Turnover box warehousing system

A turnover box and box body technology, which is applied in the field of intelligent vertical warehouse, can solve the problems of misjudging the size of the box stack and the high error rate of the turnover box storage control, and achieves the effect of solving the high error rate and accurate information tracking control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

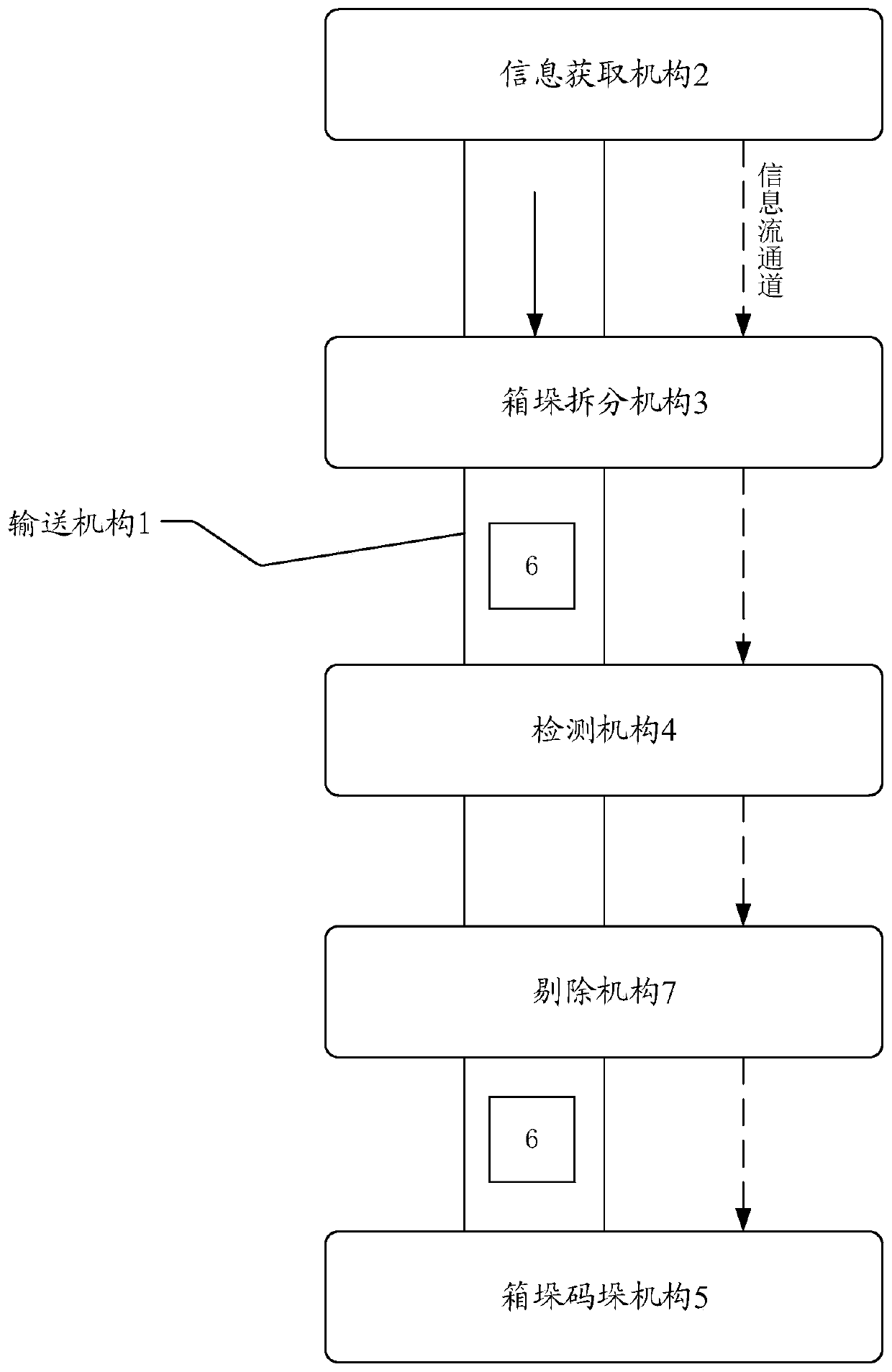

[0028] The embodiment of the present application provides a turnover box storage system, which is used in the existing method of determining the specification of the turnover box through the photoelectric detection device. In actual use, the photoelectric detection device is prone to misjudgment of the box stack size. The existing turnover box warehousing control has a technical problem of high error rate.

[0029] It should be noted that the existing turnover boxes are generally divided into small turnover boxes and large turnover boxes. The length and width of the small turnover box and the large turnover box are the same, but the height is different. The height of the small turnover box is 120cm, and the small turnover box Boxes generally form a box stack in groups of 6; the height of large turnover boxes is 200cm, and large turnover boxes generally form a box stack in groups of 3.

[0030] Based on the existing box type differences, the warehousing operations of different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com