Anti-falling mechanism suitable for suspension type vertical fin dock

A vertical tail dock and suspension technology, applied in the field of anti-drop mechanism, can solve the problems of complicated riveting operation process and safety accidents, and achieve the effect of avoiding locking operation process, ensuring safety and avoiding instantaneous impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

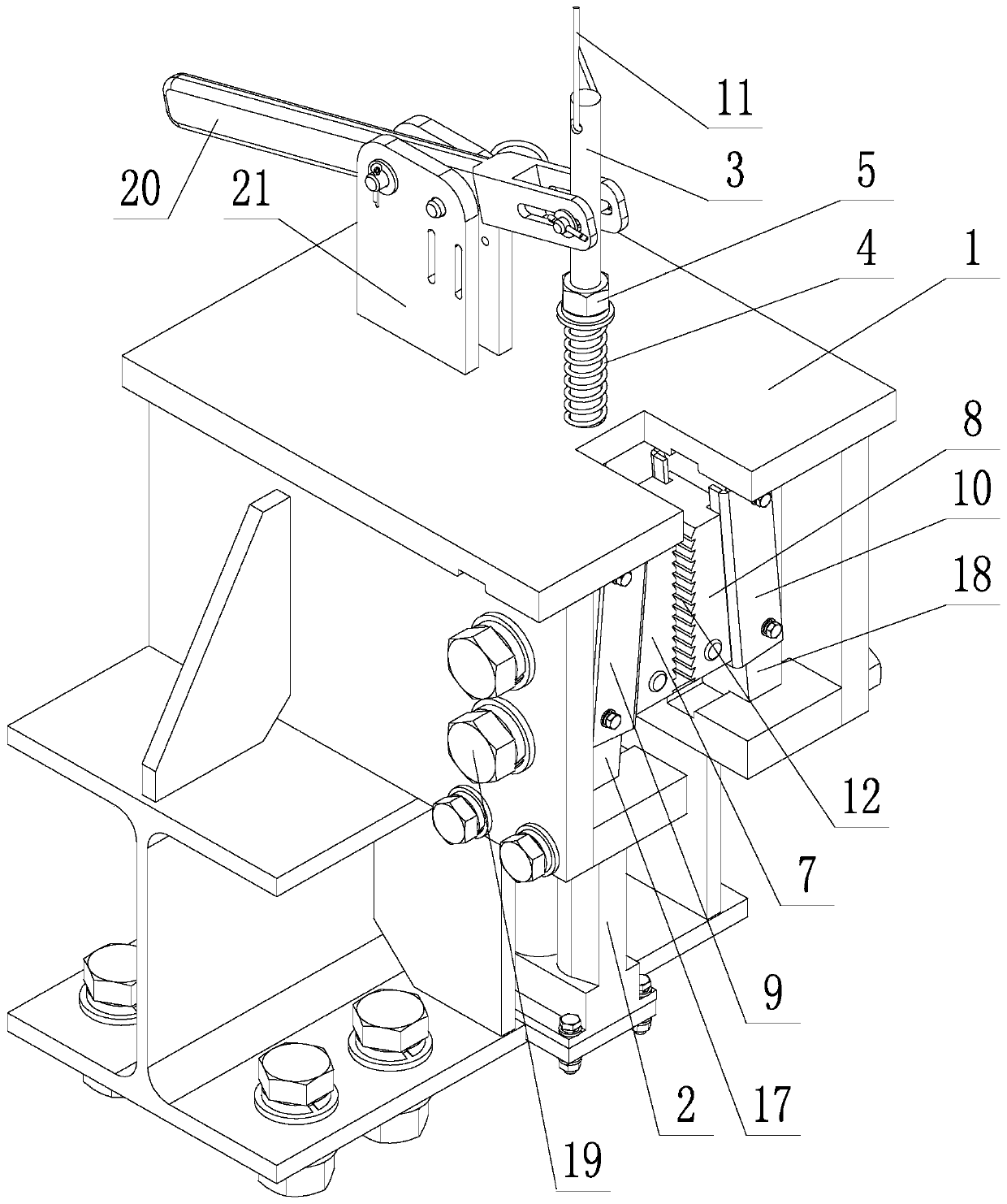

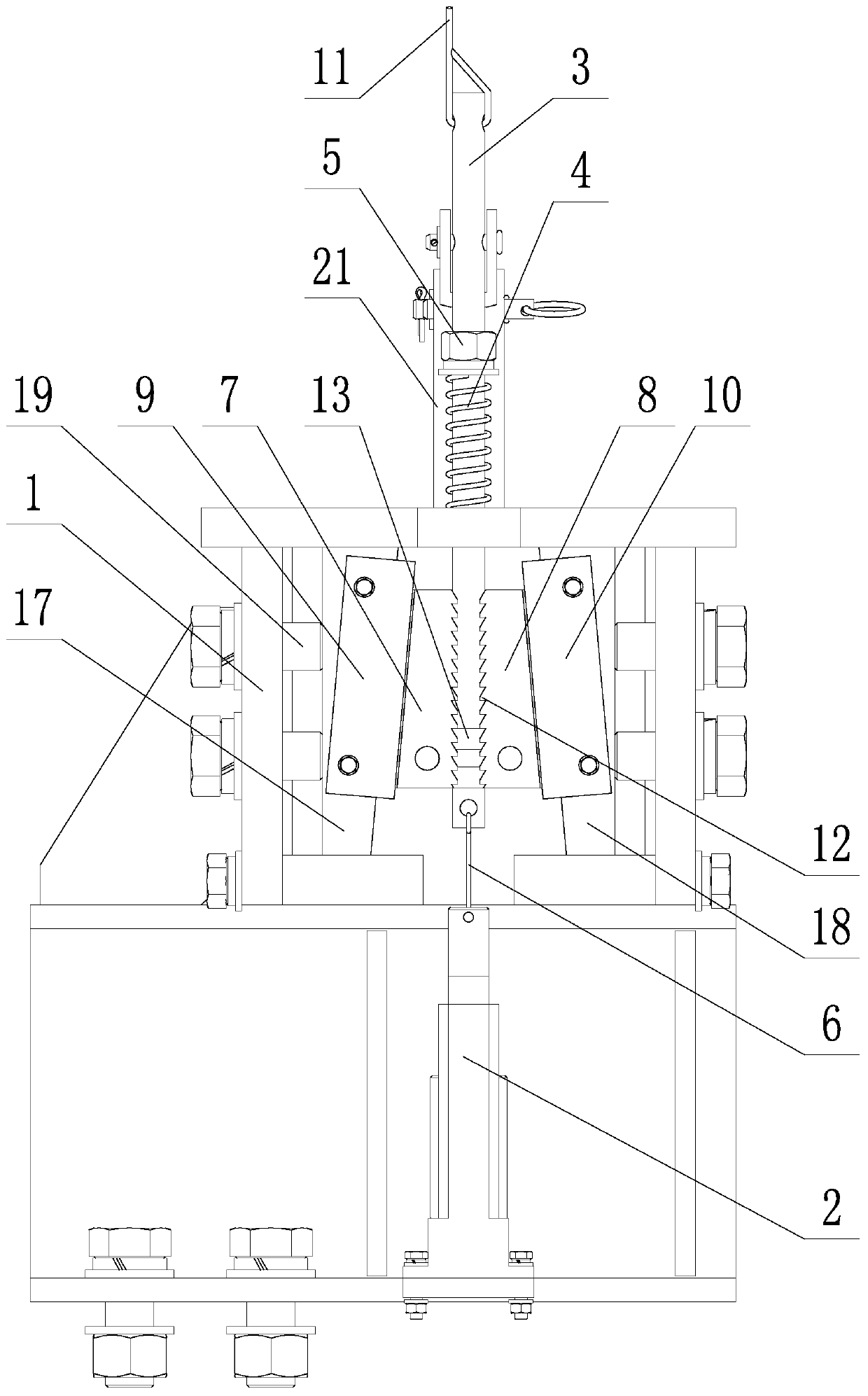

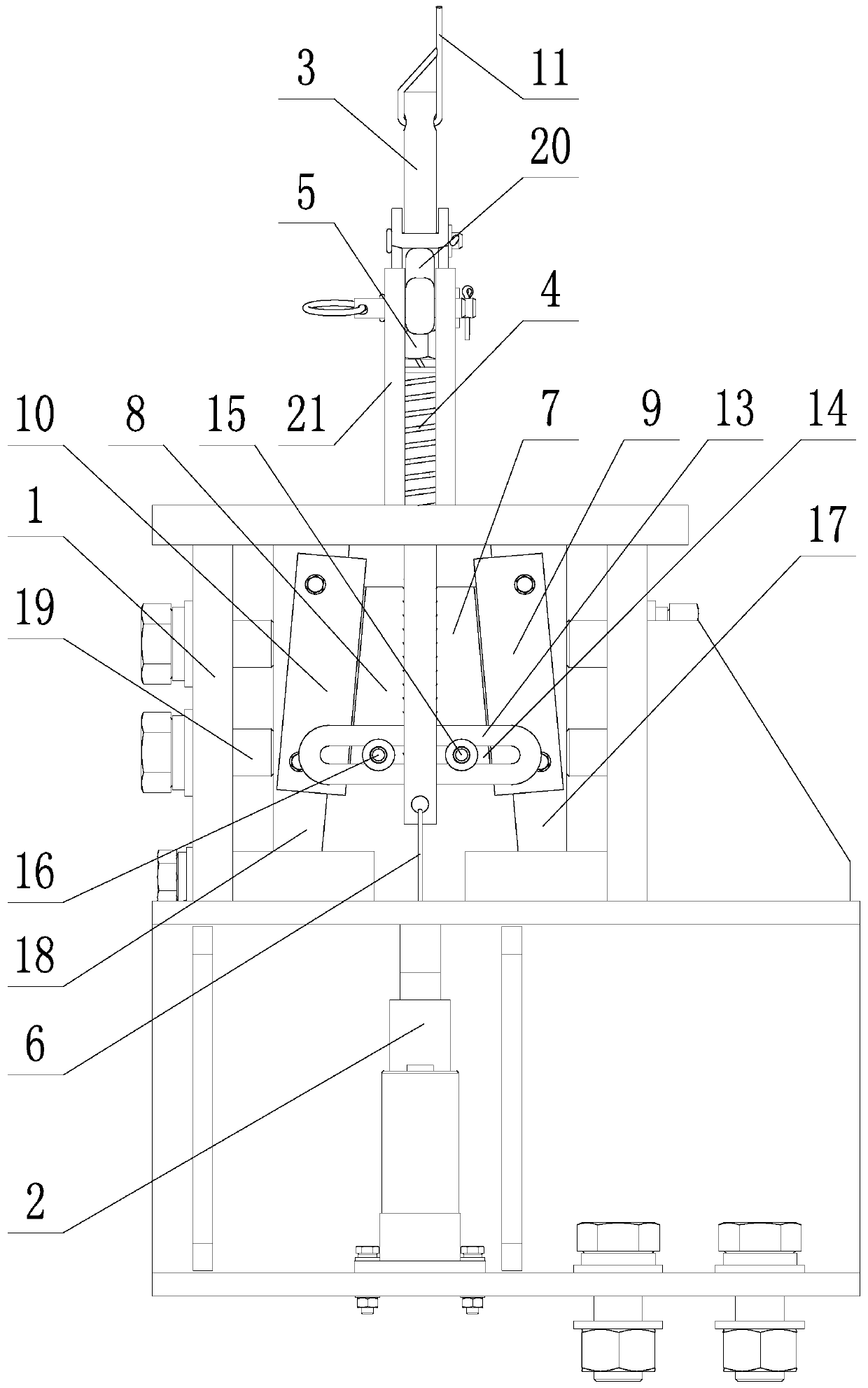

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] like Figure 1-3 As shown, an anti-drop mechanism suitable for a suspended vertical tail dock includes a frame 1, an electric push rod 2, a pull rod 3, a thrust spring 4, a limit nut 5, a safety rope 6, and the first slider chuck 7. The second slider chuck 8, the first guide rail base 9 and the second guide rail base 10; the frame 1 is fixed on the main frame of the vertical tail dock, and the electric push rod 2 is vertically fixed on the The lower part of the frame 1 is provided with a tie rod penetration hole on the top wall of the frame 1. The pull rod 3 passes through the pull rod penetration hole vertically. The pull rod 3 coincides with the central axis of the electric push rod 2, and the lower end of the pull rod 3 passes The safety rope 6 is connected with the electric push rod 2, and the upper end of the pull rod 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com