Conveying device for improving conveying efficiency of massive ore or coal

A transmission device and block technology, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of conveyor belts with baffle plates, potential safety hazards, and low transmission efficiency of conveyor belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

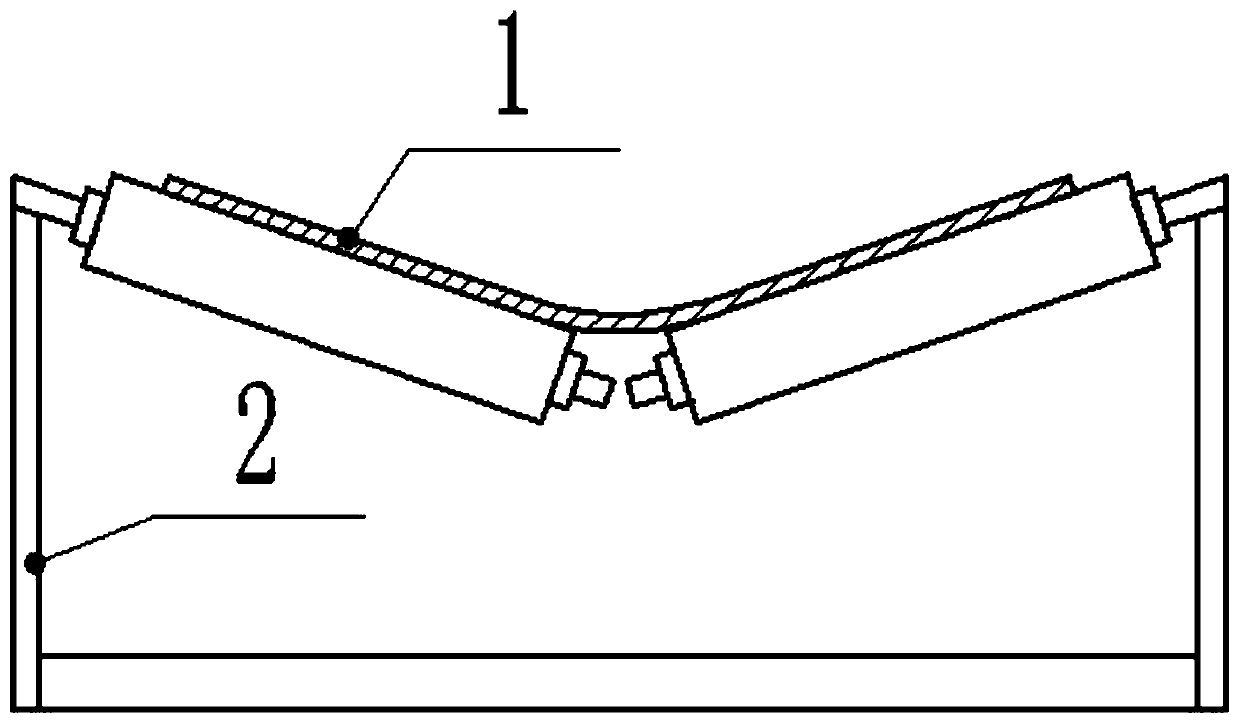

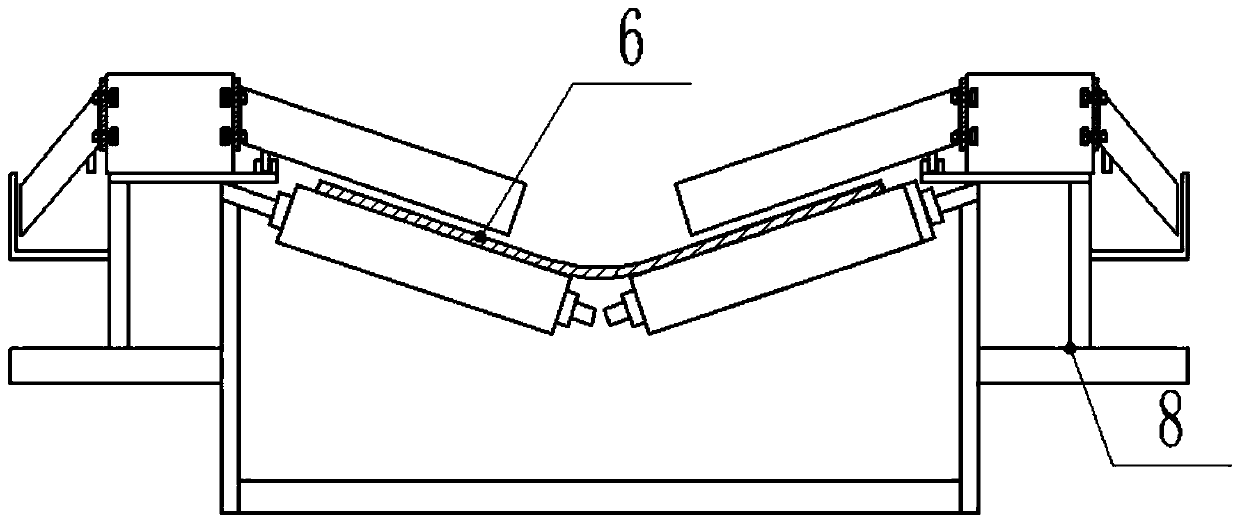

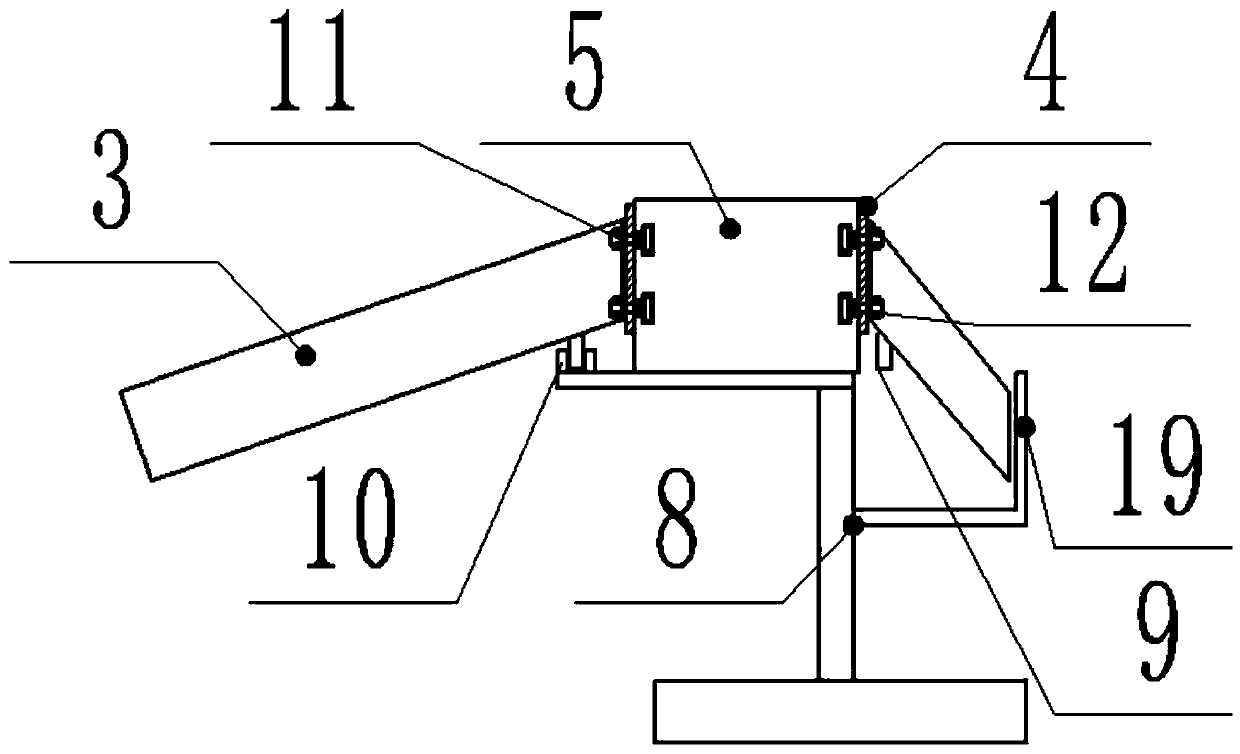

[0030] Such as Figure 1-6 As shown, the present invention is aimed at improving the conveying efficiency of lump ore or coal. The conveying device includes a conveyor belt 1, a conveyor belt V-shaped bracket 2, a baffle plate 3, a baffle plate conveyor belt 4, and a conveyor belt guide rail frame 5. The conveyor belt 1 Lay on the conveyor belt V-shaped bracket 2 to convey ore or coal in a V shape. The V-shaped conveyor belt 1 has two conveying sides 6. The conveyor belt 1 drives a circulating transmission through the power rollers 7 set at both ends of the conveyor belt V-shaped bracket 2 The conveyor belt 1 rotates, and the power roller 7 can adopt a roller and motor transmission connection structure. The motor drives the roller to rotate, and the roller is recirculated. The conveyor belt 1 and the conveyor belt V-bracket 2 are all conveyed by existing ore or coal mining Technical equipment; there are auxiliary brackets 8 on both sides of the conveyor belt V-shaped bracket 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com