Method for determining ultimate bearing capacity of gravel pile

A technology of ultimate bearing capacity and determination method, applied in soil protection, special data processing applications, instruments, etc., can solve the problems of inconsistent calculation accuracy, inconsistent results, and failure to consider the effect of the self-weight of the foundation soil on the ultimate load of the pile body, etc. problem, to achieve a clear effect of mechanical analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

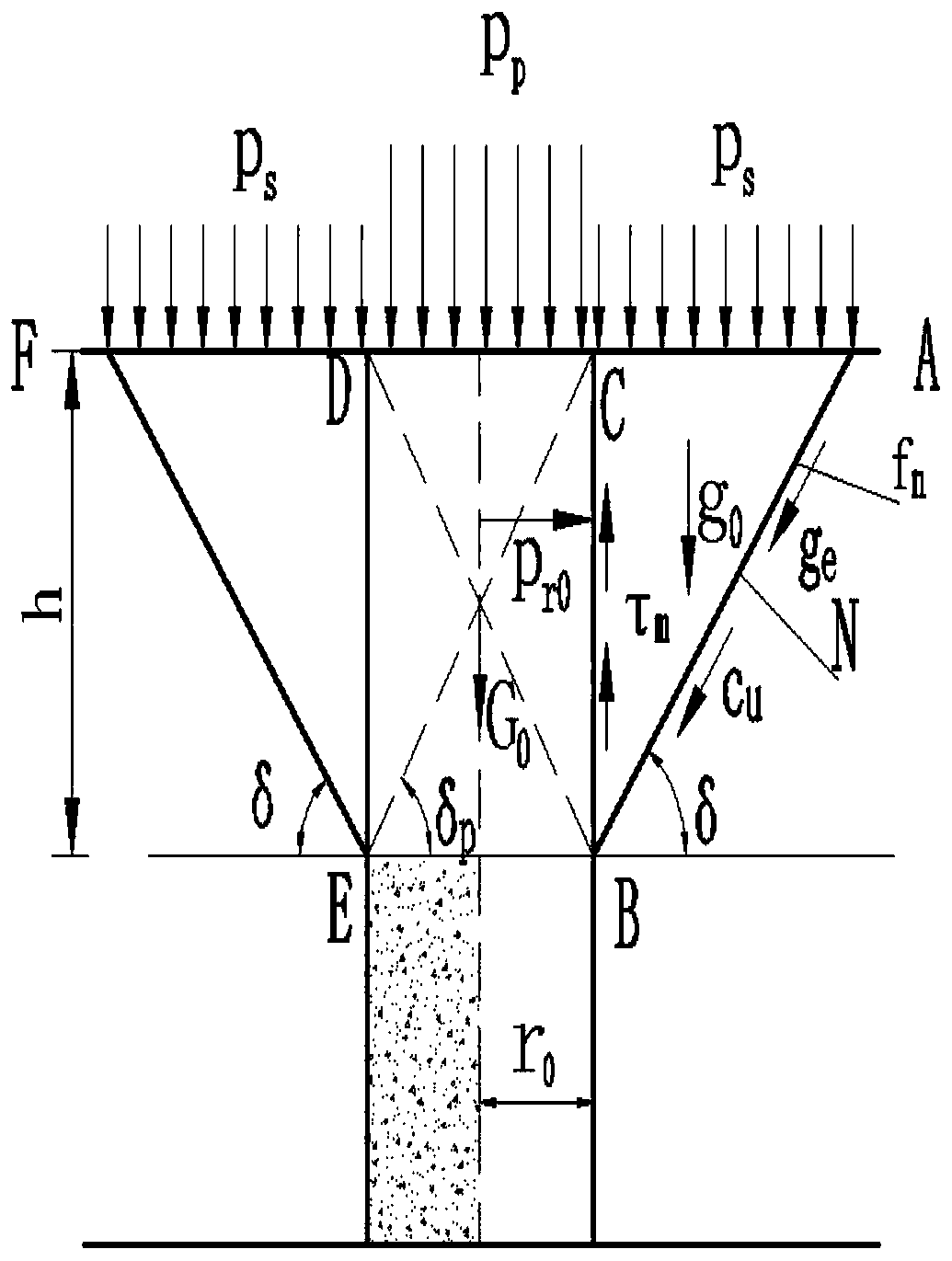

[0052] A specific embodiment of the present invention, a method for determining the ultimate bearing capacity of gravel piles, comprises the following steps:

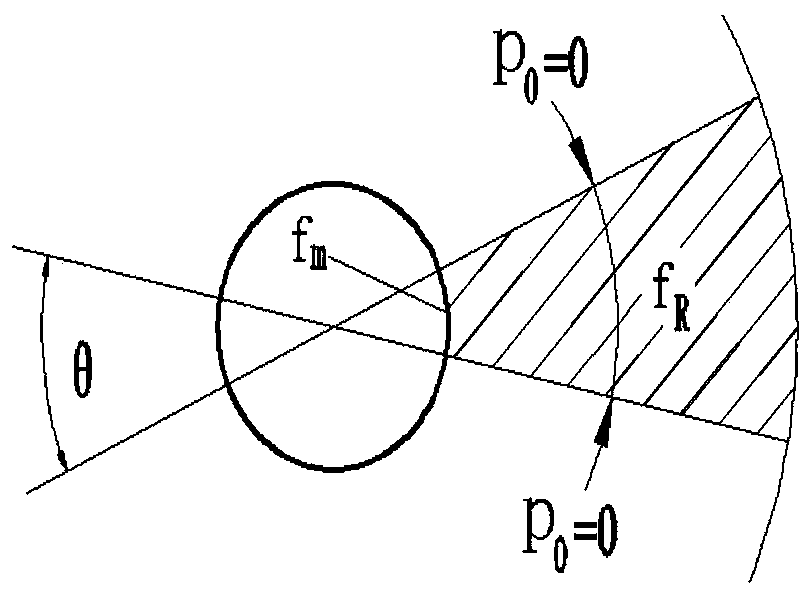

[0053] A. The inclination angle of the failure surface of the gravel pile

[0054] Calculation of the inclination angle δ of the failure surface of the pile body when the gravel pile is damaged by swelling p :

[0055]

[0056] In the formula, is the internal friction angle of the gravel pile;

[0057] B. Dip angle of failure surface of soil between piles

[0058] According to step A, the inclination angle δ of the failure surface of the pile body when the bulging failure of the gravel pile occurs p , according to the formula (2) to calculate the inclination angle δ of the failure surface of the soil between the piles when the bulging failure of the gravel pile occurs:

[0059]

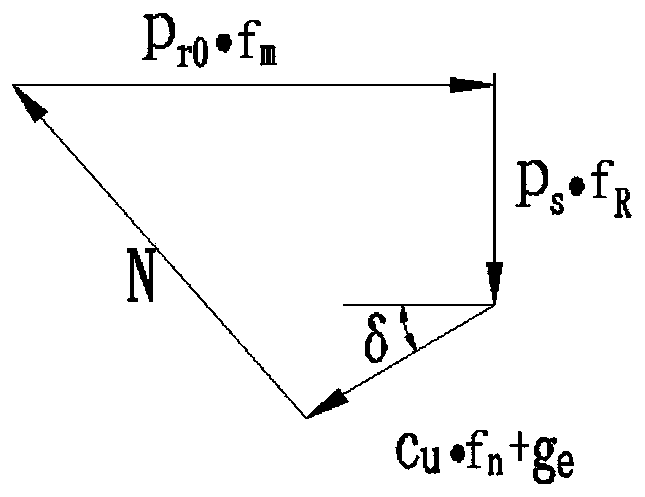

[0060] C. Determine the ultimate bearing capacity of a single pile of gravel piles

[0061] According to the inclination angle δ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com