Unloading device, round baler and discharging method

An unloading device, round bales bundling technology, applied in agricultural machinery and implements, packaging, application, etc., can solve problems such as time-consuming, and achieve the effect of shortening downtime, saving complex structure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

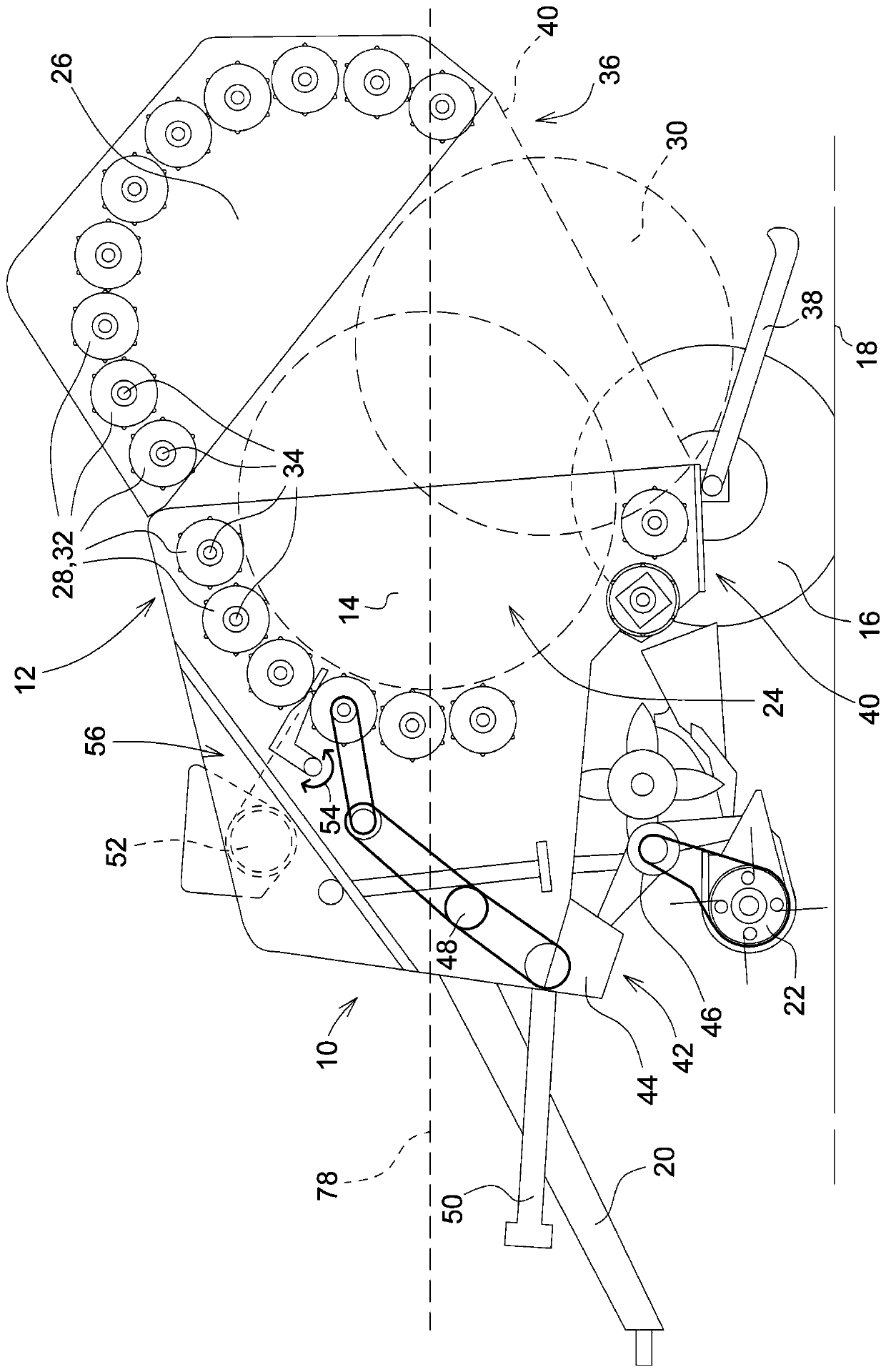

[0032] figure 1 A schematic view of a first embodiment of the inventive round baler is shown. figure 1 The shown baler 10 comprises a housing 12 with a housing part 14 which is supported on the ground 18 by means of wheels 16 and which is connectable by means of a traction shaft 20 to a tractor, not shown, such as a tractor or an agricultural tractor. tractor.

[0033] The receiving and supplying device 22 for harvest is situated on the front lower side of the housing part 14 , ie in the direction of or along the longitudinal axis, in particular in the forward travel direction of the baler 10 . The housing 12 also has a throwing valve 26 pivotally mounted on the housing part 14 about the throwing axis, the throwing valve being located at the rear upper corner of the housing part 14 . Distributed on the housing part 14 and the ejection valve 26 are drivable pressing elements 28 which delimit the baling chamber 24 on the peripheral side and by which the forming of the round ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com