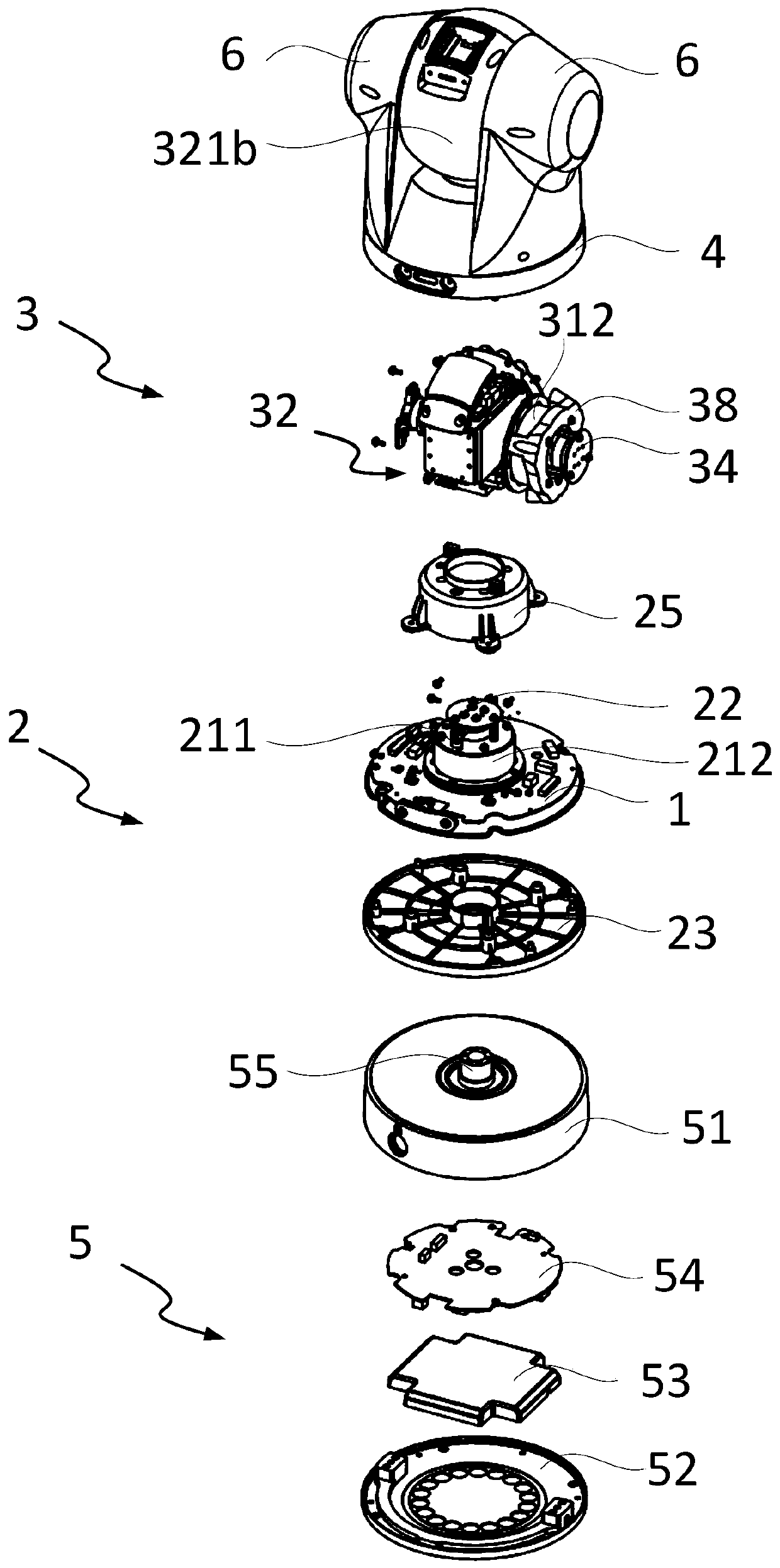

[0063] Such as figure 1 , 2 , 3, 4, and 5, the present invention provides a vehicle-mounted anti-shake cloth ball control, including an anti-shake movement assembly and a base assembly 5 for mounting on the vehicle surface, the anti-shake movement assembly and the base assembly 5 are in phase connection; among them,

[0064] The anti-shake motion assembly includes a motor control board 1, a motor, a detection unit connected to the motor for obtaining the rotational position of the motor, and a lens structure 32. The motor control board 1 is provided with a single-chip microcomputer, and inside the lens structure 32 A movement adapter plate 33 is provided, and a gyroscope for obtaining the position of the current anti-shake motion component is arranged on the movement adapter plate 33;

[0065] The motor control board 1 obtains a deviation value by comparing the position signal of the detection unit with the position signal of the gyroscope, so that the motor compensates for ...

Embodiment 2

[0099] The anti-shake movement assembly does not include a horizontal rotation assembly 2, the water rotation assembly 2 is connected to the anti-shake movement assembly, and the first motor 21 is not connected with a detection unit for detecting the rotational position of the first motor 21 The first magnetic encoding control board 22, the first magnet 212a, and other technical features are the same as those in Embodiment 1.

[0100] The gyroscope is used to detect the position deviation of the vertical rotation assembly 3 and transmit the position deviation information to the TI F28069 single-chip microcomputer on the motor control board, and the single-chip microcomputer receives the vertical position detected by the MA732 magnetic encoder on the second magnetic coding control board 34 in real time. The position information of the rotating assembly 3 is compared and calculated with the position deviation information of the vertical rotating assembly 3 transmitted by the gyro...

Embodiment 3

[0102] The anti-shake movement assembly does not include a vertical rotation assembly 3, the vertical rotation assembly 3 is connected to the anti-shake movement assembly, and the second motor 31 is not connected with a detection unit for detecting the rotational position of the second motor 31 The second magnetic encoding control board 34, the second magnet 312a, and other technical features are the same as those in Embodiment 1.

[0103] The gyroscope is used to detect the position deviation of the horizontal rotation assembly 2 and transmit the position deviation information to the TI F28069 single-chip microcomputer on the motor control board, and the single-chip microcomputer receives the level detected by the MA732 magnetic encoder on the first magnetic coding control board 22 in real time. The position information of the rotating assembly 2 is compared and calculated with the position deviation information of the horizontal rotating assembly 2 transmitted by the gyroscop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com