A steel plate position tracking control system and method for a medium-thick plate heat treatment furnace

A heat treatment furnace, tracking control technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of being too simple, the human-computer interaction of steel plates in the furnace has not established a systematic and effective method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

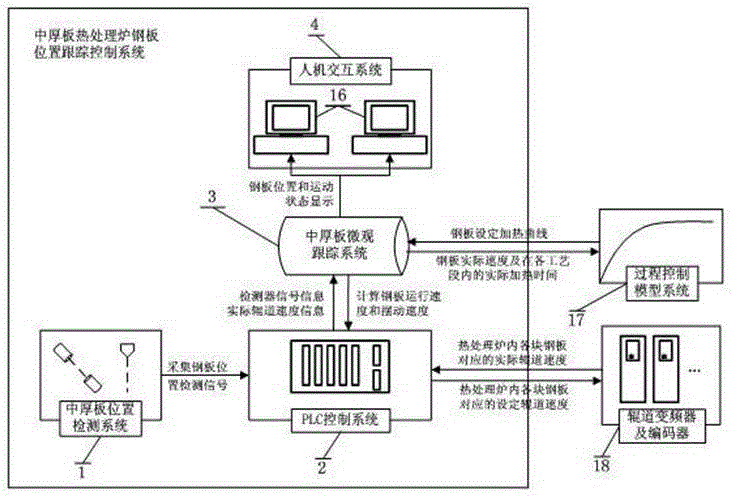

[0021] The steel plate position tracking control system of the medium-thick plate heat treatment furnace of the present invention is suitable for the medium-thick plate position tracking control in the medium-thick plate heat treatment furnace area, the logic control of the steel plate movement and the speed control of the heat treatment furnace roller table corresponding to the steel plate. The specific embodiment of the invention is described in detail:

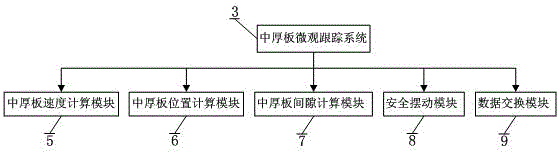

[0022] The steel plate position tracking control system in this example includes the plate position detection system 1, the PLC control system 2, the plate micro tracking system 3 and the human-computer interaction system 4, wherein the plate micro tracking system 3 also includes the plate speed Calculation module 5 , plate position calculation module 6 , plate gap calculation module 7 , safety swing module 8 and data exchange module 9 .

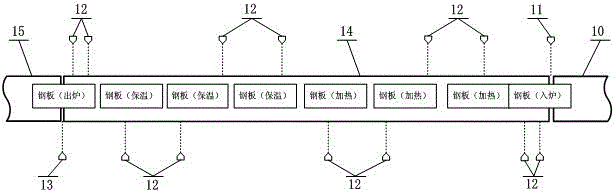

[0023] During normal production, medium and thick plates are made of figure 2 The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com